Professional Documents

Culture Documents

FB100 - Eng - Morgan

Uploaded by

6t7qcmkf5jOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FB100 - Eng - Morgan

Uploaded by

6t7qcmkf5jCopyright:

Available Formats

FireMaster® FB100

Fire Protection Spray System

Product Data Sheet

Product Description

FireMaster FB100 is a medium density spray-applied fire protection material developed especially for fire protection of

loadbearing structures against high temperature hydrocarbon fuel fires. FireMaster FB100 is supplied as a dry powder

mixed with water on site and spray applied onto the substrate to be protected.

FireMaster FB100 is suitable for application onto steel or concrete structures and has the following advantages:

• Low rebound during spraying resulting in low wastage and clean installation

• Excellent adhesion allowing the entire applied thickness to be installed with a single spray application

• Efficient thickness requirements for fire protection

Fire Performance Testing

FireMaster FB100 has been tested, certified and is UL listed for UL 1709 structural steel fire protection for

up to 4 hours duration.

Reaction to Fire EN 13501-1: Class A1

Resistance to Fire UL 1709 Fire Protection

UL Listing BYBU.XR749

Rating, Hour Thickness, minimum, mm (in)

1 20 (0.79)

1 1/2 26 (1.03)

2 33 (1.30)

2 1/2 39 (1.54)

3 44 (1.74)

3 1/2 49 (1.93)

4 54 (2.13)

Load bearing Concrete Structures EN 13381-33381-3

44 32 (1.28)

Whilst the values and application information in this datasheet are typical, they are given for guidance only. The values and the information

given are subject to normal manufacturing variation and may be subject to change without notice. Morgan Advanced Materials – Thermal

Ceramics makes no guarantees and gives no warranties about the suitability of a product and you should seek advice to confirm the

product’s suitability for use with Morgan Advanced Materials - Thermal Ceramics.

Publication Date: 1 March 2022 www.morganthermalceramics.com

Code: CA.28 Email: marketing.tc@morganplc.com

1 of 2 Thermal Ceramics is a business of Morgan Advanced Materials

FireMaster® FB100

Fire Protection Spray System

Product Data Sheet

Density, applied, kg/m3 (pcf)

Applied 624 - 672 (38.9 - 41.9)

Dry @ 50°C (122°F) 595 (37.1)

Estimated weight of dry material/ m3 for installation, kg (lb) 630 (39.3)

Cold crushing strength, MPa (psi), ASTM C133

50°C (122°F) 1.6 (232)

Packaging, kg (lb) 20 (44)

Thermal Conductivity, W/m•K (BTU•in/hr•ft2•°F), ASTM C177-19

100°C (212°F) 0.174 (1.21)

200°C (392°F) 0.176 (1.22)

300°C (572°F) 0.181 (1.26)

400°C (752°F) 0.189 (1.31)

500°C (932°F) 0.199 (1.39)

600°C (1112°F) 0.211 (1.46)

700°C (1292°F) 0.225 (1.56)

Thermal Diffusivity and Specific Heat, ASTM E-1461 and DIN EN 821

Temperature, °C (°F) Specific Heat, J/g•K Thermal Diffusivity, mm 2/s

300°C (572°F) 0.95 0.27

500°C (932°F) 1.47 0.26

800°C (932°F) 2.58 0.32

Storage and Shelf Life

• Should be stored in dry conditions, unopened packaging on pallets. Do not store on ground. Keep out of rain and

damp conditions.

• Shelf life is of twelve months with original packaging, double shrink film and dehydrating agent provided if the

monolithic is stored under these recommended conditions.

Whilst the values and application information in this datasheet are typical, they are given for guidance only. The values and the information

given are subject to normal manufacturing variation and may be subject to change without notice. Morgan Advanced Materials – Thermal

Ceramics makes no guarantees and gives no warranties about the suitability of a product and you should seek advice to confirm the

product’s suitability for use with Morgan Advanced Materials - Thermal Ceramics.

Publication Date: 1 March 2022 www.morganthermalceramics.com

Code: CA.28 Email: marketing.tc@morganplc.com

2 of 2 Thermal Ceramics is a business of Morgan Advanced Materials

You might also like

- 4 Evonik Cationicsurfactantshousehold2014 140821133037 Phpapp01Document96 pages4 Evonik Cationicsurfactantshousehold2014 140821133037 Phpapp01topguitar100% (1)

- Volatile Oils: Resins and Resins CombinationDocument22 pagesVolatile Oils: Resins and Resins CombinationVikash KushwahaNo ratings yet

- RHI Refractory-3Document24 pagesRHI Refractory-3Mashiur RahmanNo ratings yet

- Gromacs Tutorial 2 (Protein) PDFDocument19 pagesGromacs Tutorial 2 (Protein) PDFEliasSMonteiroFilhoNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- Dokumen - Pub The Beauty Geeks Guide To Skin Care 1000 Essential Definitions of Common Product Ingredients 9781641523592 9781641523608Document290 pagesDokumen - Pub The Beauty Geeks Guide To Skin Care 1000 Essential Definitions of Common Product Ingredients 9781641523592 9781641523608Hajer SarwatNo ratings yet

- LADLE DRAWING & Refractory DATA SHEETDocument10 pagesLADLE DRAWING & Refractory DATA SHEETMashiur RahmanNo ratings yet

- LADLE LINING R Efractory Data SheetDocument10 pagesLADLE LINING R Efractory Data SheetMashiur RahmanNo ratings yet

- TUNDISH COVER RefractoryDocument3 pagesTUNDISH COVER RefractoryMashiur RahmanNo ratings yet

- Science Grade 9: Quarter 2 - Module 2 Chemical BondingDocument16 pagesScience Grade 9: Quarter 2 - Module 2 Chemical BondingElla Suan Tero100% (6)

- Zirconia Coating DSMTS-0038.1 - CeZrODocument3 pagesZirconia Coating DSMTS-0038.1 - CeZrObotan_mihaiNo ratings yet

- SUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFDocument1 pageSUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFgiuseppe.timpone1No ratings yet

- Firecrete-3x EngDocument2 pagesFirecrete-3x EngFay MichailNo ratings yet

- 1 MAGKOR - K - Zement - ISO - ENDocument1 page1 MAGKOR - K - Zement - ISO - ENValyJaraFariasNo ratings yet

- TDS Marlotherm LHDocument2 pagesTDS Marlotherm LHManu Fernandez AfonsoNo ratings yet

- Insulating and Refractory FirebrickDocument3 pagesInsulating and Refractory FirebrickAleem QureshiNo ratings yet

- lc140 EngDocument2 pageslc140 EnganassNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- ANKRAL Q1 Zement ISO ENDocument1 pageANKRAL Q1 Zement ISO ENengr kazamNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- InsulationDocument23 pagesInsulationFabio TemporiniNo ratings yet

- MultimediaDocument4 pagesMultimediaVIVEK SAININo ratings yet

- HT Cast: Product DescriptionDocument2 pagesHT Cast: Product DescriptionanassNo ratings yet

- Ht-Cast EngDocument2 pagesHt-Cast EnganassNo ratings yet

- Technical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketDocument2 pagesTechnical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketMohamed KhaledNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Magnum 3416 SC: Product InformationDocument2 pagesMagnum 3416 SC: Product InformationDridi BadredineNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- Kaolite 2300 Li Gun - EngDocument2 pagesKaolite 2300 Li Gun - EngLuis EscobedoNo ratings yet

- Kaolite 2500hs Gun - EngDocument2 pagesKaolite 2500hs Gun - EngLuis EscobedoNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- TECASINT 2011 Natural 14Document1 pageTECASINT 2011 Natural 14e.montgomeryNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

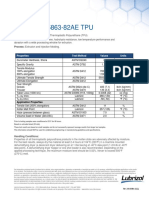

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Block InsulationDocument2 pagesBlock Insulation1repsaperuNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Elring Sealing Compound Dirko Gray: Technical DatasheetDocument7 pagesElring Sealing Compound Dirko Gray: Technical Datasheetperico_No ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- 1000 MM PolytheleneDocument1 page1000 MM PolytheleneJaokNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- DSMTS-0033.2 ZrTiY OxideDocument3 pagesDSMTS-0033.2 ZrTiY OxideAndrei MazurcheviciNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- TDS PEEK Filament 1Document2 pagesTDS PEEK Filament 1Krzysztof KardachNo ratings yet

- TDS PEEK Filament PDFDocument2 pagesTDS PEEK Filament PDFRui MatiasNo ratings yet

- SABIC® HDPE - P6006 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - P6006 - Global - Technical - Data - Sheetjemish limbaniNo ratings yet

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument1 pageSABIC® HDPE - P6006AD - Global - Technical - Data - SheetNaren RawatNo ratings yet

- Standard Specification For Lightweight Aggregates For Insulating Concrete PDFDocument3 pagesStandard Specification For Lightweight Aggregates For Insulating Concrete PDFAndy OliveraNo ratings yet

- SUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60)Document1 pageSUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60)giuseppe.timpone1No ratings yet

- Superwool Plus HT Pyroblocmodules EngDocument2 pagesSuperwool Plus HT Pyroblocmodules Engมิตร อันมาNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- C332-09 Standard Specification For Lightweight Aggregates For Insulating ConcreteDocument3 pagesC332-09 Standard Specification For Lightweight Aggregates For Insulating ConcreteAlabbas FadhelNo ratings yet

- ASTM C592-22aDocument9 pagesASTM C592-22a22238.spoNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- TECAPEEK GF30 Natural - Stock ShapesDocument1 pageTECAPEEK GF30 Natural - Stock ShapesHARSHANo ratings yet

- PB Uddeholm Elmax EnglishDocument8 pagesPB Uddeholm Elmax EnglishWolfNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Tubo TermocontraíbleDocument3 pagesTubo TermocontraíbleALEXIS BRICEÑONo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Neural Control and Co-Ordination - Biology Notes For NEET - AIIMS - JIPMERDocument24 pagesNeural Control and Co-Ordination - Biology Notes For NEET - AIIMS - JIPMERlegal eagleNo ratings yet

- Organic For NursingDocument6 pagesOrganic For NursingLady DanielleNo ratings yet

- GI and OI ReditedDocument8 pagesGI and OI ReditedRoboNo ratings yet

- 03 - Different Types of CorrosionDocument3 pages03 - Different Types of CorrosionAnushka SahuNo ratings yet

- Instant Download Cell Biology 3rd Edition Ebook PDF PDF ScribdDocument36 pagesInstant Download Cell Biology 3rd Edition Ebook PDF PDF Scribdconstance.whitesell736100% (43)

- Cumene: Process Features Process BenefitsDocument2 pagesCumene: Process Features Process BenefitsGerman Arrieta ZapaNo ratings yet

- Materials: Microstructure, Mechanical, and Corrosion Behavior of Al O Reinforced Mg2Zn Matrix Magnesium CompositesDocument17 pagesMaterials: Microstructure, Mechanical, and Corrosion Behavior of Al O Reinforced Mg2Zn Matrix Magnesium CompositesYashwanth VNo ratings yet

- 2012 Tannin-Soy-Aerogels GCDocument8 pages2012 Tannin-Soy-Aerogels GCGisele AmaralNo ratings yet

- HumboldtiaMS ReviewDocument7 pagesHumboldtiaMS ReviewKrishnaraj M VNo ratings yet

- Highly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberDocument9 pagesHighly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberTeddy KimNo ratings yet

- Product Data Sheet: Transolac Finish 3.31Document2 pagesProduct Data Sheet: Transolac Finish 3.31Sachin NambiarNo ratings yet

- Limit Values For LubricantsDocument28 pagesLimit Values For LubricantsSindley LimaferNo ratings yet

- Journal of Environmental Science and Health, Part B: Pesticides, Food Contaminants, and Agricultural WastesDocument8 pagesJournal of Environmental Science and Health, Part B: Pesticides, Food Contaminants, and Agricultural WastesAdam StankiewiczNo ratings yet

- Final PaperDocument51 pagesFinal PaperRheyven JuanNo ratings yet

- Hybrid CompositeDocument15 pagesHybrid CompositeAlpaslan AtalayNo ratings yet

- Chemistry Homework Material (Electrolysis) by Adaugo Olaedo UbahDocument3 pagesChemistry Homework Material (Electrolysis) by Adaugo Olaedo UbahAdaugo UbahNo ratings yet

- Development of Nanolubricants From Waste Cooking OilDocument3 pagesDevelopment of Nanolubricants From Waste Cooking OilGOVIND S 170170No ratings yet

- 2018 G12 Chemistry E Clor PDFDocument403 pages2018 G12 Chemistry E Clor PDFMaximillion AnthonyNo ratings yet

- 304 Stainless Steel Chemical Compatibility Chart From ISM - 304-Stainless-Steel-Chemical-Compatibility-Chart-From-IsmDocument1 page304 Stainless Steel Chemical Compatibility Chart From ISM - 304-Stainless-Steel-Chemical-Compatibility-Chart-From-IsmchenNo ratings yet

- CM1-CU3 - CellsDocument15 pagesCM1-CU3 - CellsKat JornadalNo ratings yet

- Noble Metalfree Hydrogen Evolution Catalysts For Water Splitting2015chemical Society ReviewsDocument34 pagesNoble Metalfree Hydrogen Evolution Catalysts For Water Splitting2015chemical Society ReviewsDaniel Camilo CanoNo ratings yet

- Analysis of Roman Enamelled BroochesDocument16 pagesAnalysis of Roman Enamelled BroochesDanielnjbNo ratings yet

- SPLENDA Sucralose Granular 113011Document6 pagesSPLENDA Sucralose Granular 113011rolandoNo ratings yet

- Effect of Droplet Size On The Reaction Kinetics of Emulsified Acid With CalciteDocument11 pagesEffect of Droplet Size On The Reaction Kinetics of Emulsified Acid With CalciteFaris DanialNo ratings yet

- Activity Sheet 10 & 11 GenBio1Document6 pagesActivity Sheet 10 & 11 GenBio1Marlou GayaneloNo ratings yet