Professional Documents

Culture Documents

Caterpillar

Uploaded by

robert_candra_tarunaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterpillar

Uploaded by

robert_candra_tarunaCopyright:

Available Formats

® 403 bkW / 540 bhp

C15 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore......................................................... 137.2 mm (5.4 in)

Stroke.................................................... 171.4 mm (6.75 in)

Displacement.......................................... 15.2 L (927.56 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio....................................................... 18:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)........ 1332 kg, 2937 lb

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 3, Stage IIIA emission requirements. Tier 3 Wide range of bolt-on system expansion attachments,

refers to EPA (U.S.) standards. Stage IIIA refers to factory designed and tested.

European standards.

Unmatched Product Support Offered Through

Worldwide Supplier Capability Worldwide Caterpillar Dealer Network

Caterpillar More than 1,800 dealer outlets

- Casts engine blocks, heads, cylinder liners, and Caterpillar factory-trained dealer technicians service

flywheel housings every aspect of your industrial engine

- Machines critical components 99.7% of parts orders filled within 24 hours worldwide

- Assembles complete engine Caterpillar parts and labor warranty

- Factory-designed systems built at Caterpillar ISO Preventive maintenance agreements available for repair

9001:2000 certified facilities before failure options

Ownership of these manufacturing processes enables

Caterpillar to produce high quality, dependable product. Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to determine:

Testing - internal engine component condition

- presence of unwanted fluids

Prototype testing on every model: - presence of combustion by-products

- proves computer design

- verifies system torsional stability

- functionality tests every model Web Site

For all your industrial power requirements, visit

Every Caterpillar engine is dynamometer tested under www.cat-industrial.com.

full load to ensure proper engine performance.

7 August 2006 1:31 AM

®

C15 ACERT ™ INDUSTRIAL ENGINE

403 bkW (540 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

ATAAC MEUI injection

Turbocharged Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT™ Technology

Electronic governing

PTO speed control

Programmable ratings Lube System

Cold mode start strategy Crankcase breather

Automatic altitude compensation Oil cooler

Power compensation for fuel temperature Oil filler

Programmable low and high idle and total engine limit Oil filter

Electronic diagnostics and fault logging Oil pan front sump

Engine monitoring system Oil dipstick

J1939 Broadcast (diagnostic and engine status) Oil pump (gear driven)

ADEM™ A4

General

Cooling System Paint, Caterpillar Yellow

Thermostats and housing, vertical outlet Vibration damper

Jacket water pump, centrifugal Lifting eyes

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 7 August 2006 1:31 AM

®

C15 ACERT ™ INDUSTRIAL ENGINE

403 bkW (540 bhp)

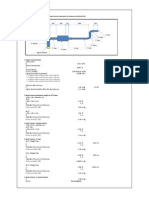

PERFORMANCE CURVES

IND - C (Intermittent) - DM7520-00

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 403 1832 227.7 109.4

2000 403 1924 226.5 108.8

1900 403 2025 225 108.1

1800 403 2138 223.5 107.4

1700 398 2236 222 105.3

1600 390 2325 220.8 102.5

1500 378 2404 219.7 98.9

1400 362 2466 218.7 94.2

1300 331 2434 218.1 86.1

1200 268 2134 217.3 69.5

1100 242 2102 215.9 62.3

3 7 August 2006 1:31 AM

®

C15 ACERT ™ INDUSTRIAL ENGINE

403 bkW (540 bhp)

RATINGS AND CONDITIONS

IND - C (Intermittent) Intermittent service where Engine Performance Diesel Engines — 7 liter and

maximum power and/or speed are cyclic (time at full higher

load not to exceed 50%). All rating conditions are based on SAE J1995, inlet air

standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1381.0 mm Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 910.4 mm (Drawing # 2579952 ).

(3) Height 1274.5 mm

Performance Number: DM7520-00 © 2006 Caterpillar

Feature Code: C15DI12 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

7657008 CAT, CATERPILLAR, their respective logos and "Caterpillar Yellow," as

well as corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

® 470 bkW / 630 bhp

C18 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore....................................................... 145.0 mm (5.71 in)

Stroke...................................................... 183.0 mm (7.2 in)

Displacement....................................... 18.1 L (1,104.53 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 16.3:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)....... 1332 kg (2937 lb)

Image shown may not reflect

actual engine

FEATURES

Worldwide Supplier Capability Full Range of Attachments

Caterpillar Wide range of bolt-on system expansion attachments,

- Casts engine blocks, heads, cylinder liners, and factory designed and tested.

flywheel housings

- Machines critical components Unmatched Product Support Offered Through

- Assembles complete engine Worldwide Caterpillar Dealer Network

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities More than 1,800 dealer outlets

Ownership of these manufacturing processes enables Caterpillar factory-trained dealer technicians service

Caterpillar to produce high quality, dependable product. every aspect of your industrial engine

99.7% of parts orders filled within 24 hours worldwide

Caterpillar parts and labor warranty

Testing Preventive maintenance agreements available for repair

Prototype testing on every model: before failure options

- proves computer design

- verifies system torsional stability Scheduled Oil Sampling program matches your oil

- functionality tests every model sample against Caterpillar set standards to determine:

- internal engine component condition

Every Caterpillar engine is dynamometer tested under - presence of unwanted fluids

full load to ensure proper engine performance. - presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

2 November 2006 3:13 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

470 bkW (630 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Aftercooled -- 429-470 bkW (575-630 MEUI injection

bhp) Fuel filter, secondary (2 micron high performance)

Twin Turbocharged Aftercooled -- 522-597 bkW Fuel transfer pump

(700-800 bhp) Fuel priming pump

ATAAC ACERT™ Technology

Lube System

Crankcase breather

Control System Oil cooler

Electronic governing Oil filler

PTO speed control Oil filter

Programmable ratings Oil pan front sump

Cold mode start strategy Oil dipstick

Automatic altitude compensation Oil pump (gear driven)

Power compensation for fuel temperature

Programmable low and high idle and total engine limit General

Electronic diagnostics and fault logging

Engine monitoring system Paint, Caterpillar Yellow

J1939 Broadcast (diagnostic and engine status) Vibration damper

ADEM™ A4 Lifting eyes

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, centrifugal

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 2 November 2006 3:13 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

470 bkW (630 bhp)

PERFORMANCE CURVES

IND - C (Intermittent) - DM7699-01

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 470 2137 233.8 131.0

2000 470 2244 229.9 128.8

1900 470 2362 224.5 125.8

1800 470 2493 218.9 122.6

1700 465 2611 214.5 118.8

1600 455 2714 212.5 115.2

1500 441 2807 211.4 111.1

1400 422 2879 210.7 106.0

1300 387 2842 210.3 97.0

1200 309 2457 211.3 77.8

1100 258 2243 214.4 66.0

3 2 November 2006 3:13 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

470 bkW (630 bhp)

RATINGS AND CONDITIONS

IND - C (Intermittent) Intermittent service where Engine Performance Diesel Engines — 7 liter and

maximum power and/or speed are cyclic (time at full higher

load not to exceed 50%). All rating conditions are based on SAE J1995, inlet air

standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1388.2 mm Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 920.7 mm (Drawing # 2588747 ).

(3) Height 1243.1 mm

Performance Number: DM7699-01 © 2006 Caterpillar

Feature Code: C18DI01 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

8678268 CAT, CATERPILLAR, their respective logos, "Caterpillar Yellow," and the

POWER EDGE™ trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without

permission.

® 522 bkW / 700 bhp

C18 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore....................................................... 145.0 mm (5.71 in)

Stroke...................................................... 183.0 mm (7.2 in)

Displacement....................................... 18.1 L (1,104.53 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 16.3:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)....... 1332 kg (2937 lb)

Image shown may not reflect

actual engine

FEATURES

Worldwide Supplier Capability Full Range of Attachments

Caterpillar Wide range of bolt-on system expansion attachments,

- Casts engine blocks, heads, cylinder liners, and factory designed and tested.

flywheel housings

- Machines critical components Unmatched Product Support Offered Through

- Assembles complete engine Worldwide Caterpillar Dealer Network

- Factory-designed systems built at Caterpillar ISO

9001:2000 certified facilities More than 1,800 dealer outlets

Ownership of these manufacturing processes enables Caterpillar factory-trained dealer technicians service

Caterpillar to produce high quality, dependable product. every aspect of your industrial engine

99.7% of parts orders filled within 24 hours worldwide

Caterpillar parts and labor warranty

Testing Preventive maintenance agreements available for repair

Prototype testing on every model: before failure options

- proves computer design

- verifies system torsional stability Scheduled Oil Sampling program matches your oil

- functionality tests every model sample against Caterpillar set standards to determine:

- internal engine component condition

Every Caterpillar engine is dynamometer tested under - presence of unwanted fluids

full load to ensure proper engine performance. - presence of combustion by-products

Web Site

For all your industrial power requirements, visit

www.cat-industrial.com.

17 August 2006 6:37 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

522 bkW (700 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Aftercooled -- 429-470 bkW (575-630 MEUI injection

bhp) Fuel filter, secondary (2 micron high performance)

Twin Turbocharged Aftercooled -- 522-597 bkW Fuel transfer pump

(700-800 bhp) Fuel priming pump

ATAAC ACERT™ Technology

Lube System

Crankcase breather

Control System Oil cooler

Electronic governing Oil filler

PTO speed control Oil filter

Programmable ratings Oil pan front sump

Cold mode start strategy Oil dipstick

Automatic altitude compensation Oil pump (gear driven)

Power compensation for fuel temperature

Programmable low and high idle and total engine limit General

Electronic diagnostics and fault logging

Engine monitoring system Paint, Caterpillar Yellow

J1939 Broadcast (diagnostic and engine status) Vibration damper

ADEM™ A4 Lifting eyes

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, centrifugal

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 17 August 2006 6:37 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

522 bkW (700 bhp)

PERFORMANCE CURVES

IND - C (Intermittent) - DM7700-01

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 522 2374 228.4 142.1

2000 522 2493 224.4 139.6

1900 522 2624 221.5 137.8

1800 522 2769 219 136.3

1700 516 2899 216.6 133.3

1600 505 3014 214.2 129.0

1500 490 3120 211.9 123.8

1400 469 3199 210.2 117.5

1300 430 3159 209.4 107.4

1000 296 2822 212.6 74.9

3 17 August 2006 6:37 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

522 bkW (700 bhp)

RATINGS AND CONDITIONS

IND - C (Intermittent) Intermittent service where Engine Performance Diesel Engines — 7 liter and

maximum power and/or speed are cyclic (time at full higher

load not to exceed 50%). All rating conditions are based on SAE J1995, inlet air

standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1409.3 mm Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 974.0 mm (Drawing # 2621427 ).

(3) Height 1256.1 mm

Performance Number: DM7700-01 © 2006 Caterpillar

Feature Code: C18DI02 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

7657637 CAT, CATERPILLAR, their respective logos and "Caterpillar Yellow," as

well as corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

® 448 bkW / 600 bhp

C18 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore....................................................... 145.0 mm (5.71 in)

Stroke...................................................... 183.0 mm (7.2 in)

Displacement.............................................. 18.1 L, 1106 in³

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 16.5:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)....... 1332 kg (2937 lb)

Length................................................1388.2 mm (54.65 in)

Width....................................................920.7 mm (36.25 in)

Height................................................ 1243.1 mm (48.94 in)

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 3, Stage IIIA emission requirements. Tier 3 Wide range of bolt-on system expansion attachments,

refers to EPA (U.S.) standards. Stage IIIA refers to factory designed and tested.

European standards.

Unmatched Product Support Offered Through

Worldwide Supplier Capability Worldwide Caterpillar Dealer Network

Caterpillar More than 1,800 dealer outlets

- Casts engine blocks, heads, cylinder liners, and Caterpillar factory-trained dealer technicians service

flywheel housings every aspect of your industrial engine

- Machines critical components 99.7% of parts orders filled within 24 hours worldwide

- Assembles complete engine Caterpillar parts and labor warranty

- Factory-designed systems built at Caterpillar ISO Preventive maintenance agreements available for repair

9001:2000 certified facilities before failure options

Ownership of these manufacturing processes enables

Caterpillar to produce high quality, dependable product. Scheduled Oil Sampling program matches your oil

sample against Caterpillar set standards to determine:

Testing - internal engine component condition

- presence of unwanted fluids

Prototype testing on every model: - presence of combustion by-products

- proves computer design

- verifies system torsional stability

- functionality tests every model Web Site

For all your industrial power requirements, visit

Every Caterpillar engine is dynamometer tested under www.cat-industrial.com.

full load to ensure proper engine performance.

23 December 2005 2:45 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

448 bkW (600 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Aftercooled -- 429-470 bkW (575-630 MEUI injection

bhp) Fuel filter, secondary (2 micron high performance)

Twin Turbocharged Aftercooled -- 522-597 bkW Fuel transfer pump

(700-800 bhp) Fuel priming pump

ATAAC ACERT™ Technology

Lube System

Crankcase breather

Control System Oil cooler

Electronic governing Oil filler

PTO speed control Oil filter

Programmable ratings Oil pan front sump

Cold mode start strategy Oil dipstick

Automatic altitude compensation Oil pump (gear driven)

Power compensation for fuel temperature

Programmable low and high idle and total engine limit General

Electronic diagnostics and fault logging

Engine monitoring system Paint, Caterpillar Yellow

J1939 Broadcast (diagnostic and engine status) Vibration damper

ADEM™ A4 Lifting eyes

Cooling System

Thermostats and housing, vertical outlet

Jacket water pump, centrifugal

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 23 December 2005 2:45 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

448 bkW (600 bhp)

PERFORMANCE CURVES

IND - B - DM8169-00

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 448 2035 225.3 120.2

2000 448 2137 223.5 119.2

1900 448 2249 219.3 117.0

1800 448 2374 214.7 114.5

1700 443 2486 211.4 111.5

1600 433 2584 211.5 109.2

1500 420 2673 212.5 106.4

1400 402 2742 212.9 102.0

1300 368 2706 211.1 92.7

1200 294 2340 209.1 73.3

1100 246 2136 208.1 61.0

3 23 December 2005 2:45 AM

®

C18 ACERT ™ INDUSTRIAL ENGINE

448 bkW (600 bhp)

RATINGS AND CONDITIONS

IND - B For service where power and/or speed are Engine Performance Diesel Engines — 7 liter and

cyclic (time at full load not to exceed 80%). higher

All rating conditions are based on SAE J1995, inlet air

standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length See page Note: Do not use for installation design. See

1-Specifications general dimension drawings for detail

(2) Width (Drawing # null ).

for Dimensions

(3) Height

Performance Number: DM8169-00 © 2005 Caterpillar

Feature Code: C18DI03 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

5959430 CAT, CATERPILLAR, their respective logos and "Caterpillar Yellow," as

well as corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

® 653 bkW / 875 bhp

C27 ACERT ™

2100 rpm

Engine

CATERPILLAR ENGINE

SPECIFICATIONS

Vee 12 Cylinder, 4-Stroke-Cycle Diesel

Bore......................................................... 137.2 mm (5.4 in)

Stroke...................................................... 152.4 mm (6.0 in)

Displacement..................................... 27.03 L (1,649.47 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 16.5:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)....... 2946 kg (6495 lb)

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 2 emissions requirements. Tier 2 refers to Wide range of bolt-on system expansion attachments,

EPA (U.S) standards. factory designed and tested.

Worldwide Supplier Capability Unmatched Product Support Offered Through

Caterpillar Worldwide Caterpillar Dealer Network

- Casts engine blocks, heads, cylinder liners, and More than 1,800 dealer outlets

flywheel housings Caterpillar factory-trained dealer technicians service

- Machines critical components every aspect of your industrial engine

- Assembles complete engine 99.7% of parts orders filled within 24 hours worldwide

- Factory-designed systems built at Caterpillar ISO Caterpillar parts and labor warranty

9001:2000 certified facilities Preventive maintenance agreements available for repair

Ownership of these manufacturing processes enables before failure options

Caterpillar to produce high quality, dependable product.

Scheduled Oil Sampling program matches your oil

Testing sample against Caterpillar set standards to determine:

- internal engine component condition

Prototype testing on every model: - presence of unwanted fluids

- proves computer design - presence of combustion by-products

- verifies system torsional stability

- functionality tests every model

Web Site

Every Caterpillar engine is dynamometer tested under For all your industrial power requirements, visit

full load to ensure proper engine performance. www.cat-industrial.com.

20 March 2007 5:09 AM

®

C27 ACERT ™ Engine

653 bkW (875 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Air to Air Aftercooled MEUI injection

Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT™ Technology

Electronic governing

PTO speed control

Programmable ratings Lube System

Cold mode start strategy Crankcase breather

Automatic altitude compensation Oil cooler

Power compensation for fuel temperature Oil filler

Programmable low and high idle and total engine limit Oil filter

Electronic diagnostics and fault logging Oil pan front sump

Engine monitoring system Oil dipstick

J1939 Broadcast (diagnostic and engine status) Oil pump (gear driven)

ADEM™ A4

General

Cooling System Paint, Caterpillar Yellow

Thermostats and housing, vertical outlet Vibration damper

Jacket water pump, centrifugal Lifting eyes

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 20 March 2007 5:09 AM

®

C27 ACERT ™ Engine

653 bkW (875 bhp)

PERFORMANCE CURVES

IND - B - DM9038-00

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 653 2968 206.6 160.8

2000 653 3117 202.9 157.8

1900 653 3281 200.3 155.8

1800 653 3463 198.3 154.3

1700 646 3628 197.7 152.2

1600 632 3771 197.9 149.1

1500 613 3900 199.9 146.0

1400 586 4000 201.8 141.1

1300 538 3949 202.6 129.8

3 20 March 2007 5:09 AM

®

C27 ACERT ™ Engine

653 bkW (875 bhp)

RATINGS AND CONDITIONS

IND - B For service where power and/or speed are Engine Performance Diesel Engines — 7 liter and

cyclic (time at full load not to exceed 80%). higher

All rating conditions are based on SAE J1995, inlet air

standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1917.1 mm Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 1464.3 mm (Drawing # 2823892 ).

(3) Height 1320.6 mm

Performance Number: DM9038-00 © 2007 Caterpillar

Feature Code: C27DI01 Arr. Number: 2520148 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

9607603 CAT, CATERPILLAR, their respective logos, "Caterpillar Yellow," and the

POWER EDGE trade dress, as well as corporate and product identity

used herein, are trademarks of Caterpillar and may not be used without

permission.

® 709 bkW / 950 bhp

C32 ACERT ™

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

Vee 12 Cylinder, 4-Stroke-Cycle Diesel

Bore......................................................145.0 mm (5.71 in)

Stroke...................................................162.0 mm (6.38 in)

Displacement..................................... 32.1 L (1,958.86 in3)

Aspiration...............................Turbocharged Aftercooled

Compression Ratio...................................................16.5:1

Rotation (from flywheel end).............. Counterclockwise

Weight, Net Dry (approximate kg. lb).. 2946 kg (6495 lb)

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 2 emissions requirements. Tier 2 refers Wide range of bolt-on system expansion

to EPA (U.S) standards. attachments, factory designed and tested.

Worldwide Supplier Capability Unmatched Product Support Offered Through

Caterpillar Worldwide Caterpillar Dealer Network

- Casts engine blocks, heads, cylinder liners, and More than 1,800 dealer outlets

flywheel housings Caterpillar factory-trained dealer technicians service

- Machines critical components every aspect of your industrial engine

- Assembles complete engine 99.7% of parts orders filled within 24 hours

- Factory-designed systems built at Caterpillar ISO worldwide

9001:2000 certified facilities Caterpillar parts and labor warranty

Ownership of these manufacturing processes Preventive maintenance agreements available for

enables Caterpillar to produce high quality, repair before failure options

dependable product.

Scheduled Oil Sampling program matches your oil

Testing sample against Caterpillar set standards to

determine:

Prototype testing on every model: - internal engine component condition

- proves computer design - presence of unwanted fluids

- verifies system torsional stability - presence of combustion by-products

- functionality tests every model

Every Caterpillar engine is dynamometer tested Web Site

under full load to ensure proper engine For all your industrial power requirements, visit

performance. www.cat-industrial.com.

14 November 2008 4:40 AM

®

C32 ACERT ™ INDUSTRIAL ENGINE

709 bkW (950 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Air to Air Aftercooled MEUI injection

Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT™ Technology

Electronic governing

PTO speed control

Programmable ratings Lube System

Cold mode start strategy Crankcase breather

Automatic altitude compensation Oil cooler

Power compensation for fuel temperature Oil filler

Programmable low and high idle and total engine Oil filter

limit Oil pan front sump

Electronic diagnostics and fault logging Oil dipstick

Engine monitoring system Oil pump (gear driven)

J1939 Broadcast (diagnostic and engine status)

ADEM™ A4 General

Paint, Caterpillar Yellow

Cooling System Vibration damper

Thermostats and housing, vertical outlet Lifting eyes

Jacket water pump, centrifugal

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 14 November 2008 4:40 AM

®

C32 ACERT ™ INDUSTRIAL ENGINE

709 bkW (950 bhp)

PERFORMANCE CURVES

IND - B - DM9030-00

Torque Metric

N•m

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N•m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

3 14 November 2008 4:40 AM

®

C32 ACERT ™ INDUSTRIAL ENGINE

709 bkW (950 bhp)

PERFORMANCE CURVES

IND - B - DM9030-00

Engine English

Torque

lb•ft

Engine

Power bhp

BSFC

lb/bhp-hr

Engine Speed rpm

Engine Speed Engine Power Engine Torque BSFC lb/bhp-hr Fuel Rate

rpm bhp lb•ft gal/hr

4 14 November 2008 4:40 AM

®

C32 ACERT ™ INDUSTRIAL ENGINE

709 bkW (950 bhp)

RATINGS AND CONDITIONS

IND - B For service where power and/or speed are Engine Performance Diesel Engines — 7 liter and

cyclic (time at full load not to exceed 80%). higher

All rating conditions are based on SAE J1995, inlet

air standard

conditions of 99 kPa (29.31 in. Hg) dry barometer

and 25ºC (77ºF)

temperature. Performance measured using a

standard fuel with fuel

gravity of 35º API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29º C (84.2º F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1915.3 mm (75.41 in) Note: Do not use for installation design.

See general dimension drawings for

(2) Width 1478.7 mm (58.22 in) detail (Drawing # 2833535 ).

(3) Height 1319.2 mm (51.94 in)

Performance Number: DM9030-00 © 2008 Caterpillar

Feature Code: C32DI01 Arr. Number: 2638150 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

13457541 CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of

Caterpillar and may not be used without permission.

® 839 bkW / 1125 bhp

C32 ACERT

2100 rpm

Industrial

CATERPILLAR ENGINE

SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel

Bore....................................................... 145.0 mm (5.71 in)

Stroke.................................................... 162.0 mm (6.38 in)

Displacement....................................... 32.1 L (1,958.86 in3)

Aspiration................................... Turbocharged Aftercooled

Compression Ratio.................................................... 16.5:1

Rotation (from flywheel end).................... Counterclockwise

Weight, Net Dry (approximate kg. lb)....... 2946 kg (6495 lb)

Image shown may not reflect

actual engine

FEATURES

Emissions Full Range of Attachments

Meets Tier 2 emissions requirements. Tier 2 refers to Wide range of bolt-on system expansion attachments,

EPA (U.S) standards. factory designed and tested.

Worldwide Supplier Capability Unmatched Product Support Offered Through

Caterpillar Worldwide Caterpillar Dealer Network

- Casts engine blocks, heads, cylinder liners, and More than 1,800 dealer outlets

flywheel housings Caterpillar factory-trained dealer technicians service

- Machines critical components every aspect of your industrial engine

- Assembles complete engine 99.7% of parts orders filled within 24 hours worldwide

- Factory-designed systems built at Caterpillar ISO Caterpillar parts and labor warranty

9001:2000 certified facilities Preventive maintenance agreements available for repair

Ownership of these manufacturing processes enables before failure options

Caterpillar to produce high quality, dependable product.

Scheduled Oil Sampling program matches your oil

Testing sample against Caterpillar set standards to determine:

- internal engine component condition

Prototype testing on every model: - presence of unwanted fluids

- proves computer design - presence of combustion by-products

- verifies system torsional stability

- functionality tests every model

Web Site

Every Caterpillar engine is dynamometer tested under For all your industrial power requirements, visit

full load to ensure proper engine performance. www.cat-industrial.com.

11 March 2008 2:27 AM

®

C32 ACERT INDUSTRIAL ENGINE

839 bkW (1125 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Fuel System

Turbocharged Air to Air Aftercooled MEUI injection

Fuel filter, secondary (2 micron high performance)

Fuel transfer pump

Control System Fuel priming pump

ACERT Technology

Electronic governing

PTO speed control

Programmable ratings Lube System

Cold mode start strategy Crankcase breather

Automatic altitude compensation Oil cooler

Power compensation for fuel temperature Oil filler

Programmable low and high idle and total engine limit Oil filter

Electronic diagnostics and fault logging Oil pan front sump

Engine monitoring system Oil dipstick

J1939 Broadcast (diagnostic and engine status) Oil pump (gear driven)

ADEM A4

General

Cooling System Paint, Caterpillar Yellow

Thermostats and housing, vertical outlet Vibration damper

Jacket water pump, centrifugal Lifting eyes

Water pump, inlet

Exhaust System

Exhaust manifold, dry

Optional exhaust outlet

Flywheels and Flywheel Housing

SAE No. 1 Flywheel housing

2 11 March 2008 2:27 AM

®

C32 ACERT INDUSTRIAL ENGINE

839 bkW (1125 bhp)

PERFORMANCE CURVES

IND - C (Intermittent) - DM9031-00

Torque N m Metric

Engine

Power kW

BSFC

g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power Torque N m BSFC g/kW-hr Fuel Rate L/hr

rpm kW

2100 839 3815 214.7 214.7

2000 839 4006 210.6 210.6

1900 839 4217 209.7 209.8

1800 839 4451 207 207.0

1700 830 4662 204.7 202.6

1600 812 4846 203.6 197.1

1500 787 5010 203.1 190.5

1400 754 5143 202.4 181.9

1300 691 5076 202.2 166.6

1200 599 4764 204.6 146.0

1100 512 4448 205.8 125.7

3 11 March 2008 2:27 AM

®

C32 ACERT INDUSTRIAL ENGINE

839 bkW (1125 bhp)

RATINGS AND CONDITIONS

IND - C (Intermittent) Intermittent service where Engine Performance Diesel Engines 7 liter and higher

maximum power and/or speed are cyclic (time at full All rating conditions are based on SAE J1995, inlet air

load not to exceed 50%). standard

conditions of 99 kPa (29.31 in. Hg) dry barometer and

25°C (77°F)

temperature. Performance measured using a standard

fuel with fuel

gravity of 35° API having a lower heating value of

42,780 kJ/kg

(18,390 btu/lb) when used at 29° C (84.2° F) with a

density of 838.9 g/L.

Engine Dimensions

(1) Length 1914.4 mm Note: Do not use for installation design. See

general dimension drawings for detail

(2) Width 1478.7 mm (Drawing # 2833535 ).

(3) Height 1319.2 mm

Performance Number: DM9031-00 © 2008 Caterpillar

Feature Code: C32DI02 Arr. Number: 2638150 All rights reserved.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

11699832 CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos,

"Caterpillar Yellow," and the POWER EDGE trade dress, as well as

corporate and product identity used herein, are trademarks of Caterpillar

and may not be used without permission.

You might also like

- C15 Acert: Industrial Caterpillar Engine SpecificationsDocument4 pagesC15 Acert: Industrial Caterpillar Engine Specificationsyash singhNo ratings yet

- Cat c9 300 HP Spec SheetDocument7 pagesCat c9 300 HP Spec SheetDennis K ThomasNo ratings yet

- SS-003484 Industrial-C9 Dita-2200 RPM-224 KW-DM8117-01Document5 pagesSS-003484 Industrial-C9 Dita-2200 RPM-224 KW-DM8117-01Agung TriyonoNo ratings yet

- Caterpillar Engine Specifications: C15 Acert Industrial Power UnitDocument5 pagesCaterpillar Engine Specifications: C15 Acert Industrial Power UnitGoran MatovicNo ratings yet

- C18 ACERT 470bkWDocument5 pagesC18 ACERT 470bkWAlief FadilNo ratings yet

- Especificaciones Motor CatDocument5 pagesEspecificaciones Motor CatWalter TaucherNo ratings yet

- Cat® Engine Specifications: C18 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C18 Acert Industrial EngineAsif MehmoodNo ratings yet

- C18-Rating ADocument5 pagesC18-Rating AFirzan Yudhistira PutraNo ratings yet

- c7 168 KW Spec Sheet Abby PDFDocument4 pagesc7 168 KW Spec Sheet Abby PDFAlfonzo PerezNo ratings yet

- Cat® Engine Specifications: C18 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C18 Acert Industrial Enginevo phuongNo ratings yet

- C11 ACERT 261bkWDocument5 pagesC11 ACERT 261bkWJulio huanriNo ratings yet

- C7 ACERT 205bkWDocument5 pagesC7 ACERT 205bkWsheronNo ratings yet

- C9 ACERT 224bkWDocument5 pagesC9 ACERT 224bkWAlief FadilNo ratings yet

- 03 Engine Specification Sheet - C9Document5 pages03 Engine Specification Sheet - C9avinash_1229No ratings yet

- CAT-C15 ACERT-Ind - EngineDocument5 pagesCAT-C15 ACERT-Ind - EngineRakesh DoshiNo ratings yet

- C7 Acert EspecificaciónDocument5 pagesC7 Acert EspecificaciónFabrizio Jesus Morales Salirrosas100% (1)

- Motor CAT C9Document4 pagesMotor CAT C9avictoras100% (2)

- Caterpillar 3408Document5 pagesCaterpillar 3408Fernando Padilla100% (3)

- C93 310bkW Spec Sheet HEXDocument5 pagesC93 310bkW Spec Sheet HEXHammad AneesNo ratings yet

- Cat® Engine Specifications: C13 Acert Industrial EngineDocument5 pagesCat® Engine Specifications: C13 Acert Industrial EngineالمهندسوليدالطويلNo ratings yet

- Engine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01Document5 pagesEngine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01maekel abdul HakimNo ratings yet

- Cat 3412e PDFDocument4 pagesCat 3412e PDFCristina CoceasuNo ratings yet

- CAT C9 ACERT Engine PDFDocument4 pagesCAT C9 ACERT Engine PDFettoscar100% (1)

- Industrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselDocument5 pagesIndustrial Caterpillar Engine Specifications: V12, 4-Stroke-Cycle DieselLuis Eduardo Albarracin RugelesNo ratings yet

- Spec Sheet Industry 170HP Tot 450HPDocument34 pagesSpec Sheet Industry 170HP Tot 450HPJonh BladerNo ratings yet

- CaterpillarDocument4 pagesCaterpillarrobert_candra_tarunaNo ratings yet

- Mobile Equipment Caterpillar Engine Specifications: V8, 4-Stroke-Cycle DieselDocument5 pagesMobile Equipment Caterpillar Engine Specifications: V8, 4-Stroke-Cycle DieselJefferson MolinaNo ratings yet

- CAT Engine Specifications: 3508B Land Mechanical EngineDocument4 pagesCAT Engine Specifications: 3508B Land Mechanical Enginemehdi kamaliNo ratings yet

- LEHH0541-00 (1)Document3 pagesLEHH0541-00 (1)Dedi MaryadiNo ratings yet

- Cat 3516Document4 pagesCat 3516Muhammad IshfaqNo ratings yet

- Cat C15 Specifications PDFDocument30 pagesCat C15 Specifications PDFdiony182No ratings yet

- CAT Engine Specifications: 3508B Offshore Emergency Generator SetDocument6 pagesCAT Engine Specifications: 3508B Offshore Emergency Generator SetGazNo ratings yet

- Cat C18 SpecSheetDocument4 pagesCat C18 SpecSheetmschaefer_zf100% (1)

- Manual 3306 CaterpillarDocument5 pagesManual 3306 CaterpillarCRISTOBAL HUMBERTO AGUILAR ROSENDONo ratings yet

- C7 Petroleum EngineDocument4 pagesC7 Petroleum Engineavinash_1229No ratings yet

- 3508 Ind C A 1800 RPMDocument5 pages3508 Ind C A 1800 RPMJeinnerCastroNo ratings yet

- Lehw0053 00Document4 pagesLehw0053 00kumarraghuNo ratings yet

- Manual 3306 Caterpillar PDFDocument4 pagesManual 3306 Caterpillar PDFmuhammad aliNo ratings yet

- Cat 3406 Fuel ConsumptionDocument5 pagesCat 3406 Fuel Consumptionayman akrab100% (2)

- Lehh0025-00 C6.6 Acert Power Unit For Irrigation & Ind PumpDocument2 pagesLehh0025-00 C6.6 Acert Power Unit For Irrigation & Ind PumpAgung TriyonoNo ratings yet

- CAT Engine Specifications: 3516B Offshore Generator SetDocument6 pagesCAT Engine Specifications: 3516B Offshore Generator SetKarel GómezNo ratings yet

- Lehw0067 01Document6 pagesLehw0067 01majed al.madhajiNo ratings yet

- CAT 3406 C Heavy Duty Truck EngineDocument5 pagesCAT 3406 C Heavy Duty Truck EngineAS_865025438100% (1)

- 3512 Land Electric - LEHW0066-00 P2Document4 pages3512 Land Electric - LEHW0066-00 P2AustinNo ratings yet

- CAT Engine Specifications: C32 Acert Petroleum EngineDocument4 pagesCAT Engine Specifications: C32 Acert Petroleum EngineArvind HarryNo ratings yet

- LEHW0027 00 Cat 3306 PDFDocument4 pagesLEHW0027 00 Cat 3306 PDFHassan ShathakNo ratings yet

- Lehw0124 01Document6 pagesLehw0124 01Hosam HamdyNo ratings yet

- Mss-Ind-18429639-013 C7 Iopu SpecsheetDocument3 pagesMss-Ind-18429639-013 C7 Iopu SpecsheetJoko SusiloNo ratings yet

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 pagesCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)avinash_1229100% (1)

- Motores CaterpillarDocument4 pagesMotores CaterpillarSa CruCerNo ratings yet

- Caterpillar 3412EDocument4 pagesCaterpillar 3412Esaftbond00733% (3)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Designing and Tuning High-Performance Fuel Injection SystemsFrom EverandDesigning and Tuning High-Performance Fuel Injection SystemsRating: 3.5 out of 5 stars3.5/5 (7)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Gantrail MKV11 Pad On C6BADocument2 pagesGantrail MKV11 Pad On C6BArobert_candra_tarunaNo ratings yet

- Port Zayed Abu DhabiDocument2 pagesPort Zayed Abu Dhabirobert_candra_tarunaNo ratings yet

- CaterpillarDocument4 pagesCaterpillarrobert_candra_tarunaNo ratings yet

- BANDO V Belt Design ManualDocument38 pagesBANDO V Belt Design ManualJie Lee Chuin Chee100% (1)

- CaterpillarDocument4 pagesCaterpillarrobert_candra_tarunaNo ratings yet

- Return To IndexDocument8 pagesReturn To Indexrobert_candra_tarunaNo ratings yet

- NORSOK STANDARD CATHODIC PROTECTIONDocument14 pagesNORSOK STANDARD CATHODIC PROTECTIONbreeeeezzzzzeNo ratings yet

- All About ScrewsDocument20 pagesAll About Screwshon choong chongNo ratings yet

- NippleDocument2 pagesNipplerobert_candra_tarunaNo ratings yet

- Pneumatic Conveying Systems 622Document12 pagesPneumatic Conveying Systems 622sachindherange100% (1)

- K R - 35H-V R Ough T Errain Crane: (Power Jib)Document17 pagesK R - 35H-V R Ough T Errain Crane: (Power Jib)Testing GmailNo ratings yet

- Interthane 990Document4 pagesInterthane 990DuongthithuydungNo ratings yet

- BingoDocument15 pagesBingoBrainerd Rein DatumbanuaNo ratings yet

- Stainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)Document2 pagesStainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)achillesntroyNo ratings yet

- Metric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless SteelDocument2 pagesMetric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless Steelrobert_candra_tarunaNo ratings yet

- Design of Steel StructuresDocument26 pagesDesign of Steel StructuresMfon UdoitaNo ratings yet

- Hydrostatic Pressure Testing RevDocument7 pagesHydrostatic Pressure Testing RevMuhammadTaherNo ratings yet

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Document3 pagesFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNo ratings yet

- Curing Concrete - Normal, Hot and Cold Weather: Composition of CementDocument3 pagesCuring Concrete - Normal, Hot and Cold Weather: Composition of Cementrobert_candra_tarunaNo ratings yet

- Specified Anchor Bolt Category Bolt Standards Nut StandardsDocument3 pagesSpecified Anchor Bolt Category Bolt Standards Nut StandardsrefaeNo ratings yet

- Concrete - Wikipedia, The Free EncyclopediaDocument24 pagesConcrete - Wikipedia, The Free Encyclopediarobert_candra_tarunaNo ratings yet

- Add Base Floor Plate To New Be BuildingDocument3 pagesAdd Base Floor Plate To New Be Buildingrobert_candra_tarunaNo ratings yet

- Metric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless SteelDocument2 pagesMetric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless Steelrobert_candra_tarunaNo ratings yet

- Technical Overview of Honda's New R18 I-VTEC ImplementationDocument7 pagesTechnical Overview of Honda's New R18 I-VTEC ImplementationDiegoNo ratings yet

- V2500 & CFM56 Difference PDFDocument5 pagesV2500 & CFM56 Difference PDFBahador100% (3)

- Adding Turbo To VR6 3.2 QA #2Document9 pagesAdding Turbo To VR6 3.2 QA #2LucasPalombaNo ratings yet

- 1999 Geo Metro 1.3L Torque SpecificationDocument2 pages1999 Geo Metro 1.3L Torque SpecificationJohnny M MillaNo ratings yet

- Oregon Fuel Injection Inc - Stanadyne Pump Diagnostic TroubleshootingDocument3 pagesOregon Fuel Injection Inc - Stanadyne Pump Diagnostic TroubleshootingDanielNo ratings yet

- 7 Overhaul Protocol COP 4050CR - LR-ForMDocument2 pages7 Overhaul Protocol COP 4050CR - LR-ForMChachou MohamedNo ratings yet

- Design and Simulation of Two-Stroke Engines - Blair PDFDocument641 pagesDesign and Simulation of Two-Stroke Engines - Blair PDFnoahb110100% (1)

- Fuel Sistem D4EB 2.2 PDFDocument544 pagesFuel Sistem D4EB 2.2 PDFcarnori100% (1)

- Despiece QuadDocument63 pagesDespiece QuadRaul Soteras EstebanNo ratings yet

- 3GYB3821789 Aml630l6a Baf Doubly Fed InductionDocument2 pages3GYB3821789 Aml630l6a Baf Doubly Fed InductionCarlos HuamanNo ratings yet

- PC210-8M0 Tunnel SpascdsdscecDocument2 pagesPC210-8M0 Tunnel Spascdsdscecgaurav champawatNo ratings yet

- 2010 To 2011indmar Operators ManualDocument94 pages2010 To 2011indmar Operators Manualinforlex100% (3)

- MAN Service ManualD2842Document140 pagesMAN Service ManualD2842OSCAR DAGA CARAVANTES50% (2)

- AC Motors and Control Options EbookDocument49 pagesAC Motors and Control Options EbookmunjaNo ratings yet

- Instalacion de Culata MOTOR 3306Document6 pagesInstalacion de Culata MOTOR 3306tonomart79No ratings yet

- Egr Prelude Ts BDocument3 pagesEgr Prelude Ts BswooshcmkNo ratings yet

- Cumi BondedDocument18 pagesCumi BondedAvijitSinharoyNo ratings yet

- Back Pressure Calculation 1 PDFDocument2 pagesBack Pressure Calculation 1 PDFRanu Januar100% (6)

- 4000 Series: Clean, Efficient PowerDocument2 pages4000 Series: Clean, Efficient PowerDaniel Ricardo Quintero SuavitaNo ratings yet

- How Will You Detect That Misalignment Is The Probable Cause of Excessive Vibration?Document2 pagesHow Will You Detect That Misalignment Is The Probable Cause of Excessive Vibration?சுஜித் குமார்No ratings yet

- CATDocument42 pagesCATsergio blandon lNo ratings yet

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- Radial Flow Turbine Tutorial and ProblemsDocument20 pagesRadial Flow Turbine Tutorial and ProblemsChetanPrajapatiNo ratings yet

- Group: 25LD Engine: 25LD 330-2 Drawing: F: Pos. Code Description QtyDocument3 pagesGroup: 25LD Engine: 25LD 330-2 Drawing: F: Pos. Code Description QtyDavid DíazNo ratings yet

- Diesel Engines 12V/16V 2000 M72 for High Load VesselsDocument2 pagesDiesel Engines 12V/16V 2000 M72 for High Load VesselsAlberto100% (1)

- Performance ParametersDocument18 pagesPerformance ParametersBinh TaiNo ratings yet

- MAXXFORCE 11 & 13 ENGINES FEATURES, SPECS & REPAIR GUIDEDocument114 pagesMAXXFORCE 11 & 13 ENGINES FEATURES, SPECS & REPAIR GUIDEPhạm Nhất100% (1)

- NEMA Standard Motor CurvesDocument1 pageNEMA Standard Motor CurvesbradrogerNo ratings yet

- 2010-12 600 800 Rush Switchback RMK Service Manual PDFDocument430 pages2010-12 600 800 Rush Switchback RMK Service Manual PDFBrianCook73% (11)

- Ole Buhl Racing (UK) LTD.: Pinout Euro-4 - Right Connector (Black) - (November 2016)Document4 pagesOle Buhl Racing (UK) LTD.: Pinout Euro-4 - Right Connector (Black) - (November 2016)SUELENNo ratings yet