Professional Documents

Culture Documents

3M TC-2707-TDS

Uploaded by

JavierCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3M TC-2707-TDS

Uploaded by

JavierCopyright:

Available Formats

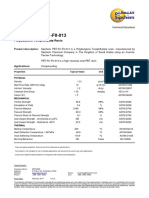

Technical Data | September 2018

3M™ Thermally Conductive Epoxy Adhesive TC-2707

Product Description

3M™ Thermally Conductive Epoxy Adhesive TC-2707 is a thermally conductive 2-part epoxy using aluminum metal

filler for good thermal conductivity with high adhesion.

Key Features

• High adhesive strength

• Slight tack allows pre-assembly

• Good surface wet out

• Low viscosity for potting applications

• Good gap filling

• Thin bonding line

• Good thermal conductivity (0.72 W/m-K)

• Low Cl ion content and outgassing

• Thermally and electrically conductive

Typical Uncured Properties

Note: The following technical information and data should be considered representative or typical only and should not be used for

specification purposes.

3M™ Thermally Conductive Epoxy Adhesive TC-2707

Property Value

*Viscosity Base 95,00 cps

Accelerator 25,000 cps

Mixed 60,000 cps

Base Resin Base Epoxy

Accelerator Amine

Filler Aluminum 50% by weight

Mix Ratio Volume 2:1

(B:A) Weight 2.00:0.96

Worklife 60 minutes at 23°C (72°F)

*Viscosity it measured 40mm, 2°cone at 10 1/sec.

Applications

• LED Assembly

• Thermal fixing battery cell and thermal management for EV/HEV battery

• Potting applications

• General gap filling

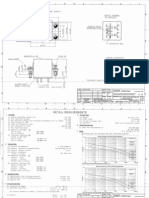

Application Techniques and Product Use

For bonding rigid to rigid parts, it is suggested that the bond line thickness and edge fill be designed to optimize:

3M™ Thermally Conductive Epoxy TC-2707

1. Bond Strength

2. Thermal Resistance

A typical suggested bond line is in the 3-7 mil (0.076- 0.018mm) thickness range,

For improved thermal performance (lower Thermal Resistance), a thinner bond line is suggested. A thinner bond line

can reduce the bond strength, so each application needs to be tested to find correct balance

Bond Line Thickness vs Thermal Resistance vs Bond Strength

A “fillet” at the edge of a bond line is suggested to increase bond strength. The fillets are formed as the epoxy squeezes

out past the side edges. Fillets can add strength to the assembly.

3™ Thermal Conductive Epoxy TC-2707 is supplied in dual syringe plastic duo-pak cartridges as part of the 3™ EPX™

Plus II Applicator System. The duo-pak cartridges are supplied in a 37 or 50 ml configuration. To use the cartridge

simply insert the duo-pak cartridge into the EPX applicator and start the plunger into the cylinders using light pressure

on the trigger. Next, remove the duo-pak cartridge cap and expel and discard a small amount of adhesive to be sure

both sides of the duo-pak cartridge are flowing evenly and freely (i.e.: no voids, “plugs of adhesive”, dis-continuity in

flow, etc.) Once even side to side and uniform flow from both sides of the duo-pak is confirmed, attach the 3M EPX

mixing nozzle to the duo-pak cartridge to ensure proper and uniform mixing of the Part A and Part B and begin

dispensing the adhesive.

Partially used cartridges must follow the above use instructions to ensure consistent product performance.

Complete and uniform mixing as noted above of the two components is required to obtain consistent product

performance.

3M™ EPX™ Plus II Applicator Mix Nozzles

Use only 3M™ EPX™ Plus II Applicator and Mix Nozzles to ensure optimum product performance.

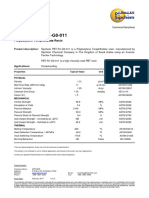

Typical Cured Physical Properties and Performance Characteristics

Note: The following technical information and data should be considered representative or typical only and should not be used for

specification purposes. Final product specifications and testing methods will be outlined in the products Certificate of Analysis

(COA) that is shipped with the commercialized product once it is approved by 3M for general commercialization and development

work is completed.

3M™ Thermally Conductive Epoxy Adhesive TC-2707

Property Method* Value

Color Gray

Shore D Hardness ASTM D2240 80

Glass Transition Temperature ASTM 1356 See Chart on page 3

Thermal Coefficient of Expansion ASTM E831 75 X 10 -6C (below Tag)

160 X10 -6/C (above Tg)

Thermal Conductivity ASTM D5470 0.72 W/m-K

Thermal Impedance ASTM D5470 3.51X 10-5 m°K/W (1 mil)

3M™ Thermally Conductive Epoxy TC-2707

Volume Resistivity1 ASTM D257 1.6 x 1011ohm-cm

Total Outgassing ASTM 5116 <1000 ug/g (GC/MS, 85 C/3

hours)

Siloxane Outgassing ASTM 5516 <5 ug/g (GC/MS, 85C/3 hours

Extractable Chloride ASTM D7994 <30 ug/g (hexane extraction)

*Methods listed as ASTM are tested in accordance with the ASTM method noted

*Disclaimer if applicable to chart above

1) As the 3M™ Thermally Conductive Epoxy Adhesive TC-2707 uses aluminum metal fillers, under certain end use application conditions the effective

resistivity and/or effective dielectric strength could be significantly lower than noted. If the metal filler is “trapped” or “pinched” between two

surfaces, an electrical bridge path via the aluminum fillers could occur between these surfaces. Epoxy Adhesive TC-2707 is not suggested for

application where a powered electrical circuit is used or where a reliable volume resistivity and/or dielectric strength is desired. 3M™ Thermally

Conductive Epoxy Adhesive TC-2810 uses ceramic filler and is a suggested product to test for these types of application performances needs.

Curing

Cure Schedule: 23°C/24 hours

50°C/270 minutes

70°C/90 minutes

90°C/30 minutes

120°C/10 minutes

Typical Shear Strength, Peel Strength, Tg vs Cure Temperature/Time

Note: The following technical information and data should be considered representative or typical only and should not be used for

specification purposes. Final product specifications and testing methods will be outlined in the products Certificate of Analysis

(COA) that is shipped with the commercialized product once it is approved by 3M for general commercialization and development

work is completed.

3M™ Thermally Conductive Epoxy Adhesive TC-2707

23 °C 90 °C 120 °C

(72 °F) (194 °F) (248 °F)

24 hours 30 minutes 10 minutes

Overlap Shears N/mm2 (psi) >18.62 (2700) >18.62 (2700) >18.62 (2700)

(ASTM D-1002)

T-Peel (piw) >7 >7 >7

(ASTM D-1876)

Tg (°C) 60 66 66

(ASTM E-1356)

*Methods listed as ASTM are tested in accordance with the ASTM method noted

*Disclaimer if applicable to chart above

Storage and Shelf Life

The shelf life of 3M™ Thermally Conductive Epoxy Adhesive TC-2707 is 12 months from the date of manufacture when

stored in original cartons at 21C (70F) and 50% relative humidity

Certificate of Analysis (COA)

The COA contains the 3M specifications and test methods for the products performance limits that the product will be

supplied against. The 3M product is supplied to 3M COA test specifications and the COA test methods. Contact your

local 3M representative for this product’s COA.

3M™ Thermally Conductive Epoxy TC-2707

Safety Data Sheet: Consult Safety Data Sheet before use.

Technical Information: The technical information, recommendations and other statements contained in this document are based

upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and

performance of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a

3M product, user is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and

suitable for user’s method of application.

Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable 3M product packaging or product literature, 3M warrants

that each 3M product meets the applicable 3M product specification at the time 3M ships the product. 3M MAKES NO OTHER

WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR

CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION

ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this

warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price.

Safety

Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product,

whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract,

negligence or strict liability.

Electronics Materials Solutions Division

3M Center, Building 224-3N-11

St. Paul, MN 55144-1000 3M is a trademark of 3M Company.

1-800-251-8634 phone Please recycle.

651-778-4244 fax ©3M 2018. All rights reserved.

www.3M.com/electronics 60-5005-0111-3

You might also like

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- 3M DP125Document7 pages3M DP125echobravo1No ratings yet

- Thermacool TC2007G Gap Filler TDS 1280Document2 pagesThermacool TC2007G Gap Filler TDS 1280xingdrewNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639No ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- Renolin Therm 300Document1 pageRenolin Therm 300Mohamed SalemNo ratings yet

- Futong Ism Tds SCG Hdpe h2001wc 20jul20Document3 pagesFutong Ism Tds SCG Hdpe h2001wc 20jul20Aung Thein OoNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Pds Covalence Htlp80 v3 Dec16 Aarps 0199Document2 pagesPds Covalence Htlp80 v3 Dec16 Aarps 0199Benaknaik S GajannavarNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Thermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002Document5 pagesThermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002chayanunNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- Tds Panaoil Amon SHCDocument1 pageTds Panaoil Amon SHCMuhammad FarhanNo ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed NouzerNo ratings yet

- Perfecto T RangeDocument2 pagesPerfecto T RangecarmaNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- 3M™ Adhesive Transfer Tape 9471 - 20231201Document8 pages3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- LG PVC Ls100H: Straight PVC: Extrusion GradeDocument1 pageLG PVC Ls100H: Straight PVC: Extrusion GradeJhon Angel Molina LeonNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Gii Turbine Oil 32 46 68 77 100Document1 pageGii Turbine Oil 32 46 68 77 100Thaer HamedeNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- LG PVC Ls100H: Straight PVC: Extrusion GradeDocument1 pageLG PVC Ls100H: Straight PVC: Extrusion GradeKishan PatelNo ratings yet

- Thermally Conductive Adhesive Transfer Tapes: Technical Data September, 2002Document6 pagesThermally Conductive Adhesive Transfer Tapes: Technical Data September, 2002Kozma BélaNo ratings yet

- Damping Foil: Technical Data January, 2012Document4 pagesDamping Foil: Technical Data January, 2012Nilma Rosa Barsallo PachecoNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Covalence HTLP80: Product Data SheetDocument3 pagesCovalence HTLP80: Product Data SheetJuan Carlos Contreras CherresNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- 3M2216Document8 pages3M2216pat_kunal1601No ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- (201207) (PDS) Ex4700Document3 pages(201207) (PDS) Ex4700Abdelrahman AwadallahNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- SH8900-H (White) EngDocument4 pagesSH8900-H (White) EngKollinNo ratings yet

- Texol Texotherm HT Series Irhdr8Document2 pagesTexol Texotherm HT Series Irhdr8Vusal HasanovNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- 3M 8810 Thermal AdhesiveDocument8 pages3M 8810 Thermal Adhesivecsanders7No ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Busbar Insulation Tubing (BPTM) : Voltage Class 25 KV, Application Ø 6.5-220 MMDocument2 pagesBusbar Insulation Tubing (BPTM) : Voltage Class 25 KV, Application Ø 6.5-220 MMCarlos Alirio Vera ANo ratings yet

- Astm Lupoy ns5000c - EngDocument2 pagesAstm Lupoy ns5000c - EngJosh DineshNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Hercules EngDocument1 pageHercules EngTAREK HAMADNo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- 3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926Document7 pages3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926bnzelectricianshopNo ratings yet

- H70SDocument1 pageH70SJustin SantiagoNo ratings yet

- Search Codes - WazeDocument2 pagesSearch Codes - WazeJavierNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- CETAVER Adhesive TapeDocument1 pageCETAVER Adhesive TapeJavierNo ratings yet

- Topology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006Document9 pagesTopology Planning and Routing: Dean Wiltshire, SDD Product Architect - Mentor Graphics Corporation September 2006JavierNo ratings yet

- National Instr Tutorial 3092Document4 pagesNational Instr Tutorial 3092JavierNo ratings yet

- Mentorpaper 35429Document13 pagesMentorpaper 35429JavierNo ratings yet

- tt610 PDFDocument4 pagestt610 PDFJavierNo ratings yet

- Extenso MetersDocument22 pagesExtenso MetersJavierNo ratings yet

- Design For AssemblyDocument19 pagesDesign For AssemblyJavierNo ratings yet

- Therm6.3 10211 ValidationDocument7 pagesTherm6.3 10211 ValidationJavierNo ratings yet

- Loctite 235564 Do It Right Users GuideDocument44 pagesLoctite 235564 Do It Right Users GuideJavierNo ratings yet

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDocument32 pagesTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNo ratings yet

- Ethernet Train Bus ArticleDocument6 pagesEthernet Train Bus ArticleJavierNo ratings yet

- Texas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesDocument32 pagesTexas Instruments - Understanding Buck-Boost Power Stages in Switch Mode SuppliesJavierNo ratings yet

- Omnicon Sneak Analysis BrochureRevA8.5x11Document2 pagesOmnicon Sneak Analysis BrochureRevA8.5x11JavierNo ratings yet

- Loctite 235564 Do It Right Users GuideDocument44 pagesLoctite 235564 Do It Right Users GuideJavierNo ratings yet

- Omnicon Sneak Analysis BrochureRevA8.5x11Document2 pagesOmnicon Sneak Analysis BrochureRevA8.5x11JavierNo ratings yet

- Overvoltage Protection in Railway ABBDocument32 pagesOvervoltage Protection in Railway ABBJavierNo ratings yet

- LC ThesisDocument73 pagesLC ThesisJavierNo ratings yet

- Understanding Boost Power StagesDocument32 pagesUnderstanding Boost Power StagesphanioletyNo ratings yet

- Safety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDDocument25 pagesSafety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDJavierNo ratings yet

- Lessons in Electric Circuits, Volume I - DCDocument560 pagesLessons in Electric Circuits, Volume I - DCyoonghmNo ratings yet

- Mentor Paper 52590 BGA Fanout BreakoutDocument192 pagesMentor Paper 52590 BGA Fanout BreakoutMiriam DrathNo ratings yet

- Imeko WC 2012 TC4 O18Document5 pagesImeko WC 2012 TC4 O18JavierNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- IUIa GiV EnglDocument3 pagesIUIa GiV EnglJavierNo ratings yet

- Iwnicki 01 12Document63 pagesIwnicki 01 12JavierNo ratings yet

- WP BScan For Designers enDocument5 pagesWP BScan For Designers enJavierNo ratings yet

- Non Latching Relay - Leach InternationalDocument2 pagesNon Latching Relay - Leach InternationalJavierNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- Gr4 Reading InterventionDocument2 pagesGr4 Reading InterventionEvelyn Del RosarioNo ratings yet

- Data Sheet: Experiment 1: Chemical ReactionsDocument17 pagesData Sheet: Experiment 1: Chemical ReactionsThông LêNo ratings yet

- Most Popular Bootstrap Interview Questions and AnswersDocument6 pagesMost Popular Bootstrap Interview Questions and Answershassan TariqNo ratings yet

- 08 LCD Slide Handout 1Document5 pages08 LCD Slide Handout 1Jana Gabrielle Canonigo0% (1)

- Sokkia MagnetDocument9 pagesSokkia Magnetbbutros_317684077No ratings yet

- RAB PLTS Hybrid 1kWp-ScheneiderDocument4 pagesRAB PLTS Hybrid 1kWp-ScheneiderilhamNo ratings yet

- Sigma JsDocument42 pagesSigma JslakshmiescribdNo ratings yet

- Math10 q2 Week1 Module1 Polynomial-Functions For-ReproductionDocument32 pagesMath10 q2 Week1 Module1 Polynomial-Functions For-ReproductionChaz grant borromeo89% (9)

- SM QuestionDocument7 pagesSM QuestionPRiNCEMagNus100% (1)

- Fleet Management 101 Training Part 1:: Presenters Gary Hatfield, Mercury Associates William Gookin, Mercury AssociatesDocument22 pagesFleet Management 101 Training Part 1:: Presenters Gary Hatfield, Mercury Associates William Gookin, Mercury AssociatesAdolphe Hotereshi100% (1)

- Air Pollution Modelling With Deep Learning A ReviewDocument6 pagesAir Pollution Modelling With Deep Learning A ReviewliluNo ratings yet

- Yogesh Kadam (ABC)Document5 pagesYogesh Kadam (ABC)vipin HNo ratings yet

- Science Experiment Week 5 Lesson PlanDocument5 pagesScience Experiment Week 5 Lesson Planapi-451266317No ratings yet

- H-Beam Catalogue JindalDocument4 pagesH-Beam Catalogue JindalVikram DalalNo ratings yet

- Servo Drive TechnologyDocument102 pagesServo Drive Technologyirijskivrtovi4973No ratings yet

- z01 PDFDocument12 pagesz01 PDFZdravko RusevNo ratings yet

- Competency Based Learning Materials: Housekeeping NciiDocument54 pagesCompetency Based Learning Materials: Housekeeping NciiNickolodian AsuncionNo ratings yet

- Date CalcDocument8 pagesDate CalcPaolaNo ratings yet

- Product Positioning & Promotional Strategy of FevicolDocument5 pagesProduct Positioning & Promotional Strategy of FevicolBhat NaieemNo ratings yet

- Muetd - Session 3 - 2022 - 030716-08-1238 2Document1 pageMuetd - Session 3 - 2022 - 030716-08-1238 2Laila HaliliNo ratings yet

- Laboratory Activity 1CDocument4 pagesLaboratory Activity 1CAini HasshimNo ratings yet

- Punch Fear in The Face Escape AverageDocument12 pagesPunch Fear in The Face Escape AverageRezaBachtiarNo ratings yet

- Chapter 11Document3 pagesChapter 11Kristine TiuNo ratings yet

- AX Performance Tools1Document21 pagesAX Performance Tools1Htun Lin AungNo ratings yet

- What Is Your Future Plan EssayDocument3 pagesWhat Is Your Future Plan Essayafhbexrci100% (2)

- Cyber CXDocument2 pagesCyber CXhplzNo ratings yet

- Stats 2B03 Test #1 (Version 4) October 26th, 2009Document7 pagesStats 2B03 Test #1 (Version 4) October 26th, 2009examkillerNo ratings yet

- Agrasar Lecture and Demonstration Programme On Water, Food and Climate ChangeDocument20 pagesAgrasar Lecture and Demonstration Programme On Water, Food and Climate ChangeMinatiBindhaniNo ratings yet

- SAP On ASE Development UpdateDocument16 pagesSAP On ASE Development Updatebetoy castroNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Fighting Westway: Environmental Law, Citizen Activism, and the Regulatory War That Transformed New York CityFrom EverandFighting Westway: Environmental Law, Citizen Activism, and the Regulatory War That Transformed New York CityNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet