Professional Documents

Culture Documents

Indium10.8hf Pbfree Solder Paste 99040 A4 r9

Uploaded by

rigoberto solOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indium10.8hf Pbfree Solder Paste 99040 A4 r9

Uploaded by

rigoberto solCopyright:

Available Formats

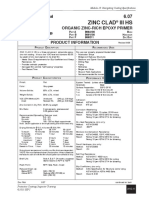

PRODUCT DATA SHEET

Indium10.8HF

Pb-Free Solder Paste

Introduction Standard Product Specifications

Indium10.8HF is an air reflow, no-clean solder paste Alloy Metal Load

specifically formulated to accommodate the higher

Name Composition Type 4/4.5 Type 5/T5-MC

processing temperatures required by the SnAgCu, SnAg,

and other alloy systems favored by the electronics industry SAC387 95.5Sn/3.8Ag/0.7Cu

to replace conventional Pb-bearing solders. Indium10.8HF SAC305 96.5Sn/3.0Ag/0.5Cu

offers unprecedented stencil print transfer efficiency to 89% 88.0–88.5%

work in the broadest range of processes. SAC105 98.5Sn/1.0Ag/0.5Cu

SAC0307 99Sn/0.3Ag/0.7Cu

Features

• Excellent NWO performance Compatible Products

• Very wide reflow profile window under both air and • Rework Flux: TACFlux ® 020B, TACFlux ® 089HF

nitrogen • Cored Wire: CW-807

• Excellent HIP performance • Wave Flux: WF-9945, WF-9958

• Excellent soldering performance and process yield

− Excellent wetting to all fresh and aged surface Storage and Handling Procedures

finishes, including, but not limited to:

Refrigerated storage will prolong the shelf life of solder paste.

• OSP Solder paste packaged in syringes and cartridges should be stored

• Immersion Ag tip down.

• Immersion Sn

Storage Conditions

• ENIG Packaging Shelf Life

(unopened containers)

− Low-bridging, tombstoning, and solder beading Syringe <-10°C 6 months

− Low-voiding in all joints including QFN and BGA

Jar/Cartridge <10°C 6 months

assemblies

• Clear post-reflow residue Solder paste should be allowed to reach ambient working

temperature prior to use. Generally, paste should be removed

from refrigeration at least 2 hours before use. Actual time to

Alloys reach thermal equilibrium will vary with container size. Paste

temperature should be verified before use. Jars and cartridges

Indium Corporation manufactures low-oxide spherical powder should be labeled with date and time of opening.

composed of a variety of Pb-free alloys that cover a broad range

of melting temperatures. Type 3, Type 4, and Type 5 powders are

standard offerings with Pb-free alloys. The metal percent is the Packaging

weight percent of the solder powder in the solder paste and is Indium10.8HF is currently available in 500g jars or 600g cartridges.

dependent upon the powder type and application. Standard Packaging for enclosed print head systems is also readily

product offerings are detailed in the specifications table. available. Alternate packaging options may be available upon

request.

J-STD Tests and Results

Indium10.8HF Industry Standard Test Results and Classification

Typical Solder

Flux

ROL0 Paste Viscosity for 1,400kcps

Classification

Type 4/4.5 Solder

Based on the testing required

by IPC J-STD-004B (IPC-TM-650)

Conforms with all

Halogen-free per requirements from

<900ppm Cl

IEC 61249-2-21, J-STD-005 (IPC-TM-650)

<900ppm Br

Test Method

<1,500ppm Total

EN14582

All information is for reference only.

Not to be used as incoming product specifications.

Form No. 99040 (A4) R9

PRODUCT DATA SHEET

Indium10.8HF Pb-Free Solder Paste

Printing Cleaning

Stencil Design: Indium10.8HF is designed for no-clean applications; however,

the flux can be removed, if necessary, by using a commercially

Electroformed and laser cut/electropolished stencils produce

available flux residue remover.

the best printing characteristics among stencil types. Stencil

aperture design is a crucial step in optimizing the print process. Stencil Cleaning is best performed using isopropyl alcohol (IPA)

The following are a few general recommendations: as a solvent. Most commercially available non-water-based

stencil cleaners work well.

• Discrete components—A 10–20% reduction of stencil

aperture has significantly reduced or eliminated the

occurrence of mid-chip solder beads. The “home plate”

Reflow

design is a common method for achieving this reduction. Recommended Profile:

• Fine-pitch components—A surface area reduction is

recommended for apertures of 20mil pitch and finer. This

reduction will help minimize solder balling and bridging

that can lead to electrical shorts. The amount of reduction

necessary is process-dependent (5–15% is common).

• For optimum transfer efficiency and release of the solder

paste from the stencil apertures, industry standard aperture

and aspect ratios should be adhered to.

Printer Operation

Solder Paste Bead Size ~20–25mm in diameter

Print Speed 25–150mm/second

Squeegee Pressure 0.018–0.027kg/mm of blade length

Start at once per every 5 prints and The stated profile recommendations apply to most Pb-free

Underside Stencil Wipe decrease frequency until optimum value alloys in the SnAgCu (SAC) alloy system, including SAC305

is reached (96.5Sn/3.0Ag/0.5Cu). This can be used as a general guideline

Metal with appropriate length/ in establishing a reflow profile when using Indium10.8HF Solder

Squeegee Type/Angle Paste. Deviations from these recommendations are acceptable,

~60 degrees

and may be necessary, based on specific process requirements,

5–20mm/second or per equipment including board size, thickness, and density. Start with the linear

Separation Speed

manufacturer’s specifications profile, then move to the optional soak profile, if needed. The

Solder Paste flat soak portion of the linear profile (linear shoulder) may also

Up to 12 hours (at 30–60% RH and 22–28°C) be eliminated.

Stencil Life

SAC305 Parameters

Reflow Profile Details Comments

Recommended Acceptable

Ramp Profile (Average Ambient to Peak)—

1.0–1.5°C/second 0.5–2.5°C/second To minimize solder balling, beading, hot slump

Not the Same as Maximum Rising Slope

20–60 seconds 30–120 seconds May minimize BGA/CSP voiding

Soak Zone Profile (optional) Eliminating/reducing the soak zone may help to

140–160°C 140–170°C reduce HIP and graping

Time Above Liquidus (TAL) 45–60 seconds 30–100 seconds Needed for good wetting/reliable solder joint

Peak Temperature 230–260°C 230–262°C As measured with thermocouple

Cooling Ramp Rate 2–6°C/second 0.5–6°C/second Rapid cooling promotes fine-grain structure

Reflow Atmosphere Air or N 2 N 2 preferred for small components

All parameters are for reference only.

Modifications may be required to fit process and design.

This product data sheet is provided for general information only. It is not intended, and shall not be construed, to warrant or guarantee the performance

of the products described which are sold subject exclusively to written warranties and limitations thereon included in product packaging and invoices.

All Indium Corporation’s products and solutions are designed to be commercially available unless specifically stated otherwise.

All of Indium Corporation’s solder paste and preform manufacturing facilities are IATF 16949:2016 certified. Indium Corporation is an ISO 9001:2015 registered company.

Contact our engineers: askus@indium.com

Learn more: www.indium.com

ASIA +65 6268 8678 • CHINA +86 (0) 512 628 34900 • EUROPE +44 (0) 1908 580400 • USA +1 315 853 4900 ©2021 Indium Corporation

You might also like

- Indium10.1HF Ultra-Low Voiding: Pb-Free Solder PasteDocument2 pagesIndium10.1HF Ultra-Low Voiding: Pb-Free Solder PasteBeto CRNo ratings yet

- Durafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Document2 pagesDurafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Karthik ManiNo ratings yet

- Indium8.9HFA 98549 R10Document2 pagesIndium8.9HFA 98549 R10José Antonio CuberoNo ratings yet

- Indium10.1 Pbfree Solder Paste 98881 r7Document2 pagesIndium10.1 Pbfree Solder Paste 98881 r7instagk99No ratings yet

- Indium8 9HF-TDSDocument2 pagesIndium8 9HF-TDSSlavisa VeljkovicNo ratings yet

- Indium5.5LT Solder Paste: Product Data SheetDocument2 pagesIndium5.5LT Solder Paste: Product Data SheetluismcmcNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- NC-SMQ81: Solder PasteDocument2 pagesNC-SMQ81: Solder Pastealireza221369No ratings yet

- ncsmq92 SolderDocument2 pagesncsmq92 SolderSergio MoyaNo ratings yet

- ncsmq92j Solder Paste 97703 r13Document2 pagesncsmq92j Solder Paste 97703 r13Beto CRNo ratings yet

- Indium5.1 Pbfree Solder Paste 97901 r8Document2 pagesIndium5.1 Pbfree Solder Paste 97901 r8Gustavo Kubo LacerdaNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Carboweld 11P PDSDocument4 pagesCarboweld 11P PDS이선엽No ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Indium6.4R: Water-Soluble Pb-Free and SNPB Solder PasteDocument6 pagesIndium6.4R: Water-Soluble Pb-Free and SNPB Solder PasteKenn Jaspher QuinitNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Brochura PROTECTIVE COATINGSDocument9 pagesBrochura PROTECTIVE COATINGStuanNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- NC-SMQ®90 Solder Paste: Product Data SheetDocument2 pagesNC-SMQ®90 Solder Paste: Product Data SheetbrunizzaNo ratings yet

- Mol Freez Ultra 68Document1 pageMol Freez Ultra 68Mohamed SalemNo ratings yet

- Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationDocument8 pagesZinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationThennarasu VelloreNo ratings yet

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- Plasite 7159 HAR abrasion resistant epoxyDocument4 pagesPlasite 7159 HAR abrasion resistant epoxyRobertoNo ratings yet

- 00.2.TDS - RS 500 PDocument4 pages00.2.TDS - RS 500 PMuhammad TantowiNo ratings yet

- Carbozinc 858 (3K)Document4 pagesCarbozinc 858 (3K)DuongthithuydungNo ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- Sanitile 755 PDSDocument4 pagesSanitile 755 PDSnarmathaNo ratings yet

- Alpha Om-338-T CNP TB SM871-20 English 20190604Document6 pagesAlpha Om-338-T CNP TB SM871-20 English 20190604Красимир КостадиновNo ratings yet

- Ukl KPVDocument6 pagesUkl KPVMeet JaniNo ratings yet

- ALPHA CVP-520 Solder Paste EN 25nov19 TBDocument6 pagesALPHA CVP-520 Solder Paste EN 25nov19 TBDeep SharmaNo ratings yet

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

- Inorganic Zinc Rich Primer RO123 GDH977 0517Document3 pagesInorganic Zinc Rich Primer RO123 GDH977 0517Dante GimenezNo ratings yet

- Intumescent Paint - Nullifire - Solvent - SC602Document2 pagesIntumescent Paint - Nullifire - Solvent - SC602ewqeqNo ratings yet

- Carbozinc 11: Performance DataDocument4 pagesCarbozinc 11: Performance Datakanha15102003No ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- Alpha Om-353 Solder Paste en 08nov19 TBDocument7 pagesAlpha Om-353 Solder Paste en 08nov19 TBShamsur RahmanNo ratings yet

- PDSDetail PageDocument3 pagesPDSDetail PageOSPEN NOAH SITHOLENo ratings yet

- PPG HI-TEMP 1027 NewDocument7 pagesPPG HI-TEMP 1027 NewsachinpsawantNo ratings yet

- Hempadur Zinc SeriesDocument2 pagesHempadur Zinc SerieskylegazeNo ratings yet

- Shell Gadus S4 OGT Open Gear GreaseDocument2 pagesShell Gadus S4 OGT Open Gear GreaseMuhammad SaputraNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Ul Ul Ul Ultracote Tracote Tracote TracoteDocument3 pagesUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleNo ratings yet

- Nullifire SC601 PDSDocument4 pagesNullifire SC601 PDSPeter ThomsonNo ratings yet

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDocument2 pagesD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveNo ratings yet

- Renolin CLP - PIDocument6 pagesRenolin CLP - PIDương LêNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- J STD 006BDocument4 pagesJ STD 006BAlejandra G0% (3)

- SMD Soldering: Information & InstructionsDocument6 pagesSMD Soldering: Information & Instructionsnod69assNo ratings yet

- Weller CatalogDocument97 pagesWeller CatalogИлья ХинкинNo ratings yet

- 372 140 Weller WTCPT Manual 41680Document4 pages372 140 Weller WTCPT Manual 41680VictorFaucheretNo ratings yet

- Soldering - TLEDocument2 pagesSoldering - TLELady StaAnaNo ratings yet

- Aws WJ 201411Document161 pagesAws WJ 201411Remmy Torres VegaNo ratings yet

- Reflow Solder SPC ChartDocument6 pagesReflow Solder SPC Chartsmtdrkd100% (1)

- Chapter 2 - Soldering Techniques PDFDocument21 pagesChapter 2 - Soldering Techniques PDFfaiz_84No ratings yet

- ZD-939L Manual RusDocument10 pagesZD-939L Manual RusSzutyok97No ratings yet

- PBL Proposal AssessmentDocument5 pagesPBL Proposal Assessmentyogi arohmanNo ratings yet

- Quiz on steps in solderingDocument2 pagesQuiz on steps in solderingJoseph Reposar GonzalesNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- How To Solder A Through-Hole Component: InstructablesDocument6 pagesHow To Solder A Through-Hole Component: InstructablesBobKatNo ratings yet

- Iso 2553Document54 pagesIso 2553lokesh38100% (2)

- Pma2 6Document9 pagesPma2 6EllyYanaNo ratings yet

- Soldering ToolsDocument7 pagesSoldering ToolsThamilselvan VengatasalamNo ratings yet

- Solder Hand Solder Training PDFDocument52 pagesSolder Hand Solder Training PDFftafedeNo ratings yet

- How To Use The Solder GlossariesDocument9 pagesHow To Use The Solder Glossaries02Aditya Pradana PutraX TMK 1No ratings yet

- Soldering and Brazing PDFDocument4 pagesSoldering and Brazing PDFnaresh naikNo ratings yet

- Rules For SolderingDocument3 pagesRules For SolderingMichelle ArellanoNo ratings yet

- Rework Procedura e CurveDocument6 pagesRework Procedura e CurveMarco ZeldNo ratings yet

- Alpha CVP-390Document5 pagesAlpha CVP-390sasimithun91No ratings yet

- ALPHA CVP-520 Solder Paste EN 25nov19 TBDocument6 pagesALPHA CVP-520 Solder Paste EN 25nov19 TBDeep SharmaNo ratings yet

- Presentation Topic:: Soldering and BrazingDocument27 pagesPresentation Topic:: Soldering and BrazingSarath ChandraNo ratings yet

- Instructions ReportDocument3 pagesInstructions Reportapi-593712140No ratings yet

- Interpretation of J-STD-001 and J-STD-004 Regarding FluxesDocument15 pagesInterpretation of J-STD-001 and J-STD-004 Regarding FluxesCamilo SouzaNo ratings yet

- E Hakko General PDFDocument97 pagesE Hakko General PDFSilver SelwayneNo ratings yet

- Soldering 101: A Really TopicDocument24 pagesSoldering 101: A Really TopicGanesh ThakurNo ratings yet

- Basics of SolderingDocument4 pagesBasics of SolderingNAIR KRISHNA RAVEENDRAN100% (2)

- Weekly DPM Monitor SpreadsheetDocument3 pagesWeekly DPM Monitor SpreadsheetsmtdrkdNo ratings yet