Professional Documents

Culture Documents

Pipeline Cleaning Folder

Uploaded by

Sabino LaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline Cleaning Folder

Uploaded by

Sabino LaraCopyright:

Available Formats

KATHAR E CLEANING

Kathar Cleaning offers Turnkey Services

great advantages

®

PIPELIN

Pipesurvey International offers complete customer

A Kathar cleaning operation pays back in terms of service. It will conduct the operation from sample

increased throughput, lower transmission costs, less analysis to waste disposal. Prior to each operation,

nuisance and reduction on costs of repetitive cleaning Pipesurvey International will hold a pre-cleaning

and inspection runs. meeting, to determine the customers’ objective of the

The advantages are numerous: operation, operational, safety and environmental

- improvement of product quality, e.g. gas, fuel or crude oil procedures, the time frame and the mutual

- increase of pipeline efficiency responsibilities. For each job, Pipesurvey International

- reduction of unexpected and unplanned maintenance mobilizes a complete team of field engineers with all the

costs required equipment and spares, so as to complete the job

- improvement of effectiveness of corrosion inhibitors within the specified time frame. The company complies

- prevention of further pipeline degradation with all international standards with regard to quality

- reduction of pipe wall friction and safety and guarantees the level of service that you

- improvement of quality and reliability of inspection want to depend upon.

data

The use of hydrocarbon-based cleaning agents relieves

the necessity of drying operations since no water is

introduced into the pipeline! The Kathar liquids leave a

harmless microfilm on the pipe wall which acts as a

retardant for future contamination and reduces friction

for product and future scraper runs. Kathar cleaned lines

have proven to show very smooth runs of inspection

tools, which obtained excellent measurements!

Pipesurvey International C.V. Tel + 31 78 610 1428

Schrijnwerkersstraat 13 Fax + 31 78 610 2128

P.O.Box 117, 3330 AC Zwijndrecht info@pipesurveyinternational.com

the Netherlands www.pipesurveyinternational.com

Why Pipesurvey International? Kathar Cleaning Liquids

Pipesurvey International is an internationally operating service company for the pipeline industry. The company was raised to coverage of the pipe wall. This technique has proven

meet with a growing demand of latest technology cleaning and inspection services.

Wire Brush Pig

to be more efficient than the technique of a batch

Being relatively new and dynamic, its personnel can boast on decades of experience in pipeline pigging. Pipesurvey International with one trail pig only. Kathar Cleaning operations can

employs a team of highly qualified experts on the field of pig design, chemistry, corrosion control, and in-line operation of be applied for the removal of wax growth, black pow-

pressurized pipelines. Pipesurvey International has the expertise to handle complex operations on a turn-key basis; it offers unbe- der, loosely adhered scale and many other

atable quality of service and technology against competitive terms. contaminations. Kathar cleaning is done before

pipeline inspection, commissioning or abandonment.

How contaminations affect your pipeline A pipeline cleaning operation

Kathar Cleaning operations can be performed in

Pipelines are pigged for several purposes, such as prove to be very stubborn and hard to remove by either in-line or off-line mode. In the latter case, the

increasing pipeline efficiency, removal of debris, pigs alone. Fortunately, Pipesurvey International pipeline is out of operation and compressed air is

removal of condensates, corrosion prevention, offers advanced cleaning technology to overcome used to propel the batches.

preparation for commissioning or inspection and such difficulties, where pigs alone fail. In the in-line mode, Pipesurvey International

Kathar ® Cleaning

pipeline conversion. In many cases, pigs will mobilizes and operates pressure equipment in order

encounter contaminations which can be classified as to perform the cleaning with a minimal interference

corrosion by-products, scales, black powder, com- Kathar Cleaning is an operation where the action of to the regular pipeline operation, which again offers

pressor oils, asphaltenics, paraffin and waxes, bio- specially designed cleaning agents is combined with great cost savings to the operator. Pipeline cleaning

mass, moisture, down-hole products or construction the mechanical agitation of cleaning pigs. is recognized to be a complex operation. Pipesurvey

left-overs. Pipeline contaminations affect safe and Kathar cleaning liquids are based on unique International discerns four phases:

healthy pipeline operation in the way that they: chemistry. The products are a blend of specially - Preparation phase: design the cleaning program

- create and ideal environment for oxygen reduces developed surfactants, dispersants and wetting based on pipeline characteristics, operational

to react with pipeline steel agents. Kathar cleaning agents can be applied on a restrictions, selection of cleaning pigs and

- accumulate in corrosion spots and mask metal loss basis of water or hydrocarbons. cleaning agents, analysis of pipeline contamina-

to corrosion inspection pigs Kathar cleaning agents will: tions as well as pig run history

- cause sensor lift-off, speed excursions or other - penetrate even dehydrated contaminations and - Mobilization phase: determine time frame, working

malfunction which creates data-loss or generation lift them off the surface procedure, mobilization and installation of high

of spurious data from expensive inspection - change the surface properties and create a stable pressure injection and separation equipment

operations dispersion - Operational phase: a team of highly qualified

- cause plugging fouling or damage of downstream - facilitate the removal of the contaminations by experts performs the complete operation; they will

equipment such as turbine blades filters and means of pigs continually monitor, measure and evaluate the pro-

compressors Kathar cleaning agents are environmentally friendly, gress of the operation Bi-Di Pig

- will cause degradation of the pipeline product, to biodegradable liquids; they are not based on - Demobilization phase: Pipesurvey International

such an extent that operators may face claims solvents or acids and have no adverse effect on line cares for environmental issues and complies with

from end-users steel, gaskets or internal coatings. They are safe to governmental regulations for waste disposal.

- lead to increased costs due to damaged facilities, handle and easy to dispose of which offers great Pipesurvey International generates an operation

stuck cleaning or inspection tools, down-time, cost savings. report with an exact indication of the amount of

remedial work, Kathar cleaning agents are combined with a solids that have been removed.

- interfere with effectiveness of corrosion inhibitors selected choice of pipeline pigs at each stage of the In one recent case, Pipesurvey International

or flow improvers cleaning operation to obtain the maximum result. removed 6560 kg of solids from a 22 x 18 km natural

- increase surface roughness and thus significantly Pipesurvey International performs the cleaning gas pipeline which had in the months preceding

reduce pipeline efficiency operation with full batches of cleaning liquids undergone more than 20 runs with various types of

Moreover, these pipeline contaminations often between two pigs, in order to guarantee complete pigs!

You might also like

- Beeswax Craft RecipesDocument19 pagesBeeswax Craft RecipesCpetrean100% (3)

- PETRONAS Technology & SES BrochureDocument61 pagesPETRONAS Technology & SES BrochureAbdulaziz AlrawiNo ratings yet

- Cleanwell System Technology: Completion SolutionsDocument8 pagesCleanwell System Technology: Completion SolutionslaaliautoNo ratings yet

- BX10/BX10 MB: Weighing Terminals Technical ManualDocument60 pagesBX10/BX10 MB: Weighing Terminals Technical Manualfelipezambrano50% (2)

- Passenger Ship SubdivisionDocument6 pagesPassenger Ship SubdivisionPunit Pandey100% (2)

- Furnace Tube Pipeline PiggingDocument8 pagesFurnace Tube Pipeline PiggingPervez0% (1)

- Cochlear ImplantsDocument53 pagesCochlear ImplantsSovitJungBaralNo ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFAbhiyan Anala Arvind100% (1)

- Bill of Qty. N.C. Sharma, BILSI, BadaunDocument47 pagesBill of Qty. N.C. Sharma, BILSI, BadaunNazim AliNo ratings yet

- Cleaning and Smart PiggingDocument8 pagesCleaning and Smart PiggingAde Aris SatriaNo ratings yet

- Aqseptence IntakeDocument16 pagesAqseptence IntakearrikanNo ratings yet

- Ben'S Muffler RepairDocument9 pagesBen'S Muffler RepairDana LantoNo ratings yet

- How Yeast Growth is AffectedDocument9 pagesHow Yeast Growth is AffectedMisika AlamNo ratings yet

- Case Studies in Pre Inspection: CleaningDocument4 pagesCase Studies in Pre Inspection: CleaningSamtron610No ratings yet

- New Controller Eliminates Manual Filter Leak Inspections: Online Cost of Grit Calculator To Predict Efficiency SavingsDocument1 pageNew Controller Eliminates Manual Filter Leak Inspections: Online Cost of Grit Calculator To Predict Efficiency SavingsNadiar IswanNo ratings yet

- Tailings Filtration Using Viper Filtration TechnolDocument7 pagesTailings Filtration Using Viper Filtration TechnolNicoViljoenNo ratings yet

- Nitrogen ServicesDocument2 pagesNitrogen ServicesDilipNo ratings yet

- PROCESS AND PIPELINE SERVICES OVERVIEWDocument16 pagesPROCESS AND PIPELINE SERVICES OVERVIEWMohamed HassanNo ratings yet

- What Is A Pipeline Pig and How Are They UsedDocument3 pagesWhat Is A Pipeline Pig and How Are They UsedBensmatNo ratings yet

- ROSEN Group - Pipeline Cleaning SolutionsDocument20 pagesROSEN Group - Pipeline Cleaning SolutionsAnonymous 6ufCs96TLNo ratings yet

- Transvac TransPACDocument12 pagesTransvac TransPACDmitrii ChernushkinNo ratings yet

- ADI - Sales BrochureDocument9 pagesADI - Sales BrochureTehleelNo ratings yet

- Kemet Ultrasonic Cleaning CatalogueDocument20 pagesKemet Ultrasonic Cleaning CataloguePhạm Bá HiếuNo ratings yet

- Vogel 11sangDocument9 pagesVogel 11sangdumb2471817No ratings yet

- Diva Envitec Contufilt-MDocument6 pagesDiva Envitec Contufilt-MThe Sur StudioNo ratings yet

- Process Filtration & EquipmentDocument8 pagesProcess Filtration & EquipmentleslieNo ratings yet

- On-Belt Conductive Material Moisture Analyser: CM 100 Applications CM 100 AdvantagesDocument2 pagesOn-Belt Conductive Material Moisture Analyser: CM 100 Applications CM 100 AdvantagesalejgonzNo ratings yet

- Jiujiang 707 Precision Mechatronics Co ProfileDocument26 pagesJiujiang 707 Precision Mechatronics Co ProfileBillNo ratings yet

- Matec Concrete CatalogDocument13 pagesMatec Concrete Catalogkssn1981No ratings yet

- Innovative Pigging Solutions For Pipelines: DevelopmentDocument2 pagesInnovative Pigging Solutions For Pipelines: DevelopmentMohamed HassanNo ratings yet

- Brochure Coal Fired Power Industry PDFDocument12 pagesBrochure Coal Fired Power Industry PDFdedison_rNo ratings yet

- IrtDocument16 pagesIrtMd Irshad AlamNo ratings yet

- Pipeline Pre-Commissioning: Service DatasheetDocument1 pagePipeline Pre-Commissioning: Service DatasheetSteve WawukNo ratings yet

- Tegra BrochureDocument24 pagesTegra BrochurejopejiNo ratings yet

- WT WaterIntake Brochure enDocument16 pagesWT WaterIntake Brochure enAswindana Ibnu SenaNo ratings yet

- System Overview: Problems SolvedDocument2 pagesSystem Overview: Problems SolvedMas Bagaz NoviantoNo ratings yet

- Ipc2022-86892 Pig Sweep Nanoparticles Transform PipelineDocument5 pagesIpc2022-86892 Pig Sweep Nanoparticles Transform PipelineOswaldo MontenegroNo ratings yet

- IJETR022421Document4 pagesIJETR022421erpublicationNo ratings yet

- 1.1 Live Line Dry Cleaning in Electrical Installations FPDocument3 pages1.1 Live Line Dry Cleaning in Electrical Installations FPWalter PossoNo ratings yet

- 00 MBR - Aml - enDocument2 pages00 MBR - Aml - enBiagio SeniseNo ratings yet

- Aquionics UV - Inline BrochureDocument2 pagesAquionics UV - Inline Brochuremiguel_vera6592No ratings yet

- Interceptors Tech Data PDFDocument3 pagesInterceptors Tech Data PDFXAVIER RUBIONo ratings yet

- CEDA's Industrial Cleaning & Environmental ServicesDocument6 pagesCEDA's Industrial Cleaning & Environmental ServicesHendi RustandiNo ratings yet

- uPVC Soil, Waste and Rain Water Drainage System Technical ManualDocument40 pagesuPVC Soil, Waste and Rain Water Drainage System Technical ManualNikita KadamNo ratings yet

- 10 - 0201 Aqua-Nova Lo - Res PDFDocument4 pages10 - 0201 Aqua-Nova Lo - Res PDFjl181No ratings yet

- 6 SWR Drainage SystemDocument8 pages6 SWR Drainage Systemashish kumar pandeyNo ratings yet

- XX-CLONE Through-Flow CleanerDocument4 pagesXX-CLONE Through-Flow CleanerEdson CastelliNo ratings yet

- CRAsiaebrochure2012 PDFDocument25 pagesCRAsiaebrochure2012 PDFsarathoonvNo ratings yet

- Vedra Trade Services (VTS) ProfileDocument94 pagesVedra Trade Services (VTS) ProfileMathias OnosemuodeNo ratings yet

- ScrubberDocument4 pagesScrubberjaviermartinmariaNo ratings yet

- KIRK Filter Separator SolutionsDocument2 pagesKIRK Filter Separator SolutionsGomathi ShankarNo ratings yet

- STR Reject ChambersDocument4 pagesSTR Reject ChambersMiguel VenzNo ratings yet

- Solutions CatalogDocument28 pagesSolutions CatalogLuis MiguelNo ratings yet

- All Product Eng RevDocument24 pagesAll Product Eng RevZuzer FakhriNo ratings yet

- Transvac-Ejector Test FacilityDocument8 pagesTransvac-Ejector Test FacilityDmitrii ChernushkinNo ratings yet

- Integrity Speed Performance Oil Gas ServicesDocument10 pagesIntegrity Speed Performance Oil Gas Servicesbenandy2018No ratings yet

- Riopipeline2019 1138 Rio Paper Rev01 PDFDocument11 pagesRiopipeline2019 1138 Rio Paper Rev01 PDFMarcelo Varejão CasarinNo ratings yet

- Case Study: Sand Removal From 3 Phase Production Separators and VesselsDocument5 pagesCase Study: Sand Removal From 3 Phase Production Separators and VesselssterlingNo ratings yet

- Sewer Cleaning and InspectionDocument11 pagesSewer Cleaning and InspectionKwang Je Lee100% (1)

- MagazineDocument12 pagesMagazineEyad AboshamlehNo ratings yet

- Macon Profile - Corporateppppjan17Document8 pagesMacon Profile - Corporateppppjan17Vishal SalveNo ratings yet

- Don'T Take Risks: With Chemical DrainageDocument8 pagesDon'T Take Risks: With Chemical DrainageyusrieNo ratings yet

- Miele Professional Medium Capacity Washer Disinfectors From SiCDocument40 pagesMiele Professional Medium Capacity Washer Disinfectors From SiCÖzcan KaraculaNo ratings yet

- Automatic Tank Cleaning PsDocument1 pageAutomatic Tank Cleaning PsSami ArebiNo ratings yet

- Total Product Brochure Goyen and MecairDocument3 pagesTotal Product Brochure Goyen and MecairEuniko Masih MenungguNo ratings yet

- Factsheet: Membrane Filtration TechnologyDocument2 pagesFactsheet: Membrane Filtration TechnologyDheeraj ShuklaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Antea IDMSDocument4 pagesAntea IDMSSabino LaraNo ratings yet

- Antea RBIDocument2 pagesAntea RBISabino LaraNo ratings yet

- Amc Catalogue en RopeDocument6 pagesAmc Catalogue en RopeSabino LaraNo ratings yet

- Antea IDMSDocument4 pagesAntea IDMSSabino LaraNo ratings yet

- Limpiador 18M14KDocument3 pagesLimpiador 18M14KIvan Morales AguilarNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- Udfn/Lnh) Odzv3Uhvvxuh9Hvvho) LWQHVV) Ru6Huylfh$Vvhvvphqwv Dqg6Riwzduh3Urjudpplqj%Dvhgrq$3,53Document12 pagesUdfn/Lnh) Odzv3Uhvvxuh9Hvvho) LWQHVV) Ru6Huylfh$Vvhvvphqwv Dqg6Riwzduh3Urjudpplqj%Dvhgrq$3,53Flávio LasmarNo ratings yet

- 2001v05 ResponsibilitiesDocument8 pages2001v05 ResponsibilitiesanoopkumarNo ratings yet

- 01 - 1400 David Parramore - TSC Eddyfi TechnologiesDocument30 pages01 - 1400 David Parramore - TSC Eddyfi TechnologiesSabino LaraNo ratings yet

- DuraProd ALL 7.26.07Document4 pagesDuraProd ALL 7.26.07Sabino LaraNo ratings yet

- 17 Flanged Nipple Outlet - 3dDocument1 page17 Flanged Nipple Outlet - 3dSabino LaraNo ratings yet

- State of CUI Testing ReviewDocument21 pagesState of CUI Testing ReviewSabino LaraNo ratings yet

- FINAL - DuraProd Maintenance&Troubleshooting Guide - 2.27.08Document2 pagesFINAL - DuraProd Maintenance&Troubleshooting Guide - 2.27.08Sabino LaraNo ratings yet

- 2 AtiDocument8 pages2 AtiSachin SithikNo ratings yet

- Microwave Testing ( T) : An Overview: Figure 1: Electromagnetic SpectrumDocument7 pagesMicrowave Testing ( T) : An Overview: Figure 1: Electromagnetic SpectrumSabino LaraNo ratings yet

- Innogy Invitation For Seminar PCODocument6 pagesInnogy Invitation For Seminar PCOTivorshio MacabodbodNo ratings yet

- Caffeine Natural Coffee BeanDocument1 pageCaffeine Natural Coffee BeanMayang TariNo ratings yet

- Telephone Directory Updated 24.04.2020Document139 pagesTelephone Directory Updated 24.04.2020Manpal SinghNo ratings yet

- Designing Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesDocument12 pagesDesigning Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesSheilani MartinsNo ratings yet

- Riel Comun Fstguide2Document2 pagesRiel Comun Fstguide2Rosita TejedaNo ratings yet

- NanocatalysisDocument9 pagesNanocatalysisNouran ElbadawiNo ratings yet

- Analysis of Alloy Constituents (Cu and ZnDocument5 pagesAnalysis of Alloy Constituents (Cu and Znaryan kushwaha100% (2)

- Sps 500 (STD) ProgramDocument164 pagesSps 500 (STD) Programwahyu100% (1)

- Piriformis MuscleDocument3 pagesPiriformis MuscleBen CampbellNo ratings yet

- Wazaif Totaky Home Remedies Receiver Software Powervu Key-1Document18 pagesWazaif Totaky Home Remedies Receiver Software Powervu Key-1Habib MohammedNo ratings yet

- Different Mesh Sizes and Mesh To Micron ConversionDocument10 pagesDifferent Mesh Sizes and Mesh To Micron ConversionDevanandDongreNo ratings yet

- APC Symmetra PX-2Document8 pagesAPC Symmetra PX-2drastir_777No ratings yet

- Arthur Kleinman The Illness Narratives Suffering Healing and The Human ConditionDocument46 pagesArthur Kleinman The Illness Narratives Suffering Healing and The Human Conditionperdidalma62% (13)

- 465 886 1 SMDocument8 pages465 886 1 SM17Annisa Muthmainnah067No ratings yet

- Grade 5. Unit 15Document6 pagesGrade 5. Unit 15Đình ThuậnNo ratings yet

- Kshitija's ResumeDocument1 pageKshitija's ResumeNavinNo ratings yet

- Online Pharmacy: Customer ProfilingDocument6 pagesOnline Pharmacy: Customer ProfilingGeorge SebastianNo ratings yet

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- Technical Data Book: RAC For SEDA (INV, R410A, 60Hz, C/O)Document43 pagesTechnical Data Book: RAC For SEDA (INV, R410A, 60Hz, C/O)joserosineiassisdasilvaNo ratings yet

- Facilitating Civic Engagement Through Consultation: Learning From Local Communities Through The NHI-Accountability Project in South AfricaDocument64 pagesFacilitating Civic Engagement Through Consultation: Learning From Local Communities Through The NHI-Accountability Project in South AfricaOxfamNo ratings yet

- Odonata 35 PDFDocument40 pagesOdonata 35 PDFJose VelasquezNo ratings yet

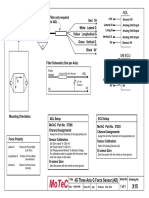

- Filter and wiring schematic for 3-axis ADL G-force sensorDocument1 pageFilter and wiring schematic for 3-axis ADL G-force sensorJuan Ramón Pérez LorenzoNo ratings yet

- GP2A25J0000F Series: Detecting Distance: 1 To 9mm OPIC Output, Refl Ective Photointerrupter With ConnectorDocument10 pagesGP2A25J0000F Series: Detecting Distance: 1 To 9mm OPIC Output, Refl Ective Photointerrupter With Connectoralias_johndeere2301No ratings yet