Professional Documents

Culture Documents

Indg463 2022

Uploaded by

Omar RababahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indg463 2022

Uploaded by

Omar RababahCopyright:

Available Formats

Health and Safety

Executive

Control of exposure

to silica dust

A guide for employees

This leaflet explains what your employer and you should do to

prevent lung disease caused by exposure to silica at work.

What is silica?

Silica is a natural substance found in most rocks, sand and clay and in products

such as bricks and concrete. Silica is also used as filler in some plastics. In the

workplace these materials create dust when they are cut, sanded, carved etc.

Some of this dust may be fine enough to breathe deeply into your lungs and

cause harm to your health. The fine dust is called respirable crystalline silica

(RCS) and is too fine to see with normal lighting.

The quantity of silica contained in stone and other materials varies considerably

This is a web-friendly between different types of stone:

version of leaflet INDG463,

published 03/13

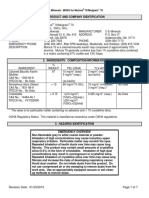

Approximate crystalline silica content Crystalline silica content (%w/w)

of different materials

Sandstone, gritstone, quartzite above 70%

Mortar, concrete 25–70%

Shale 40–60%

China stone up to 50%

Granite 20–45% (typically 30%)

Slate 20–40%

Ironstone Up to 15%

Basalt, dolerite Up to 5%

Limestone, chalk Up to 5% (typically less than 2%)

Marble Up to 5% (but can contain veins of

crystalline silica so the overall content

may be a lot higher)

Occupational exposure to RCS can occur in many industries, including:

construction and demolition processes – concrete, stone, brick, mortar;

quarrying;

slate mining and slate processing;

potteries, ceramics, ceramic glaze manufacture, brick and tile manufacture;

foundries;

refractory production and cutting;

Control of exposure to silica dust: A guide for employees Page 1 of 5

Health and Safety

Executive

concrete product manufacture;

monumental and architectural masonry manufacture, stone fireplace and

kitchen worktop manufacture;

grit and abrasive blasting, particularly on sandstone.

Certain activities create dust containing RCS, such as:

grinding, drilling, cutting, sanding, chiselling, blasting;

polishing, conveying;

fettling;

mixing and handling, shovelling dry material;

rock drilling/breaking/crushing/screening.

In workplaces, the following can happen:

leaks or spillages cause a build-up of dust containing RCS;

dust containing RCS is not cleaned up safely, eg by dry sweeping rather

than wet cleaning (see below);

clothing and surfaces are contaminated with dust containing RCS;

accumulated dust containing RCS is ‘raised’ from the ground or other

surfaces by moving vehicles and people;

fine dusts remain in the air from work activities.

How can RCS harm your health?

By breathing in RCS, you could develop the following lung diseases:

Silicosis: Silicosis is a lung disease caused by inhaling respirable crystalline silica

(RCS). It results in a hardening or scarring (fibrosis) of the lung tissue with loss of

lung function. It usually develops after at least 10 years of RCS exposure, with there

being no symptoms initially and the changes in the lungs being found on x-ray.

Chronic obstructive pulmonary disease (COPD): COPD is a group of lung

diseases, including bronchitis and emphysema, resulting in severe breathlessness,

prolonged coughing and chronic disability. It may be caused by breathing in any

fine dusts, including RCS. It can be very disabling and is a leading cause of death.

Cigarette smoking can make it worse.

Lung cancer: Heavy and prolonged exposure to RCS can cause lung cancer.

When someone already has silicosis, there is an increased risk of lung cancer.

The health risks from RCS are almost entirely preventable when exposure to dust

is adequately controlled – you do not need to become ill through work activities.

What should your employer do to protect you?

Employers must comply with The Control of Substances Hazardous to Health

Regulations 2002 (COSHH) (as amended) and need to:

assess the risks to your health – this is called a ‘risk assessment’;

keep a written record of the risk assessment if they employ more than five

people;

tell you anything significant about the risk assessment;

consider where practicable substituting material with a lower RCS content;

Control of exposure to silica dust: A guide for employees Page 2 of 5

Health and Safety

Executive

prevent or control exposures to RCS by:

— Implementing adequate control measures – more advice can be found in

HSE’s COSHH essentials (see ‘Find out more’);

— for RCS, control measures must be effective in keeping exposure below

the Workplace Exposure Limit (WEL) (0.1 mg/m3 respirable dust, averaged

over 8 hours);

where necessary, provide you with personal protective equipment, including

respiratory protective equipment (RPE), when the risk cannot be controlled

by engineering controls alone;

maintain all equipment used as control measures in good working order;

instruct and train you to use equipment properly, and tell you about health risks;

monitor to ensure that controls are effective and that the WEL for RCS is not

exceeded, (this may include measurement of the dust levels in your work area);

where appropriate arrange health surveillance.

What should you do?

Your employer must tell you about the risks from RCS, and how to avoid them.

Make sure you understand what you have to do and do it.

You should:

ask if the material you are using, or dust from the work you are doing,

contains silica;

ask how the job should be done safely, without creating risks to your health;

follow all safe working procedures, including cleaning procedure;

use controls such as dust extraction as you were trained to do;

wear protective clothing properly.

If you have to wear RPE, make sure that:

you are wearing the right type of RPE for the job;

you are face-fit tested for tight-fitting RPE, to ensure it fits properly – you

need to be clean shaven for this tight fit type of RPE to work effectively;

you have been trained to use, check and clean the RPE;

disposable respirators are changed regularly;

the filters on reusable RPE respirators are changed in accordance with

manufacturer’s recommendations;

the equipment is stored in a clean, dust-free place;

you tell your supervisor or employer if you find any defects, or your RPE

does not fit, is dirty or its filter is old – your employer must put it right.

Do not:

dry sweep – use a vacuum of dust class M or H, or wet cleaning;

use compressed air for removing dust from clothing.

If the controls to protect you from dust exposure include dust extraction (local

exhaust ventilation (LEV)) or other engineering control equipment, you should ask

yourself the following questions:

Were you involved in the design and selection of control equipment – the way

you work may need to change to maximise the protection you get?

Are the proposed changes workable – if they are not you could suggest

alternatives; the way you work may need to change to maximise the

protection you get?

Control of exposure to silica dust: A guide for employees Page 3 of 5

Health and Safety

Executive

Have you been trained in how the control equipment works – you need to

know how to use it effectively, your employer, the equipment supplier or

some other competent person should do this?

Can you tell if the control equipment is not working effectively – you should

be trained to recognise the signs, eg dust extraction equipment should have

an airflow indicator to show that it is working properly?

Is the control equipment easy to use properly – if it forces you to work in an

awkward way or prevents you doing the task properly tell your employer and

suggest improvements?

Your employer may also need to arrange for you to be placed under health

surveillance. This may include:

health and working history questionnaires;

lung function tests;

chest X-rays.

Decisions on the appropriate form of health surveillance may require the advice

of an occupational health professional. The precise form of health surveillance

will depend on the particular circumstances of exposure (level, frequency and

duration) identified by the risk assessment.

You should co-operate with your employer or works doctor/nurse if health

surveillance is required.

You are not entitled to see someone else’s personal medical records and your

employer is not entitled to see yours. But the staff representative or union

official can be given an idea of the workforce’s overall ill health effects.

If you have concerns about working with RCS after talking to you employer, ask

your trade union or employee health and safety representative for help, or speak

to the doctor/nurse involved in the health surveillance.

Find out more

To protect employees and others, employers should comply with the workplace

health and safety requirements in the Control of Substances Hazardous to Health

Regulations 2002 (COSHH). HSE has produced simple COSHH essentials

guidance sheets on how to control RCS exposure:

Brick and tile making series

www.hse.gov.uk/pubns/guidance/bkseries.htm

Ceramics series

www.hse.gov.uk/pubns/guidance/crseries.htm

Construction series

www.hse.gov.uk/pubns/guidance/cnseries.htm

Foundries series

www.hse.gov.uk/pubns/guidance/fdseries.htm

Manufacturing series

www.hse.gov.uk/pubns/guidance/mnseries.htm

Control of exposure to silica dust: A guide for employees Page 4 of 5

Health and Safety

Executive

Quarries series

www.hse.gov.uk/pubns/guidance/qyseries.htm

Stonemasons series

www.hse.gov.uk/pubns/guidance/stseries.htm

Controlling exposure to stone dust HSG201

www.hse.gov.uk/pubns/priced/hsg201.pdf

G403 – Health surveillance for occupational contact dermatitis (OCD)

www.hse.gov.uk/pubns/guidance/g403.pdf

G409 – Exposure measurement: Air sampling

www.hse.gov.uk/pubns/guidance/g409.pdf

Guidance on respiratory protective equipment (RPE) fit testing Leaflet

INDG479(rev1) HSE 2019

www.hse.gov.uk/pubns/indg479.htm

Fit2fit Accreditation - Fit2Fit RPE Fit Test Providers Accreditation Scheme

Direct advice sheets - COSHH e-tool (hse.gov.uk)

Health surveillance series

www.hse.gov.uk/pubns/guidance/g404.pdf

Respiratory protective equipment series

www.hse.gov.uk/pubns/guidance/rseries.htm

You can find out more about health surveillance at

www.hse.gov.uk/coshh/basics/surveillance.htm

Using cut-off saws: A guide to protecting your lungs Leaflet INDG461 HSE and

The Highways Agency 2012 www.hse.gov.uk/pubns/indg461.htm

Further information

For information about health and safety, or to report inconsistencies or

inaccuracies in this guidance, visit www.hse.gov.uk. You can view HSE

guidance online and order priced publications from the website. HSE priced

publications are also available from bookshops.

This guidance is issued by the Health and Safety Executive. Following the

guidance is not compulsory, unless specifically stated, and you are free to take

other action. But if you do follow the guidance you will normally be doing

enough to comply with the law. Health and safety inspectors seek to secure

compliance with the law and may refer to this guidance.

This leaflet is available at www.hse.gov.uk/pubns/indg463.htm.

© Crown copyright If you wish to reuse this information visit

www.hse.gov.uk/copyright.htm for details. First published 03/13.

Published by the Health and Safety Executive 10/22 INDG463 Page 5 of 5

You might also like

- Silica Dust Safety TalkDocument2 pagesSilica Dust Safety TalkmjbotelhoNo ratings yet

- Mine Dust HazardsDocument9 pagesMine Dust HazardsDinesh dhakarNo ratings yet

- Cis36 - SilicaDocument4 pagesCis36 - SilicaIlgar KarimovNo ratings yet

- Guide Printing - Business and Industry - Queensland GovDocument23 pagesGuide Printing - Business and Industry - Queensland GovIvanRomanovićNo ratings yet

- Silica Sand 2Document10 pagesSilica Sand 2Charles Dewey BandaNo ratings yet

- 10 Must Knows Words Related To Silica DustDocument3 pages10 Must Knows Words Related To Silica DustGRTNo ratings yet

- Crystalline Silica Dust 2Document2 pagesCrystalline Silica Dust 2Serdal SözüneerNo ratings yet

- Bricklayer Fact SheetDocument2 pagesBricklayer Fact SheetMarkNo ratings yet

- HSE Free Ceramics COSHH For ManagersDocument3 pagesHSE Free Ceramics COSHH For ManagersTony RobertsNo ratings yet

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustIoana UrsanNo ratings yet

- Dry CuttingDocument4 pagesDry CuttingNishadh 83No ratings yet

- Dust Can Kill: Raising Awareness To Protect LivesDocument3 pagesDust Can Kill: Raising Awareness To Protect LivesAmit RNo ratings yet

- Worksafe Bulletin: The Dangers of Breathing Silica DustDocument162 pagesWorksafe Bulletin: The Dangers of Breathing Silica DustHonest Raj GanapathyNo ratings yet

- Silica Factsheet - TBADocument2 pagesSilica Factsheet - TBABrett RobertsNo ratings yet

- Caesarstone Good Practice Guide AustraliaDocument45 pagesCaesarstone Good Practice Guide AustraliasummerNo ratings yet

- Silica Toolbox TalkDocument1 pageSilica Toolbox TalkDivyang TrivediNo ratings yet

- Stone Benchtop ChecklistDocument13 pagesStone Benchtop ChecklistAde HundeNo ratings yet

- Worker Exposure To Silica During Countertop Manufacturing, Finishing and InstallationDocument8 pagesWorker Exposure To Silica During Countertop Manufacturing, Finishing and InstallationShahid BhattiNo ratings yet

- Lead and SilicaDocument11 pagesLead and SilicayawarhassanNo ratings yet

- Protect Your Lungs: Guide to Silica Dust ExposureDocument2 pagesProtect Your Lungs: Guide to Silica Dust ExposureMohamad Hidayat Zainul MasriNo ratings yet

- Abrasive Blasting PDFDocument21 pagesAbrasive Blasting PDFDaniel_Parker_k4B6oNo ratings yet

- Silica Dust Factsheet 2023 - TBADocument2 pagesSilica Dust Factsheet 2023 - TBABrett RobertsNo ratings yet

- Material Safety Data Sheet: MSDS: Limestone and DolomiteDocument6 pagesMaterial Safety Data Sheet: MSDS: Limestone and DolomiteMisr RaymondNo ratings yet

- C-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Document7 pagesC-E Minerals: MSDS For Mulcoa 70/mulgrain 70: Revision Date: 01/23/2013 Page 1 of 7Muniruddin AmranNo ratings yet

- C-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7Document7 pagesC-E Minerals: MSDS For Mulcoa 60/mulgrain 60/mulblast 60: Revision Date: 01/23/2013 Page 1 of 7Muniruddin AmranNo ratings yet

- Mine Gases and Mine Dust (Their Sources and Control)Document32 pagesMine Gases and Mine Dust (Their Sources and Control)Ali WassanNo ratings yet

- WSBC Developing A Silica ECPDocument25 pagesWSBC Developing A Silica ECPKarhysNo ratings yet

- Dgms Tech ST Circular No 01 of 2010 Respirable DustDocument6 pagesDgms Tech ST Circular No 01 of 2010 Respirable DustDurga PrasadNo ratings yet

- Paint Department: Health and Safety Guidelines: August 2001Document20 pagesPaint Department: Health and Safety Guidelines: August 2001Wil Gabuay Jr.No ratings yet

- Airborne DustDocument3 pagesAirborne DustMilind SwaroopNo ratings yet

- TBT Cut Off Saw DustDocument1 pageTBT Cut Off Saw DustWasifNo ratings yet

- BCCEC - CBH DownloadableDocument57 pagesBCCEC - CBH DownloadableDev MasihNo ratings yet

- Msds p500 NagpurDocument7 pagesMsds p500 NagpurAnkur BarsainyaNo ratings yet

- 316D GRS Natural Aggregates Safety Data SheetDocument4 pages316D GRS Natural Aggregates Safety Data SheetDavidBurt0% (1)

- OSHA3768Document6 pagesOSHA3768Shazayn KhanNo ratings yet

- Rapid Set Repair MaterialDocument7 pagesRapid Set Repair Materialsam damsNo ratings yet

- Activity Control Measures: SI/HE-2 (Claudia Van Den Berg) July 24 2001 1Document6 pagesActivity Control Measures: SI/HE-2 (Claudia Van Den Berg) July 24 2001 1adammzjinNo ratings yet

- Understanding Silica-3Document5 pagesUnderstanding Silica-3Ahmed FoudaNo ratings yet

- Construction Dust Toolbox TalkDocument2 pagesConstruction Dust Toolbox TalkPravin GowardunNo ratings yet

- Foundry 1Document6 pagesFoundry 1Lo Li IngNo ratings yet

- Material Safety Data Sheet: Silica FumeDocument3 pagesMaterial Safety Data Sheet: Silica FumeHemlata LodhaNo ratings yet

- Holcim PremixedConcrete SDSDocument7 pagesHolcim PremixedConcrete SDSameliasulistianiNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetskNo ratings yet

- MSDS-2017 Ca (Oh) 2Document6 pagesMSDS-2017 Ca (Oh) 2mayaNo ratings yet

- Geoscience Testing Laboratory: Material Safety Data SheetDocument4 pagesGeoscience Testing Laboratory: Material Safety Data SheetAnonymous G6ceYCzwtNo ratings yet

- Abra 508Document23 pagesAbra 508Kiatchai IttivikulNo ratings yet

- 6207-10123 Dealing With Graphite DustDocument4 pages6207-10123 Dealing With Graphite Dustsrinivas rao rayuduNo ratings yet

- Managing Dust in ConstructionDocument83 pagesManaging Dust in ConstructionGadNo ratings yet

- Martin Marietta Materials MSDS for Ready-mix ConcreteDocument8 pagesMartin Marietta Materials MSDS for Ready-mix Concretemanil_5No ratings yet

- Risk Assessment of Abrasive Blasting Environment in Pressure Vessel FabricationDocument16 pagesRisk Assessment of Abrasive Blasting Environment in Pressure Vessel FabricationHussam AbdoalKelaqNo ratings yet

- MSDS AAC Hebel Blocks - 2002Document4 pagesMSDS AAC Hebel Blocks - 2002aditarian .pNo ratings yet

- Silica Sand ProductDocument19 pagesSilica Sand ProductJeEJyZa100% (2)

- Safety Science: Shichao Fan, Yuen-Wah Wong, Liyin Shen, Weisheng Lu, Tao Wang, Ann Yu, Qiping ShenDocument6 pagesSafety Science: Shichao Fan, Yuen-Wah Wong, Liyin Shen, Weisheng Lu, Tao Wang, Ann Yu, Qiping ShenpaulNo ratings yet

- Material Safety Data Sheet: Silica FumeDocument3 pagesMaterial Safety Data Sheet: Silica FumeEzequiel BeitiaNo ratings yet

- Fire Barrier 135 Msds PDFDocument8 pagesFire Barrier 135 Msds PDFE Hammam El MissiryNo ratings yet

- Dust Control in Hard Rock Mines: What You Can't See Can Kill YouDocument27 pagesDust Control in Hard Rock Mines: What You Can't See Can Kill YouDinesh KumarNo ratings yet

- DustcontrolDocument27 pagesDustcontrolVero ColladoNo ratings yet

- 09-Silica DustDocument1 page09-Silica DustFlancer SauNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Monthly BudgetDocument2 pagesMonthly Budgetddemo17demoNo ratings yet

- Safety in Gas Welding & Cutting Process PDFDocument11 pagesSafety in Gas Welding & Cutting Process PDFviswamanojNo ratings yet

- Local Exhaust Ventilation (LEV) : Offshore Coshh EssentialsDocument3 pagesLocal Exhaust Ventilation (LEV) : Offshore Coshh EssentialsOmar RababahNo ratings yet

- Local Exhaust Ventilation (LEV) : Offshore Coshh EssentialsDocument3 pagesLocal Exhaust Ventilation (LEV) : Offshore Coshh EssentialsOmar RababahNo ratings yet

- Local Exhaust Ventilation (LEV) : Offshore Coshh EssentialsDocument3 pagesLocal Exhaust Ventilation (LEV) : Offshore Coshh EssentialsOmar RababahNo ratings yet

- Local Exhaust Ventilation (LEV) : Offshore Coshh EssentialsDocument3 pagesLocal Exhaust Ventilation (LEV) : Offshore Coshh EssentialsOmar RababahNo ratings yet

- Safety in Gas Welding & Cutting Process PDFDocument11 pagesSafety in Gas Welding & Cutting Process PDFviswamanojNo ratings yet

- Literature StudyDocument7 pagesLiterature StudySilver ShadesNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- ADC0804 Datasheet - ADC 0804 Pin Diagram & Description - EngineersGarageDocument3 pagesADC0804 Datasheet - ADC 0804 Pin Diagram & Description - EngineersGarageMehanathan Maggie MikeyNo ratings yet

- Summer Training Report Lean Process OptimisationDocument19 pagesSummer Training Report Lean Process OptimisationKrishna RaoNo ratings yet

- 1 A Simulation Based Model For The BerthDocument9 pages1 A Simulation Based Model For The Berthmonu_vitsNo ratings yet

- Blogger TemplateDocument15 pagesBlogger TemplateSteffi Jasmyn BelderolNo ratings yet

- 342 Mechanical and Fluid Drive Maintenance Course DescriptionDocument2 pages342 Mechanical and Fluid Drive Maintenance Course Descriptionaa256850No ratings yet

- University Library Management SystemDocument10 pagesUniversity Library Management Systemkochi jerryNo ratings yet

- Warsaw Pact Order of Battle - 1989Document61 pagesWarsaw Pact Order of Battle - 1989Zero Knight100% (1)

- Env203Geo205 Map - ElementsDocument14 pagesEnv203Geo205 Map - ElementsFarhana SuptiNo ratings yet

- Section 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument7 pagesSection 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- China Holidays, Public Holidays Calendar in 2020 - 2021 - 2022Document15 pagesChina Holidays, Public Holidays Calendar in 2020 - 2021 - 2022eric retkoNo ratings yet

- Estatement 2020022506Document1 pageEstatement 2020022506ALL IN ONE. BOOLIWOOd SONGNo ratings yet

- ZEOLITEDocument13 pagesZEOLITEShubham Yele100% (1)

- 21st Century Literature Quarter 2 Week 7Document5 pages21st Century Literature Quarter 2 Week 7SHERRY MAE MINGONo ratings yet

- Dayton Audio Classic Series Subwoofers and Series II Woofer SpecificationsDocument1 pageDayton Audio Classic Series Subwoofers and Series II Woofer Specificationssales diyaudiocart.comNo ratings yet

- BEETLE /M-II Plus: POS System For The Highest Standards of PerformanceDocument2 pagesBEETLE /M-II Plus: POS System For The Highest Standards of PerformanceHeather JensenNo ratings yet

- PEC ReviewerDocument17 pagesPEC ReviewerJunallyn ManigbasNo ratings yet

- Tafila Technical University Course Syllabus for Manufacturing Processes (1) / Metal CuttingDocument4 pagesTafila Technical University Course Syllabus for Manufacturing Processes (1) / Metal CuttingG. Dancer GhNo ratings yet

- PPF Pumps CatalogDocument112 pagesPPF Pumps Catalogesau hernandezNo ratings yet

- Parts List of Engine Assy Ofdz-00536Document1 pageParts List of Engine Assy Ofdz-00536CwsNo ratings yet

- MVC PaperDocument14 pagesMVC PaperManal MkNo ratings yet

- Virus Programming Basics 1 Hacking Virus Programming AsmDocument17 pagesVirus Programming Basics 1 Hacking Virus Programming AsmMegamozgNo ratings yet

- Sbi KukkatpallyDocument2 pagesSbi KukkatpallyRavi Babu KonkatiNo ratings yet

- Duoc Dien Duoc Lieu Dai Loan - 3rd - 2019Document639 pagesDuoc Dien Duoc Lieu Dai Loan - 3rd - 2019Hương Nguyễn100% (1)

- How To Avoid PlagiarismDocument2 pagesHow To Avoid PlagiarismShiny Deva PriyaNo ratings yet

- Salary Income Tax Calculation in EthiopiaDocument4 pagesSalary Income Tax Calculation in EthiopiaMulatu Teshome95% (37)

- E44 - Wet Cooling Tower: InstructionsDocument3 pagesE44 - Wet Cooling Tower: InstructionsMarc AnmellaNo ratings yet

- Anna University Project Work Submission FormDocument1 pageAnna University Project Work Submission FormaddssdfaNo ratings yet

- Photoshop Cheat SheetDocument11 pagesPhotoshop Cheat SheetGiova RossiNo ratings yet