Professional Documents

Culture Documents

149 TD N20v-Vi 0304 GB

149 TD N20v-Vi 0304 GB

Uploaded by

DanielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

149 TD N20v-Vi 0304 GB

149 TD N20v-Vi 0304 GB

Uploaded by

DanielCopyright:

Available Formats

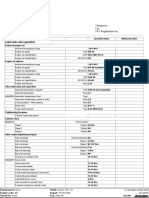

TECNICAL DATA TYPE 149 5 TORQUES: Thread Nm

N20V / N20VI

5.1 Drive - motors:

1 PRESSURE SETTINGS bar bar

1.2 Pressure limiter Maxi/mini

5.2 Drive - Gearboxes:

Initial lift circuit ( end of opening ) 235

High lift circuit ( end of opening ) 220

5.3 Chassis:

2 SETTINGS mm 5.4 Steering axle and steering-wheels:

2.1 Electromagnetic brake Driving wheel

Maxi gap 0,5 Wheel nuts 140

Normal gap 0,25 Stabilizer wheel

Pivot attachment screw 125

3 WEAR LIMITS mm mm Load bearing wheel

3.1 Motor brushes New / mini lenght Mounting bolt 50

Traction motor 32 15

5.5 Electrical system:

Pump motor

High lift 22,5 14

5.6 Hydraulic system:

Initial lift 27 8

149 804 3521.0304

Steering motor 16 5,5

5.7 Mast and tilt cylinders:

4 FILLING QUANTITIES Litres Lubricant*

4.1 Gearbox 1,5 Gear oil

4.2 Hydraulic system 6.8 Hydraulic

fluid

4.3 Battery electrolyte As Distilled

required water

4.4 Lubricate

Pinion and steering gear As Silicone

required grease

Various hinge pins As Lithium

required grease

4.5 Flyer chain protection As Chain

required spray

* See recommanded lubricants

6 RECOMMENDED LUBRICANTS: 9 MAINTENANCE AND INSPECTION CHART

Hydraulic fluid Maintenance as required

ISO VG 46 H-L or H-LP (DIN 51524). Manufacturer’s code, 5-litre cans: FM 8101521. - Truck cleaning

For cold-room operation: FM 8101489 (25-litre cans). - Chain cleaning and lubrication

- Mast lubrication

Gearbox oil - Wheel condition and fixing check

SAE 80 W 90, API. GL5, MIL.L 21DSC. Manufacturer’s code, 5-litre cans: 8100560. - Stabilising wheel height adjustment

- Electrolyte level check and top-up

Multi-purpose grease - Electrolyte specific gravity check

Lithium-based grease, high-pressure with anti-wear additive: Standard DIN 51825 - KPF 2K - 30, - Fuse check

KPF 2K - 20, KPF 2N- 30. - Check on condition of cables, terminals and battery connector

Manufacturer’s code, cartridge: 7.337.475 140. - Battery and battery compartment cleaning

- Truck operation tests

Chain spray

Manufacturer’s code: 7326300602 Inspection and maintenance ervery 500 hours or every 6 months

For cold-room operation: 7326300615 - Drive unit steering bearing lubrication

- Steering ring gear pinion cleaning

Grease for steering gear and pinion - Hydraulic oil level check

Silicone grease in aerosol (600 ml) - Hydraulic circuit leak check

Reference: FM 8 107 219 - Check on condition and fixing of electrical cables and connections

- Check on condition and fixing of mast and chains

7 SERVICES AFTER THE FIRST 50 SERVICE HOURS - Chain length adjustment

- Braking system check - Variator panel cleaning

- Wheel fixing check - Contact wear check

- Wheel condition check - Traction motor brush check and replacement if necessary

- Hydraulic oil level check - Steering motor brush check and replacement if necessary

- Hydraulic circuit leak check - Electromagnetic brake adjustment

- Hydraulic filter cleaning - Articulation check

- Replace the L.S.L. (Linde Soft Lifting ) distributor filter - Gearbox oil level check

- Battery electrolyte level and specific gravity check - Truck operation tests

- Check on condition and fixing of electrical cablesand connections

- Mechanical and chassis fixing check Inspection and maintenance every 1000 hours or one years

- Check on condition of mast and chains - Check and replace if necessary pump motor brush

- General lubrication - Cleaning the high pressure hydraulic filter

- Lubrication of drive unit steering bearing - Replace the L.S.L. (Linde Soft Lifting ) distributor filter

- Battery charger check - Check the mechanical parts

- Truck operation tests - Truck operation tests

Inspection and maintenance every 2000 service hours or 2 years

8 DAILY CHECKS - Hydraulic oil replacement

- Check forward/reverse and lift/lower controls - Gearbox oil replacement

- Check steering operation - Truck operation tests

- Check braking

- Check emergency stop button

NOTE

- Check horn operation

In case of malfunctions and all truck servicing, always first disconnect the battery

- Check battery charge state

plug.

- Check on battery cover locks

Due to the danger of a short, never place tools on the battery.

You might also like

- Caterpillar 236D, 242D, 246D, 262D, 257D, 277D, 287D, 289D Diagrama Electrico 29 PáginasDocument29 pagesCaterpillar 236D, 242D, 246D, 262D, 257D, 277D, 287D, 289D Diagrama Electrico 29 PáginasOscar Tello86% (14)

- M47D20 VP44: Seminar Working MaterialDocument69 pagesM47D20 VP44: Seminar Working MaterialIongornistu67% (6)

- Schlumberger JET Manual 23 Fracturing Pump UnitsDocument68 pagesSchlumberger JET Manual 23 Fracturing Pump UnitsVladyslav67% (3)

- Honda Vezel Hybrid RS Honda Sensing 2018Document9 pagesHonda Vezel Hybrid RS Honda Sensing 2018maddiNo ratings yet

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- 139 L12R-L16R 0100 GB PDFDocument63 pages139 L12R-L16R 0100 GB PDFDaniel100% (1)

- Top 150 Civil Engineer Interview Questions Asked in Top CompaniesDocument17 pagesTop 150 Civil Engineer Interview Questions Asked in Top CompaniesBURDWAN COMMUNITYNo ratings yet

- Operating Instruction Gear Box AFM04,05,06Document20 pagesOperating Instruction Gear Box AFM04,05,06Bang OchimNo ratings yet

- Busch R 5 RA 0165, 0205, 0255, 0305 DDocument20 pagesBusch R 5 RA 0165, 0205, 0255, 0305 DEduardo Efrain Rubio100% (2)

- It 28 EngineDocument403 pagesIt 28 Engineintegralov100% (4)

- Busch 0872-900-823 R 5 0025-0101 E & 0250 C 0511 PDFDocument20 pagesBusch 0872-900-823 R 5 0025-0101 E & 0250 C 0511 PDFRodolfo M. PortoNo ratings yet

- Tyre Modelling - Pacejka '96 Model: Links To Page 133 of Race Car Design by Derek SewardDocument5 pagesTyre Modelling - Pacejka '96 Model: Links To Page 133 of Race Car Design by Derek SewardahmadNo ratings yet

- 149 TD N20l-Li-Lx 0304 GBDocument1 page149 TD N20l-Li-Lx 0304 GBDanielNo ratings yet

- Tecnical Data TYPE 149 N 20 / N 25Document1 pageTecnical Data TYPE 149 N 20 / N 25DanielNo ratings yet

- Tecnical Data TYPE 139 L12R / L16RDocument1 pageTecnical Data TYPE 139 L12R / L16RLada LabusNo ratings yet

- Tecnical Data TYPE 131 T20/24AP - T20/24SPDocument1 pageTecnical Data TYPE 131 T20/24AP - T20/24SPLada LabusNo ratings yet

- SMT Crane Maintenance ManualDocument84 pagesSMT Crane Maintenance ManualArun Tiwari100% (1)

- 18 Engine Lubrication - Unimog 435 Workshop ManualDocument30 pages18 Engine Lubrication - Unimog 435 Workshop ManualJuan JapNo ratings yet

- 2008 ARCTIC CAT 366 Service Repair Manual PDFDocument40 pages2008 ARCTIC CAT 366 Service Repair Manual PDFfuksekfmmd100% (1)

- 2 - Introduction To The ME Engine (June2012v2Document14 pages2 - Introduction To The ME Engine (June2012v2GiovanniJara100% (1)

- 2 - Introduction To The ME Engine PDFDocument14 pages2 - Introduction To The ME Engine PDFVikash Khaliyav Yadav50% (2)

- Engine - Gtdi 2.0L PetrolDocument5 pagesEngine - Gtdi 2.0L PetrolroryNo ratings yet

- Ford Fiesta Mk5-WP Specifications 200411Document8 pagesFord Fiesta Mk5-WP Specifications 200411Warrior Scholar0% (1)

- MAN ME Introduction To The ME EngineDocument17 pagesMAN ME Introduction To The ME Engineironmanz316No ratings yet

- 307 Automatic TransmissionTransaxleDocument113 pages307 Automatic TransmissionTransaxleNoureddine MerabtiNo ratings yet

- SM 51Document152 pagesSM 51belaghmasNo ratings yet

- 04 - Lubrication SystemDocument10 pages04 - Lubrication SystemMarcos Mo CatalanNo ratings yet

- Transsmicion Mitsubishi Montero f5mr1-f55mr2Document12 pagesTranssmicion Mitsubishi Montero f5mr1-f55mr2Miguel ruizNo ratings yet

- Barrel Pump-MOTORISED-TDocument1 pageBarrel Pump-MOTORISED-TEVEREST ANALYTICALS MEGHANANo ratings yet

- Manual Busch - Seco - SV - 1010 - 1040C - MRDocument16 pagesManual Busch - Seco - SV - 1010 - 1040C - MRignacio35127935No ratings yet

- Ingenium I4 2.0l PetrolDocument1,502 pagesIngenium I4 2.0l Petrolkhaledserag23No ratings yet

- Man Diesel Primeserv Academy Introduction To The Me EngineDocument17 pagesMan Diesel Primeserv Academy Introduction To The Me EngineRoman SydorovNo ratings yet

- Starting Air Compressor HATLAPA L 35 (Broshure)Document2 pagesStarting Air Compressor HATLAPA L 35 (Broshure)Jezrell JaravataNo ratings yet

- Hatlapa L20, L35Document2 pagesHatlapa L20, L35hao33% (3)

- VRC CNG BookDocument111 pagesVRC CNG BookJeff LNo ratings yet

- LPW2 3 4 DatasheetDocument2 pagesLPW2 3 4 DatasheetYouba FofanaNo ratings yet

- Vmo 50HZ PDFDocument1 pageVmo 50HZ PDFСаво ЂокићNo ratings yet

- AC Datasheet 582 65hpDocument2 pagesAC Datasheet 582 65hpArtur FrancoNo ratings yet

- Mitsibushi Fuso 4d33 Engine Power SteeringDocument44 pagesMitsibushi Fuso 4d33 Engine Power SteeringMarat AidinbyekNo ratings yet

- Citytrac 4200Document112 pagesCitytrac 4200h45xlmNo ratings yet

- Ford Courier 1991 1.3 Techincal DataDocument2 pagesFord Courier 1991 1.3 Techincal DatacosminNo ratings yet

- Air Cooled Diesel EnginesDocument16 pagesAir Cooled Diesel EnginesDaniela Andrea Acosta ForeroNo ratings yet

- LOMBARD DIESEL AIR COOL 4 A 12 HPDocument16 pagesLOMBARD DIESEL AIR COOL 4 A 12 HPErnesto Alonzo Avater AvaterNo ratings yet

- Js205 Tracked Excavator I Specification: EngineDocument4 pagesJs205 Tracked Excavator I Specification: EngineKasidin100% (1)

- Wheel LoaderDocument2 pagesWheel LoaderfitriNo ratings yet

- KOEL EngineDocument82 pagesKOEL EnginechittineniNo ratings yet

- F1 SAE Pump - Fixed Displacement General InformationDocument3 pagesF1 SAE Pump - Fixed Displacement General InformationPSNo ratings yet

- Series H - Industrial Gearbox: Installation & MaintenanceDocument24 pagesSeries H - Industrial Gearbox: Installation & MaintenanceManisankar IrukuvajjalaNo ratings yet

- SSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesDocument60 pagesSSP 100 16 L Tdi and 20 L Tdi Engines With The Common Rail Injection System Ea288 Design SeriesSamad100% (1)

- Installation and Operating Instructions: 0.1 Mbar VersionsDocument20 pagesInstallation and Operating Instructions: 0.1 Mbar Versionsinge VazquwzNo ratings yet

- 18 FR-FR Fiche PubliqueDocument2 pages18 FR-FR Fiche PubliqueChafik AlbadraouiNo ratings yet

- Spare Parts Manual: ModelsDocument96 pagesSpare Parts Manual: ModelsSARAMQRNo ratings yet

- Section 4 Brake SystemDocument5 pagesSection 4 Brake SystemAndré TarginoNo ratings yet

- Mxu 400Document158 pagesMxu 400domi engremyNo ratings yet

- 3850-SNS-TEE1-MCV Parts ManualDocument23 pages3850-SNS-TEE1-MCV Parts ManualJavier Pilquiman GaticaNo ratings yet

- SECOND4Document3 pagesSECOND4WillNo ratings yet

- Page 27Document1 pagePage 27ccssaa123No ratings yet

- Picanto Automatic Transaxle System.Document2 pagesPicanto Automatic Transaxle System.Esquisof100% (1)

- ME Engine (Intelligent Engine)Document95 pagesME Engine (Intelligent Engine)Mahesh More100% (1)

- 28 GBDocument40 pages28 GBjahzooneNo ratings yet

- General SpecificationDocument1 pageGeneral SpecificationPHUONG NGUYENNo ratings yet

- H 100Document8 pagesH 100thabo tsoeliNo ratings yet

- HL635VHL665VDocument55 pagesHL635VHL665VRamiro Castro Pacheco100% (1)

- KXR50 Cap 01 (Info Generali)Document31 pagesKXR50 Cap 01 (Info Generali)tutifruti649No ratings yet

- 149exgas 0904 GBDocument66 pages149exgas 0904 GBDanielNo ratings yet

- 141exgas 0902gbDocument58 pages141exgas 0902gbDanielNo ratings yet

- 141 L16as 0200 GB PDFDocument53 pages141 L16as 0200 GB PDFDanielNo ratings yet

- 149exgas LI 0305 GBDocument68 pages149exgas LI 0305 GBDanielNo ratings yet

- 141 L12L L12LP 1299 GB PDFDocument61 pages141 L12L L12LP 1299 GB PDFDanielNo ratings yet

- Lucas TD5 Diagnostic (Land Rover) (SM010) PDFDocument11 pagesLucas TD5 Diagnostic (Land Rover) (SM010) PDFDaniel100% (2)

- 126aex 1201gb PDFDocument70 pages126aex 1201gb PDFDanielNo ratings yet

- Innovations in Urban Resettlement - Mumbai Urban Transport ProjectDocument16 pagesInnovations in Urban Resettlement - Mumbai Urban Transport ProjectSatya MishraNo ratings yet

- Sebp4547 05 00 All PDFDocument679 pagesSebp4547 05 00 All PDFRoberto Tenemas100% (1)

- Passat No. 86 / 1: Radio-Navigation System (RNS), With Digital Sound Package (DSP)Document8 pagesPassat No. 86 / 1: Radio-Navigation System (RNS), With Digital Sound Package (DSP)Михаил СтрунгарьNo ratings yet

- CMRL Phase-2 General Consultancy Services For JICA PortionDocument5 pagesCMRL Phase-2 General Consultancy Services For JICA PortionsubhashkumarmandalamcivilNo ratings yet

- MF 6400 7400 Series BrochureDocument40 pagesMF 6400 7400 Series BrochureEricNo ratings yet

- Al-Darwish KULI Cranes BrochureDocument10 pagesAl-Darwish KULI Cranes BrochureAl-Darwish KuliNo ratings yet

- RecommendationDocument3 pagesRecommendationKams KingNo ratings yet

- Audit Mojul Dan MPK 06 Desember 2023Document206 pagesAudit Mojul Dan MPK 06 Desember 2023pikrayandaNo ratings yet

- DTDCDocument1 pageDTDCAbdullah siddikiNo ratings yet

- Resolution No. R2021-14: Proposed Action Key Features SummaryDocument13 pagesResolution No. R2021-14: Proposed Action Key Features SummaryThe UrbanistNo ratings yet

- 11 Wind ShearDocument15 pages11 Wind ShearFrederick OteikwuNo ratings yet

- Culverts and Low Level Water CrossingsDocument9 pagesCulverts and Low Level Water Crossingstewele brhaneNo ratings yet

- Role of HRM in An Organization (Automobile Industry)Document17 pagesRole of HRM in An Organization (Automobile Industry)Saransh NeeradNo ratings yet

- Port Hedland Mooring Management Standard FINALDocument2 pagesPort Hedland Mooring Management Standard FINALJeongheeseokNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- Fuse Box Diagram Skoda Superb (B6 - 3T 2008-2015)Document35 pagesFuse Box Diagram Skoda Superb (B6 - 3T 2008-2015)ranjitv10No ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument21 pagesJeppview For Windows: List of Pages in This Trip KitboobaNo ratings yet

- Web ScrapingDocument15 pagesWeb ScrapingRano KravchenkoNo ratings yet

- 02 Sleeper Pads For Ballasted Tracks PDFDocument16 pages02 Sleeper Pads For Ballasted Tracks PDFSzabolcs Attila KöllőNo ratings yet

- Tools For Servicing Electric and Hybrid VehiclesDocument25 pagesTools For Servicing Electric and Hybrid VehiclesL ESNo ratings yet

- 3 Electrical P120 6VDocument28 pages3 Electrical P120 6Vmalte winbaldNo ratings yet

- Design ReviewerDocument11 pagesDesign ReviewerMary Kirsteen SisonNo ratings yet

- Fronius Gen24 Plus Provides New Levels of VersatilityDocument2 pagesFronius Gen24 Plus Provides New Levels of VersatilityDiego SalasNo ratings yet

- Abc of Thermal Power Plant - Land Requirement For Themal Power Plant FinalDocument3 pagesAbc of Thermal Power Plant - Land Requirement For Themal Power Plant FinalAnonymous 5XvUbWynnNo ratings yet

- 0023 Westconnex SummaryDocument61 pages0023 Westconnex SummaryRachata SuesatNo ratings yet

- Operational Factors Human Performance - Attachment 13 - Rhoades Aviation Quick Reference Handbook (Excerpt) - RelDocument30 pagesOperational Factors Human Performance - Attachment 13 - Rhoades Aviation Quick Reference Handbook (Excerpt) - RelGFNo ratings yet