Professional Documents

Culture Documents

Microsoft Word - 1IntroductionFINAL 13-09

Uploaded by

Djou KetataCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microsoft Word - 1IntroductionFINAL 13-09

Uploaded by

Djou KetataCopyright:

Available Formats

1.

Introduction

Table of content

Section Title Page

1.1. The Jotun Group 1.2.

1.2. Why do we paint? 1.4.

1.3. Why is education and knowledge so important? 1.5.

Section 1 : “Introduction” Page 1.1

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

1.1 The Jotun Group

The Jotun Group is one of the world's leading manufacturers of paints, coatings and

powder coatings.

The group has 74 companies and 40 production facilities on all continents. Including

the total network of legal companies, agents, branch offices and distributors Jotun is

represented in more than 80 countries. Jotun's operations cover development,

production, marketing and sales of various paint systems and products to protect

and decorate surfaces in the residential, shipping and industrial markets. In 2009 the

Jotun Group had a total sales income of USD 1.885 million, and has today 7 400

employees.

Head office is located in Sandefjord, Norway.

Since its founding in 1926, Jotun has remained a pioneer in the

development of innovative coatings solutions for an increasingly

broad range of industries. That tradition continues today, with the

company working with new additives to produce innovative coatings

tailored to meet the emerging demands of consumers and

professionals alike.

Section 1 : “Introduction” Page 1.2

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

The Jotun Group consists of four divisions, each

with specific products, segments and geographical

responsibilities.

• Jotun Dekorativ has segment responsibility for Jotun’s

decorative paints, stains and varnish deliveries to the

trade and Do it Yourself (DI Y) markets in Scandinavia.

• Jotun Paints has segment responsibility for decorative

paints in all markets outside Scandinavia. This

responsibility includes marine and protective coatings for

selected markets in the Middle East and South East Asia.

• Jotun Coatings has global segment responsibility

for marine and protective coatings. This responsibility

includes decorative paints in selected local markets in

Europe and markets in Asia.

• Jotun Powder Coatings has global segment

responsibility for powder coatings. The product portfolio

caters for the architectural, functional and industrial

market segments to both protect metal surfaces from

corrosion and add colour and style to their appearance.

Jotun

Jotun Jotun Jotun Jotun Powder

Dekorativ Paints Coatings Coatings

Decorative Decorative Marine Functional

Protective Architectural

Industrial & specialties

Section 1 : “Introduction” Page 1.3

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

1.2 Why do we paint?

The reason for using paint can basically be put into two categories:

1. Protection

2. Cosmetic

First of all the industry wishes to preserve their investments to avoid accidents. The

safety aspect is partly governed by legislative authorities and partly taken care of by

the industries own safety standards and procedures.

Secondly, protection is done to save money. If it was cheaper to let constructions

corrode, and simply build new ones when the safety limit was passed, we would

have seen many more rusty plants, ships and platforms. The fact is, that by proper

corrosion protection the industry saves a lot of money. The question is therefore not

if the structure should be protected, but rather to find the most cost effective way

of protection. In many cases it is found that the optimal form is to use paint as

protection against rust.

Is it cheap to paint? No, painting can indeed cost a great deal of money and can

require considerable work. However, many people do not realise that adequate

pre-treatment of the substrate before the paint is applied often costs many times

more than the paint itself. As we will see later the pre-treatment method and the

quality of the work done have great influence on the final result, and it is of major

importance to select a paint system with properties that are compatible with the

pre-treatment. Typical examples of cost ratios are:

1. Total new building cost: 100 %

2. Cost for surface treatment 10 %

(Pre-treatment, scaffolding, lightning, application etc.)

3. Cost of paint 2%

In addition, painting makes the surroundings attractive. It is sometimes difficult to

draw a definite line between what is protection and what is cosmetic. Very often

there is a close connection between appearance and protection. A good-looking

facility is in most cases also well maintained. For some objects the cosmetics are of

no importance at all, while for others, like cruise ships the appearance is crucial.

Section 1 : “Introduction” Page 1.4

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

1.3 Why is education and knowledge so

important?

A few years ago an investigation was carried out to find out why paint systems

failed. The result is summarised below.

Investigation by a Guarantee

Insurance company has shown:

• 95 % of all coating failures result from

– Poor surface preparation

– Poor application

• 85 % of all failures appear after 1-2 years

This fits in well with our own experience

Another way of illustrating the same point is the “Coating quality chain” (See figure

below). On the axis to the left, the life time expected by the owner for a paint

system is given. The axis to the right shows the real lifetime for the paint system

after completion of the paint work.. The chain on the top of the figure gives the

consecutive activities from the planning and all the way through the paint work

process. The “quality line” illustrates the quality level through the process. When

moving from left to right along the “quality line”, the figure illustrates that the

expected quality can be maintained more easily through the “Philosophy-”,

“Specification-” and “Coating selection” stages, than during the “Pre-blasting-”,

“Pre-treatment-” and “Application-” stages, where a significant drop can be

experienced. The different stages in the reduction of quality have one thing in

common: The human factor.

Section 1 : “Introduction” Page 1.5

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

Expectation Result

1.Philosophy 3.Coating selection 5.Pre-treatment

2.Specification 4.Pre-blasting 6.Application

The quality line

The coating quality chain

This means that we all have to realise that the paint in the tin is by no means a

complete product. The end-product, with all its strengths and weaknesses, is the

paint applied on the structure. If the end-product is to comply with the expectations

regarding lifetime of the coating, protection of a structure must be looked upon as a

chain of quality influencing processes, where the end- result is determined by the

weakest link of the chain. To achieve a good result, with no reduction in quality,

requires good workmanship and adequate quality control and/or inspection at each

step of the job

Coating technology, like any other technology, is improving. However, the

improvements actually lead to greater variations with respect to pre-treatment

methods, application and coating systems to be used. This will require a higher

degree of education and practical training / experience from the personnel involved

in coating technology. Again: The quality of the final result depends most of all on

the “human factor”.

Since there is a growing need to have good knowledge about the whole coating

process, Jotun decided to establish a Paint School as a tool for educating our own

personnel. We also offer these courses as a service to personnel in the industry

dealing with paint. As a consequence of the points made above, the present course

will not only focus on knowledge of different types of paints and application, but will

also highlight the most important factors for having a well protected structure:

1. Steel preparation and Pre-treatment

2. Application of paint

3. Quality and property of different generic types of paint

4. Quality control

Section 1 : “Introduction” Page 1.6

Copyright© 2010 Jotun Paints South Africa (Pty.) Ltd. All rights reserved.

You might also like

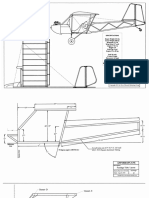

- Plans PDFDocument49 pagesPlans PDFEstevam Gomes de Azevedo85% (34)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- Anti Corrosive PaintsDocument3 pagesAnti Corrosive PaintsMallinatha PNNo ratings yet

- Painting MannualDocument81 pagesPainting MannualArunkumar Rackan100% (1)

- Atlas Coatings Durability White Paper 2015Document40 pagesAtlas Coatings Durability White Paper 2015gowtham50% (2)

- ICI Paints BusinessDocument43 pagesICI Paints Businessmuhammadtaimoorkhan100% (1)

- BergerMasterFile PDFDocument74 pagesBergerMasterFile PDFSumanta RoyNo ratings yet

- 12 Key Principles On Bhava AnalysisDocument28 pages12 Key Principles On Bhava AnalysisDhineshNo ratings yet

- Paint School: Training Course HandoutsDocument71 pagesPaint School: Training Course HandoutsShaaban Hamed93% (14)

- Paint Factory Makurdi PDFDocument210 pagesPaint Factory Makurdi PDFAnthonyNo ratings yet

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionFrom EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNo ratings yet

- Dawn of Solar PV CookingDocument5 pagesDawn of Solar PV CookingAbhinav AgrawalNo ratings yet

- Pediatric EmergenciesDocument47 pagesPediatric EmergenciesahmedNo ratings yet

- Introduction of Automotive PaintDocument26 pagesIntroduction of Automotive PaintPraveen BanThia100% (1)

- Common Paints Problems & Possible SolutionsDocument72 pagesCommon Paints Problems & Possible SolutionsRajesh SharmaNo ratings yet

- Tuberculosis PowerpointDocument69 pagesTuberculosis PowerpointCeline Villo100% (1)

- Training Report On Self Contained Breathing ApparatusDocument4 pagesTraining Report On Self Contained Breathing ApparatusHiren MahetaNo ratings yet

- Criteria For Paints and CoatingsDocument15 pagesCriteria For Paints and Coatingsjuli_radNo ratings yet

- Painting Guide BookDocument65 pagesPainting Guide Booklwin_oo2435No ratings yet

- Additives in Water-Borne CoatingsDocument90 pagesAdditives in Water-Borne CoatingsWa Lao Eh100% (1)

- Liver: Anatomy & FunctionsDocument18 pagesLiver: Anatomy & FunctionsDR NARENDRANo ratings yet

- Jo Tamasic 87 Mio Application GuideDocument10 pagesJo Tamasic 87 Mio Application GuideJurijs BNo ratings yet

- EXP4 The Diels Alder ReactionsDocument3 pagesEXP4 The Diels Alder ReactionsLaura GuidoNo ratings yet

- Role of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiDocument64 pagesRole of Influencer & Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints, RanchiBibhuti Garnaik100% (1)

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Document31 pagesArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008No ratings yet

- Malvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasDocument71 pagesMalvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasMary Cruz Meza CahuanaNo ratings yet

- HPI BrochureDocument20 pagesHPI BrochurePramod AthiyarathuNo ratings yet

- IT ReportDocument29 pagesIT ReportKingsley OgbavwuduNo ratings yet

- Role of Influencer Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints RanchiDocument64 pagesRole of Influencer Dealers in Promoting Loyalty Program in Paint Industry A Study On Nerolac Paints RanchiKeshav ShankarNo ratings yet

- Hapter: Otun More Than PaintDocument10 pagesHapter: Otun More Than Painttanuj ranaNo ratings yet

- JOTUN Topcoats 0306Document9 pagesJOTUN Topcoats 0306cashlover100% (1)

- Training Technical Report FormDocument12 pagesTraining Technical Report FormLaila Al-shafieNo ratings yet

- A Technical Report On Six 6 Months StudeDocument24 pagesA Technical Report On Six 6 Months StudeAdeyinka Samuel AdedejiNo ratings yet

- Design SupportDocument2 pagesDesign SupportKiruba N EshwaranNo ratings yet

- Swep Morning Evening SessionDocument42 pagesSwep Morning Evening SessionNosa EhiaguinaNo ratings yet

- An Industrial Training ReportDocument26 pagesAn Industrial Training Reportkhodevedant980No ratings yet

- Majestic Perfect Beauty and Care: Technical Data SheetDocument4 pagesMajestic Perfect Beauty and Care: Technical Data SheetekoNo ratings yet

- Pew 105.04 (P)Document174 pagesPew 105.04 (P)Raj BindasNo ratings yet

- Handbook On Comprehensive Guide On Painting For BuildingsDocument41 pagesHandbook On Comprehensive Guide On Painting For BuildingsRohan GoyalNo ratings yet

- Coatings Knowledge, Basic Paint Technology - HMG Paints LimitedDocument3 pagesCoatings Knowledge, Basic Paint Technology - HMG Paints LimitedShyam Yadav0% (1)

- Jotashield Decor TravertineDocument4 pagesJotashield Decor TravertineMazenNo ratings yet

- Spray Painting Unit 1.4Document18 pagesSpray Painting Unit 1.4arun3kumar00_7691821No ratings yet

- Painting GuideDocument3 pagesPainting GuideShiva Kumar ShivaNo ratings yet

- Marine Coatings Technical Modules: Module 0: IntroductionDocument4 pagesMarine Coatings Technical Modules: Module 0: IntroductionHung DinhNo ratings yet

- Fenomastic Emulsion Primer (OM) EngDocument4 pagesFenomastic Emulsion Primer (OM) Engمحمد عزتNo ratings yet

- Hpi Brochure PDFDocument20 pagesHpi Brochure PDFShayma'a H. HarranNo ratings yet

- MPC Training Manual EnglishDocument338 pagesMPC Training Manual EnglishChrisNo ratings yet

- Majestic True Beauty Matt: Technical Data SheetDocument3 pagesMajestic True Beauty Matt: Technical Data SheetBilher SihombingNo ratings yet

- Jotashield Colourlast matt-TDSDocument4 pagesJotashield Colourlast matt-TDSvinnykg_789519104No ratings yet

- Epoguard - Introduction To Industrial CoatingsDocument18 pagesEpoguard - Introduction To Industrial CoatingsPushkar Naresh Patil100% (1)

- Jotamastic 90: Technical Data Sheet Application GuideDocument1 pageJotamastic 90: Technical Data Sheet Application GuideTamerTamerNo ratings yet

- PaintDocument64 pagesPaintnirmala periasamyNo ratings yet

- RomanoDocument3 pagesRomanoMazenNo ratings yet

- Acrylic Emulsion Primer: Technical Data SheetDocument4 pagesAcrylic Emulsion Primer: Technical Data SheetXuân Nam NguyễnNo ratings yet

- M3U5Document18 pagesM3U5agama1188No ratings yet

- FENOMASTIC Emulsion PrimerDocument4 pagesFENOMASTIC Emulsion PrimerlovedesuzaNo ratings yet

- Coating JotungDocument11 pagesCoating JotungEllypar Sutisna SigalinggingNo ratings yet

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

- Technical Paper MER - Effect of Leached LayerDocument4 pagesTechnical Paper MER - Effect of Leached LayerDanashekar SelvarajNo ratings yet

- The Role of The Coating AdvisorDocument4 pagesThe Role of The Coating AdvisorirwanNo ratings yet

- Additves For Non Aqueos OcatingsDocument4 pagesAdditves For Non Aqueos OcatingsImranAhmadNo ratings yet

- InternshipDocument60 pagesInternshipSanjay RayNo ratings yet

- PaintDocument4 pagesPaintabdulrahman hallakNo ratings yet

- Fenomastic My Home Smooth SilkDocument4 pagesFenomastic My Home Smooth Silkمحمد عزتNo ratings yet

- Fenomastic My Home Rich MattDocument3 pagesFenomastic My Home Rich Mattمحمد عزتNo ratings yet

- TDS 48682 Fenomastic Wonderwall Lux Euk EGDocument4 pagesTDS 48682 Fenomastic Wonderwall Lux Euk EGkhalid khanNo ratings yet

- Hempel ExplanatoryNotesDocument22 pagesHempel ExplanatoryNotesSathishkumar Ravi100% (1)

- The Chemistry of Printing Inks and Their Electronics and Medical ApplicationsFrom EverandThe Chemistry of Printing Inks and Their Electronics and Medical ApplicationsNo ratings yet

- Guia de CondensadoresDocument193 pagesGuia de CondensadoresPaola Segura CorreaNo ratings yet

- Manual PipsDocument5 pagesManual PipsOzzyNo ratings yet

- Grade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaDocument25 pagesGrade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaPenke Mejado BelenNo ratings yet

- Paediatric Intake Form Modern OT 2018Document6 pagesPaediatric Intake Form Modern OT 2018SefNo ratings yet

- Goliath 90 v129 eDocument129 pagesGoliath 90 v129 eerkanNo ratings yet

- Straight LineDocument15 pagesStraight LineAyanNo ratings yet

- Potassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDocument4 pagesPotassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDr Amrit Kumar JhaNo ratings yet

- Extract From The Painted Door' by Sinclair RossDocument2 pagesExtract From The Painted Door' by Sinclair RosssajifisaNo ratings yet

- FRP Handrail Fittings CatalogDocument6 pagesFRP Handrail Fittings CatalogAl Adel MorenoNo ratings yet

- The Indian Mining Sector: Effects On The Environment & FDI InflowsDocument10 pagesThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaNo ratings yet

- Twilight PrincessDocument49 pagesTwilight PrincessHikari DiegoNo ratings yet

- Basic Geriatric Nursing 6th Edition Williams Test BankDocument10 pagesBasic Geriatric Nursing 6th Edition Williams Test Bankmaryrodriguezxsntrogkwd100% (49)

- AoS Soulbound - Pregens - Skyrigger Malgra DainssonDocument2 pagesAoS Soulbound - Pregens - Skyrigger Malgra DainssonAdrien DeschampsNo ratings yet

- 300 PSI CTS (MP-1115) Operation Manual Rev1.3Document18 pages300 PSI CTS (MP-1115) Operation Manual Rev1.3Juan Manuel VizosoNo ratings yet

- Determination of Drop-Impact Resistance of Plastic BottlesDocument11 pagesDetermination of Drop-Impact Resistance of Plastic BottlesAndres BrañaNo ratings yet

- IV. Network Modeling, Simple SystemDocument16 pagesIV. Network Modeling, Simple SystemJaya BayuNo ratings yet

- Indor Lighting DesignDocument33 pagesIndor Lighting DesignRajesh MalikNo ratings yet

- Determinants - DPP 01 (Of Lec 02) - Lakshya JEE 2.0 2024Document3 pagesDeterminants - DPP 01 (Of Lec 02) - Lakshya JEE 2.0 2024Apurv ChitranshNo ratings yet

- Tugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaDocument18 pagesTugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaAndre Fahriz Perdana HarahapNo ratings yet

- AKI in ChildrenDocument43 pagesAKI in ChildrenYonas AwgichewNo ratings yet