Professional Documents

Culture Documents

SVSW-007002-P02-0001 Rev A Hydrostatic Test Procedures - Code 1

Uploaded by

chuminh0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

SVSW-007002-P02-0001 Rev A Hydrostatic Test Procedures_Code 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesSVSW-007002-P02-0001 Rev A Hydrostatic Test Procedures - Code 1

Uploaded by

chuminhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

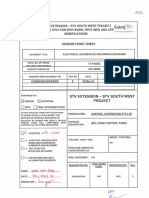

STV EXTENSION - STV SOUTH WEST PROJECT. njona)

(SVSW) EPCI FOR WHP-SVSW, PIPELINES AND CPI

MODIFICATIONS

VENDOR FRONT SHEET

[wettest

eoreeoert corszae

‘VENDORS OWN DOCUNENTNO | REV.NO | DATE el

SMC z eae

end ie STV EXTENSION — STV SOUTH WEST

Bireview [&] APPROVAL PROJECT

Cro ()FINAL DOCUMENTATION

‘renew pocsnorconaTmuTeaceeravct | vengoR NAME: CONTROL AUTOMATION PTE LTD

aera ers recite, WELLHEAD CONTROL PANEL

at

Hs accerren are west for

Oo: meee ma

1 ornare SYNT | pupctase onDER ne

Es ce cee rasan

C1 4. For mFoRMATiON ONLY. VORL CATEGORY: poz

Requismiouno, | “®SEERME | sequence no. | Ray

NAME Bel

DATE anf ‘svsw-o07002| a

‘SIGNATURE : Beg

lourket. + co-za0 Document No COL3285/ HCP MTP

‘oulpment WELLHEAD CONTRCL PANEL "Rew 8

HYDROSTATIC TEST PROCEDURES

‘or

[WELLHEAD CONTROL PANEL

‘STV SOUTH WEST PROJECT

41 Introduction

‘This procedure cover the requirements and conlions for Hydrotestof Wellhead Control

Panel & Hydraulic Pressure Unit, Tag. Numbers WHCP-2880,

To conform no leakage ata joints and connections between tubings tings and materials.

To conform the ting iting and components can take upto design pressure,

2 Procedure

Preparation

= Cary-out 2 Too! Box Meeting / Safety Tak with al personnel involved in testing the

system plo to work commencing.

= The use of personel protective equipments mandatory.

{(coverallong sleeves, hard hat, safety google safety hoes as minimum)

= Safety sons & bares tobe paced inthe testing area,

Ensure reservokisfled with Aqualin H7804

= Ensure accumulate are charged up wth nitrogen

“+ MP Accumulator {ACC2-1, ACC2-2, ACC2-3, ACC2-4, ACC2-5,ACC3-1) precharge

ressure: 82 barg

“+ HP Accumulator {ACCI-1, ACCL-2) pre-charge pressure: 165 borg

[Ensure 24VDC is conneted and power up check before tured.

= Ensure 490VAC 3 chase 60 Hz ae ready. Poner-up check before tur on.

= Ensure 120VAC 1 hase 60 Hz are ready fr lighting. Power-up check before turn on

+ Hydraulic output point to be plugged:

++ To Sub-Surface Valves (SCSSVS), To Master Vales (SV), To Wing Valves (WS),

To Gas Lif Vabes(UG¥s)

++To SDV, BDV, fs, To Production Choke Valves

+ Pally erst de erg J

~ ine ey 1 rel I

Cal ee

war vesicle tae Ler Pa Seiad

- eam TH a te a

fs ce phe

ounce + co.080 Document Na COIZ2SONHCRNTE

‘ulpment + WELLHEAD COWTRCL PANEL "Ren 4

HYDROSTATIC TEST PROCEDURES

‘or

WELLHEAD CONTROL PANEL

‘STV SOUTH WEST PROJECT

‘Al needle valves & bal valves aren dosed poston,

‘All pressure regulators tur an-dockise until springs are no longer leaded.

Remave ri valves PSV-2880h,PSV-28808, PSV.2880AB, P5V-2880C, PSV-2880D,

SV-2880CD, PSV-2683,PSV-2885 and plug at tubing connection,

(Open all NVI valve (14 nos.)

Testing

1 Open ball valve 223, BV3-4

‘Open ball valves 8V2-1,BV2-2, BV2-3,BV2-4,BV2'S, BV2-6, BV3-3, BVS-1, BVS-2

‘Open ball valves BVI-1, BVI-2,BVI-3, BVI-4,BVI-S,BVI-G, BV3-4, BVS-3, BVS4

‘Open 5 ways manifolds of DPT-2882-1, DPT-2881-1

MP Header

2 Open valves DB8-7, B®-8, DBB-S, 085-10, DB-11,088-12,BVG-1, BV7-7 to BV7-28,

Rn pump PBE-2880C to raise pressure to 210 bag and stop,

3 Start manual pume PBE-2882 to raise up the MP header press, 0 35 barg

He Header

4 Open valves 088-1, DBB-2, DBB-3, 085-4, DBB-5, DBE-6, BV7-1

Run ump PBE-2880 to raise up HP header press. o 300 barg

5 Start manual pum PBE-2871 to rase up HP header press yp to 450 bara

Header

6 Open ball valves BV6-28, 86.29, BVB-7

7 Turn regulator HOR clockwise to set pressure of 7.5 barg

8 Energize two solenald valve ESD-2880-2 & ESD-2660-3,

urket, —; cosmo Document No COIS60WHCHNTP

‘ouipment WELLHEAD COVTRCL Px "Rew A

HYDROSTATIC TEST PROCEDURES

WELLHEAD CONTROL PANEL

‘STV SOUTH WEST PROJECT

9) Hold and observe L Header, MP Header & HP Header pressure for 1 hour.

10 Release pressure ter testing ished, instal back all le valves,

“est Meum Aquaiok HT 804

Test Equipment: (tobe filed on ste)

Pressure Gauge (tobe filed on site)

Calbration Report No: (tobe filed on ste)

hart Recorder + Yes

Note: In case any leakage /elstortin occurred, panel shal be de-pressurized,

de-energizs, repaired then return back to step 1.

3 Acceptance criteria

Al sins, connections and components must have no signs of any leakages and distortion.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- CLJOC-FAC-WPK-40-0158 WP For Vessel Inspection of Glycol Coalescer (MAD-2445) On CPP - Rev.0Document25 pagesCLJOC-FAC-WPK-40-0158 WP For Vessel Inspection of Glycol Coalescer (MAD-2445) On CPP - Rev.0chuminhNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Cljoc Fac WPK 40 0158Document24 pagesCljoc Fac WPK 40 0158chuminhNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- SVSW-007002-P01-0001 Rev A Quality Manual - Code 1Document54 pagesSVSW-007002-P01-0001 Rev A Quality Manual - Code 1chuminhNo ratings yet

- SVSW-007002-M02-0001 Rev A Maintenance and Lubrication Recommendations - Code 1Document3 pagesSVSW-007002-M02-0001 Rev A Maintenance and Lubrication Recommendations - Code 1chuminhNo ratings yet

- SVSW-007002-OM-1-0001 Rev A Operating Maintenance Data Book Index - Code 1Document2 pagesSVSW-007002-OM-1-0001 Rev A Operating Maintenance Data Book Index - Code 1chuminhNo ratings yet

- SVSW-007002-P03-0001 Rev A NDT Procedure & Report - Code 1Document15 pagesSVSW-007002-P03-0001 Rev A NDT Procedure & Report - Code 1chuminhNo ratings yet

- SVSW-007002-P05-0001 Rev B Factory Acceptance Test Procedure - Code 1Document186 pagesSVSW-007002-P05-0001 Rev B Factory Acceptance Test Procedure - Code 1chuminhNo ratings yet

- SVSW-007002-P04-0001 Rev B Welding Procedure Specification & Welder Qualification - Code 1Document13 pagesSVSW-007002-P04-0001 Rev B Welding Procedure Specification & Welder Qualification - Code 1chuminhNo ratings yet

- SVSW-007002-G06-0001 R.A - Equipment Weight & Center of Gravity - Code 1Document10 pagesSVSW-007002-G06-0001 R.A - Equipment Weight & Center of Gravity - Code 1chuminhNo ratings yet

- SVSW-007002-G04-0001 Rev C Bill of Material - Code 1Document7 pagesSVSW-007002-G04-0001 Rev C Bill of Material - Code 1chuminhNo ratings yet

- SVSW-007002-G16-0001 Rev.A - Instrument Datasheets - Code 3Document16 pagesSVSW-007002-G16-0001 Rev.A - Instrument Datasheets - Code 3chuminhNo ratings yet

- SVSW-007002-G25-0001 Rev B IO List - Code 1Document4 pagesSVSW-007002-G25-0001 Rev B IO List - Code 1chuminhNo ratings yet

- SVSW-007002-G05-0001 Rev A Utility Requirements - Code 2Document2 pagesSVSW-007002-G05-0001 Rev A Utility Requirements - Code 2chuminhNo ratings yet

- SVSW-007002-G01-0001 Rev A Vendor Document Register - Code 2Document3 pagesSVSW-007002-G01-0001 Rev A Vendor Document Register - Code 2chuminhNo ratings yet

- SVSW-007002-G07-0001 Rev D Motor & Pump Datasheet - Code 1Document10 pagesSVSW-007002-G07-0001 Rev D Motor & Pump Datasheet - Code 1chuminhNo ratings yet

- SVSW-007002-D08-0001 Rev D Instrument Schematic and Control Diagrams - Code 1Document9 pagesSVSW-007002-D08-0001 Rev D Instrument Schematic and Control Diagrams - Code 1chuminhNo ratings yet

- SVSW-007002-DD-1-0001 Rev A Design Data Book Index - Code 1Document2 pagesSVSW-007002-DD-1-0001 Rev A Design Data Book Index - Code 1chuminhNo ratings yet

- SVSW-007002-D01-0001 Rev D General Arrangement Drawing - Code 1Document17 pagesSVSW-007002-D01-0001 Rev D General Arrangement Drawing - Code 1chuminhNo ratings yet

- SVSW-007002-D23-0001 R.A - Lighting Layout Drawing - Code 2Document8 pagesSVSW-007002-D23-0001 R.A - Lighting Layout Drawing - Code 2chuminhNo ratings yet

- SVSW-007002-C13-0001 R.B Hydraulic Calculation - Code 2Document7 pagesSVSW-007002-C13-0001 R.B Hydraulic Calculation - Code 2chuminhNo ratings yet

- SVSW-007002-D24-0001 Rev C ELectrical and Instrument Cable Routing Layout - Code 1Document8 pagesSVSW-007002-D24-0001 Rev C ELectrical and Instrument Cable Routing Layout - Code 1chuminhNo ratings yet

- Huong Dan Su Dung mst100p 1Document29 pagesHuong Dan Su Dung mst100p 1chuminhNo ratings yet

- SVSW-007002-D36-0001 R.A - Lifting Arrangement - Code 3Document4 pagesSVSW-007002-D36-0001 R.A - Lifting Arrangement - Code 3chuminhNo ratings yet

- SVSW-007002-D16-0001 Rev E Electrical Schematics & Wiring Diagrams - Code 1Document17 pagesSVSW-007002-D16-0001 Rev E Electrical Schematics & Wiring Diagrams - Code 1chuminhNo ratings yet

- CLJOC LinksDocument1 pageCLJOC LinkschuminhNo ratings yet

- Ch10-Ch14 Bently Book-Vib AnalysisDocument110 pagesCh10-Ch14 Bently Book-Vib AnalysischuminhNo ratings yet

- Ch5-Ch10 Bently Book-Vib AnalysisDocument85 pagesCh5-Ch10 Bently Book-Vib AnalysischuminhNo ratings yet

- Ch14-Ch17 Bently Book-Vib AnalysisDocument96 pagesCh14-Ch17 Bently Book-Vib AnalysischuminhNo ratings yet

- Ch1-Ch5 Bently Book-Vib AnalysisDocument108 pagesCh1-Ch5 Bently Book-Vib AnalysischuminhNo ratings yet

- CPP Equipment HistoryDocument97 pagesCPP Equipment HistorychuminhNo ratings yet