Professional Documents

Culture Documents

2K Epoxy Mastic Coating 80

Uploaded by

Sachin SinghalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2K Epoxy Mastic Coating 80

Uploaded by

Sachin SinghalCopyright:

Available Formats

2K EPOXY MASTIC COATING 80

It is two pack, cold curing high performance Epoxy Mastic coating, based on epoxy resin

and anticorrosive pigment. It can also be used as an anticorrosive primer on ferrous

surface in mild to medium environment. It has excellent chemical & water resistance.

PRODUCT INFORMATION SURFACE PREPARATION

White, Grey & other

Color : STEEL SURFACES :

shades.

Degrease and blast clean Sa 2½ grade

Egg shell to Semi minimum of Swedish specification SIS-05-

Finish :

Glossy. 5900-1967. If blast cleaning is not

practical make full use of mechanical

Flash Point : Above 23°C tools along with manual cleaning and

wire brushing to remove loose rust/scale

to St2 or St3 grade of Swedish

80 ± 2 %

Volume Solids : specification. Surface should be perfectly

approximately

clean and dry before applying ROZC

primer.

Recommended

100 - 125 µm per coat

dry film thickness :

APPLICATION DETAILS

Theoretical

Method of application : Airless spray /

Covering 6.5-8 Sq.m/ltr

Brush / Roller / Air spray.

Capacity :

Base : Hardener :: 3 : 1 Notes on Airless Spray : Tip Range 15-21

Mixing Ratio :

(by volume) thou.

Surface dry - within 2 – Total output fluid pressure : 2500 - 3000

3 hours psi.

Hard dry - within 24

Drying Time : (176-211 kg/sq. cm.)

hours

Full curing - within 7

days Thinner : BRITISH Epoxy thinner.

Interval before Minimum 18 hours.

Over coating : Maximum 4 days.

USES

Pot Life : 6-8 hours. General Structural Steel

Up to 12 months so Mining and Machinery Industries

long as the material is Fertilizers

stored in sealed Petrochemical Installations

Storage life :

containers under Petrochemical Refineries

standard warehouse

Pre-Engineering Building

storage conditions.

Dry Heat Up to 100°C

Chemical Manufacturing Units.

Resistance : (Intermittent).

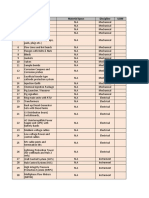

SURFACE SELECTION GUIDE

SURFACE 1st COAT 2nd COAT 3rd COAT

EPOXY MASTIC COATING

Steel M.I.O EPOXY/PU FINISH

80

NOTES

1. This cancels all previous literature on this product and is subject to revision without notice.

2. Do not apply when temperature fall below 10°C or rises above 50°C and when relative

humidity rises above 90%. Do not apply during rain, fog or mist.

3. Primed steel work should not be exposed for a long period and preferably should be

coated with suitable top coat at the earliest.

HEALTH AND SAFETY

Please refer to the separate safety data sheet available with detailed information.

DISCLAIMER

The information in this leaflet is given in good faith. The company will not be liable for loss

and damage may be suffered by the user of the data contained therein. It is the user's

responsibility to conduct all necessary tests intended use. No guarantee of result is

extended since condition of use are beyond our control.

A division of Berger Paints India Ltd.

19-DDA, Comercial Complex, Kailash Colony Extension, Zamrudpur, New Delhi-110048

Phone : +91-11-29240394

Mail : tss.ind@britishpaints.in; industrial@britishpaints.in

Website : www.britishpaints.in

You might also like

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehNo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- Highway MaterialsDocument45 pagesHighway Materialsfarahazura67% (9)

- Formability of Perforated Sheet Metals by FEADocument14 pagesFormability of Perforated Sheet Metals by FEAHari KrishnaNo ratings yet

- TDS - Supra Epoxy HB Mio CoatingDocument2 pagesTDS - Supra Epoxy HB Mio CoatingSachin SinghalNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- Zinc Anode 304 MZV Protects Steel Against Severe CorrosionDocument2 pagesZinc Anode 304 MZV Protects Steel Against Severe CorrosionMANIMARAN QCNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Paint Specification HamadourDocument2 pagesPaint Specification HamadourAbdul Majid LodhiNo ratings yet

- Epoxy Mastic Primer Epiplus 556Document2 pagesEpoxy Mastic Primer Epiplus 556rh decoratorsNo ratings yet

- Hyperdesmo®-Ady-E - enDocument4 pagesHyperdesmo®-Ady-E - enMajd M. KhalilNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZvkvc soodNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZsojeckNo ratings yet

- Hempadur Quattro InglesDocument3 pagesHempadur Quattro InglesElizabeth Maria Bazán MoralesNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Sigmazinc 109 HS: Description Principal CharacteristicsDocument4 pagesSigmazinc 109 HS: Description Principal CharacteristicsАлексейNo ratings yet

- Tuffkote: Epigard Epoxy Finish Epigard HB MioDocument2 pagesTuffkote: Epigard Epoxy Finish Epigard HB MioSHATABDI- DELNo ratings yet

- Asian Paints SmartCare Flexi Seal PUDocument4 pagesAsian Paints SmartCare Flexi Seal PUNational WaterproofingNo ratings yet

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 pagesPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawNo ratings yet

- 220 Amercoat - 0220 Styralux PDSDocument2 pages220 Amercoat - 0220 Styralux PDSMuniyappan TNo ratings yet

- Bipigard ST Cte Black PDFDocument2 pagesBipigard ST Cte Black PDFKhirod KroutNo ratings yet

- HEMPADUR MASTIC 45880 Product DataDocument3 pagesHEMPADUR MASTIC 45880 Product DataQA QCNo ratings yet

- High Build Epoxy Coating Technical DataDocument3 pagesHigh Build Epoxy Coating Technical Databehrooz rajabshehniNo ratings yet

- HEMPADUR SPEED-DRY ZP 500 Product Data SheetDocument3 pagesHEMPADUR SPEED-DRY ZP 500 Product Data SheetDHANOOPNo ratings yet

- Ceramic Coating Product Data SheetDocument3 pagesCeramic Coating Product Data SheetANIBALLOPEZVEGANo ratings yet

- Tuffkote: Epigard Epoxy Finish Bipigard Cte XLDocument2 pagesTuffkote: Epigard Epoxy Finish Bipigard Cte XLSHATABDI- DELNo ratings yet

- APCS-26T HempelDocument5 pagesAPCS-26T HempelarjunmohananNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- Product Data for HEMPATHANE HS 55610 Protective CoatingDocument3 pagesProduct Data for HEMPATHANE HS 55610 Protective CoatingAnonymous HPlNDhM6ejNo ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBalouisNo ratings yet

- Chemstat ESDDocument3 pagesChemstat ESDpadmanabh alatNo ratings yet

- Aluminum Filled Epoxy Resin Cement: Product OverviewDocument2 pagesAluminum Filled Epoxy Resin Cement: Product OverviewAli KhezeliNo ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- Hempadur Mastic 45880 Product Data SheetDocument3 pagesHempadur Mastic 45880 Product Data SheetDeepak YadavNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- 2006-035 - Shalithane HB FinishDocument2 pages2006-035 - Shalithane HB FinishNupesh Katre100% (1)

- DS - 752-Rev01 - Epilux 485 HB IntermediateDocument2 pagesDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainNo ratings yet

- High-solids zinc epoxy primer data sheetDocument4 pagesHigh-solids zinc epoxy primer data sheetMina RemonNo ratings yet

- HEMPEL'S GALVOSIL 15790 Product Data SheetDocument2 pagesHEMPEL'S GALVOSIL 15790 Product Data SheetRoberto_PrrNo ratings yet

- Hi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFDocument5 pagesHi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFPushpendraNo ratings yet

- Hyperdesmo®-Pb-Mono - enDocument3 pagesHyperdesmo®-Pb-Mono - enMajd M. KhalilNo ratings yet

- Epilux 44 Enamel: Product Data Resistance GuideDocument2 pagesEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kNo ratings yet

- Hyperdesmo Polyurea 2K HCDocument3 pagesHyperdesmo Polyurea 2K HCmeena nachiyarNo ratings yet

- DS 066 Epilux 84 ClearDocument2 pagesDS 066 Epilux 84 ClearShodhan M AminNo ratings yet

- Ultracote Ultracote Ultracote Ultracote: Ultrazinc 2120Document3 pagesUltracote Ultracote Ultracote Ultracote: Ultrazinc 2120Cherbee FerrerNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- DS - 122 - Rev-01 - Epilux 4 High Build Epoxy FinishDocument2 pagesDS - 122 - Rev-01 - Epilux 4 High Build Epoxy Finishvkvc soodNo ratings yet

- Sigacoat 111: Technical Data SheetDocument2 pagesSigacoat 111: Technical Data SheetAmirhossein LotfiNo ratings yet

- Loctite 7232 High Temperature Wear Resistant Putty: Product Description SheetDocument1 pageLoctite 7232 High Temperature Wear Resistant Putty: Product Description SheetjohnNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971No ratings yet

- Hempel Shopprimer 15890ZSDocument2 pagesHempel Shopprimer 15890ZSAnuar SalehNo ratings yet

- Neromastic_4000Document2 pagesNeromastic_4000m pallonjiNo ratings yet

- Hempadur Mastic 45881-12170Document3 pagesHempadur Mastic 45881-12170Bang OchimNo ratings yet

- Solvent-Free Epoxy Floor Coating for 200-400 MicronsDocument4 pagesSolvent-Free Epoxy Floor Coating for 200-400 Micronsosama mohNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- DESMOFLEX TOP COΑΤ v2 ENDocument3 pagesDESMOFLEX TOP COΑΤ v2 ENprestigebuild888No ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 7 ContinentsDocument15 pages7 ContinentsSachin SinghalNo ratings yet

- JOTUN TDS - Penguard E50Document5 pagesJOTUN TDS - Penguard E50Sachin SinghalNo ratings yet

- 12-How Do You Make A Giraffe LaughDocument16 pages12-How Do You Make A Giraffe LaughSachin SinghalNo ratings yet

- Stories From The PuranasDocument172 pagesStories From The PuranasSachin SinghalNo ratings yet

- 1st Worksheet Evs Edu Score MoreDocument6 pages1st Worksheet Evs Edu Score MoreSachin SinghalNo ratings yet

- Look at The Chart and Write The Opposites of The Adjectives: - All Rights ReservedDocument1 pageLook at The Chart and Write The Opposites of The Adjectives: - All Rights ReservedAnaBelenNo ratings yet

- Pds - Epigard TL 543 Hs Finish (f15)Document2 pagesPds - Epigard TL 543 Hs Finish (f15)Sachin SinghalNo ratings yet

- Heat Resistant Aluminum Paint Data SheetDocument2 pagesHeat Resistant Aluminum Paint Data SheetSachin SinghalNo ratings yet

- Vco Type B Rev 6 (Ms-02-40)Document2 pagesVco Type B Rev 6 (Ms-02-40)herysyam1980No ratings yet

- Welding Advanced Chromium Alloys for High-Temperature ServiceDocument5 pagesWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- Gasket HandbookDocument48 pagesGasket Handbookgladiatork00796% (24)

- Tall Vessels PDFDocument29 pagesTall Vessels PDFVenkatesh Sivarchana100% (1)

- 24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsDocument1 page24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsHewa PCNo ratings yet

- 2501 Solid Drawn Copper Tubes For General Engineering PurposesDocument8 pages2501 Solid Drawn Copper Tubes For General Engineering PurposesKaushik SenguptaNo ratings yet

- Basic Boiler Construction GuideDocument8 pagesBasic Boiler Construction GuideIonescu FlorinNo ratings yet

- Edinburgh Tram Case StudyDocument5 pagesEdinburgh Tram Case StudySiddarth SinghNo ratings yet

- Ast II RSC 610 X 610 X 105 MMDocument80 pagesAst II RSC 610 X 610 X 105 MMHARSHANo ratings yet

- Muscat International Airport plaster specificationDocument23 pagesMuscat International Airport plaster specificationDiana Alexandra Comaromi0% (1)

- Roofing ShinglesDocument4 pagesRoofing ShinglesFaizal HaziziNo ratings yet

- Ventilation and Heating Unit GEA MultiMAXX®Document27 pagesVentilation and Heating Unit GEA MultiMAXX®parth sapariaNo ratings yet

- Chilled Water System Installation Operation Maintenance Manual 2811 15340Document36 pagesChilled Water System Installation Operation Maintenance Manual 2811 15340MONANo ratings yet

- Design and Fabrication of Alternate Energy Storage Device Using PMCsDocument40 pagesDesign and Fabrication of Alternate Energy Storage Device Using PMCsMujassamNazarKhanNo ratings yet

- Mechanical, Electrical, Instrumentation Material SpecsDocument9 pagesMechanical, Electrical, Instrumentation Material SpecsNoor A QasimNo ratings yet

- (Esben Byskov) Elementary Continuum Mechanics For EveryoneDocument598 pages(Esben Byskov) Elementary Continuum Mechanics For EveryoneMadhushree ProdhanNo ratings yet

- Fluent and Multi Phase FlowsDocument18 pagesFluent and Multi Phase FlowsMuhammad Shafiq Bin RoslanNo ratings yet

- Masterlife Sra 50: Description Expanding PropertiesDocument2 pagesMasterlife Sra 50: Description Expanding PropertiesSavalia HardikNo ratings yet

- BS en 10088-4-2009Document48 pagesBS en 10088-4-2009khanhNo ratings yet

- Transparent BOPP Films for PackagingDocument10 pagesTransparent BOPP Films for PackagingНельсон МигNo ratings yet

- Rittal Industrial Enclosure Solutions - Issue 7 5 3464Document76 pagesRittal Industrial Enclosure Solutions - Issue 7 5 3464yongNo ratings yet

- WrapperDocument2 pagesWrapperRufus D SNo ratings yet

- Wavepro-II Catalogue en 1sxh3432001 Rev B 08-2021Document32 pagesWavepro-II Catalogue en 1sxh3432001 Rev B 08-2021Suki GalNo ratings yet

- Cleanroom air conditioning unitsDocument8 pagesCleanroom air conditioning unitsmacanipharoldf6220No ratings yet

- Final Ard Report 112 Vepari HardikDocument32 pagesFinal Ard Report 112 Vepari HardikHardik Kashyap VepariNo ratings yet

- Estimating Bond Wire Current-Carrying CapacityDocument2 pagesEstimating Bond Wire Current-Carrying Capacitywalker fanNo ratings yet

- To Write Me150p-1Document27 pagesTo Write Me150p-1Cloie ChavezNo ratings yet

- CG-107-F Bulk EarthworksDocument1 pageCG-107-F Bulk EarthworksJose AmorimNo ratings yet