Professional Documents

Culture Documents

Snla 044 B

Snla 044 B

Uploaded by

Sreelekshmi UnnithanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Snla 044 B

Snla 044 B

Uploaded by

Sreelekshmi UnnithanCopyright:

Available Formats

Application Report

SNLA044B – January 2000 – Revised April 2013

AN-1031 TIA/EIA-422-B Overview

.....................................................................................................................................................

ABSTRACT

This application report covers topics associated with concerns for implementing a balanced interface

circuit utilizing the TIA/EIA-422-B (formerly RS-422-A) electrical interface standard.

Contents

1 Introduction .................................................................................................................. 2

2 Cable Length and Data Rate .............................................................................................. 2

3 Termination .................................................................................................................. 3

4 Failsafe ....................................................................................................................... 4

5 Configuration ................................................................................................................ 5

6 ESD Protection .............................................................................................................. 5

7 Live Insertion ................................................................................................................ 7

8 By-Pass Capacitors ......................................................................................................... 7

9 Stub Length .................................................................................................................. 8

10 Receiver Power Off Characteristics ...................................................................................... 8

11 Typical Cable Media ........................................................................................................ 9

12 Summary ................................................................................................................... 10

13 References ................................................................................................................. 10

List of Figures

1 Terminated Configuration .................................................................................................. 2

2 Receiver Operating Range ................................................................................................ 2

3 Cable Length Versus Data Rate .......................................................................................... 3

4 Multi-Drop Application With Parallel Termination ....................................................................... 4

5 Types of Failsafe ............................................................................................................ 4

6 Example of Multi-Point Configuration .................................................................................... 6

7 A Point-to-Point RS-422 System With TransZorbs ..................................................................... 6

8 Example of Protected Connectors ........................................................................................ 7

9 Stub Reflections ............................................................................................................. 9

10 Receiver ON/OFF Characteristics ........................................................................................ 9

TransZorbs is a registered trademark of General Semiconductor Industries !nc.

All other trademarks are the property of their respective owners.

SNLA044B – January 2000 – Revised April 2013 AN-1031 TIA/EIA-422-B Overview 1

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

Introduction www.ti.com

1 Introduction

TIA/EIA-422-B (RS-422) is an industry standard specifying the electrical characteristics of a balanced

interface circuit. Other prefixes are commonly used with the RS-422 standard. These include EIA, EIA/TIA,

and RS; although previously correct, today TIA/EIA is the correct prefix. However, for simplicity, RS-422

wil be used throughout the rest of this application report. Also, a suffix letter denotes the different revisions

of the standard but various prefixes with the same suffix reference the same identical standard.

RS-422 was introduced to solve the limitation problems of single-ended standards like TIA/EIA-232-E.

Single-ended interfaces lack common-mode noise rejection capability; ideal for noisy environments. Also,

data rates are usually limited to less than 0.5 Mbps. A RS-422 interface may be implemented to overcome

these limitations.

A RS-422 driver can drive up to ten unit loads (4 kΩ to circuit common is one unit load). The driver is

capable of transmitting data across 4000 feet (recommended limit) of cable; but not at maximum data

rates (see Figure 3 ). Standard RS-422 drivers are assured to source and sink a minimum 20 mA across a

100 Ω load. This corresponds to a minimum differential output voltage, VOD, of 2 V across the load (see

Figure 1).

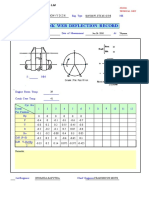

Figure 1. Terminated Configuration

The complement RS-422 receiver must be equal to or less than one unit load. This is represented by the

slope of the shaded region in Figure 2. The operating range of the receiver is defined between ±10 V and

is represented by the shaded area in Figure 2.

Figure 2. Receiver Operating Range

Also, RS-422 receivers have a ±200 mV threshold over the entire common mode range of ±7 V. A

differential noise margin ≥1.8 V is assured between the driver's differential output swing and the receiver's

threshold.

RS-422 drivers and receivers are designed for point-to-point and multi-drop configurations but not multi-

point. For multi-drop configurations, a daisy chain is the recommended interface configuration.

Caution, at long distances or high data rates, termination is recommended to reduce reflections caused by

a mismatch in the impedance of the cable and the impedance of the receiver's input. For further

information, see Section 3.

Significantly, the RS-485 differential interface standard is very similar to RS-422. However, there are

differences that distinguish the two standards from one another; which include the output stage of the

driver, the common mode range of the interface, the input resistance of the receiver, and the drive

capability of the driver. For more details concerning the comparison of RS-422 and RS-485, see AN-759

Comparing EIA-485 and EIA-422-A Line Drivers and Receivers in Multipoint Applications (SNLA023).

2 Cable Length and Data Rate

Cable length and data rate have an inverse affect on each other. When operating at either the

recommended maximum cable length or data rate, the other can not be obtained. For instance, it is not

possible to operate at 4000 feet when operating at 10 Mb/s or vice-versa.

2 AN-1031 TIA/EIA-422-B Overview SNLA044B – January 2000 – Revised April 2013

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

www.ti.com Termination

A chart displaying the recommended operational region of a typical RS-422 standard interface is shown in

Figure 3. Other electrical interface standards operating regions are also shown for comparison. The

curves were obtained from empirical data using a 24 AWG, copper, 16 pF/ft, twisted-pair cable parallel

terminated with a 100 Ω load.

Figure 3. Cable Length Versus Data Rate

3 Termination

Termination is recommended for use when designing a RS-422 interface that is considered to be a

transmission line. An interface is considered to be a transmission line if the propagation delay of the cable

is greater than ⅛ the transition (rise or fall) time of the signal. This is a time-domain analysis. The same is

also true in frequency-domain.

For clarification, the transition time for the time-domain analysis is measured from zero to one hundred

percent of the transition. The rising or falling edge may be used for analysis, whichever edge is the

fastest.

Transmission lines may restrict the use of a multi-drop configuration and limit the maximum data rate of

the RS-422 interface.

Transmission line theory will not be discussed in this application report but is useful knowledge. For more

details on transmission line theory, see AN-806 Data Transmission Lines and Their Characteristics

(SNLA026), AN-807 Reflections: Computations and Waveforms (SNLA027), and AN-808 Long

Transmission Lines and Data Signal Quality (SNLA028).

3.1 Parallel Termination

Parallel termination, a very popular form of termination, has the advantage of allowing higher data rates

and longer cable lengths than an interface using some other termination schemes because transmission

line effects are minimized. This is possible because the termination resistor (Rt) is chosen to closely

match the cable impedance (ZO) (see Figure 4). The cable impedance can be obtained from the cable

manufacturer. The cable impedance may also be measured using TDR, time domain reflectometry,

techniques. Additionally, because of the minimized affect of the transmission line, multi-drop configurations

with good signal quality are also possible, as long as the stubs (discussed later) are not transmission lines

themselves.

A disadvantage of parallel termination is the high power dissipation associated with the heavy termination

load. This also leads to a smaller differential output voltage and lower DC noise margins than with a series

termination. Also, if the receiver has built-in failsafe circuitry, a known output can not be ensured with this

type of termination scheme unless the receiver specifically says that it supports “terminated” failsafe. The

cost associated with purchasing the one external component should also be considered.

Other schemes exist to choose from and each type has its advantages and disadvantages. For more

detailed information on parallel and other termination schemes, see AN-903 A Comparison of Differential

Termination Techniques (SNLA034).

SNLA044B – January 2000 – Revised April 2013 AN-1031 TIA/EIA-422-B Overview 3

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

Failsafe www.ti.com

4 Failsafe

For typical RS-422 interfaces, open, terminated, and shorted input are the three types of failsafe to

consider as shown in Figure 5. A receiver with full failsafe protection assures a known receiver output for

all three types failsafe conditions.

4.1 Open Input Failsafe

Open input failsafe is the condition when the receiver's output is known when its inputs are left open or

floating. The driver is not connected but the receiver is powered. A receiver that provides failsafe for an

open input condition, may provide failsafe for idle (driver's output idle) and TRI-STATE (driver's output

disabled) conditions if the bus is not parallel terminated. Therefore, the output state of the receiver may be

known for both idle and TRI-STATE bus conditions in some instances.

A receiver is able to provide open input failsafe with internal pull-up and pull-down resistors, typically >50

kΩ. Sometimes only one bias resistor is used on one input and the other input biased to a voltage

reference point. Note that any receiver that does not have built-in failsafe, may use external pull-up and

pull-down resistors to provide failsafe protection.

Rt = ZO

where:

Rt = termination resistor

ZO = characteristic impedance of cable

Figure 4. Multi-Drop Application With Parallel Termination

4.2 Terminated Input Failsafe

A receiver has terminated failsafe when its output can be determined while its inputs are under terminated

conditions. This must be valid for various types of termination schemes; otherwise the receiver does not

have terminated failsafe. Additionally, terminated idle line and terminated TRI-STATE line conditions

should also be supported. For RS-422 receivers with built-in open input failsafe, the protection circuitry

does not ensure terminated failsafe operation. If a receiver does not have this feature, external bias

resistors may be used to provide terminated failsafe protection. For more information, see AN-847

FAILSAFE Biasing of Differential Buses (SNLA031) that is devoted to this topic.

Figure 5. Types of Failsafe

4 AN-1031 TIA/EIA-422-B Overview SNLA044B – January 2000 – Revised April 2013

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

www.ti.com Configuration

4.3 Shorted Input Failsafe

Shorted failsafe is when the receiver output is known when the receiver inputs are shorted together. If a

receiver does not have this type of failsafe, external pull-up and pull-down resistors alone may not help.

However, using an alternate-failsafe termination technique will provide protection. For details about

alternate-failsafe termination, see AN-903 A Comparison of Differential Termination Techniques

(SNLA034).

TI's DS36276 and DS36277 are interface devices that provide all three forms of failsafe protection with no

external components required. To accomplish this, the threshold point of the receiver was shifted, violating

the RS-422 ±200 mV threshold specification.

5 Configuration

For RS-422 interface devices, usually three types of configurations are commonly used.

5.1 Point-to-Point Configuration

First, point-to-point, is a one driver and one receiver system. Point-to-point applications may be thought of

as using single-ended standards like TIA/EIA-232-E because this is the configuration single-ended

standards are popular for. However, differential standards are not restricted from use in point-to-point

applications. A typical point-to-point system is shown in Figure 7.

5.2 Multi-Drop Configuration

The second configuration, multi-drop, is one driver with two or more receivers normally connected in a

daisy chain layout. For RS-422, the maximum number of receivers is 10 if the receiver's input impedance

(RIN) is equal to 4 kΩ or one unit load. If a receiver's RIN is equal to 8 kΩ then that receiver is equal to ½ a

unit load. Therefore, a RS-422 driver that can drive 10 unit loads can drive 20 receivers with a RIN = 8 kΩ.

An example of a multi-drop application is shown in Figure 4.

5.3 Multi-Point

The last type of configuration is multi-point, which uses two or more drivers connected to one or more

receivers (see Figure 6 ). RS-422 drivers are normally not designed into this type of configuration.

However, a multi-point system can be accomplished if certain issues are addressed. The three issues are

ground potential differences between drivers, contention between drivers, and the drive capability of the

drivers. Therefore, RS-485 devices are recommended for multi-point applications.

For further details and illustrations concerning these issues, see AN-759 Comparing EIA-485 and EIA-

422-A Line Drivers and Receivers in Multipoint Applications (SNLA023).

6 ESD Protection

Electrostatic discharge (ESD) is normally an event of very high potential for a short period of time. This

may be damaging to some integrated circuits (IC). ESD is not limited to a one time occurence in the life of

an IC, unless it is fatal the very first time. It may be an ongoing transpiration that can wear down an IC

until it eventually fails fatally.

The RS-422 standard does not specify requirements for ESD protection. However, the industry has

developed a defacto minimum standard of 2,000 V ESD protection under human body model (HBM)

conditions. However, many systems today require much higher levels of ESD protection. Possibly as high

as 10 kV or 15 kV.

ESD protection may be enhanced in different ways. IC protection circuitry, TransZorbs®, and protected

connectors are three possible solutions for increasing an IC's ESD protection. The first method is built-in

IC protection circuitry that requires no external components. This type of protection is the result of the

manufacturer's IC design. In the early years of IC manufacturing, ESD was not as well publicized or

standardized as it is today. Today, IC designers strive to achieve five, ten, even fifteen thousand Volts of

ESD protection.

SNLA044B – January 2000 – Revised April 2013 AN-1031 TIA/EIA-422-B Overview 5

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

ESD Protection www.ti.com

Figure 6. Example of Multi-Point Configuration

Figure 7. A Point-to-Point RS-422 System With TransZorbs

The later two solutions, TransZorbs and protected connectors, are both external to the IC and usually

implemented, by the system manufacturer, to provide additional protection, if needed, beyond that which is

supplied by the IC itself.

6.1 Integrated Circuits

IC protection circuitry is normally designed into the die at the input and output stages of the device. This is

because these are the stages that connect to the outside world (via cables or other media). Thus, these

are the locations damaged most often by ESD phenomenon. The purpose of the circuitry is to, one, be

able to drain off very large amounts of current very quickly, and two, keep the high current away from

sensitive areas of the IC. An analogy may be made with lightning rods that channel away large amounts of

current, caused by a very large electric field (potential), from your house.

6.2 TransZorb

TransZorbs are like back-to-back diodes. They are connected between the interface line that needs

protection and ground. They act like voltage clamps, clamping voltages that are above the TransZorb's

specified reverse stand-off voltage (Vrs). Take care when selecting a TransZorb, if the Vrs is too high, the

IC may become damaged before the TransZorb ever turns on. One TransZorb should be used per

interface line. This solution could become expensive as the number of interface lines requiring protection

increases. Figure 7 shows an example of a RS-422 point-to-point system with TransZorbs.

6.3 Protected Connectors

Protected connectors, another solution for increasing ESD protection of an IC, provides the same type of

clamping protection that TransZorbs do. However, only one device is needed per interface connector.

Therefore, if you have a DB-25 pin connector, all 25 lines receive the same increase in ESD damage

resistance. Additionally, designers do not need to worry about lack of additional PC board space, since the

device is built into the connector. Also, the protected connector only adds an additional 5 pF or 6 pF of

capacitance to the signal load. Designers will be able to find protected connectors in a variety of connector

sizes. Figure 8 shows a diagram of two connectors with built-in ESD protection.

6 AN-1031 TIA/EIA-422-B Overview SNLA044B – January 2000 – Revised April 2013

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

www.ti.com Live Insertion

In the later two solutions, the system manufacturer provides additional ESD protection. Ideally, system

manufacturers would like the IC manufacturers to provide all the ESD protection required for their

systems, internal to the device. Texas Instruments interface group recognizes the importance of ESD

protection and has released the DS36276 and the DS36277 with ESD protection up to 7,500 V. Future

Interface products will trend toward higher ESD protection.

7 Live Insertion

RS-422 does not specify how to insert an IC (driver or receiver) into a live interface. The same is true for

removing the IC. PC board connectors, cable connectors, and sockets are likely interface points. A device

may be inserted live via one of these interfaces. Live insertion is a larger concern, since removing an IC,

from a live interface, normally is less damaging to an IC. For live insertion, the device may not be powered

up when being inserted. Thus, the RS-422 device may receive bus potentials that exceed the power

supply voltage (VCC). First, this may cause biasing of diodes and bus clamping, or result in large current

faults that damage devices. Second, the potential difference between ICs connections and the interface

connector may be large enough to cause ESD strikes which may be harmful to the IC. In addition, the IC

may transmit signals when the supply voltage is below minimum operating level which may result in data

transfer errors. On the other hand, when removing an IC from an active interface, the VCC should be within

normal operating levels with no device pins higher than the supply pin. Also, the potential difference at the

instance of the disconnect is minimized since the potential is the equivalent just prior.

Figure 8. Example of Protected Connectors

Recommendations for implementing a live interface are, one, use an IC that supports the feature. Look for

this feature in the device's datasheet. However, it will not always appear there so be sure to ask the chip

manufacturer's technical support group, to be certain. These ICs usually have specially designed input

and output structures that prevent damage to the device even if bus voltages exceed VCC. Two, since

removal is less harmful than inserting, try to create similar conditions for inserting the chip that would exist

when removing the chip. In other words, it is ideal to have the device powered and referenced to the same

ground potential as the interface before the inputs and outputs make physical contact.

For a PC board, a staggered connection where the ground trace is the longest, so that it makes contact

first, and the VCC trace is the second longest followed by the input traces then the output traces last would

suffice. Live insertion via cables or sockets may require special design but should make contact in the

same pattern.

8 By-Pass Capacitors

By-pass capacitors help reduce transients on output signals. Therefore, by-pass capacitors are

recommended for better signal quality. One 0.1 μF capacitor is recommended for each powered IC in the

system. If a device has more than one power supply (VCC and VEE) then use one capacitor for each supply.

The capacitor should be placed between the power supply pin and ground. Place the capacitor as close to

the VCC pin of the device as possible. Additionally, a 10 μF capacitor may be used near the main path

where VCC is delivered to the system for bulk charge storage. If a system is large, additional bulk

capacitance may be distributed across the system.

SNLA044B – January 2000 – Revised April 2013 AN-1031 TIA/EIA-422-B Overview 7

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

Stub Length www.ti.com

9 Stub Length

Since RS-422 is a multi-drop standard, receivers may be connected to the bus via a stub. The length of

the stub is important because of the affect it may have on the signal. As the stub length is increased, its

characteristics begin to act as a transmission line. When is a stub considered to be a transmission line? A

typical guideline for stubs and transmission lines is stated here:

Time Domain:

If the propagation delay of the stub (one way trip) is greater than ⅛ the transition time, measured from 0%

to 100% of the signal transition, then the stub may be considered a transmission line.

The boundary conditions at which a stub begins to act as a transmission line are not precise. Therefore,

designers may use slightly different ratios.

Furthermore, the maximum length of the stub depends on the transition time measured at the point of the

stub interconnect. This is very important to remember because if the total length of the cable is 1,000 feet,

a longer stub can be hung off the cable at 750 feet away from the driver than at 75 feet away from the

driver. This is because the cable capacitance slows the transition time of the driver's output as it

propagates down the cable and the transition time is longer.

The length of the stub may be increased by slowing down the transition edge at the stub interconnect.

This can be done using a bulk capacitance load or a RS-422 driver with output wave shape control like

TI's DS3691, DS3692, or DS36C280.

To implement a RS-422 interface with stubs of equal length. Apply the stub guideline rule to the stub(s)

closest to the driver's output and use this length for the maximum length for all stubs on the interface bus.

If a stub is too long and causes a noticeable reflection, it will be measured positive on the stub because

the voltage reflection coefficient is positive since the load impedance ZL is larger than the stub impedance

Zo. The formula for the reflection coefficient at the load is shown in Equation 1.

(1)

Note, the load impedance is equivalent to the input impedance of the receiver, which is equal to or greater

than 4 kΩ. The stub impedance is typically about 100 Ω–130 Ω. The reflection created at the stub will

propagate in both directions away from the stub (see Figure 9). Keep in mind that reflections are time

dependent events.

10 Receiver Power Off Characteristics

The receivers characteristics powered down are similar to those when powered up (see Figure 10).

Therefore, the receiver, when physically connected, may be powered up or down transparent to the RS-

422 driver.

10.1 Receiver Input Impedance

The receiver input impedance curve is identical for both inputs while the receiver is powered off. The

characteristic curves also pass through the (0 V, 0 mA) coordinate (see Figure 10). While the receiver is

powered on, the impedance of both inputs are the same but the input impedance curves do not pass

through the (0 V, 0 mA) point. Additionally, the curves may or may not cross the x and y axis at the same

points (see Figure 10). For receivers with built-in open input failsafe, the curves will differ by at least 200

mV over operating range.

The input impedance of a RS-422 receiver is assured from −10 V to +10 V, which is the operating range

for RS-422 receivers. The 10 V is equal to the 7V common mode voltage plus 3 V offset voltage.

8 AN-1031 TIA/EIA-422-B Overview SNLA044B – January 2000 – Revised April 2013

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

www.ti.com Typical Cable Media

Figure 9. Stub Reflections

Figure 10. Receiver ON/OFF Characteristics

10.2 Receiver Breakdown Voltage

The receiver breakdown voltage is assured to be greater than ±10 V whether the receiver is powered on

or off. The breakdown point may be found by curve tracing the device out past ±10 V. Breakdown voltages

may be more than twice the maximum operating voltage.

11 Typical Cable Media

11.1 Cable Type

Flat or round cables may be used when connecting a RS-422 driver and receiver(s). Twisted pair or non-

twisted conductors may be used. Twisted pair cables have an advantage over non-twisted when

transmitting differential signals. Twisted pair cables couple noise more symmetrically than non-twisted pair

cables. This helps preserve the noise rejection limits of the RS-422 receiver (±7 V).

11.2 Cable Size

The defacto standard gauge size is 24 AWG. A range of 22 AWG to 28 AWG is acceptable for most

applications. For cable length, see Section 2 in this application report.

SNLA044B – January 2000 – Revised April 2013 AN-1031 TIA/EIA-422-B Overview 9

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

Summary www.ti.com

11.3 More on Cables

For more details on cable selections, including information concerning shields, insulation, and cable

characteristics, see AN-916 A Practical Guide To Cable Selection (SNLA219).

12 Summary

RS-422 is a standardized differential electrical interface capable of transmitting data in point-to-point and

multi-drop applications. When implementing a RS-422 interface, make sure design-in concerns are

addressed at the early stages of design to eliminate problems later in the application, which may be a lot

more costly. Understanding RS-422 means understanding the issue associated with the interface.

RS-422 is a well-defined standard and has many applications. However, RS-422 has been superseded by

RS-485, which builds onto the existing foundation and creates an even more rugged standard. For more

information on RS-485, see AN-979 The Practical Limits of RS-485 (SNLA042).

13 References

• TIA/EIA-422-B, Electrical Characteristics of Balanced Digital Interface Circuits, Electronic Industries

Association Engineering Department. Washington D.C. 1994.

• INTERFACE: Data Transmission Databook

• AN-759 Comparing EIA-485 and EIA-422-A Line Drivers and Receivers in Multipoint Applications

(SNLA023)

• AN-806 Data Transmission Lines and Their Characteristics (SNLA026)

• AN-807 Reflections: Computations and Waveforms (SNLA027)

• AN-808 Long Transmission Lines and Data Signal Quality (SNLA028)

• AN-847 FAILSAFE Biasing of Differential Buses (SNLA031)

• AN-903 A Comparison of Differential Termination Techniques (SNLA034)

• AN-916 A Practical Guide To Cable Selection (SNLA219)

• AN-979 The Practical Limits of RS-485 (SNLA042)

10 AN-1031 TIA/EIA-422-B Overview SNLA044B – January 2000 – Revised April 2013

Submit Documentation Feedback

Copyright © 2000–2013, Texas Instruments Incorporated

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

You might also like

- RSER200-4 HW Mod Description 300993CDocument26 pagesRSER200-4 HW Mod Description 300993CTEUKU100% (9)

- 1900 TB067Document199 pages1900 TB067anon_94758426667% (3)

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- CANopen For ASDA-A2 - M - EN - 20140430Document69 pagesCANopen For ASDA-A2 - M - EN - 20140430Rubens PaivaNo ratings yet

- TIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Document8 pagesTIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Iman AkbariNo ratings yet

- TIA-EIA-422-B Overview (AN-1031)Document7 pagesTIA-EIA-422-B Overview (AN-1031)EingerNo ratings yet

- RS1600 Installation GuideDocument22 pagesRS1600 Installation GuidengocanhvyNo ratings yet

- Snoa 405 ADocument8 pagesSnoa 405 ADeniz GülerNo ratings yet

- RS-422 and RS-485 Application Note: B&B Electronics Mfg. Co. IncDocument44 pagesRS-422 and RS-485 Application Note: B&B Electronics Mfg. Co. IncPandemic SorcererNo ratings yet

- RS-422 and RS-485 Application Note: B&B Electronics Mfg. Co. IncDocument43 pagesRS-422 and RS-485 Application Note: B&B Electronics Mfg. Co. IncabababababNo ratings yet

- The RS-485 Design GuideDocument9 pagesThe RS-485 Design GuideZoran FabekovicNo ratings yet

- Selecting and Using RS-232, RS-422, and RS-485 Serial Data StandardsDocument9 pagesSelecting and Using RS-232, RS-422, and RS-485 Serial Data StandardssoumyajitemdmNo ratings yet

- Catalog Datacom Products Telebite 2006Document21 pagesCatalog Datacom Products Telebite 2006doddyNo ratings yet

- 1mrk507004-Uen B en Radhl User S GuideDocument40 pages1mrk507004-Uen B en Radhl User S Guideali surfNo ratings yet

- SEL Relays New York Application GuideDocument32 pagesSEL Relays New York Application Guidepistola2No ratings yet

- WEG Sca06 Wegtp Manual 10001626001 Manual EnglishDocument19 pagesWEG Sca06 Wegtp Manual 10001626001 Manual EnglishJoelson MeneghelliNo ratings yet

- High-Speed Layout Guidelines For Signal ConditionersDocument25 pagesHigh-Speed Layout Guidelines For Signal ConditionersnaveenkumarNo ratings yet

- Reference Design Report For A 12 W Pow Er Supply Using Tinysw Itch - 4 Tny288PgDocument36 pagesReference Design Report For A 12 W Pow Er Supply Using Tinysw Itch - 4 Tny288PgVinayNo ratings yet

- Delta Ia-Plc Plc-Link An en 20160127Document151 pagesDelta Ia-Plc Plc-Link An en 20160127Pato LlumiNo ratings yet

- AN-1849 An Audio Amplifier Power Supply Design: Application ReportDocument17 pagesAN-1849 An Audio Amplifier Power Supply Design: Application ReportJuzt AdhitNo ratings yet

- sx1232 Lna and Pa Impedance Matching TechniquesDocument13 pagessx1232 Lna and Pa Impedance Matching TechniquesĐinh Bảo NgânNo ratings yet

- Snaa 046 ADocument10 pagesSnaa 046 Acereayram1No ratings yet

- An-960 RS 485 Incl Termination DetailsDocument12 pagesAn-960 RS 485 Incl Termination Detailsqafqgibsonq4543100% (1)

- How Far and How Fast Can You Go With RS-485?Document12 pagesHow Far and How Fast Can You Go With RS-485?Dhani Aristyawan SimangunsongNo ratings yet

- CAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionDocument18 pagesCAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionbuitanmanNo ratings yet

- SN75176A Differential Bus Transceiver: 1 FeaturesDocument24 pagesSN75176A Differential Bus Transceiver: 1 FeaturesCharbel TadrosNo ratings yet

- Px3x C434 EN REB B22Document58 pagesPx3x C434 EN REB B22Tiến Trần ThanhNo ratings yet

- Adm485 PDFDocument16 pagesAdm485 PDFrezaNo ratings yet

- THVD1500 500 Kbps RS-485 Transceivers With 8-kV IEC ESD ProtectionDocument29 pagesTHVD1500 500 Kbps RS-485 Transceivers With 8-kV IEC ESD ProtectionsyahabdulrizalNo ratings yet

- THVD 1400Document33 pagesTHVD 1400victorvpaiva07No ratings yet

- An 903 Line TerminationDocument10 pagesAn 903 Line Terminationder_gaertnerNo ratings yet

- An2674 Application Note: PCB Layout Guidelines For Spear3XxDocument22 pagesAn2674 Application Note: PCB Layout Guidelines For Spear3XxPep DizNo ratings yet

- Simple 1.5-V Boost Converter For MSP430 - Slaa105Document7 pagesSimple 1.5-V Boost Converter For MSP430 - Slaa105Daniel ZancoNo ratings yet

- Cable Guide: Including All Portserver and Digi One ProductsDocument21 pagesCable Guide: Including All Portserver and Digi One ProductsMarcos Ribeiro da AnunciaçãoNo ratings yet

- EIA-422 Bus Interface DescrDocument6 pagesEIA-422 Bus Interface DescralbertomiguezNo ratings yet

- Pca 9306Document32 pagesPca 9306Adhiezzz GamingNo ratings yet

- Technical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Document29 pagesTechnical Specification For 11kV, 20kV and 33kV Pole Mounted Auto-Reclose Circuit Breakers NPS001 - 009Indika Withanage100% (1)

- Tia Eia 612Document20 pagesTia Eia 612joshuac4No ratings yet

- Design Notes: Interface Circuits For Tia/Eiać232ĆfDocument22 pagesDesign Notes: Interface Circuits For Tia/Eiać232ĆfJacson FagundesNo ratings yet

- Sinumerik 800 Universal Interface GuideDocument95 pagesSinumerik 800 Universal Interface Guidemanuel_plfNo ratings yet

- Canopen: Cia Draft Recommendation Proposal 303-1Document25 pagesCanopen: Cia Draft Recommendation Proposal 303-1Mank UduyNo ratings yet

- Tda 7388Document11 pagesTda 7388Lucas Meister BarichelloNo ratings yet

- AN-979 The Practical Limits of RS-485: Application ReportDocument9 pagesAN-979 The Practical Limits of RS-485: Application ReportAkhilNo ratings yet

- Solderless Terminals and Cable Lugs For Signalling ApplicationsDocument10 pagesSolderless Terminals and Cable Lugs For Signalling Applicationsjiguparmar20094903No ratings yet

- Digital Equipment Server DECServer 300 Hardware Installation - Cable BC16E-Xx and Adapter H8571-xDocument109 pagesDigital Equipment Server DECServer 300 Hardware Installation - Cable BC16E-Xx and Adapter H8571-xVinicius Almeida SantosNo ratings yet

- OP177Document16 pagesOP177rahms79No ratings yet

- LVDS SignalsDocument37 pagesLVDS SignalsDariel Hernández CarmonaNo ratings yet

- AN5032Document12 pagesAN5032Ashwin BhatNo ratings yet

- Figure 3.2. RS-485 BusDocument42 pagesFigure 3.2. RS-485 BusMichal Cousins100% (1)

- RS 485Document6 pagesRS 485Venkatesh Venkataramani100% (1)

- SN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RDocument32 pagesSN65HVD82 Robust RS-485 Transceiver: 6 7 A B 3 4 2 1 RE RAmir Reza BeheshtianNo ratings yet

- RS-485 BiasingDocument12 pagesRS-485 BiasingDirceu Rodrigues JrNo ratings yet

- Reactor de LineaDocument20 pagesReactor de LineaDaniel SanchezNo ratings yet

- CAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable SelectionDocument18 pagesCAN - Wiring: Notes On The Wiring of CAN-Bus Systems and The Cable Selectionamadeo magnusNo ratings yet

- Use Receiver Equalization To Extend RS-485 Data CommunicationsDocument29 pagesUse Receiver Equalization To Extend RS-485 Data CommunicationsTaranpreet KhuranaNo ratings yet

- ETS12-01-04 - 12-24KV Current Limiting Fuse For OH ApplicationsDocument12 pagesETS12-01-04 - 12-24KV Current Limiting Fuse For OH ApplicationsTerex14253No ratings yet

- 003-1007-028 Issue 5 PDFDocument37 pages003-1007-028 Issue 5 PDFJeya ChandranNo ratings yet

- NOJA SCADA Interface Description PDFDocument44 pagesNOJA SCADA Interface Description PDFbrykymaNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Instrumentation and Test Gear Circuits ManualFrom EverandInstrumentation and Test Gear Circuits ManualRating: 5 out of 5 stars5/5 (1)

- Qsgmii SpecificationDocument20 pagesQsgmii Specificationreza_azadNo ratings yet

- Description Features: 3-Channel High-Performance TCXO/LVCMOS Clock Buffer Family 5PB12xx DatasheetDocument16 pagesDescription Features: 3-Channel High-Performance TCXO/LVCMOS Clock Buffer Family 5PB12xx Datasheetreza_azadNo ratings yet

- Femtoclock NG Universal Frequency Translator With Phase Build-OutDocument42 pagesFemtoclock NG Universal Frequency Translator With Phase Build-Outreza_azadNo ratings yet

- NPort 5100 Series - Moxa-Pcomm-Lite-Utility-V1.6.zip - Software Release HistoryDocument4 pagesNPort 5100 Series - Moxa-Pcomm-Lite-Utility-V1.6.zip - Software Release Historyreza_azadNo ratings yet

- 74LVC16245A 74LVCH16245A: 1. General DescriptionDocument21 pages74LVC16245A 74LVCH16245A: 1. General Descriptionreza_azadNo ratings yet

- AN1208: Choosing The Correct Oscillator To Meet Your IEEE 1588v2 Network Synchronization Holdover RequirementsDocument17 pagesAN1208: Choosing The Correct Oscillator To Meet Your IEEE 1588v2 Network Synchronization Holdover Requirementsreza_azadNo ratings yet

- Low - Pow Er, 1.62V To 3.63V, 1Mhz To 150Mhz, 1:2 Fanout Buffer IcDocument5 pagesLow - Pow Er, 1.62V To 3.63V, 1Mhz To 150Mhz, 1:2 Fanout Buffer Icreza_azadNo ratings yet

- Si5338 EVBDocument12 pagesSi5338 EVBreza_azadNo ratings yet

- 7 Series FPGAs OverviewDocument16 pages7 Series FPGAs Overviewreza_azadNo ratings yet

- Microsemi Time Interfaces WertheimerDocument29 pagesMicrosemi Time Interfaces Wertheimerreza_azadNo ratings yet

- Stanag / Havequick Synchronization Stanag / Havequick SynchronizationDocument4 pagesStanag / Havequick Synchronization Stanag / Havequick Synchronizationreza_azad100% (2)

- Aliant Ommunications: IEEE-1588v2 PTP SlaveDocument2 pagesAliant Ommunications: IEEE-1588v2 PTP Slavereza_azadNo ratings yet

- Timespy Elite - Portable Precision Time MeasurementDocument5 pagesTimespy Elite - Portable Precision Time Measurementreza_azadNo ratings yet

- Managing The Impact of Cable DelaysDocument10 pagesManaging The Impact of Cable Delaysreza_azadNo ratings yet

- CE Time Catcher 1588Document2 pagesCE Time Catcher 1588reza_azadNo ratings yet

- Ulp Aluminum Electrolytic CapacitorsDocument10 pagesUlp Aluminum Electrolytic Capacitorsreza_azadNo ratings yet

- Samsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFDocument9 pagesSamsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFreza_azadNo ratings yet

- Revisions C: D REVISED PER ECO-14-005095 AP RP E REVISED PER ECO-16-008845 AP RPDocument1 pageRevisions C: D REVISED PER ECO-14-005095 AP RP E REVISED PER ECO-16-008845 AP RPreza_azadNo ratings yet

- 244 31300 15 - enDocument5 pages244 31300 15 - enreza_azadNo ratings yet

- Cat24c208 DDocument11 pagesCat24c208 Dreza_azadNo ratings yet

- Configuring Clocking and TimingDocument52 pagesConfiguring Clocking and Timingreza_azadNo ratings yet

- Hardware and Layout Design Considerations For DDR2 SDRAM Memory InterfacesDocument16 pagesHardware and Layout Design Considerations For DDR2 SDRAM Memory Interfacesreza_azadNo ratings yet

- San Ace 60 9G: General SpecificationsDocument3 pagesSan Ace 60 9G: General Specificationsreza_azadNo ratings yet

- Rje 481881 X 01Document1 pageRje 481881 X 01reza_azadNo ratings yet

- RJ45 Down Without LEDDocument1 pageRJ45 Down Without LEDreza_azadNo ratings yet

- SD387EVK: LMH0387 Evaluation Board User GuideDocument24 pagesSD387EVK: LMH0387 Evaluation Board User Guidereza_azadNo ratings yet

- Transformer Test ReportDocument2 pagesTransformer Test Reportprum sophearithNo ratings yet

- Copper Catalog BeldenDocument80 pagesCopper Catalog BeldenIve Fagua GarcíaNo ratings yet

- Key To Safe Wiring: TW Flat Cord Auto Wire Magnet WireDocument2 pagesKey To Safe Wiring: TW Flat Cord Auto Wire Magnet WireProperty Baguio ListingNo ratings yet

- Checklist - Self Assessment of HSE Controls at Retail Outlets 200520Document1 pageChecklist - Self Assessment of HSE Controls at Retail Outlets 200520Sagar691No ratings yet

- Mitsubishi Colt Component LocationsDocument18 pagesMitsubishi Colt Component LocationsnalokinNo ratings yet

- Digitron Semiconductors: MBR2060CT-MBR20100CT 20A Schottky RectifiersDocument2 pagesDigitron Semiconductors: MBR2060CT-MBR20100CT 20A Schottky RectifiersShawn ClearNo ratings yet

- Plug Screw Calc (APS100) 150208Document16 pagesPlug Screw Calc (APS100) 150208Subam ProjectsNo ratings yet

- TM 11-6130-413-24P - Battery - Charger-Analyzer - AN - USM-432 - 1980 PDFDocument25 pagesTM 11-6130-413-24P - Battery - Charger-Analyzer - AN - USM-432 - 1980 PDFWurzel1946100% (1)

- Digital PowerDocument20 pagesDigital PowerPacebok PacebokNo ratings yet

- Interlight CatalogDocument40 pagesInterlight CatalogrfffffNo ratings yet

- Calculating Decap and Bulk Cap Values For High Speed DevicesDocument4 pagesCalculating Decap and Bulk Cap Values For High Speed DevicesHemantkumarNo ratings yet

- BA3Document3 pagesBA3franz_passariniNo ratings yet

- Led TV : Owner'S ManualDocument24 pagesLed TV : Owner'S Manualhadi yanNo ratings yet

- 2822 HDocument3 pages2822 HKrank101No ratings yet

- OfflineOrderNumber Tool Ver15 50d 758059ENmDocument77 pagesOfflineOrderNumber Tool Ver15 50d 758059ENmEmir Kamberović100% (1)

- Ficha Tecnica ZS21KAE-PFV InglesDocument2 pagesFicha Tecnica ZS21KAE-PFV InglesPascual DuqueNo ratings yet

- Main Eng and DG Crank ShaftDocument3 pagesMain Eng and DG Crank Shaftabdullah putraNo ratings yet

- 7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitDocument52 pages7.1 - en-US - 2022-04 - BRK - Flygt Basic Repair KitFernando ChavesNo ratings yet

- Single Comparator: Features DescriptionDocument10 pagesSingle Comparator: Features DescriptionJose PerezNo ratings yet

- Electronic Circuit Analysis and Design-1Document20 pagesElectronic Circuit Analysis and Design-1abd syNo ratings yet

- Janome QC6260 Sewing Machine Instruction ManualDocument52 pagesJanome QC6260 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Manual Smartwatch U8Document19 pagesManual Smartwatch U8nageswara reddyNo ratings yet

- MR J2 A Installation ManualDocument346 pagesMR J2 A Installation ManualtranhoachbnNo ratings yet

- Linearlight Power Flex Lm10pDocument4 pagesLinearlight Power Flex Lm10pFandy Aditya WiranaNo ratings yet

- Blastgate Catalog 2018 PDFDocument24 pagesBlastgate Catalog 2018 PDFLeDzungNo ratings yet

- Diagnosis Tool Repair CaterpillarDocument14 pagesDiagnosis Tool Repair CaterpillarGuido Giovanni Franco RodriguezNo ratings yet

- EXCETEKDocument21 pagesEXCETEKLegi YangNo ratings yet

- Robotic Gripper DesignDocument22 pagesRobotic Gripper DesignHaider-e-KararNo ratings yet

- MidD - APS 1500A-230 SolutionsDocument25 pagesMidD - APS 1500A-230 SolutionsJoseric21No ratings yet