0% found this document useful (0 votes)

53 views2 pagesControl Chart Analysis for Inductance

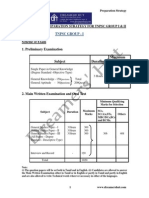

This document summarizes the results of a process capability study (Cpk) for inductance measurements of a product (part number HA00-17355LF) over a one week period. The study involved measuring the inductance of 5 samples per shift at 2 times per shift, for a total of 25 measurements. The measurements were within specification limits, but one reading was above the upper control limit, indicating an out-of-control process. Analysis of the data found the process to have a capability index (Cpk) of 1.75, suggesting the process is capable of meeting specifications.

Uploaded by

FaizulCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

53 views2 pagesControl Chart Analysis for Inductance

This document summarizes the results of a process capability study (Cpk) for inductance measurements of a product (part number HA00-17355LF) over a one week period. The study involved measuring the inductance of 5 samples per shift at 2 times per shift, for a total of 25 measurements. The measurements were within specification limits, but one reading was above the upper control limit, indicating an out-of-control process. Analysis of the data found the process to have a capability index (Cpk) of 1.75, suggesting the process is capable of meeting specifications.

Uploaded by

FaizulCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd