Professional Documents

Culture Documents

59714602rvC - OPMANPXS5 822 822WB

Uploaded by

Calidad CocoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

59714602rvC - OPMANPXS5 822 822WB

Uploaded by

Calidad CocoCopyright:

Available Formats

Cover Sheet

Operation Manual 5971-4602 Rev. C

TITLE: PXS5-822SA / PXS5-822-WB

ORIGINATOR: Jeff Wimsatt

Approved By: Date:

Revision Record

Rev. Date Changes

1 8-8-00 Established per ER 0448

A 11/07/01 Released per ECO 3408

B 07/09/12 Per ECO 5973 Add WB model, update company and brand names.

C 1/4/18 ECO5405 - Added Data and Procedures from 5900-5034, 5900-0034, 5900-

0035, 5900-0062, & 5900-0063 to this operation manual under section 8.

APPENDIX A, and Updated sheet paging numbers

OPERATION MANUAL

PORTABLE X-RAY SOURCE

MODELS: PXS5-822SA / PXS5-822-WB

CONTENTS

Page Number

1. Introduction 2

2. General Description 2

3. Specifications 2

3.1 X-Ray Output 2

3.2 Mechanical 3

3.3 Electrical 3

4. Installation and Operation 5

5. Test Procedures 6

6. Run-up Procedure 6

7. Schematic, PXS5, Customer Interface, 8

5971-0720

8. APPENDIX A 9

8.1 X-RAY SOURCE RUN-UP PROCEDURE 9

8.2 COLD RUN-UP TIME FOR INACTIVE 11

X-RAY SOURCES

8.3 WARNING, TUBE TEMP 12

8.4 MARTERIAL SAFTEY DATA SHEET 13

8.5 RADIATION SAFETY DATA SHEET 15

NOTES

1. The x-ray window on the source is fabricated from beryllium foil. This should be handled with

care due to its fragility and due to the toxic nature of beryllium compounds when introduced into

the body.

5971-4602 Rev C, Page 1

1. INTRODUCTION

Thermo Fisher Scientific manufactures x-ray sources which are sold to customers as

components for incorporation into equipment for sale or for use within their own operations.

These instructions are intended to provide the equipment assembler with information needed

for the installation, adjustment and testing of the Thermo Scientific x-ray source when it is

designed into the user’s equipment. These instructions also direct attention to some features of

these sources which must be considered in order to minimize the chance of accidental

x-ray exposure to the equipment operators or to nearby people.

In most applications, the design and operation of x-ray equipment must comply with the

requirements of governmental or other regulatory agencies. It is the assembler’s responsibility

to ensure that equipment using x-ray source is in compliance with the appropriate regulations.

In the U.S.A. information regarding U.S. Government requirements may be obtained

from: Division of Radiological Products, Office of Compliance, Center for Devices

And Radiological Health, Food and Drug Administration, 8757 Georgia Avenue,

Silver Springs, Maryland 20910.

2. GENERAL DESCRIPTION

The x-ray source consists of a miniature microfocus x-ray tube combined with a high

voltage power supply in a single, compact, rugged package. The tube x-ray output

intensity is adjustable by means of customer supplied controls for tube target voltage

and current. The high voltage generator provides continuous DC output and is controlled by

all solid state components. Complete regulation of both the high voltage and tube current

ensures stable x-ray production over the input voltage range (12 – 14 VDC). In addition, long

service life is promoted by electron beam over-current protection.

3. SPECIFICATIONS

3.1 X-RAY OUTPUT

3.1.1 Output Flux:

25 + 10% R/min at 12 inches from the x-ray window at 80kV 8W. Measured with a

Keithley 96035B ion chamber and 2505A readout.

3.1.2 Stability:

Typically less than + 2% over a 4 hour period after a 10 minute warm up. Measured

with a Keithley 96035B ion chamber and 2505A readout.

3.1.3 Focal Spot:

15 microns nominal.

5971-4602 Rev C, Page 2

3.1.3 X-ray Beam Angle:

a) Standard Beam model: approximately 34 degrees, symmetric, oriented normal to

the window.

b) Wide Beam model: approximately 58 degrees, asymmetric, oriented __ degrees

from window normal, away from chassis.

In some applications the user must provide an external collimator or beam defining

system to limit the area illuminated by x-rays.

3.1.4 Focal Spot to Window Spacing: 12.5 +/- 0.5mm (0.49 in)

3.1.5 X-ray Window:

Beryllium foil 125 microns (.005 in) thick. In certain applications the user may

provide additional external filtration in order to reduce the low energy component in

the x-ray output spectrum.

3.1.5 X-ray Shielding:

Integral x-ray shielding reduces the intensity of x-ray leakage from the x-ray source to

0.5mR/hr or less measured 1” away from all housing surfaces behind the tube

mounting plate. Intensities measured in front of the mounting plate may be

substantially higher and additional shielding may be required in that area.

3.2 MECHANICAL

3.2.1 Dimensions:

3.93 in W x 12.75 in L x 2.86 in H (99.8mm x 323.9mm x 72.6mm) approx.

3.2.2 Weight:

8 lbs. (3.6 kilograms) approx.

3.2.3 Temperature Range:

0 to 32 degrees C ambient. During operation, the x-ray tube mounting plate

temperature must not be allowed to exceed 50 degrees C (below 40 degrees C is

recommended). Additional cooling air directed at the source may be required to

achieve this.

3.3 ELECTRICAL

3.3.1 Input Power:

12 - 14 VDC, 4 A.

3.3.2 Target Voltage:

Adjustable by external control, 0 to 80kV. Operating range 20 to 80kV.

3.3.3 Target Current:

Adjustable by external control, 0 to 0.1mA.

5971-4602 Rev C, Page 3

3.3.5 Voltage and Current Monitors:

Voltages proportional to target voltage and target current are available for remote

indication of operating levels.

Voltage Monitor:

4.0 volts + 0.5% at 80kV.

Current Monitor:

2.5 volts + 1.5% at 0.1mA.

Source Impedance:

1,000 ohms + 1%. Calibration is within specified limits when the impedance of the

external indicating meters is greater than 1 megohm. Lower impedance meters may

be used if the voltage drop in the source impedance is taken into account in specifying

the meter full scale sensitivity.

3.3.6 Voltage and Current Control:

The x-ray source is intended to be used with external 1,000 ohm potentiometers

for control of target voltage and current. When used in this way the maximum output

voltage and current will be 80kV + 0.5% and 0.1mA + 1.5% respectively.

Alternatively, voltage and current can be controlled by external voltage sources

variable over the range 0 – 4.0 + 0.5% volts D.C. to give 0 – 80kV and 0 to 2.5 volts +

0.5% to give 0 – 0.1mA output.

3.3.7 On-Off Control:

X-ray on-off control is by switching the input power. Refer to Customer Interface

Schematic 5971-0720. There are two switches shown, a standby and operate switch.

If the unit is to be used in an application where it is to be running for long periods of

time, then the operate switch can be eliminated; but the warm-up time for the filament

is 30-60 seconds, so there will be a delay in beam current after a cold turn on. Target

voltage and current will increase to values corresponding to the controls set points

when the 12-volt input power is applied. If both switches are used as shown, then the

unit will be preheated in the standby mode, and it will come up to programmed kV and

mA when the operate switch is closed.

5971-4602 Rev C, Page 4

4. INSTALLATION AND OPERATION

4.1 UNPACKING AND INSPECTION

Inspect package exterior for evidence of shipping and handling damage. IF

DAMAGE IS DETECTED, A CLAIM WITH THE CARRIER SHOULD BE FILED

IMMEDIATELY. DO NOT DESTROY OR REMOVE ANY OF THE PACKING

MATERIALS USED IN DAMAGED SHIPMENT. If no exterior damage is detected,

Proceed to carefully unpack the equipment. Examine the unit for any signs of damage

including leaked oil. Always use extreme care when handling the source near the

beryllium window. If any damage should be found, immediately contact

Thermo Fisher Scientific, Inc.

4.2 INTERCONNECTIONS

Refer to the Customer Interface Schematic, drawing number 5971-0720, for

connections to the control equipment. This drawing shows a simplified control panel

schematic which does not include safety interlocks, warning devices, timers, key

switches, indicator lights or other features which may be required by applicable

regulations or safety codes.

4.3 INSTALLATION

Install the x-ray source in its intended location or in an x-ray shielded test box.

If the installation requires permanent removal of the sheet metal cover on

which the identification and certification labels are mounted, it is the respons

ibility of the assembler to re-label the equipment in compliance with regulations.

4.4 OPERATION

Connect suitable meters to the voltage and current monitor terminals. Set the

output voltage and current controls to zero and apply the 12-volt input power.

Raise the voltage control and then the current control to about 20% of maximum.

Check for x-ray leaks from the x-ray shielding with a survey meter. Progressively

raise the voltage and current following the run-up procedure (Section 6) checking for x-

radiation leakage at each new level of operation. Add additional shielding if x-ray

leakage is excessive. After this initial operation of the x-ray source it is permissible to

apply the input power with the controls set to their maximum limit causing the unit to

operate at rated voltage and current.

5971-4602 Rev C, Page 5

5. TEST PROCEDURES

If it is suspected that the x-ray source does not perform according to specifications, the

following evaluation procedure should be followed:

5.1 Install the unit in a shielded enclosure. If the source has not been operated to full

power in the last 2 days, perform run-up procedure in section 6 below.

5.2 Apply 12 volts standby to the unit. Verify that the voltage control signal varies with

potentiometer setting up to 4.0 volts maximum. Turn on the operate switch and verify

the current control signal varies with potentiometer setting up to 2.5 volts maximum.

With the controls set to maximum, check that the output at the voltage monitor

terminals is 4.0 volts and the output at the current monitor terminal is 2.5 volts when

measured with a high impedance voltmeter, and that the input current is about 3.0

amps. Measure the x-ray output using a flux probe as in section 3.1.1

5.3 If any of the measurements in 5.2 are fluctuating, listen for a ticking sound which could

indicate that there is an electrical discharge in the x-ray tube. If ticking noises are

audible, repeat the run-up procedure (Section 6).

5.4 If the problem cannot be resolved, contact Thermo Fisher Scientific Inc. for further

assistance.

The x-ray source is not user repairable and no attempts should be made to dismantle

the unit or to adjust the internal pre-set controls.

6. RUN-UP PROCEDURE

An incremental run-up procedure is advised to safeguard and help prolong the life of the x-ray

source. Increasing the target voltage in steps allows the tube to completely “out-gas” itself

and the high voltage generator to become high voltage “conditioned”, which prevents

destruction of components. When operating a new source or one that has been idle for more

than one month, begin with the target voltage and tube current controls set at their minimum

values, and take 10 to 15 minutes to process the source up to full power. At each step in the

run-up schedule given on the next page, first increase the target voltage and then the tube

current, waiting at least the minimum time before proceeding to the next step.

IMPORTANT:

When Processing a source up to full power, always be alert to any ARCING. If an arc occurs,

decrease the high voltage to the previous step. Again wait at least the minimum time, step the

voltage back up and continue procedure ALWAYS BEING ALERT TO ARCING IN THE

SOURCE. (An audible ticking sound will be produced when an arc occurs.)

5971-4602 Rev C, Page 6

RUN-UP SCHEDULE

STEP % OF MAX kV % OF MAX mA MINIMUM TIME

1 20 0 1 minute

2 40 10 1 minute

3 60 30 2 minutes

4 80 50 2 minutes

5 90 70 3 minutes

6 100 100 3 minutes

Once the source has been fully conditioned, energizing the source with both the target voltage and tube

current preset for their maximum values is acceptable. However, the following guidelines are best

kept in mind when establishing your own operating routine.

1) If the source is to be used throughout the working day, continuous operation within

specified ratings will maintain the source at its normal operating temperature and minimize

warm-up drift.

2) Frequent on-off cycling to full power, although acceptable, is stressful to the source.

3) Occasional arcs are inherent in x-ray equipment and should not cause alarm, however,

frequent arcing which cannot be stopped by repeating this run-up procedure is indicative of a

fault in the x-ray source.

4) Operation at low target voltages (20kV or less) is not advised. Under these conditions the grids

intercept and operate hotter than normal, which decreases tube life expectancy.

5971-4602 Rev C, Page 7

7. SCHEMATIC, PXS5, CUSTOMER INTERFACE

5971-4602 Rev C, Page 8

8. APPENDIX A

8.1 X-RAY SOURCE RUN-UP PROCEDURE

The purpose of the Run-Up Procedure is to safeguard and help prolong the life of the source. This

incremental approach to reaching the working voltage allows the source to completely condition itself

and prevent premature damage.

When operating a new source or one that has been idle for several days, increase the beam voltage

slowly, taking typically 15 minutes (or more, depending on the idle time) to reach the full rated

voltage. At the same time, raise the beam current slowly to its maximum value, alternating increases

in Voltage and current in a manner similar to the daily run-up.

IT IS UNLIKELY THAT THE SOURCE WILL ARC, BUT IF IT DOES (as indicated by an

audible ticking or jump in the kV and mA monitor levels), SHUT OFF THE HIGH VOLTAGE

AND WAIT A MINUTE, THEN RESTART THE RUN-UP AT A SLOWER RATE.

When a source is to be used several times during a working day, turn it on at the start of the day and

leave it running. This avoids frequent on-off cycling and has the added benefit of keeping the system

at its normal operating temperature, and minimizing warm-up drift. If practical, keep the source

running at two-thirds maximum voltage and one-fourth maximum current. If the source must be shut

down when a sample is changed, when restarting, raise the voltage and current back up slowly (30 to

60 seconds) to minimize stress to the source.

Even with a source in constant use, DO NOT TURN ON MAXIMUM VOLTAGE SUDDENLY.

Instead, switch the source on at one-half voltage, then take about 30 seconds to raise the voltage to its

maximum value. This can be done at normal source current.

When using a source with a filamentary electron gun, AVOID PROLONGED OPERATION AT

LESS THAN 5kV AND HIGH CURRENTS. The filament operating temperature under these

conditions is higher than normal, thus decreasing filament life expectancy.

Ensure that the source cooling system is performing adequately. This is particularly important since

the maximum allowable housing temperature typically is 50 o C. A good target for normal operating

temperature is <40° C.

Suggested daily run-up schedules for sources by kV range are given in the following graph (Page 10).

5971-4602 Rev C, Page 9

TIME TO REACH 100% OF For an example, take a source which is rated at 90kV,

MAXIMUM RATED kV AND mA: 0.089mA:

1. Look at chart on left to find that it should take 10

Max Rated kV TIME minutes to get full kV and mA.

50 10 minutes 2. Next, equate the 90kV and .089 mA to 100%.

70 10 minutes 3. A typical run-up would then follow the graph above.

90 10 minutes 50% time would equal 5 minutes. From the graph,

110 12 minutes 50% time equals 65% kV and mA, which would be

130 15 minutes 58.5 kV and .058 mA.

160 20 minutes

This is a general daily run-up schedule.

Always be alert to arcing and reduce Kv if any arcs are

noticed.

5971-4602 Rev C, Page 10

8.2 COLD RUN-UP TIME FOR INACTIVE X-RAY SOURCES

The following run-up times should be used for an x-ray source that has been left

inactive for an extended period of time.

Run-Up Time for X-Ray Sources with Maximum Operating Voltage up to:

Off Time 50kV 90kV 130kV

1 day 10 minutes 15 minutes 15 minutes

1 week 20 minutes 25 minutes 30 minutes

1 month 50 minutes 60 minutes 70 minutes

2 months 80 minutes 90 minutes 100 minutes

2-6 months 2 hours 3 hours 3 hours

over 6 months 3 hours 4 hours 4 hours

To bring the x-ray source to full power, follow the Kevex X-Ray “SOURCE RUN-UP

PROCEDURE”. For long inactive periods (in excess of 2 months) the recommended

run-up times should be considered a minimum. Great care should be taken to bring

inactive sources up to full voltage.

Recommended Operation During Storage

*An x-ray source held in storage should be operated periodically. We recommend that

the source be brought to full power (following the run-up procedure listed above)

monthly. The source should then be left operational in an appropriate radiation

enclosure for a period of one to two hours.

5971-4602 Rev C, Page 11

8.3 WARNING, TUBE TEMP

WARNING

During normal operation of KEVEX x-ray tubes, the temperature of the tube housing

should not be permitted to rise above 55o C. Operating temperatures in excess of this

may lead to instability of the x-ray output or premature tube failure.

Depending upon the ambient temperature within the equipment using the tube and the

tube operating duty cycle, this may require the use of a fan or blower with its output

directed at the tube housing.

No KEVEX x-ray tube should be exposed to harsh chemical environments that could

result in window corrosion and premature tube failure.

Any liquid cooled tube or power supply that is returned to the factory for any reason

must have all cooling lines purged of glycol or similar coolants, by flushing them with

water.

5971-4602 Rev C, Page 12

8.4 MATERIAL SAFETY DATA SHEET

October 1, 1996

SECTION I - PRODUCT IDENTIFICATION

This x-ray tube uses a beryllium x-ray window.

SECTION II - BERYLLIUM MANUFACTURER

Brush Wellman, Inc., 14710 W. Portage River S. Road, Elmore, OH 43416-9502

24-Hour Emergency Assistance: (800) 862-4118

SECTION III - HAZARDOUS INGREDIENTS

Beryllium Metal: The x-ray window is made of 100% beryllium metal.

SECTION IV - PHYSICAL DATA BERYLLIUM

Appearance: Varies in color from a grey metallic to a dull

greyish red solid

Odor: None

Atomic Weight: 9.01

Melting Point: 1278 + 5oC

Boiling Point at 1 ATM: 2970oC

Solubility: N/A

Specific Gravity at 20o: 1.85

Vapor Pressure: N/A

SECTION V - FIRE AND EXPLOSION HAZARD DATA

Beryllium will ignite at approximately 1200oF. Since the amount of beryllium used is very small, use a

fire-fighting agent or media appropriate for the surrounding fire.

Flash Point: NE Lower Flammable Limit: NE

Upper Flammable Limit: NE Auto-Ignition Temperature: 1200oF

NE = NOT ESTABLISHED

SECTION VI - HEALTH HAZARD

Effects of Over Exposure:

Inhalation of beryllium particles may cause berylliosis, a serious chronic lung disease, with cough, chest

pain, shortness of breath, weight loss, weakness, and fatigue.

5971-4602 Rev C, Page 13

MSDS - BERYLLIUM

First Aid:

If exposed or if cut by beryllium, remove from area and consult a physician. Handling of solid shapes

presents no dermatitis or skin absorption problem.

Potential Carcinogen:

Beryllium is a material which has been listed, principally on animal tests, as a potential carcinogen in the

International Agency for Cancer Research Monograph Series and the National Toxicology Program

Annual Report on Carcinogens identifying it as a potential cancer hazard.

SECTION VII - REACTIVITY DATA

Oxidation will form on solid shapes when moist. Beryllium with acids may generate hydrogen. Moisture

will corrode beryllium and may dissolve through the window in a matter of days.

SECTION VIII - SPILL AND DISPOSAL PROCEDURES

Beryllium metal scrap, and chips are normally recycled. However, in cases where this is not justified,

solid material may be landfilled.

If a beryllium window breaks, cover the open part with plastic and tape in place. Wear gloves. Pick up

small pieces of beryllium with the sticky side of the tape. These small amounts of beryllium may be

disposed of in a landfill as mentioned above.

SECTION IX - SPECIAL PROTECTION INFORMATION

Do not touch the beryllium window, it is extremely fragile and can be toxic. Because of toxicity, it is

recommended as a precaution that if the window is accidentally touched you immediately wash your

hands with soap and water.

SECTION X - MISCELLANEOUS INFORMATION

The above information is believed to be accurate and represents the best information currently available

to us. However, because we do not manufacture the beryllium metal or the beryllium x-ray windows, we

make no warranty of merchantability or any other warranty expressed or implied with respect to such

information, and we assume no liability resulting from its use. Users should make their own

investigations to determine the suitability of the information for their particular purposes.

See Kevex X-Ray "Radiation Safety Data Sheet" for information regarding radiation hazards.

5971-4602 Rev C, Page 14

8.5 RADIATION SAFETY DATA SHEET

SECTION I - PRODUCT IDENTIFICATION

X-ray tubes and portable x-ray sources.

SECTION II – MANUFACTURER

Thermo Fisher Scientific

320 El Pueblo Road

Scotts Valley, CA 95066

Telephone: (831) 438-5940

SECTION III – HAZARDS

X-Ray radiation is a form of ionization radiation that is potentially very hazardous. The most intense and

therefore dangerous part of the instrument is the path of the incident X-ray beam. Thus care should always

be exercised to know the expected path of the incident beam. Scattered radiation is typically of such

reduced intensity that it poses a much smaller health risk to the researcher.

There are several properties of X-Rays that make this type of radiation particularly dangerous to use in the

laboratory. X-Ray radiation cannot be sensed by a human! Some people feel a tingling sensation on their

skin when they are around X-Rays from an analytical instrument. They are not feeling the X-ray beams,

but rather they are feeling charged air particles produced by the interaction of the ionizing X-Rays with

air. If you ever feel a tingling sensation when working around any analytical X-Ray instrument,

immediately turn off the instrument and contact the Radiation Safety Officer (RSO). Since only some

people feel this tingling sensation, do not assume that if the sensation is not present, that the instrument

cannot hurt you. Please note that the two shutters on the instrument are interlocked to the cabinet doors so

that if either door is opened, the shutters should close.

Care should be taken when using any analytical X-ray instrument. Never put any part of your body in the

expected path of the main beam. Avoid being around the X-Ray tube housing and main beam path as

much as possible. Keep the enclosure doors closed whenever possible.

Although X-ray instruments have the potential to be dangerous; when used properly, modern diffraction

X-ray instruments pose few risks to careful users. The manufacture and use of analytical X-ray

instruments is regulated by both federal and state governments. Current regulations require that a variety

of safety devices be built into X-ray instruments that make it very difficult for anyone to even accidentally

expose herself or himself to the dangerous incident X-ray beam. The design of the instruments limits even

accidental exposures to the hands, arms, and facial areas. Generally, the types of radiation used in

diffraction instruments (primarily Mo and Cu Kα radiation) are considered soft or low energy radiation.

Unlike medical X-Rays, these types of soft radiation generally will not penetrate more than 2-4 cm into the

body.

5971-4602 Rev C, Page 15

SECTION IV - HEALTH HAZARDS

ALARA, As Low As Reasonably Achievable, goals are also achieved by the user practicing safe

techniques when using the X-Ray instrument. As noted above, the user should keep all parts of their body

out of the expected main beam path at all times, especially when placing a sample in the instrument or

removing a sample from the instrument. When the safety enclosure is opened, the user should keep as far

from the X ray source as practical. Finally, the cabinet doors should be kept closed whenever possible.

Health effects of exposure to X-ray radiation come in two general types, direct or indirect. X Rays are

thought to create radicals in exposed cells of your body that may break or modify chemical bonds within

critical biological molecules. As a result (1) cells may be injured or damaged, although many cells repair

themselves, resulting in no residual damage, (2) cells may die, which millions of body cells do every day

and are replaced in a normal biological process, (3) or cells may incorrectly repair themselves resulting in

a biophysical change. Finally, X-Rays may pass through the body with no interaction.

Factors that determine biological effects:

Dose rate

Total dose received

Energy of the radiation

Area of the body exposed

Individual sensitivity

Cell sensitivity

Most sensitive tissues: Blood-forming organs, reproductive organs, digestive organs

Least sensitive tissues: Nervous system, muscle and connective tissues

Studies indicate that the risk of cancer in children increases if the mother is exposed to significant

X-radiation during pregnancy. The State of California and other Agreement States have established an

exposure limit of 5000 millirems per year for occupationally exposed adults. Because the effect of

radiation may be greater on an unborn child, the radiation dose limit recommended for them is 500

millirems. Women who are pregnant or expect to become pregnant soon may wish to consider the

effect of radiation on their unborn children.

SECTION V - PRECAUTIONS

Each of the following steps must be followed for personnel and equipment safety:

-Insure that portable sources are securely anchored. Tubes should be anchored securely in a

radiation proof enclosure with appropriate lead shielding. X-rays can scatter off objects and

thus get around corners.

-Operate only when window is in an x-ray shielded chamber.

-Chamber access doors must be interlocked to prevent x-ray tube operation

with the doors open.

-The beryllium window is fragile and toxic if scratched, do not subject the window to

mechanical pressures.

-User must provide adequate shielding in the window area.

5971-4602 Rev C, Page 16

-The vacuum tube is glass and therefore fragile; do not drop mishandle and/or drop.

-Ground the tube mounting surface.

-Check the high voltage cables for frays or damage.

-Never kink or sharply bend the high voltage cable as it is used to supply a ground on the tube which,

without proper grounding, is a lethal hazard.

SECTION VI - OCCUPATIONAL DOSE LIMITS

The State of California (see California Radiation Control Regulations, Title 17, California Administrative

Code, Section 30265), and other Agreement States, have established maximum dose limits for individuals

working in a radiation area. These limits have been established on a calendar quarter basis, but they may be

expressed on a yearly, monthly, and hourly basis (assuming 40 hours of exposure per week for 50 weeks

per year). The limits are as follows:

Body Part Rems/CalQuarter Rems/Year Millirems/Mo Millirems/Hr

Whole Body 1.25 5 417 2.5

Hands/Forearms/

Feet/Ankles 18.75 75 6,250 37.5

Skin of Whole Body 7.5 30 2,500 15

Differences in limits for different body parts are a direct consequence of the differences in their sensitivities

to radiation. Hands, as an example, are considerably less sensitive to radiation than the body as a whole.

Your safety governing body may have different occupational dose limits. Please see your Radiation Safety

Officer, RSO, for more information.

SECTION VII - BIOLOGICAL EFFECTS OF RADIATION

A complete description of the various effects of radiation is outside the scope of this document. Among the

documented biological effects of radiation are various types of cancers, blood diseases, weakened bones,

sterility, hearing problems, teeth loss, hair loss, digestive troubles, and skin burns. Radiation nonspecifically

damages cells and tissues and can have both cancerous and non-cancerous effects.

SECTION VIII - EMERGENCY PROCEDURES

In case of a disaster such as fire, explosion, flooding, or earthquake, the X-Ray equipment must be de-

energized immediately. Once de-energized, the x-ray equipment poses no radiation danger. After a disaster

the X-Ray equipment must be surveyed before placing it back in operation. The proper approach for

operation of X-Ray equipment is to perform the surveys at each power setting as the X-Ray equipment

power is increased in a step by step manner from no power to maximum power.

SECTION IX - MISCELLANEOUS INFORMATION

This document serves as a source of basic radiation safety information for users of Thermo Fisher

Scientific X-ray equipment. However, these guidelines are not to be used in lieu of any regulations

specified by your officially recognized regulatory authorities (i.e., U.S. Dept. of Health and Human

Services, Food and Drug Administration).

5971-4602 Rev C, Page 17

You might also like

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- 59718608rva OpMan822-HRDocument10 pages59718608rva OpMan822-HRCalidad CocoNo ratings yet

- 59713609rvC OpManPXS5-926EADocument19 pages59713609rvC OpManPXS5-926EACalidad CocoNo ratings yet

- 59713608rvD OpManPXS5-925EADocument19 pages59713608rvD OpManPXS5-925EACalidad CocoNo ratings yet

- Design of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsFrom EverandDesign of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsNo ratings yet

- 59715601rvB OpManPXS5-925RRDocument19 pages59715601rvB OpManPXS5-925RRCalidad CocoNo ratings yet

- 1260 ManualDocument215 pages1260 ManualGaurav AcharyaNo ratings yet

- CT720g S774AAR5S2NCDocument45 pagesCT720g S774AAR5S2NCAnonymous CJnGHNNo ratings yet

- EMERSON Y COMPAÑIA - Trupper ETV20Document36 pagesEMERSON Y COMPAÑIA - Trupper ETV20ponchomaresNo ratings yet

- Acer AC713Document52 pagesAcer AC713fernandoalejandroNo ratings yet

- CRT Monitor KT2914F 2914DF Service ManualDocument38 pagesCRT Monitor KT2914F 2914DF Service Manualfpanci100% (1)

- Allengers 325 RF - Installation and Service ManualDocument63 pagesAllengers 325 RF - Installation and Service Manualleopa7880% (20)

- SDL800 ManualDocument38 pagesSDL800 ManualSubdriverNo ratings yet

- Del DRV Indico 100 Operator's ManualDocument64 pagesDel DRV Indico 100 Operator's ManualBusari Oyinlola BimpeNo ratings yet

- Plasma TV: Service ManualDocument51 pagesPlasma TV: Service ManualJosias MangueiraNo ratings yet

- SAKO SKI780 ManualDocument74 pagesSAKO SKI780 ManualJordi Garcia100% (1)

- Oi Kcap300-En eDocument20 pagesOi Kcap300-En ejaime HernandezNo ratings yet

- Vmax/A: Medium Voltage Vacuum Circuit Breaker Ansi: 4.76kV-15 KV 1200-2000 A 31.5 KaDocument35 pagesVmax/A: Medium Voltage Vacuum Circuit Breaker Ansi: 4.76kV-15 KV 1200-2000 A 31.5 KaSreepriodas RoyNo ratings yet

- LG 50PB560B Chassis PU41A PDFDocument47 pagesLG 50PB560B Chassis PU41A PDFCesar Guzman100% (1)

- Aoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Document44 pagesAoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Luis Gamalier Zurita0% (1)

- 0201Document80 pages0201Ashenafi Gebremeskel MezgeboNo ratings yet

- Elenberg 1402,2108,21F08,29F08 Service ManualDocument85 pagesElenberg 1402,2108,21F08,29F08 Service ManualalexanderNo ratings yet

- Instruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENDocument79 pagesInstruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENКонстантин Гетьман100% (1)

- Color TV Service ManualDocument49 pagesColor TV Service ManualAnirudha Mhase100% (4)

- D551U/V Color Monitor Service ManualDocument52 pagesD551U/V Color Monitor Service ManualDaniel GómezNo ratings yet

- Do7 Ohmmeter 610003 Rev 9 v9 PDF 5c6e7e27011b8Document26 pagesDo7 Ohmmeter 610003 Rev 9 v9 PDF 5c6e7e27011b8Gerson DavidNo ratings yet

- Cpi CMP 200 X-Ray GeneratorDocument82 pagesCpi CMP 200 X-Ray Generatorbiomedical apolloNo ratings yet

- Product Guide Specification: Cyberex Superswitch 4 (4-Pole STS)Document14 pagesProduct Guide Specification: Cyberex Superswitch 4 (4-Pole STS)voNo ratings yet

- Operator'S Manual: High Frequency X-Ray GeneratorDocument33 pagesOperator'S Manual: High Frequency X-Ray GeneratorEder GarciaNo ratings yet

- R8618a M220Document68 pagesR8618a M220Rinda_RaynaNo ratings yet

- Samsung Mx-c830d SMDocument70 pagesSamsung Mx-c830d SMSsh NitsNo ratings yet

- Acer Color Monitor Service GuideDocument54 pagesAcer Color Monitor Service GuideMario ScheNo ratings yet

- Samsung MM-C430D EDCDocument60 pagesSamsung MM-C430D EDCbaris999100% (2)

- Service Manual: Color MonitorDocument61 pagesService Manual: Color MonitorJulio RojasNo ratings yet

- LG 42Document38 pagesLG 42D TodounpocoNo ratings yet

- Sungrow SG50KTL-M-20 - Auszug Aus Dem Prüfbericht Zum Einheiten - Zertifikat - DEDocument176 pagesSungrow SG50KTL-M-20 - Auszug Aus Dem Prüfbericht Zum Einheiten - Zertifikat - DERodrigo MussattoNo ratings yet

- Samsung MAX G55RDocument66 pagesSamsung MAX G55Rboroda241075% (4)

- McGrath MAC Video Laryngoscope Instructions For Use PDFDocument24 pagesMcGrath MAC Video Laryngoscope Instructions For Use PDFAnonymous MnaMZQWwCNo ratings yet

- Opertaor Manual GXDocument266 pagesOpertaor Manual GXGamal Abdel MoityNo ratings yet

- Samsung MAX-A55UDocument60 pagesSamsung MAX-A55UJose ManuelNo ratings yet

- GRD140D 6F2S0897 5.0Document438 pagesGRD140D 6F2S0897 5.0boopelectraNo ratings yet

- BRG200R - OPERATOR MANUAL - 74098521N - EnglishDocument82 pagesBRG200R - OPERATOR MANUAL - 74098521N - EnglishSvilen PopovNo ratings yet

- 26MR70Document28 pages26MR70jotas2525No ratings yet

- S310 OpManIssue3Document24 pagesS310 OpManIssue3service3397No ratings yet

- 27c540-Chasis GB-3U (1W)Document36 pages27c540-Chasis GB-3U (1W)Farias DilanNo ratings yet

- MedicalDocument30 pagesMedicalEuuE2008No ratings yet

- Omnistack Ls 6248Document60 pagesOmnistack Ls 6248eswaranslmNo ratings yet

- GRL100B 6F2S0835 2.7Document392 pagesGRL100B 6F2S0835 2.7Nazi SweetNo ratings yet

- 869 - IEC - 61000-4-6 Conducted RF ImmunityDocument7 pages869 - IEC - 61000-4-6 Conducted RF Immunityandrez880103No ratings yet

- LG 60pa6500-Tm Chassis Pa23aDocument49 pagesLG 60pa6500-Tm Chassis Pa23aJ Fernando GarciaNo ratings yet

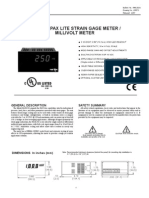

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 pagesModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNo ratings yet

- Sharp Lc-43cuf8472es 43,55cug8461ks 43,49,55cug8462ks 49,55,65cug8052e 49,55,65cug8062e 49cug8362ks 49,55cuf8372es 49,55cuf8472es SMDocument90 pagesSharp Lc-43cuf8472es 43,55cug8461ks 43,49,55cug8462ks 49,55,65cug8052e 49,55,65cug8062e 49cug8362ks 49,55cuf8372es 49,55cuf8472es SMMarko MatićNo ratings yet

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangerDocument6 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangervickersNo ratings yet

- Haier Model - 21F7A-P TVDocument26 pagesHaier Model - 21F7A-P TVGiovanny Enrique Gonzalez CastroNo ratings yet

- LG Pdp-4294lv1 Pdp4294lv1 Service ManualDocument112 pagesLG Pdp-4294lv1 Pdp4294lv1 Service ManualGuillermo Segura100% (1)

- Table5168b 411Document2 pagesTable5168b 411khemrajmahadewNo ratings yet

- Plasma TV: Service ManualDocument49 pagesPlasma TV: Service ManualВиталий МорозовNo ratings yet

- MET 2017 Child and AdolDocument193 pagesMET 2017 Child and AdolFerlyn Serio AguilarNo ratings yet

- TPL5010 Nano-Power System Timer With Watchdog Function: 1 Features 3 DescriptionDocument27 pagesTPL5010 Nano-Power System Timer With Watchdog Function: 1 Features 3 Descriptionelfak.2000No ratings yet

- 1956 Pritchard JJ, Scott JH, Girgis FG. The Structure and Development ofDocument17 pages1956 Pritchard JJ, Scott JH, Girgis FG. The Structure and Development ofplayer osamaNo ratings yet

- Valvoline Lithium Ep2 GreaseDocument1 pageValvoline Lithium Ep2 GreaseDicky PratamaNo ratings yet

- The Six-Flow Reactor Technology A Review PDFDocument17 pagesThe Six-Flow Reactor Technology A Review PDFTysir SarhanNo ratings yet

- CoadaDocument13 pagesCoadaDeny DenisaNo ratings yet

- Collaborative Inter Agency Coordination SkillsDocument10 pagesCollaborative Inter Agency Coordination SkillsMark AngihanNo ratings yet

- Water Using Volumetric Karl Fischer Titration: Standard Test Method ForDocument12 pagesWater Using Volumetric Karl Fischer Titration: Standard Test Method ForSusana Smaldone MillánNo ratings yet

- Aits Syllabus - 2018-19 Final ..-1Document4 pagesAits Syllabus - 2018-19 Final ..-1DrNaresh SahuNo ratings yet

- A Different Pond by Bao PhiDocument12 pagesA Different Pond by Bao PhiSheena AguilarNo ratings yet

- Weidmuller PRO MAX 960W 24V 40A enDocument5 pagesWeidmuller PRO MAX 960W 24V 40A enUmair MalikNo ratings yet

- Perform Duties Following Workplace InstructionsDocument2 pagesPerform Duties Following Workplace InstructionsDan Rey Miras MiñaNo ratings yet

- Determine Crop Water Needs from Soil SamplesDocument7 pagesDetermine Crop Water Needs from Soil SamplesFaris AhmadNo ratings yet

- Probability and Statistics ExamDocument4 pagesProbability and Statistics ExamLeul SolomonNo ratings yet

- Chapter No # 03 Product Innovation CharterDocument11 pagesChapter No # 03 Product Innovation CharterabzuarNo ratings yet

- C031 Management Accounting Practices in Non-Profit Religious Organization A Case Study in Lembaga Zakat Selangor (LZS)Document12 pagesC031 Management Accounting Practices in Non-Profit Religious Organization A Case Study in Lembaga Zakat Selangor (LZS)Kiki NikeNo ratings yet

- Fed Question BankDocument5 pagesFed Question BankAnonymous eWMnRr70qNo ratings yet

- Unit 1 Cultural Issues and ValuesDocument3 pagesUnit 1 Cultural Issues and ValuesACHRAF DOUKARNENo ratings yet

- @2018 em Southward ER, ERP RDocument17 pages@2018 em Southward ER, ERP RChelsey XieNo ratings yet

- Plant Pathology Curriculum Revised for BSc, MSc and PhD DegreesDocument90 pagesPlant Pathology Curriculum Revised for BSc, MSc and PhD Degreesjahangir khanNo ratings yet

- The Impact of New Normal To The Gadget Store OwnersDocument28 pagesThe Impact of New Normal To The Gadget Store OwnersKatricia Elaine VillanuevaNo ratings yet

- APPLICATION OF COMPUTERS IN PHARMACY MANAGEMENT AND SERVICESDocument109 pagesAPPLICATION OF COMPUTERS IN PHARMACY MANAGEMENT AND SERVICESvarishNo ratings yet

- Lecture 2Document15 pagesLecture 2ZUHAL TUGRULNo ratings yet

- Joel Rubano - Trader Construction Kit_ Fundamental & Technical Analysis, Risk Management, Directional Trading, Spreads, Options, Quantitative Strategies, Execution, Position Management, Data Science &Document592 pagesJoel Rubano - Trader Construction Kit_ Fundamental & Technical Analysis, Risk Management, Directional Trading, Spreads, Options, Quantitative Strategies, Execution, Position Management, Data Science &Muhammad Ali100% (1)

- MAE101 CAL V1 Chapter 2 LimitsDocument46 pagesMAE101 CAL V1 Chapter 2 LimitsHuynh Hoang Ty (K18 CT)No ratings yet

- A Review On Water Management Issues: Potential and Challenges in IndonesiaDocument15 pagesA Review On Water Management Issues: Potential and Challenges in IndonesiajameszulfanNo ratings yet

- Frankenstein Episode 2 - It's Alive!Document4 pagesFrankenstein Episode 2 - It's Alive!Jean Claude AgostiniNo ratings yet

- Mock Teaching Lesson PlanDocument2 pagesMock Teaching Lesson Planapi-354968419No ratings yet

- Sample Narrative Report and Documentation 2024 InsetDocument3 pagesSample Narrative Report and Documentation 2024 InsetWILSON CASTRONo ratings yet

- Raising Awareness of Solid Waste Management PracticesDocument143 pagesRaising Awareness of Solid Waste Management PracticesPrimo Ernesto CanoyNo ratings yet

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)From EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)No ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Transformer: The Deep Chemistry of Life and DeathFrom EverandTransformer: The Deep Chemistry of Life and DeathRating: 4.5 out of 5 stars4.5/5 (13)

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)