Professional Documents

Culture Documents

Ppc-Pipe-Hyosung-Topilene HB240P

Uploaded by

Mohamed RabeaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ppc-Pipe-Hyosung-Topilene HB240P

Uploaded by

Mohamed RabeaCopyright:

Available Formats

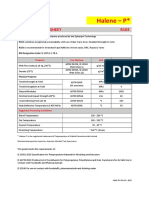

TECHNICAL DATA SHEET

HB240P Polypropylene Block Copolymer

For PP-B Pipes and Fittings(Non-Pressure Pipes)

Product Description

Topilene® HB240P is a specially designed polypropylene block copolymer (PP-B, natural colored) that features

excellent long-term hydrostatic pressure resistance. It is suitable for underground drainage & sewage pipes and

fittings. It is the outcome of HYOSUNG's integrated polymerization and crystallization technology with advanced

PP manufacturing process technique.

Characteristics

Typical Application Drainage & sewage pipes and fittings (Solid wall & twin wall corrugated pipes system) /

Industrial pipes

Features Excellent long-term hydrostatic pressure resistance / Excellent stiffness and impact strength

balance / Enhanced big diameter pipe manufacturing processability / Chemical stability /

Environment-friendly

Compliance The pipes produced with Topilene® HB240P complies with the hydrostatic pressure

requirements according to ISO/DIS 15874. It complies with the requirements of FDA 21

CFR 177.1520. This product corresponds to GB/T17219-1998 for drinking water system.

Typical Properties

Resin Properties Method Value Unit

Melt Index(230℃, 2.16kg) ASTM D1238 0.30 g/10min

Density ASTM D792 0.90 g/㎤

Tensile Strength at Yield ASTM D638 320 kg/㎠

Flexural Modulus ASTM D790 15,000 kg/㎠

Notched Izod Impact Strength(23℃ / -10℃) ASTM D256 N.B / 5.0 kg·cm/cm

Rockwell Hardness ASTM D785 85 R-Scale

Heat Deflection Temperature ASTM D648 120 ℃

Vicat Softening Point ASTM D1525 155 ℃

The values listed above are typical values for reference purpose only and shall not be construed as specifications.

Storage and Handling

This product should be stored in dry condition at temperature below 40°C and protected from UV-light. When

condensation is visible or can be expected, pre-drying is recommended. (Drying condition: 80~100℃/2~4hours at

air circulated condition)

Contacts

Head Office 235, Banpo-daero, Seocho-gu, Seoul, Korea 06578

Tel: +82-2-2146-5451~7 Fax: +82-2-2146-5428

Online www.hyosung.com

www.topilene.com

TECHNICAL DATA SHEET

HB240P Polypropylene Block Copolymer

For PP-B Pipes and Fittings(Non-Pressure Pipes)

Process Guidelines

The actual extrusion conditions will depend on the type of equipment and the SDR of pipes produced. The below

conditions may be used as guidelines for this material.

Cylinder feeding zone 170-190℃

Cylinder melting zone 190-225℃

Cylinder mixing zone 200-235℃

Head 200-235℃

Die 200-235℃

Melt temperature 200-235℃

Cooling temperature 20-30℃

Disclaimer

All information, including product characteristics, applications and properties are for reference purpose only and shall not be construed as

specifications. Before using this product, customers should carefully review the instructions for use of the product to determine whether the

product is suitable for the customer’s particular purpose. The customer is responsible for the appropriate, safe and legal use, processing and

handling of this product. HYOSUNG CORPORATION assumes no legal responsibility or liability for the contents of this document. We reserve

the right to change the contents of this document without prior notice. This document is copyrighted by HYOSUNG CORPORATION.

Topilene® is a registered trademark owned or used by HYOSUNG CORPORATION.

Contacts

Head Office 235, Banpo-daero, Seocho-gu, Seoul, Korea 06578

Tel: +82-2-2146-5451~7 Fax: +82-2-2146-5428

Online www.hyosung.com

www.topilene.com

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- PD 6698-2009Document30 pagesPD 6698-2009Dennoh Mbuthia100% (4)

- Earth Dam: (Water Resources Engineering)Document54 pagesEarth Dam: (Water Resources Engineering)Neelakash HaloiNo ratings yet

- Ghana Building Code - Part 05 PDFDocument132 pagesGhana Building Code - Part 05 PDFvasvuk100% (16)

- Improving Concrete Containment Structures Associated With Fixed-Cone ValvesDocument49 pagesImproving Concrete Containment Structures Associated With Fixed-Cone Valvesnb_norooziNo ratings yet

- Standard Penetration TestDocument7 pagesStandard Penetration TestAndres GranadosNo ratings yet

- Topilene R200PDocument2 pagesTopilene R200PNguyễn Hồng NamNo ratings yet

- Topilene R200P PDFDocument2 pagesTopilene R200P PDFEmmylouCasanovaNo ratings yet

- Topilene R200P PDFDocument2 pagesTopilene R200P PDFAli MNo ratings yet

- Polypropylene Random Copolymer: Technical Data SheetDocument2 pagesPolypropylene Random Copolymer: Technical Data SheetEmmylouCasanovaNo ratings yet

- R200P DATA SHEETDocument2 pagesR200P DATA SHEETPRIME STEEL RE-ROLLING MILLSNo ratings yet

- Topilene J640Document1 pageTopilene J640EmmylouCasanovaNo ratings yet

- Topilene HJ541CPDocument1 pageTopilene HJ541CPEmmylouCasanovaNo ratings yet

- HJ541CP: Polypropylene Block CopolymerDocument1 pageHJ541CP: Polypropylene Block CopolymerEmmylouCasanovaNo ratings yet

- Topilene J800Document1 pageTopilene J800KevinGarciaNo ratings yet

- PP-R Pipe Grade R200P Properties and ApplicationsDocument6 pagesPP-R Pipe Grade R200P Properties and ApplicationsRAJESHNo ratings yet

- WP PPR - Thermopipe SubmittalDocument36 pagesWP PPR - Thermopipe SubmittalMohammad Rashad BarakatNo ratings yet

- Topilene J700N ENDocument1 pageTopilene J700N ENJoni Sie MssNo ratings yet

- HD7000F High Density Polyethylene Film GradeDocument2 pagesHD7000F High Density Polyethylene Film GradePhuoc TranNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- TDS SCGC PP P348S Rev Mar2022Document3 pagesTDS SCGC PP P348S Rev Mar2022y.s.6saputroNo ratings yet

- Bouroge 1490Document3 pagesBouroge 1490govindNo ratings yet

- SABIC-PP-5703P-Polypropylene-Homopolymer-for-Injection-MoldingDocument2 pagesSABIC-PP-5703P-Polypropylene-Homopolymer-for-Injection-MoldingMédi ChegmaNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- High rigidity HDPE grade for 20L lubricant containersDocument1 pageHigh rigidity HDPE grade for 20L lubricant containersStella KazanciNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Borstar HE3460 BlackDocument2 pagesBorstar HE3460 Blacklamia.elgammalNo ratings yet

- Bc250mo PDS Reg - Europe en V8 PDS Eur 24537 10012335Document3 pagesBc250mo PDS Reg - Europe en V8 PDS Eur 24537 10012335Fahad AliNo ratings yet

- Bitoner Resin C5 BT-1200H TDSDocument2 pagesBitoner Resin C5 BT-1200H TDSdamiendamNo ratings yet

- Product Data Sheet for SCGC PP P303SDocument3 pagesProduct Data Sheet for SCGC PP P303Sy.s.6saputroNo ratings yet

- Taizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis ReportDocument3 pagesTaizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis ReportFabiola Sugey Gonzales CcamaNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- PPC Borealis BEC 5012Document2 pagesPPC Borealis BEC 5012Milan BajicNo ratings yet

- P750JDocument1 pageP750JTan Chen TatNo ratings yet

- Borouge HD168MODocument2 pagesBorouge HD168MOhamza hameedNo ratings yet

- Haldia PP Raffia - R103 DatasheetDocument2 pagesHaldia PP Raffia - R103 DatasheetNarender RawatNo ratings yet

- Sabic Hdpe Bm1052: High Density PolyethyleneDocument2 pagesSabic Hdpe Bm1052: High Density PolyethyleneifahNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- High Impact PP for Automotive and ElectronicsDocument1 pageHigh Impact PP for Automotive and ElectronicsGabs GabrielaNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- hopelex pc-1100uDocument2 pageshopelex pc-1100uChu ChuNo ratings yet

- Borealis Bormod BJ368MODocument2 pagesBorealis Bormod BJ368MOOfer SoreqNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- Supreme SH 03 High Impact Polystyrene Technical DatasheetDocument2 pagesSupreme SH 03 High Impact Polystyrene Technical DatasheetVignesh CmvrNo ratings yet

- Fosroc Polyurea WPEDocument4 pagesFosroc Polyurea WPEKamagara Roland AndrewNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Be961mo - EngDocument2 pagesBe961mo - EngthienttthienNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- Globalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物Document1 pageGlobalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物medo.k016No ratings yet

- Data Sheet BH975MODocument2 pagesData Sheet BH975MOyang chinaNo ratings yet

- Pala 652 e 02 15Document3 pagesPala 652 e 02 15Carmen LinaresNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- pp_homo_k1111_datasheet (1)Document1 pagepp_homo_k1111_datasheet (1)hamdany danyNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Lupolen: Technical Data SheetDocument3 pagesLupolen: Technical Data SheetJaime222No ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- Fire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandDocument12 pagesFire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandnevinkoshyNo ratings yet

- Bridgette (OTC)Document31 pagesBridgette (OTC)mhel vianney bariquitNo ratings yet

- DT-21401 1800 X 9300 - 70 - SKIRTDocument65 pagesDT-21401 1800 X 9300 - 70 - SKIRTmaupatasNo ratings yet

- Tedds Engineering Library (US)Document80 pagesTedds Engineering Library (US)Mallesh NenkatNo ratings yet

- Determination of Soil Stiffness ParametersDocument24 pagesDetermination of Soil Stiffness ParametersVenkataLakshmiKorrapatiNo ratings yet

- Rapicon Walls 2021Document10 pagesRapicon Walls 2021Amith NagalapurNo ratings yet

- Report of PresentationDocument38 pagesReport of PresentationHiNo ratings yet

- Topic:Control of Ground Water in ExcavationDocument16 pagesTopic:Control of Ground Water in Excavationashok sutharNo ratings yet

- Cellular Lightweight ConcreteDocument7 pagesCellular Lightweight ConcreteAakanksha MishraNo ratings yet

- Airdryers: HamrinDocument30 pagesAirdryers: HamrinGuillermoNo ratings yet

- CMK 13 PDFDocument228 pagesCMK 13 PDFSonja DragovicNo ratings yet

- Axialsystemsincompressionandtensionincludingsap2000 160304165516Document446 pagesAxialsystemsincompressionandtensionincludingsap2000 160304165516Sara RamliNo ratings yet

- 12.turbulent Flow Jan 2015 PDFDocument12 pages12.turbulent Flow Jan 2015 PDFburhanuddinNo ratings yet

- Ussor 2010Document811 pagesUssor 2010mallicivilNo ratings yet

- S-2 TibiaoDocument1 pageS-2 TibiaoeddieNo ratings yet

- Vacuum de - Watered Flooring Method Statement: ActivitiesDocument1 pageVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்No ratings yet

- Concrete Beam Testing ResultsDocument39 pagesConcrete Beam Testing ResultsHamza ZejnilagićNo ratings yet

- NABARD FormatforSQMDocument24 pagesNABARD FormatforSQMajay chauhan100% (1)

- Reliable Concrete Repair - A Critical ReviewDocument13 pagesReliable Concrete Repair - A Critical ReviewSheri DiĺlNo ratings yet

- Unit 45Document53 pagesUnit 45Irfan KhanNo ratings yet

- Assignment ThreeDocument3 pagesAssignment ThreeARNo ratings yet

- Din-2848-Pr - de enDocument32 pagesDin-2848-Pr - de enAhmed AbidNo ratings yet

- Guide to Structural Analysis Beam ExampleDocument6 pagesGuide to Structural Analysis Beam ExamplegertjaniNo ratings yet

- 1 LimeDocument3 pages1 LimeSteph MejiaNo ratings yet

- Hubungan Antara Skin Friction Stress Dengan Nilai N-SPT: Fs AverageDocument10 pagesHubungan Antara Skin Friction Stress Dengan Nilai N-SPT: Fs AveragedelfiadrianiNo ratings yet