Professional Documents

Culture Documents

Operation Manual For Power Transformer

Operation Manual For Power Transformer

Uploaded by

miteshsinghal210 ratings0% found this document useful (0 votes)

4 views43 pagesOriginal Title

Operation Manual for Power Transformer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views43 pagesOperation Manual For Power Transformer

Operation Manual For Power Transformer

Uploaded by

miteshsinghal21Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 43

OPERATION &

MAINTENANCE

MANUAL

nsformer, with an

INSTALLATION,

OPERATION AND

MAINTENANCE FOR

POWER TRANSFORMERS

ContTENTS

1/satety information

3/ storage

8.1 Storage OF Transformers With

Sealed Tank

82 Transformers Wih Expansion Tenk

a3

Storage OF Ineulating Ol

5/ Tests In Field And

Start Up Operation

5.1. Checking Before Field Tests

52 Tosts|n Field

53. Checking Before Statt Up Operation

5.4 NoLoad Tests

55 NoLoad Impact Closing

56 Loading Operation

G6 / Accessories

6.1 Insulating Cooling Fluid

62 Sol-Cooled Rating

63 Forwed-Air Cooled Ratings

64 Fluid Preservation

65 Inert Gas Systom

66 Bushings

67 Current Transformers

68 Surge Arrosiors

69 Gauges

6.19 Electionic Monitoring

6.11 Control Cabinet

612 Pressure Rect Dovico

6.18 De-Enorgzed Tap Changor

6.14 OnLoad Tap Changer

6.15 Radiators

6.18 Other Features And Accessorios

®

B

DAELIM BELEFIC

‘2/ General Information

2.1. Acceptance And Inspection Upon Receipt

22 Power Transformer Shipping Requiremants

Littina Fer Transiomer Body

Harding

Unvoasing

AV Install

n

4.1 Preparations Before Installation

42 Instruction Of Ambiont And Timo Of Transfermor Core Lifting Inspection

43. Requirements And Notices Of Transformer Core Liting

4.4 — Main Equipment And Tools Needed At Installation Sito

45 Core Liting Inspection Of Oi Filled Production

46 Core Liting Inspection Of Nitrogen Filled Production

47 Universal Operating Provisions Of Overall Installation

48 Tho Insialaton Of Accessories

4.8.1 Notiove Of Bushing Inotalstion

4.82 insialaton Of 69Kv And Above Bushing And Lead-Wire

4.83 insalaton Of Draw Lead Bushing On Lv Side

4.84 insialaton Of Through'Shaft Bushing On Ly Side

4.85 insialaton Of Core Eathing Bushing

486 insialaton Of Cocling Equipment

4.87 insiaiaton Of Pressure Fie! Yave

4.8.8 insialiaton Of Gas Raley

489 insialaton O1 No-Load Tap Changer

48. 10 Intallation Of Consorvator And Moisture Absosber

48.11 Installation Of Thermometer

4.8.12 Inotallation Of On-Load Tap Changer

48. 19 Installation Of Control Cabio

4.8.14 Installation OF Fans

7/ Maintenance During Normal Operations

7.1 Chocking Of The Insulation Of Transformer Wincings

72 Checking Of The Transtornor

7.3 Swilening-On, Switeh-Otf And Changing The Tapping Of The Transformers.

7.4 The Operation OF The Gas Relay Protecting Units

7.8. Operation in Parallol Of The Transtornor

7.6 Economical Operation Of Transformer

DUR TeUS uC a URC

01

SAFETY STATEMENT

The manua’s are not intended asa substitute for proper raining or, adequate experience in the

sale operation of the equipment described. Only competent technicians who are familiar with this

‘equipment should install, operale, and service R, These instructions cannot cover all details or

variations in the equipment, procedures, or process described, nor to provide directions for meeting

‘every possible contingency during installation, operation, of maintenance.

02

GENERAL INFORMATION

PAE Acceptance and Inspection upon Receipt

All DAELIM transformers are thoroughly tested and rigorously inspected before shioment from

the factory to ensure the highest quality.

Upon receipt:

1, Thoroughly check all materials agains! the bill of lacing,

2. Check ithe transformer has sutfered any accidental crops or if they are any twisted the reinforcements or pipes.

3, Ifthe peint is damaged orf any metal pieces ere rusted, used sendpaper and use an adequate ani-corosive

paint

4. Check that all screws and nuts are not found loose,

Locate accessory parts that may have been shipped separately.

6. Carefully check the unit and associated protecting components of main tank for eny signs of damage caused

during shipment. A damaged eralo of pallet can bo an indication of rough handling; if thie condition ie found,

pection of the base and radiators (if equipped) and verify no damage has occurred,

7. Inthe event that significant damage to the unit or any assocated equipment is noticed, rejection of the shipment

should be made before itis unloaded. In the event of miner damages (nicks, scratches, ets.) carefully inspect

tho unit and note all damage on the carriers copy of the freight receipt.

make a clos

DAELIM ships most units FOB Pointof Manufacture, and itis the customer's responsitilly o ile a claim agains! the

Note:lfaccoptanceof the transformerismade and damagoto the unitisnoticedatalatertims, itis extremely dificult to fio

a claim against the cartier.

DER TeUS ene OCC

02

GENERAL INFORMATION

bard Power Transformer Shipping Requirements

24

22

Lifting for transformer body

2.1.1 The iting equipment, epreadors and the foundation of the leacing and unloading site must bo ablo to withstand

the lifting weight of the transformer.

2. 1.2 When hoisting the transformer, tho rope should be hung in the hoisting position so that the four slings are

strossod at tho samo timo,

2.1.8 The angie ofthe sling is not more than €0°during lifting. If this requirement cannot be met due to the limitation of

the lffing height, the liting beam should be used fer iting.

2. 1.4 If you need to change the direction of the trolley or add bars at the bottom of the box during transporiation, you

reed to use a jack to jack up the ransformer atthe postion speciod in the cutine dimension drawing beiore

proveeding. The jack bracket on the lower fuel tank is sed for jacking up the main body ofthe transformer. When

jacking up the main boty, al jack brackets must bo used at the same timo. All jacks should bo raised and lowered

‘synchronously to prevent the

main body fom titng and overturning.

Handling

When is necessary to tansport the transformer i

installation site, please follow these stops in order to avoid any

damages to its structure or accidents to the personnel responsible of such operation:

* Select preferably, as means of transportaton a “Wale” of alow platform

DER EUS en eC

02

GENERAL INFORMATION

+ Bolore the delivery of the transformer is strongly recommended to mae a dalled revision of the route in order to

anticipate to any possible cbetactes (low clearance bridgoe), dangerous slepes, conditions of the highway, ete,

“AS indicated in figure 2 the transtomer must go as ceniered as possible in relation to the trailer.

+ Chock the condition of tho tio-down hooks of the trailor and verify that they aro in good cent

‘The expansion tank (ff tis to be delivered with the transformer), must be placed behind the

cabin of the truck

+ In each comer there should be at least two (2) tie-down hooks to secure the tank.

‘= Uso when possible a steel chain or eable properly tensed. Never use either rope or Nw

any thor material hat may stretch. Each cablo mest offer a minimal osistanco io

traction of 15 tons.

‘+ During traneportation thoro chould net be any slopes groater than 25° longitudinal and 30° tanevorse.

2.3 Unloading

+ Before unloading the transformer from the vehicle observe il there are any missing pieces or deformations. If $0,

inform the manulasturer of these irrogulatitios before starting any repair.

“When lifting the transformer, the suspension cables have to be maintained almost parallel to avoid any bending of

the hooking bolts or other pars of the structure,

«When a transformer can not be handled by means of a crane, it may be moved by siding ton skates or on rcllers,

‘but being careful of nat to damage the base or of not to tt

+ Tho transformer should never be lifted or movod by placing lovers or hyclaulie jacks under the purge valvo, ccoling

cil drainage, connectons of the radiators or any other devices,

+ When lerge transformers are moved on rollers, beams must be supplied to cisribule the forces on the base.

DER eUS ened

STORAGE

Aller a transformer has been received at is final destination, itis advisabie to put it (full of ol) on its

permanent place, even

itis nol going to be placed in oparation immediately. If this is not possible, the

{raneformor has tobe placod in a dry placo and tho transformer muet bo filed with ol. f tho uni ie going

to be located outdoors, the water vapor will condense inside the tank, due to the variations in

temperature and humidity. This will be at'sorbed by the winding and it wil be necessary to dty the unit

before putting it on operation, Therefore, itis preferable to place the transformer in a place where the

tomporaturo is slightly high and stablo, following the recommendations that aro given blow:

+The transformers for Instalalion indoors have to be stored in a closed place, However, fils going to

be installed in open places, these places will have to be well covered to avoid the humidity and any

foreign matiors enter tho tank.

+The transformers to be used outdoors must be stored whenever pessibie indoors.

+ Tho base or the platform for the storage of the transformers must be suffcionlly resistant as to

wihstand its weight and be perfectly tat.

+ II the transformer is going to be stored outdeors, make eure that the area for storage has a good

drainage system

+ Any incidental loss of ol will not haum the environment.

+ To avoid any moisture from entering the tank, a poriodic revision of the respirators of silica - gol andlor

of the nitrogen pipes should be performed when the tank is partially filled wih of.

+ Tako the nocossary slope to provert that water condoneation is formed in tho accoseerios and parts

that are delivered separately. Use the adequate protection against the weather elements, Ifit

is necessary place Silica gel driers inside the bags andor containers,

+ Inctall all the nocessary protection against corrosion and moshanical damages to tho tank

+ Whenever possible, charge the conirel cabinets with their corresponding electrical tension to avoid any

lure from entering their interior.

31

ER

DR US uC eae ULC)

STORAGE

‘Aiter a transiormer has been received from the factory, & is recommended to put it on service on the shortest

possible time. I the transformer is not going to be placed on operation immediately, it must be stored indoors

andin adly place by following these instructions:

Storage of transformers with sealed tank

+ Transformers completely assembled

‘Check the internal pressure of the transformer. I! the pressure gauge indicates a vacuum or pressure

lowor than 0, 1 alm. (2 Psi), pressurize with 2 or 3 pounds of Nitrogen and check at least every month the

internal pressure. In these conditions the vanslomer can be stored indefinitely. If the pressure is higher than

03 alm (5 Psi), let escape the excess pressure.

‘+ Transformers with detachable radiators

‘The transformer should be assembled totally, fil up with oil and pressurize it with Nitrogen to a pressure of 0.2

‘aim (@ Psy; folowing the recommendations from the numeral 1. 1. In ease of not being able to assembto it

{cally, the parts and pieces ehould be maintained seated to avoid moisture from geting inside tho parte

WARNING

In the event of doubts or lack of knowledge of the qualities ofthe available oil and before iling the transformer,

‘samploe willbe cont for locts to a competent laboratory. Oil that do no! comply with our epesifcations, can net

bbe used without cur approval.

Transformers with expansion tank

+ Fully Ascombled

Piace the silica gel breather following the instructions “Assembly of breathing silica gel’.

WARNING

I during tranaportation the silica gol has absorbed any moisture (pink colo), it will havo fo be dod in an oven

to 150-180 °C, unti it recovers its original blue color, orift is possible to change il by a now silica go,

In oil immersed transformers, the color ofthe silica get willbe controlled carefully every four (4) weeks, and

in topical climates every two (2) weeks. As it has been said previously, the silica gel will be replaced or wil

bo driod in an oven, if more than half of the content of the present broathor prosente diecoloration,

ERE)

DRT US uC emi ULC)

STORAGE

+ Parially filed with ot

‘The expansion tank will be mounted and will proceed to fill i up with oil up fo the corresponding level. Once

tho fill up ie finishod with ol, the silica gel breather will bo mounted. A transformer

‘complotoly full of oil can be stored indefinitely. This storage is preferable

than a transformer filed with gas.

“Fill up with Nilrogen ges

‘Verity the internal pressure of the transformer; this must be maintained in 0.2 atm (S Psi) If the nitrogen bottle

is empty, you must use for the fil up, nitrogen of a purty of 0.3% ofits volume and a degree of maximum

humicity of 250 ppm. Storing a tiansformer filled with nitrogen is possible, without other manipulations fer a

pporiod of three (3) months, For longer periods of storage, instructions to fil with oil will be requested. Each four

(4) weeks the pressure of the main tank and of the bottle will be coatioled

Storage of insulating oil

Insulating oil wil be kept exctusively n clean containers and will be protected against humidity by placing the

Cconlainers in a place where the temperature is maintained unchanged and on horizontal position. Iwill be

avoided carefully any mixture with other liquids (ol fo cables, lubricating and heating) or with solid particles,

‘Small quantifies of impuriios can highly aller the qualities of the insulating oi. Allthe containers for storage

are carefully checked and a delaied record will be kept of cleanliness and of perfect impermeabilty. will be

the responsibilty of the selling company whenever possible to wash the dirty and/or used containers. In the

event that hecomes necassary a cleaning at the same installation sta, these sleps will be folomed:

‘+The container willbe sprayed with unleaded gasoline or with refined petroteur, until the cleaning liquid does

rot present some coloration,

‘+ Once the container has been emptied thoroughiy, wil be placed to an oven or will be let to dry by means of

a died air flow for several hours. (Warning: There is explosion risk).

‘After drying the container(s) willbe closed hermetically, sono air would enter the container.

DB Transformer, with an Edge

04

\, INSTALLATION

E Sl Preparation before installation

att

Checking that if the accessories are complete, and in good conaition. I it needed, please take experiment in advance. It

‘mainly included: tho dielectric diceipation factor of oil papor condoneor bushing, the polasity and ratio of bushing current

transformer, the inspection and adjustment of gas relay, the inspection and adjustment of temperature controller and so.

Con. Winding thermometer should take current matching according to specication.

4at2

Do woll at the preparation of of filing, draining and fitoring in adtvanco, and chock whother tho quantity of traneformer oil

is enough, and the specification of oilis quatiiod

413

Preparing device for transformer installation: vacuum oil fiter (oiling machine), oll tank, oil ube, crane and other toots.

Ce Stipulation of ambient and time of transformer core lifting inspection

424

Air humidity below 85%, oxposuro fimo of active parts < 16h.

422

Air humidity within 65%-75%, exposure time of active parts < 12h.

423

Ambient temperature > §°C , machine body temperature should abeve ambient temperature 5~10°C

424

‘When environment temperature is below normal (below 0°C), you should rise the active parts’ siemperature ebove 107

by hot-cil ciuiation in advance.

425

Air humidity > 75%, it is not suitable to take Core liting inspection or nitrogen drainage insiallation.

Z i) Requirements and notices of transformer cover lifting

434

Don’t pertorm iting cover inspection if user requast no need to lit tank cover in contract.

432

Botoro porferm iting tank cover inepection, the product need lo complete working routine & requirement ae clause 7. 1

433

While top fix position of the body of transformer have mechanical connection with oil tank, relevant joint parts must be

{oosen or taken off, ater thal the operation of iting tank cover can be carry out.

DB Transformer, with an Edge

04

\, INSTALLATION

434

Dicassembling the on-load tap changor should according to instruction manuals of on-load tap changor.

435

‘The product of no need to lift tank coverin contract should perform lifting core inspection ifit was crash or

‘other unexpected accident was eccurred during transportation.

CRE! main equipments and tools needed at installation site

Or

12

13

14

Pry ary Spe

Oiltest equiprrent tset il withstand voltage. liquid water content, 1g 8 ete

Lifting appliance | ea | Liting ability according to the weight of general

(actusng sings for iting oad)

Vaccum Oilfiter

(olingmactine)

assembly drawing , while itis lifting core inspection

tset For fling transformor ol

Joints & flange should comply with valve size which

‘was shown on the general assembly crawing

il ctorago tank teot Base on oll mass, anos! 1 times

of transformer ol mass

Pipeline. tube union Fight amount

Ladder 2 5m, 3m. one for each

Nylon rope 2 pieces Use forlifing bushing, radiators, oil conservator, etc

Lifting tug 2 sets Use forlifing radiators, oil conservator, eke

Bott, screwé general tools tset

Megameter (2500V) | 1 set Measuring insulation resistance

Facility of lighting 1 set

Water-proof loth or plastic cloth Fight amount

Fire extinguisher Fight amount Use for extinguishing oil ire

White cotton cloth Fight amount For eleanning

DB Transformer, with an Edge

04

INSTALLATION

CELA core lifting inspection of oil-filled transportation product

oN) Orci Be tt

1.1. Take oil from sampling valve,specifie performance test shall conform to the

requirements of clause 6.2.1, they donot conform to the requirements should according

1 ‘Ol analysis test to 6.4 clause and judge whether body has been affected with damp:

1.2 When a vacuum filer was used for filtering oilcil temperature must be control at 75 +

SC range.

Oil storage facility 2.1 Oil iter and oil siorage tank must be clean without any particle.

2 | cleaning and eomection | 2.2 Inner of nylon pipeline must be can ard no moisture.

3.1 Drain the cil inside the transformer lank to oll storage tank , Through bottom valve of

transformer tank by oil filter.

8.2 When ol ciacharge, at frat it must open the sealing plate on the tank’ s topandithon use.

3 Diecharge of oll 5kg of cleaned silica gel and placed it into a small bag which was made of screen

‘mesh,ciameter about 200mm put it on the lark fop cil pipe and then discharge oil. In order

{0 prevent transformer body was alfected with damp.

8.8. To avoid oil tankhas any abnormalities, please open the relief plug i cil eonesrvator has,

be installed.

4.1 Open sealing plate of bushing flange and fixed lead wire on suitable position of

transformer body.

4.2 Re‘er to general assembly drawing. please open ‘ixing position device of transformer

Disassemble joint part | _body, the boll must be separated smoothly irom fixed position par.

axed posiion devico | 8 Aevordng to tap charger instruction manual, soparate tap changer fom i tarks joint

parts of transformer body,action bars must be separate reliably from connection parts

tapping position need to record down wihen disassemble the tap changer.

4.4 Disassemble joint bok of cil ank edge,

4.5 Lifting the cover of tank,

5.1 According to assembly drawings to choose the right sling hanging in the clamping unit of

lifting lug, at beginning to test intermittent lifing.adjusting the hook posttion to maich the

F Uihup tank soyet ‘center of gravity of the body in the same vertical line, through the trial and then the oil tank

an be litte.

5.2 Placing the oil tank on the cleaned material.

DUR TCUS uC eae ULCCC)

04

INSTALLATION

CC cries Rr oe cr iat

6.1 Tho too's for inspectors need to carry out ID registration, everyone’ s pockel are net allowed

fobring molal objects, itis etrctly prohibited for dust, debris into the tank of transformer.

6.2 After operation, the operating personel are asked to confirm no debrs inside,after go out

tank and itis needed to check all the tools in accordance with registration.

6.3 Main check item:

LLiting core inspection | 6.8.1 Overall chock Whothor the body of ransformor havo any displacomont or soricus distortion

and checkingitam 6.8.2 Check whother the top pad of winding has any movements,

6.8.9 Check whether lead wire has ary open vield and break,iead wire insulation stil in good

condition,

6.8.4 Check whothor prose bolt and ecrow have any looeoring,

6.8.5 Check whether standard fastener have any loosening,

6.3.6 Check the condition of cil tank and the body any other obstacle and water are not allowed,

6.8.7 Check the tap changer contact with the wire connections, tighten in yood condition.

6.2.8 Check whether the coro is one point leads to earth and the insulation’s in good condition.

7.4 Clean-up of residual oil of bottom tank chock whether have ary toole or debris loft.

7.2 Checkif the sealing gasket of the tank is intact.the installation is correct.

7.8 Lifiing of the oil tank must be stable,tne putting down speed should be gentle is necessary

fo guard against bumps the leads, the body of transformer.

7.4 As tho oil tank drop near the tank gasket. come stick should bo used to penetrate in the

screw holes.at the fime.as much as possible the bolt should be put into the screw holes to

tnetallation ef position the tank to prevent twisling of the gasket.

fe. oa 7.5 Il the upper and lower of oil tank fit not properly,upper part of oil tank should be led anc

ro-positioned agai

7.6 After check the tank gasket’s placed suitable, penetrate all the bolis,operators divided into two

‘groups fastening the bolt diagonalyy,when fastening the bol, i can not be a fastened too tight at

one time jt shouid be fastened in tums,finally all the screws achieve an appropriate tightness.

7.7 Locking and seal the fixed position device.

8 aaa Accessories insiallation in accordance with the part of General operating requirements,

installation.

04

DB Transformer, with an Edge

\, INSTALLATION

E gq Core lifting inspection of Nitrogen-filled products (Oiling and nitrogen emission)

SMC cc Tey

1 (ll analysis test

Oil storage facility

2

cleaning and connection

3 Drain cut residual

oil of tank bottom

ing and drain

of ritrogen

5 Drain out of oi

ROE Oct

1.1 Take the vansiomer oll samples to laboratory tests, specific performance should meet

the requirements of clause 6.2.1, it do net meet the requiremenis,should determine

\whothor the body was effected with damp according to clause 6.4,

1.2 When cilingool temperature should be increased higher than ambient temperature for

10-15.

2.1 Ol filter and oll storage tank must be clean without any particle,

2.2 Inner ol nylon pipeline must be clean andne moisture.

8.4 Drain oil plug near tank bottom will be used to release rosidual ol into a small containor.

8.2 Untreated residual oil sha not be re-injecied into the product

4.1 Install a tempoxary oll love incictor.

4.2 Open «80 butterly valve on top of the tank cover lo exhaust the nitrogen al same time

inject qualified transformer oil into the cil tank by « 80 sluice vaive at the bottom of oil tank.

4.8 AMter finish to inject. ithe height of oil level should lower than tank cover for 100mm.

5.1 Aller slay for 1 hourall the oll in the tank should be drained out into oll sloraye tank.

through drain valve at the bottom of the oll tank by tho oil filter,

5.2 When oil discharge.al first it must open sealing plate of the outlet on the top the tank,

then cleaning up Skg of silica gel placed the silica gel into a small bag which was made of

screen mesh, diameter 200mm, put it on the outlet of the tank top and then discharge oil. In

‘order to prevent transformer body wae aflected with damp.

5.3 To avoid cil tank has any abnormaliies,please open the relief plug of oil conservator iit

has be installed.

04

DUR ToUS uC em UCC)

INSTALLATION

SMC

Disassemble joint part

&xed position device

7 Lit up tank cover

iting core inspection

‘and checkitem

6.1 Open sealing plale of bushing flange and fixed lead wire on suitable postion of

transformer body.

6.2 Reler to general assembly drawing,please open fixed position device of transformer

body.the bolt must be separated smoothly from fixed postion part,

6.8 Acconting to tap changer instruction manual separate tap changer from il tanks@joint

parts of transtoimer body, action bars must be separate retably from connection pars.

Tapping position need to record down when disassemble the tap changer.

int bolt of el tank edge.

65 Litting the cover plete.

6.4 Disassemble

7.1 According to assombiy drawings to choose the right sing hanging in the clamping unit of,

{he Ifting tug. at beginning to test intermittent itting adjusting the hook position to match the

center of gravity of the body in he same vertical fine, through the trial and then the oil tank

an belied,

8.1 Tho loole for inepoctors nood to carry out ID registration ovoryone' ¢ pockot are not

allowed to bring metal objects.it is sticily prohibited for dusidebris into the tank of

transformer.

8.2 After operation, the operating personnel ere asked to confi no debris inside,etter go

out tark and it ie needed to check all the tools in accordance with registration,

8.8 Main check iter:

8.3.1 Overall check Whether the body of transformer have any displacement or sericus

distortion.

8.3.2 Check whothor tho top pail of winding has any movements.

8.3.3 Check whether lead wire has any open weld and break, lead wire insulation stl in good

condition,

8.8.4 Check whothor pross bolt and screw have any loosoring,

8.8.5 Check whathor standard fastener have any loosening,

8.8.6 Check the condition of oil tank and the body.any other obstacle and water are net

allowed,

8.3.7 Check the tap changer contact with tho wire connections, tighten in good condition

8.3.8 Check whathor the core is one point leads to earth and the insulation's in good

coniition.

DORE US tC ace UILCCCS

04

INSTALLATION

MCT Ree ee eed

9.1 Clean-up of residual ol of bottom tank,check whether have any too's or debris let.

9.2 Check if the sealing gasket of the tank is intac,the installation is correct,

9.3 Lifting of the oil tank must be stable, the putting dawn speed should be genileit is

necessary to quard against bumps the leads, the body of transformer.

Installation of 9.4 As the oil nk drop near the tank gasket, Some slick should be used fo penetrate in the

halal tank screw holos,at the time,as much as possible the bolt should be put into the screw holes to

position the tank to provent twisting of the gasket

9.5 Ifthe upper and lower of oi tank fit not properly. upper part of ol tank should be lifted and

‘epositioned again.

9.6 Aftor chock tho tank gaskot®s placed cuitablo,penotrate all the bots.oporators divided

into two groups.fastening the bolt ciagonally. when fastening the bolt. can not bea fastened

too light at one time; should be fastened in tums,finally all the screws achieve an

appropriate tightness.

9.7 Locking and seal tho fixed position device.

Accessories

installation

‘Accessories insialation in accordance with the part of General operating requirements.

DB Transformer, with an Edge

04

\, INSTALLATION

Fd Universal operating provision of overall installation

474

Bolore general instalation,please counting the number of components of each to be installed (Inctuding bolts,nuts,

washors),cevetul inepoction cleaning acoescorios jain tube from other ebstaclee dif, dust ote.

4.7.2

Parts and components which have instalation signs must follow the insiructions to re-installed on the site(such as

bigh-voltage,mecium voltage,low voltage bushings,pedestals,pressure release devices eic,more attention should be

ppayod fo their rlative postion and anglo to the tank,and also note the sequence of tho joint pipe,ote).

42.3

Insialation of bushing shall not be dead lit and twist the lead wir.

414

‘As for 69KV and above class load wiro load wire's insulation inclinod tip must packed into the mouth of votage-sharing

ball ofthe bushing.

418

Check the fixing posi

47.6

While assemble oil conservator joint pipe, should start from gas relay side,fastening bolts incomplete untl al the parts has

been assembled and then began to tighten from the gas relay side.

477

n parts install and seat in accordance with technical requirements,

‘Tho pedestals of thermomotor should be inject 23 transfermer oil

478

Insialing all components, parts and spare parts which have been disassembled in accordance with transformer overall

‘imension (assembly drawing).

4.7.9

‘As to there have air drain plug on the top of components(eg, L.V bushing,gas rolays,oil conservator,radiators, ote.)after

injected transformer cil he upper part of air drain plug should be opened to release accumulated air please don't close the

‘ir drain plug untl oil overliow.

4.7.40

Bolore sealing gaskets put into the slot or the flange,Please keep metal surface cleaning,and sealing surlace must be

‘grease seal and make the seeling gasket correctly seated-Fasien the bolt diagonally and stress should be made

uniformly.

47.44

Insialation of On-load tap changer, should pay more attention to the herizontal axis and vertical axis equipment,concen

‘abou! the sealing of head tlange of tap changer in good condition.use handle to turn round flexibly to see if the tapping

indication ie correct (foler to inetruction manual of on load tap changor for more detail)

CRE}

4.8.1

DROS aCe UCC

04

INSTALLATION

Installation accessories

Notices of bushing installation

4814

When bushing instalation,the location of eranes should be located in which is convenient for bushing lifting and

instalation.

4812

While bushing was Iilted by cranes, please use nylon rope or wirerope with protection sleeve and take special care

SOKV, water content

‘5 1Sppm, air content 1.5%, when 90 tg 5 ~< at 0.5%, gas chromatography was performed

LE} Checking before start up operation

5.34

Inspection before operation,

5.3.2

Chock whothor tho noulral point on tho ive sido of the traneiormor has boon reliably groundlod (it should be diroctly

grounded in case of impact)

5.3.3

Check whether the setting value and action sensi

5.3.4

Check protection. Such as gas relay, thermometer, pressure release device and bushing current transformer

measurement circuit, protection circuit and control circuit wiring is correc, if necessary, short-circuit linkage test

Record all the:mometer readings.

5.3.5

Check whether the bushing type current transformer without load has been short circuited, and open circuit

operation is nat allowed.

ity of each protection device and circuit breaker are good.

DURES uC ai UCC)

TESTS IN FIELD AND

START UP OPERATION

2.6

Check whether the respirator of oil conservator is unblocked and whether the oil level is correct.

5.3.7

Chock the setting value of the protection device. Whon the system voltage is unstable, adjust the setting value of

the protection sysiom appropriately, so as to effectively protect the transformer, such as relay, lomparature

‘controller, pressure relief valve and bushing current transformer. Check whether the wiring of the measurement

Circuit, protection circult and control circu is correct, and conduct short-circuit inkage test when necessary,

5.2.8

When no-load impact closing, the signal contact of gas relay (i! any) shall be connecied to the heavy gas action

‘contact (i.e. power tripping cireui),

5.3,

For the tost of on load tap changor: the on load tap changor chall be tostod accor

load tap changer,

5.3.10

‘The no-load tap chenger should continuously change the tep gear in the nion excitation slate to eiirinate the

influence of oil fm on tho cantact resistance, and thon align the goar. Al this timo, tho contact DC resistance

between the moving and static contacts of the switch is less than $00 uf. All tap changers should be in the same

gear and consistent with the line voltage.

19 tothe operation manual of on

LZ! No load tests

54d

‘Tho following teste can be carriod out only whon tho above inspection and tostitoms moct the roquiromonte,

5.4.2

The transtomer should be connected with voitage from the power supply side, because the power supply side is

equipped with protection device to cut off the potver supply under abnormal cenditons.

54.3

No load boost test

‘Tho power supply side of the transformer is connected with the power supply (due to the protection device on the

power supply sido, the power supply can be cut off quickly in case of abnormal conditions). After connecting to the

power supply, slowly increase to the raled vollage and keop itfor 30min,

DURES uC emi ULC)

TESTS IN FIELD AND

START UP OPERATION

LBL No load impact closing

5.5

Belore no-load switching on, the transformer shal be allowed to rest for more than 24 houre, ar the rising seat ond

bushing equipped vith von pug shall bodeflatad rogularly. Botoro noload impact losing, tho overcurrent action

shallbe sotto zer, and the signal cieut of gas relay shall be connostedt the opening circuit tomporarly

5.8.2

whon the bus protecton circuit breaker is closed, the threo-phase synchronous timo difference shall not be greator

than 0.015, the closing shall be pratected by lightning arrestor, and the neutral point of transformer shall be reliably

grounded (direct grounding),

5.5.3

No load impact closing toot

‘Tho impact closing power supply is the ratad voltage of the system, which shall nat exceed 5% of the indicated

Yoltage o! the transformer. The maximum number of closing impulses is 5 times. The duration of the first voltage

should not be less than 20min, and the closing interval should not be less than Smin. In the process of closing

impulees, if tho voltage value roachos the maximum value oneo, the test will not be centinuod, and it will bo

regarded as qualified (including the first time}. f the maximum value dees not appear for 5 times, it will also be

regarded as qualified, and the test will no be carried out.

5.54

‘Tho time limit of over-curront protection is set to instantaneous action, Switch on the transformer euddeniy with rated

voltage for 20 minutes. Listen caralully and observe the condition of the transformer in this caso. No load operation

fora long time. Under the rated voltage, the cooler can not betumed on when the oil top temperature rise

does not exceed 50K and the ne-load continuous eperation is Gh

558

Cut off the power after the test. The oil was measured by gas chromatography and compared with the data before

the test

EL-R{3 _Loaaing operation

5.6.1

IF the test result of transformer connecting voltage is good and there is no abnormality in no-load operation for 24h,

tne transformer can be transfered io ontoac operation. Te oad shouldbe increased stepby stp. The ransfommer

should be transferred to 60% lod oporation after Sin of 25% load opeaten, 7% lead oporalion alter Sin of

operation, 100% load operation after 5min of operation, and put into operation ater the cooing system is turned on.

5.6.2

‘Alor 24 hours of continuous fal operation wit oad, the main body and aocessoies ofthe ansformer are nonral,

{and tho tranefermor will ue into normal operation.

DER EUS ene UIS Cd

ACCESSORIES

DAELIM power transformers aro available with many optional features and accessories 'o satisly a customer's

special needs for the operation, protection, monitoring, and maintenance of their equipment. The following list

‘contains the most frequently requested options. Check with the factory for the availabilty of other optional features

and accessories not fisted below.

+ Coolinginsulating uid

* Bushing-mounted current iransformers

+ Surge arresters and mounting brackors

+ High-voltage andlor low-veltage terminal compartments

+ Wye-dolta or serios multiple terminal connections

+ Forced-air cooling with automatic contral system or provisions for forced-air cooling

+ Control cabinet

+ Nitrogon gas fluid preservation systom

+ Dia-type winding temperature gauge (standard for forced-cooted transformers)

+ Electronic temperature indicator

+ Fiber-optic winding temperature indicator

+ Do-onergized tap changer with padiocking provisions:

+ Onload tap changer with microprocessor-based control

‘+ Special exterior paint color

+ Galvanized or stainless-steel radators,

+ Cover-mountod fal protection dovico

(ABEL INSULATING/COOLING FLUID

6.1.1 Type Il Mineral Oil

Power transformers filed with mineral ol that complies with ASTM D-3487, TYPE II.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

pH: NA PCB: No

Auto ignition temperatura: > 3150* Relative density (H20 = 1): 0.84 Peur point: 54°C.

Evaporation rate (bulyl acetate = 1): N/A Volatile organic compounds: < 0.001 gil.

Miscibtty: mixes with other deleciric fulds excep! silicone Appearance and odor: Clear bright liquid with Mineral

odor

‘closed cup flash point: > 145°C Boiling point: >238°C.

Vapor pressure (men Hg): < 0.01 @ 20°C Vapor density (air= 1): WA

Solubility in water: negligible; <0. 1% Viscosily: 4.9 TO 45 CsTat 40°C.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- 10 Kva Up Ex 250 JobDocument1 page10 Kva Up Ex 250 Jobmiteshsinghal21No ratings yet

- 5.0 MVA For Type TestDocument1 page5.0 MVA For Type Testmiteshsinghal21No ratings yet

- 5 Mva Tank Body For L&T Rev.1Document1 page5 Mva Tank Body For L&T Rev.1miteshsinghal21No ratings yet

- Calbration 2023Document12 pagesCalbration 2023miteshsinghal21No ratings yet

- Calibration 2023-1Document10 pagesCalibration 2023-1miteshsinghal21No ratings yet

- BA ENGLISH Poetry and Drama - 3Document74 pagesBA ENGLISH Poetry and Drama - 3miteshsinghal21No ratings yet

- RHM - RIF Bushings IEEEDocument4 pagesRHM - RIF Bushings IEEEmiteshsinghal21No ratings yet

- Arcing HornDocument1 pageArcing Hornmiteshsinghal21No ratings yet

- BA ENGLISH Poetry and Drama - 2Document91 pagesBA ENGLISH Poetry and Drama - 2miteshsinghal21No ratings yet

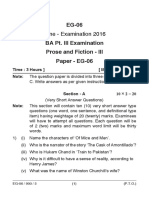

- December - Examination 2016: EG-06 BA Pt. III Examination Prose and Fiction - III Paper - EG-06Document3 pagesDecember - Examination 2016: EG-06 BA Pt. III Examination Prose and Fiction - III Paper - EG-06miteshsinghal21No ratings yet

- Ma English Maeg-11Document90 pagesMa English Maeg-11miteshsinghal21No ratings yet

- June - Examination 2016: EG-06 BA Pt. III Examination Prose and Fiction - III Paper - EG-06Document3 pagesJune - Examination 2016: EG-06 BA Pt. III Examination Prose and Fiction - III Paper - EG-06miteshsinghal21No ratings yet

- Mggs NVDN Jaipur: First Assessment Test-2021-22 Class - Iii (Evs)Document3 pagesMggs NVDN Jaipur: First Assessment Test-2021-22 Class - Iii (Evs)miteshsinghal21No ratings yet

- December - Examination 2015: Eg-06 Ba Iiird Year Examination Prose and Fiction - Iii Paper - Eg-06Document3 pagesDecember - Examination 2015: Eg-06 Ba Iiird Year Examination Prose and Fiction - Iii Paper - Eg-06miteshsinghal21No ratings yet