Professional Documents

Culture Documents

Tecnical Data TYPE 149 N 20 / N 25

Tecnical Data TYPE 149 N 20 / N 25

Uploaded by

DanielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tecnical Data TYPE 149 N 20 / N 25

Tecnical Data TYPE 149 N 20 / N 25

Uploaded by

DanielCopyright:

Available Formats

TECNICAL DATA TYPE 149 5 TORQUES: Thread Nm

N 20 / N 25

5.1 Drive - motors:

1 PRESSURE SETTINGS bar bar

1.2 Pressure limiter Maxi/mini

5.2 Drive - Gearboxes:

Start of opening 195

Full opening 215

5.3 Chassis:

2 SETTINGS mm 5.4 Steering axle and steering-wheels:

2.1 Electromagnetic brake Driving wheel

Maxi gap 0,5 Wheel nuts 140

Normal gap 0,2 Stabilizer wheel

Pivot attachment screw 125

3 WEAR LIMITS mm mm Load bearing wheel

3.1 Motor brushes New / mini lenght Mounting bolt 50

Traction motor 32 15

5.5 Electrical system:

Steering motor 22 11

5.6 Hydraulic system:

4 FILLING QUANTITIES Litres Lubricant*

149 804 3501.0304

4.1 Gearbox 1,5 Gear oil

5.7 Mast and tilt cylinders:

4.2 Hydraulic system 1,25 Hydraulic

fluid

4.3 Battery electrolyte As Distilled

required water

4.4 Lubricate

Pinion and steering gear As Silicone

required grease

Various hinge pins As Lithium

required grease

* See recommanded lubricants

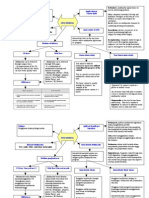

6 RECOMMENDED LUBRICANTS: 9 MAINTENANCE AND INSPECTION CHART

Hydraulic fluid Maintenance as required

ISO VG 46 H-L or H-LP (DIN 51524). Manufacturer’scode, 5-litre cans: FM 8101521. - Cleaning the truck

For cold-room operation: FM 8101489 (25-litre cans). - Checking the tightness and condition of the wheels

- Adjusting height of the stabiliser wheel

Gearbox oil - Fuse check

SAE 80 W 90, API. GL5, MIL.L 21DSC. Manufacturer’s code, 5-litre cans: 8100560. - Cleaning of steering ring and pinions

- Checking level of electrolyte and water supplement

Multi-purpose grease - Checking electrolyte s.g.

Lithium-based grease, high-pressure with anti-wear additive: Standard DIN 51825 - KPF 2K - 30, - Checking condition of battery connector, terminals and cables

KPF 2K - 20, KPF 2N- 30. - Cleaning the battery and battery compartment

Manufacturer’s code, cartridge: 7.337.475 140. - Truck operation tests

Chain spray Inspection and maintenance ervery 500 hours or every 6 months

Manufacturer’s code: 7326300602 - Greasing the turntable bearing of the motor unit

For cold-room operation: 7326300615 - Cleaning of steering ring and pinions

- Checking hydraulic oil level

Grease for steering ring and pinion - Checking tightness of hydraulic circuits

Aerosol silicon grease (600 ml) - Checking the condition, tightness of electrical connections and cables

Reference : FM 8 107 219 - Cleaning the drive unit plate

- Checking wear of contacts

7 SERVICES AFTER THE FIRST 50 SERVICE HOURS - Checking, and if necessary changing, traction motor brushes

- Checking the braking system - Checking and, if necessary, changing steering motor brushes

- Checking tightness of the wheels - Adjusting the electrohydraulic brake

- Checking the state of the wheels - Checking the various hinges

- Checking hydraulic oil level - Adjusting the sensitivity of the battery cover grip

- Checking tightness of hydraulic circuit - Truck operation tests

- Cleaning the hydraulic filter (sieve) - Checking reduction gear oil level

- Check level and s.g. of battery electrolyte

- Checking the condition and tightness of cables & electrical connections Inspection and maintenance every 1000 hours or one years

- Checking mechanical fixings of chassis, lifting system and locking of battery cover - Checking and if necessary changing pump motor brushes

- Greasing the turntable bearing of the motor unit, overall greasing - Cleaning the hydraulic filter (sieve)

- Replacing the reduction gear oil - Check the mechanical parts

- Truck operation tests - Truck operation tests

8 DAILY CHECKS Inspection and maintenance every 2000 service hours or 2 years

- Check forward/reverse and lift/lower controls - Replacing the hydraulic oil

- Check steering operation - Replace the gear reducer oil

- Check braking - Truck operation tests

- Check emergency stop button

- Check horn operation NOTE

- Check battery charge state In case of malfunctions and all truck servicing, always first disconnect the battery

plug.

Due to the danger of a short, never place tools on the battery.

You might also like

- M47D20 VP44: Seminar Working MaterialDocument69 pagesM47D20 VP44: Seminar Working MaterialIongornistu71% (7)

- Schlumberger JET Manual 23 Fracturing Pump UnitsDocument68 pagesSchlumberger JET Manual 23 Fracturing Pump UnitsVladyslav67% (3)

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Engine-Tdv8 4.4L DieselDocument613 pagesEngine-Tdv8 4.4L DieselFariz Fahmi100% (2)

- 139 L12R-L16R 0100 GB PDFDocument63 pages139 L12R-L16R 0100 GB PDFDaniel100% (1)

- Operating Instruction Gear Box AFM04,05,06Document20 pagesOperating Instruction Gear Box AFM04,05,06Bang Ochim100% (1)

- It 28 EngineDocument403 pagesIt 28 Engineintegralov100% (4)

- Busch R 5 RA 0165, 0205, 0255, 0305 DDocument20 pagesBusch R 5 RA 0165, 0205, 0255, 0305 DEduardo Efrain Rubio100% (2)

- zANTI Quick Start Guide 2 PDFDocument24 pageszANTI Quick Start Guide 2 PDFbabu100% (1)

- 149 TD N20v-Vi 0304 GBDocument1 page149 TD N20v-Vi 0304 GBDanielNo ratings yet

- 149 TD N20l-Li-Lx 0304 GBDocument1 page149 TD N20l-Li-Lx 0304 GBDanielNo ratings yet

- Tecnical Data TYPE 139 L12R / L16RDocument1 pageTecnical Data TYPE 139 L12R / L16RLada LabusNo ratings yet

- Tecnical Data TYPE 131 T20/24AP - T20/24SPDocument1 pageTecnical Data TYPE 131 T20/24AP - T20/24SPLada LabusNo ratings yet

- 2008 ARCTIC CAT 366 Service Repair Manual PDFDocument40 pages2008 ARCTIC CAT 366 Service Repair Manual PDFfuksekfmmd100% (1)

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- Transsmicion Mitsubishi Montero f5mr1-f55mr2Document12 pagesTranssmicion Mitsubishi Montero f5mr1-f55mr2Miguel ruizNo ratings yet

- 307 Automatic TransmissionTransaxleDocument113 pages307 Automatic TransmissionTransaxleNoureddine MerabtiNo ratings yet

- SM 51Document152 pagesSM 51belaghmasNo ratings yet

- 18 Engine Lubrication - Unimog 435 Workshop ManualDocument30 pages18 Engine Lubrication - Unimog 435 Workshop ManualJuan JapNo ratings yet

- Hatlapa L20, L35Document2 pagesHatlapa L20, L35hao33% (3)

- Starting Air Compressor HATLAPA L 35 (Broshure)Document2 pagesStarting Air Compressor HATLAPA L 35 (Broshure)Jezrell JaravataNo ratings yet

- MAN ME Introduction To The ME EngineDocument17 pagesMAN ME Introduction To The ME Engineironmanz316No ratings yet

- VRC CNG BookDocument111 pagesVRC CNG BookJeff LNo ratings yet

- Citytrac 4200Document112 pagesCitytrac 4200h45xlmNo ratings yet

- Engine - Gtdi 2.0L PetrolDocument5 pagesEngine - Gtdi 2.0L PetrolroryNo ratings yet

- Man Diesel Primeserv Academy Introduction To The Me EngineDocument17 pagesMan Diesel Primeserv Academy Introduction To The Me EngineRoman SydorovNo ratings yet

- 2 - Introduction To The ME Engine (June2012v2Document14 pages2 - Introduction To The ME Engine (June2012v2GiovanniJara100% (1)

- 2 - Introduction To The ME Engine PDFDocument14 pages2 - Introduction To The ME Engine PDFVikash Khaliyav Yadav50% (2)

- Manual Busch - Seco - SV - 1010 - 1040C - MRDocument16 pagesManual Busch - Seco - SV - 1010 - 1040C - MRignacio35127935No ratings yet

- 3850-SNS-TEE1-MCV Parts ManualDocument23 pages3850-SNS-TEE1-MCV Parts ManualJavier Pilquiman GaticaNo ratings yet

- Ingenium I4 2.0l PetrolDocument1,502 pagesIngenium I4 2.0l Petrolkhaledserag23No ratings yet

- KOEL EngineDocument82 pagesKOEL EnginechittineniNo ratings yet

- Mxu 400Document158 pagesMxu 400domi engremyNo ratings yet

- SECOND4Document3 pagesSECOND4WillNo ratings yet

- Section 4 Brake SystemDocument5 pagesSection 4 Brake SystemAndré TarginoNo ratings yet

- Spare Parts Manual: ModelsDocument96 pagesSpare Parts Manual: ModelsSARAMQRNo ratings yet

- Ford Fiesta Mk5-WP Specifications 200411Document8 pagesFord Fiesta Mk5-WP Specifications 200411Warrior Scholar0% (1)

- Page 27Document1 pagePage 27ccssaa123No ratings yet

- 03 1957 BU-EngineDocument44 pages03 1957 BU-EngineSheriff ServiceNo ratings yet

- SSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesDocument60 pagesSSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesSamad100% (1)

- AC Datasheet 582 65hpDocument2 pagesAC Datasheet 582 65hpArtur FrancoNo ratings yet

- Js205 Tracked Excavator I Specification: EngineDocument4 pagesJs205 Tracked Excavator I Specification: EngineKasidin100% (1)

- 350 SeriesDocument238 pages350 SeriesFernandoNo ratings yet

- Aisin Af406Document18 pagesAisin Af406emiliqn velikov100% (1)

- Workshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainDocument86 pagesWorkshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainCarlos Luis Santos Somcar100% (1)

- E25s 1Document1 pageE25s 1Asif JavedNo ratings yet

- 04 - Lubrication SystemDocument10 pages04 - Lubrication SystemMarcos Mo CatalanNo ratings yet

- F1 SAE Pump - Fixed Displacement General InformationDocument3 pagesF1 SAE Pump - Fixed Displacement General InformationPSNo ratings yet

- HPR StartupDocument24 pagesHPR StartupArleyTrujillo1224No ratings yet

- Service Manual Nissan Engine Model PDocument10 pagesService Manual Nissan Engine Model Pmichel100% (57)

- LPW2 3 4 DatasheetDocument2 pagesLPW2 3 4 DatasheetYouba FofanaNo ratings yet

- Audi SSP 45-1-2 LTR 3 Cylinder Petrol EnginesDocument2 pagesAudi SSP 45-1-2 LTR 3 Cylinder Petrol Enginesmark100% (58)

- Linde OperatingInstructions OpenLoop PDFDocument24 pagesLinde OperatingInstructions OpenLoop PDFlzlinuxNo ratings yet

- ME Engine (Intelligent Engine)Document95 pagesME Engine (Intelligent Engine)Mahesh More100% (2)

- Danfoss PumpDocument32 pagesDanfoss PumpĐồng Ngọc TrungNo ratings yet

- BW24RH Service Manual PDFDocument606 pagesBW24RH Service Manual PDFLuis Alfredo Alarcón Calderón100% (1)

- 1 9 Tdi PDDocument21 pages1 9 Tdi PDMohd Fairus100% (1)

- Ford Courier 1991 1.3 Techincal DataDocument2 pagesFord Courier 1991 1.3 Techincal DatacosminNo ratings yet

- Hydroirma Catalog Gear PumpDocument104 pagesHydroirma Catalog Gear PumpEng-Mohammed Salem100% (1)

- 141exgas 0902gbDocument58 pages141exgas 0902gbDanielNo ratings yet

- 149exgas 0904 GBDocument66 pages149exgas 0904 GBDanielNo ratings yet

- 149exgas LI 0305 GBDocument68 pages149exgas LI 0305 GBDanielNo ratings yet

- 141 L16as 0200 GB PDFDocument53 pages141 L16as 0200 GB PDFDanielNo ratings yet

- 141 L12L L12LP 1299 GB PDFDocument61 pages141 L12L L12LP 1299 GB PDFDanielNo ratings yet

- Lucas TD5 Diagnostic (Land Rover) (SM010) PDFDocument11 pagesLucas TD5 Diagnostic (Land Rover) (SM010) PDFDaniel100% (3)

- 126aex 1201gb PDFDocument70 pages126aex 1201gb PDFDanielNo ratings yet

- Java-Frequently Asked Interview QuestionsDocument2 pagesJava-Frequently Asked Interview QuestionsS.S. AmmarNo ratings yet

- FDP - Cryptography & Network Security BrochureDocument2 pagesFDP - Cryptography & Network Security Brochureaishuvc1822No ratings yet

- Cerwin Vega Sds 525 Guia Del UsuarioDocument6 pagesCerwin Vega Sds 525 Guia Del UsuarioJorge SalgadoNo ratings yet

- Prerequisites Courses:Basic Electrical Engineering and MathematicsDocument4 pagesPrerequisites Courses:Basic Electrical Engineering and MathematicsmuthukumarNo ratings yet

- Impulse 6000D/7000DP: Sending Test Data To A PC: Application NoteDocument2 pagesImpulse 6000D/7000DP: Sending Test Data To A PC: Application NoteMarielena ZabalaNo ratings yet

- High Court Recruitment Portal Signup and Profile UpdationDocument27 pagesHigh Court Recruitment Portal Signup and Profile Updationsunanda salilNo ratings yet

- IA8710Document2 pagesIA8710Narendra KumarNo ratings yet

- As 2548.1-1998 Battery Chargers For Lead-Acid Traction Batteries Battery Chargers For Vented CellsDocument7 pagesAs 2548.1-1998 Battery Chargers For Lead-Acid Traction Batteries Battery Chargers For Vented CellsSAI Global - APACNo ratings yet

- Manual Corning HX 709C006801 PDFDocument46 pagesManual Corning HX 709C006801 PDFtomNo ratings yet

- SP Series Hydraulic Gear Pump: Outstanding FeaturesDocument3 pagesSP Series Hydraulic Gear Pump: Outstanding FeaturessolserengsaNo ratings yet

- GameRanger Launch LogDocument2 pagesGameRanger Launch LogNguyễn LươngNo ratings yet

- Ic-2730a-Tcb-Fcc Id-Afj359800Document1 pageIc-2730a-Tcb-Fcc Id-Afj359800Francisco GomesNo ratings yet

- Multimedia F5 Mind MapDocument2 pagesMultimedia F5 Mind MapHerdiey HaronNo ratings yet

- HiPath Cordles IP DataDocument4 pagesHiPath Cordles IP Dataleandros2006No ratings yet

- DDCA - Skill ProfileDocument14 pagesDDCA - Skill ProfilePrakash TripathiNo ratings yet

- Volvo Penta - Catalogo MotoresDocument76 pagesVolvo Penta - Catalogo MotoresЕвгенийNo ratings yet

- Unit 1Document29 pagesUnit 1SwaasNo ratings yet

- Vibrating Feeder FMF 300/ - 150 X 1230: Operating ManualDocument102 pagesVibrating Feeder FMF 300/ - 150 X 1230: Operating ManualivanbeljinNo ratings yet

- Heart Rate Detection With PiezoDocument5 pagesHeart Rate Detection With PiezoEmilio Cánepa100% (1)

- Compensation Step by StepDocument92 pagesCompensation Step by StepAnthonyZegarraChamorroNo ratings yet

- COC 3 Set Up Computer Server - 1 - 8Document7 pagesCOC 3 Set Up Computer Server - 1 - 8jannahaimi 1234No ratings yet

- Risks and Benefits of ERPDocument13 pagesRisks and Benefits of ERPDevanarayanan SajiNo ratings yet

- Innovus Study Notes-CSDN BlogDocument6 pagesInnovus Study Notes-CSDN BlogAgnathavasiNo ratings yet

- Chapter 2 - G S: Etting TartedDocument33 pagesChapter 2 - G S: Etting Tartedkilladorsp killadorNo ratings yet

- LG OLED TV Owner's Manual For OLED CX ModelsDocument33 pagesLG OLED TV Owner's Manual For OLED CX ModelsTom KakanowskiNo ratings yet

- Iso7816 3Document15 pagesIso7816 3Tolu CollinsNo ratings yet

- CV Instrumentation EngineerDocument4 pagesCV Instrumentation EngineerisukuruNo ratings yet

- Distributed System Design Issues - NfinalDocument10 pagesDistributed System Design Issues - NfinalAimee Joy L HermosoraNo ratings yet

- Inverse Response - Control NotesDocument5 pagesInverse Response - Control NotesCarlos TomeyNo ratings yet