Professional Documents

Culture Documents

Afe 2 16

Uploaded by

ชลธิชา โยชาลีOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Afe 2 16

Uploaded by

ชลธิชา โยชาลีCopyright:

Available Formats

ISSN (1897-3310)

ARCHIVES Volume 14

Issue 2/2014

of

79 – 84

FOUNDRY ENGINEERING

16/2

Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences

Research on Technology of Alloyed Copper

Casting

St. Rzadkosz a, *, M. Kranc b, A. Garbacz-Klempka a, M. Piękoś a, J. Kozana a, W. Cieślak a,

a

AGH-University of Science and Technology, Faculty of Foundry Engineering, Reymonta 23, 30-059 Krakow, Poland

b

Foundry Research Institute, Zakopiańska 73, Krakow, Poland

*Corresponding author. E-mail address: rzadkosz@agh.edu.pl

Received 31.03.2014; accepted in revised form 10.04.2014

Abstract

The work presents experiment results from the area of copper casting technology and chosen examples of alloyed copper. At present,

copper casting technology is applied in many branches of industrial manufacturing, especially in the sector of construction,

communications, arms and power engineering. Alloyed copper, containing slight additions of different elements and having special

physio-chemical properties, is used in a special range of applications. Copper technology and alloyed copper analyses have been presented,

these materials being used for cast manufacturing for power engineering. The quality of casts has been assessed, based on their

microstructure analysis, chemical content and the cast properties. During the research, special deoxidizing and modifying agents were

applied for copper and chosen examples of alloyed copper; also exemplary samples were tested with the help of metallographic analysis,

electrical conductivity and gaseous impurities research.

Keywords: Casting technology, Copper, Alloyed copper, Copper deoxidation, Heat treatment

Producing chromium copper casts is connected with

1. Introduction technological problems, especially during melting and liquid

metal preparation process. This is caused by unfavourable

Modern industry, and especially the sector of power

properties of the material, among others significant differences in

engineering and electronics, sets very high standards for the

melting temperature and specific gravity of the alloyed elements,

materials used there. They should be characterised by high

namely of Cu and Cr. But the greatest difficulties are caused by

physical and functional properties, such as high electrical and

their different oxygen affinity. [5]

thermal conductivity, high strength, resistance to abrasion and

Copper, having low activity in comparison to oxygen, creates

corrosion [1-4]. The basic material used for casts manufactured

easily soluble oxides, while chromium creates Cr2O3, which is

for power engineering industry is copper. Its electrical

insoluble and difficult to remove from the bath. It it the reason of

conductivity is the highest of all technical metals used in casting

many defects lowering the cast properties, mainly through

(58MS). However, the mechanical properties of copper are

creating discontinuities of structure, which has direct influence on

relatively low, that is why, often small additions of other elements

strength parameters; thermal and electrical conductivity. High

are introduced, which improve resistance to mechanical wear.

shrinkage and the proclivity to create slag which is difficult to

One of the copper alloys meeting high strength and functionality

remove, causes the appearance of shrinkage cavities and slag

requirements, and also characterised by good thermal and

inclusions. A negative phenomenon resulting from high

electrical conductivity is chromium copper. [5]

chromium affinity for oxygen is a significant melting loss,

ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84 79

causing changes of chemical composition and physio-chemical Nikon Eclipse LV150 type, with a magnification of 50x – 500x.

properties of the material melted. [7-8] The exemplary results for copper deoxidized with different agents

The difficult technology of melting and casting copper and are collated in Table 1.

alloyed copper poses a set of challenges. Conducting research and

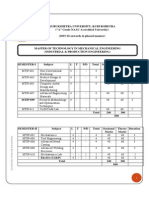

attempts of optimization of the melting technology and refining Table 1.

the metal bath of copper and alloyed copper is indispensable for Deoxidizing influence on the oxygen content and electrical

achieving the highest levels of cast quality. conductivity of copper

Electrical

Oxygen content

Agent Amount,% conductivity

O2 [ppm]

2. Researching copper casts MS

1 - - 24 2260

2 - - 30 1290

2.1. Researching copper melting and deoxi- 4 Logas 0,15 54 73

5 CuP12 0,2 48 98

dation technologies 6 CuP12 0,3 55 34

Copper casts were analysed from the perspective of melting 8 Li 0,05 54 39

parameters and the efficiency of the influence of deoxidation 9 P3 0,5 55 93

technology on the structure and properties of copper and copper 10 ODM2 0,3 55 16

alloys. Also, the influence of modifying elements applied in the 11 Kupmod 2B 0,2 53 24

refining agents was tested in order to obtain the optimal cast

properties, of among others, primary coils used in power The analysis of deoxidizing treatments shows varied influence

engineering. Microstructure changes and cast properties were of different agents. Phosphor introduced into the metal bath

analysed. The most important copper properties are electrical and causes reduction of copper oxide (I) 5Cu2O + 2P = P2O5 + l0Cu

thermal conductivity as well as mechanical properties of casts. [1], and in the final stage it increases the flowing power of the

Next, the resistivity to corrosion was tested. The high values of liquid metal, which allows the slags, oxides and other impurities

the above-mentioned properties are obtained by the proper to float to the surface of copper bath. This treatment makes it

preparation of liquid metal, mainly by removing gaseous possible to obtain a structure free from solid non-metallic

impurities. Oxygen and hydrogen are gasses, which are absorbed inclusions, which in an obvious way influences technological

in copper. Their presence causes porosity (Fig. 1) and properties of an alloy.

unfavourable eutectic microstructure in casts. [6-8] Introducing active lithium into the metal bath causes an

intense reaction with oxygen in the deoxidizing process

temperature, according to 2Li + O2 → Li2O + 136 kcal. Also, it

reacts with hydrogen, according to Li +1/2H2=:LiH + 22 kcal. The

created lithium oxide floats to the surface and passes into the slag,

but the lithium hydride solves into the bath and lowers the metal

properties [2]. Strong deoxidizing properties of boron are

connected with active binding of oxygen into an oxide. B2O3

oxide reacts with oxidized copper, creating 2Cu2O.B2O3 [6]. The

addition of 0,02% of beryllium is introduced into copper in CuBe

treatments. Copper deoxidized with beryllium does not show

porosity or surface defects, also it has high thermal conductivity

and increased strength. Microstructures characteristic for copper

in the original state, and also after melting and deoxidizing

process are presented in Figure 2.

Modern refining technologies for liquid metal that is designed

Fig. 1. Gaseous porosity in the copper cast section for special casts are more and more efficient and they make it

possible to obtain high purity material.

Nowadays, to remove impurities a range of elements with The effect observed in copper caused by different deoxidizing

high affinity for oxygen is used, the most important of them being or deoxidizing and modifying agents is distinctly visible. Also,

phosphorus, lithium, magnesium, boron and beryllium. Electrical deoxidizing copper with the help of different complex formulas is

conductivity was analysed with the help of SIGMA TEST 2.067, interesting because they influence the microstructure and oxygen

a conductivity testing appliance, manufactured by Forster. content to a significant degree.

Strength parameters were tested on the machined samples cast Copper as matrix shows high values of electrical and thermal

into ceramic moulds. The samples cut from the casts were conductivity and it is rather resistant to atmospheric corrosion,

machined with Metasinex metalographic grinder, and next the however, pure copper has relatively low strength.

samples were polished using Montasupal machine. The polished Well-deoxidized copper was used in further research for

sections were etched by a mixture of acids. The microstructures preparing melts of alloyed copper. Within the scope of our

were observed with the help of metallographic microscope of research, structure and properties of various kinds of alloyed

80 ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84

copper were investigated, including slight additions of, e.g., and rocket engines. A characteristic feature of this material is its

chromium, nickel, zirconium, silicon, beryllium, iron, titanium relatively high electrical conductivity in comparison with other

and other elements. copper alloys. A great advantage of chromium copper is its heat

workability, resulting from changeable solubility of chromium in

a) b) copper. The maximum solubility of chromium in copper in solid

state is in the temperature of 1076.6°C and it equals 0.89%. It

decreases in step with decreasing temperature, and, for example in

700°C – 0.07%, in 400°C it is 0.02% and it falls to 0.01% in room

temperature [5].

Table 2.

The influence of chromium additions on copper properties

Cr addition, % Rm, MPa A5, % MS HV

0 150,20 48 57 50

0,4 192,50 36,1 45,2 105

Fig. 2. Original copper microstructure. Oxygen content 2600 ppm. 0,8 255,30 30,8 35,4 162

Dendritic crystallites of copper are visible (light) on the Cu-Cu2O 1,3 271,00 22,2 27,4 191

eutectic background (dark) (a). Copper microstructure after the 1,6 282,70 20,8 23 210

deoxidizing CuP treatment. Oxygen content 230 ppm. Dendritic 2,1 270,50 15 19,5 208

crystallites of copper are visible (light) and Cu-Cu2O eutectic 2,4 248,10 11,4 16 214

precipitates (dark) in the interdendritic regions (b). Magn. 200x.

The attempts at obtaining chromium copper with optimal

Particular properties of some kinds of alloyed copper are functional properties are connected with examining the

connected not only with its chemical content but also with the deoxidation process. The tests were carried out on samples

alloy structure and the refining treatment applied. These alloys obtained from alloys containing from 0.4 to 2.4 % of Cr (Table 2).

show relatively low technological properties as well as a tendency The electrical conductivity tests show that this property decreases

for many casting defects, which decrease their physio-chemical as the chromium content grows. During our investigations

properties. different formulas were used, but in this paper the exemplary

A difficult technology of the above-mentioned materials results are shown for the formulas containing phosphor and boron

requires further research aimed at implementing new solutions in Table 3 and in Figure 3-4.

that would result in their increased quality. [9-12]

A lot of attention is paid to the problems of shaping structures Table 3.

of the Cu-Cr, Cu-Cr-Zr, Cu-Ni-Si, Cu-Ni-Cr alloy types, among The influence of deoxidation on electrical conductivity of

others. Within the research framework, macro-and microstructure chromium copper

of the alloys was analysed, as well as their intermetallic phases Conductivity, Oxygen,

No. Alloy Deoxidizer

and properties of the chosen alloys. The influence of deoxidation MS ppm

processes, refining and modifications on the structure and 13 pure Cu - 53 200

properties of the alloys was investigated. Protective and refining 14 CuCr (1,4%Cr) - 26 61

slags were applied during melting, as well as characteristic micro- 15 CuCr (1,4%Cr) CuP (0,22%) 27 75

additives, deoxidizing and modifying the structure of the chosen 16 CuCr (1,8%Cr) - 20 550

alloys. Also, the properties were analysed in connection with the

Desofin0,26

heat treatment parameters. During the stock melting process, to 17 CuCr (1,8%Cr) 24 50

%

minimize the non-returnable losses, the argon protective

atmosphere was used or protective coating in the form of 18 CuCr (1,8%Cr) CuB2 1,5% 23 65

charcoal, as well as protective-refining slags, with fluoride salts

were applied. The effects were assessed form the point of view of a) b)

changes in macro- and microstructure, changes of mechanical

properties and electrical conductivity. High conductivity copper

and electrolytic copper were used as metal stock.

2.2. Casting of chromium copper

Chromium copper is used for manufacturing welding

electrodes, electrical cable connectors, switches, collectors, Fig. 3. The microstructure of chromium copper CuCr1.3, cast into

machine parts subject to intense abrasion under electric voltage a ceramic mould. Magnification 500x. Etched with Mi 17 (a). The

and high temperatures, heat exchangers, parts of blast-furnace microstructure of chromium copper CuCr1.3, deoxidized with

burners and blowpipes as well as parts of valves, nuclear reactors 0.1% P, cast into a ceramic mould. Magnification 500x. Etched

with Mi 17 (b)

ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84 81

a) b) After the heat treatment, in the microstructure, there are spherical

chromium precipitates against the background of equiaxial,

recrystallized grains of chromium in copper solution; the hardness

increase after ageing results from dispersive chromium

precipitates in the grains.

Table 5.

The influence of ageing on properties

Time, HB hardness Conductivity, MS

Fig. 4. The microstructure of chromium copper CuCr1.8, cast into h Ageing temperature Ageing temperature

a ceramic mould. Magnification 500x. Etched with Mi 17 (a). The 0 600 500 450 400 600 500 450 400

microstructure of chromium copper CuCr1.8 with 1% CuB2 0,1 41 41 41 41 20 20 20 20

addition, cast into a ceramic mould. Magnification 500x. Etched 0,2 42 43 42 41 21 21 21 21

with Mi 17 (b) 0,5 100 130 62 43 24 22 22 23

1,0 90 120 115 122 34 28 24 38

2,0 80 105 120 130 37 35 32 40

2.3. The influence of zirconium additions 4,0 70 100 115 122 40 40 37 41

8,0 60 100 110 117 40 41 39 41

Among many modifying agents, there were analysed

additions of nucleation elements such as zirconium, boron,

titanium, vanadium, tungsten, as well as salt formulas of the 3. The influence of silicon additions on

above-mentioned elements; used as modifying mixtures or

complex, modifying and oxidizing slags (Table 4). After the CuNiSi alloy properties

introducing zirconium additions its positive influence on the

structure of chromium copper can be observed. A series of tests were conducted of the influence of nickel,

At the same time, zirconium additions lower electrical chromium and silicon additions on the structure and properties of

conductivity of chromium copper. CuNi2SiCr copper. Next, the simultaneous influence of these

elements was researched, with a changeable amount of silicon

Table 4. addition. The range of metals examined makes an interesting

The conductivity of alloyed copper CuCr and CuCrZr group of copper matrix materials, with good physio-chemical

No. Alloy Conductivity, MS properties, and especially good mechanical features, accompanied

1 pure Cu 50 by good thermal and electrical properties. The influence of varied

2 CuCr (1,5%Cr 24 chromium additions was analysed, within the range of up to

3 CuCr (1,5%Cr) 22 0.6%, as well as varied silicon additions of up to 2.2%.

4 CuCr (2,2%Cr) 22,5 Microstructure changes were analysed, as well as changes in

5 CuCrZr (2,2%Cr, 0,2%Zr) 20,5 hardness and electrical conductivity. These characteristics are

6 CuCrZr (2,2%Cr, 0,2%Zr) 20 typical of the group of alloys researched, and are decisive about

7 CuCrZr (2,2%Cr, 0,2%Zr) 18,5 their application in engineering.

8 CuCrZr (2,16%Cr, 0,2%Zr) 18,5 The research conducted showed, that the alloy hardness increases

significantly after introducing 0.6% chromium addition. It is

connected with the fact that in the microstructure there are

2.4. Heat treatment chromium phases appearing, located inside the grains at their

boundaries. Also, after introducing into deoxidized copper the

Heat treatment is an important element of technological

additions of chromium (0.8%) and nickel (2.1%), and casting the

process, and it is applied with the aim of obtaining casts with high

initial samples, the varied additions of silicone were administered,

functional properties. This process consists of two parts: solution

in the amounts ranging from 0.4 to 2.2%. The tests results were

heat treatment and ageing. During solution heat treatment the

casts are first held at the temperature of 20-50°C above the compared with the test results for the initial sample (Table 6).

solidus line, and next there is a quick cooling, most often in water,

with the aim of arresting chromium in the matrix. Soaking time Table 6.

The influence of silicone additions on the CuNi2,1Cr0,6Si, cast

should be long enough to ensure that all of the chromium is

into metal mould

solved within the whole volume of the cast [7-8]. Solution heat

treatment causes lowering electrical conductivity to the value of Addition Conductivity,

No. Rm, MPa HB A5, %

20–24 MS (Table 5). Si, % MS

The second stage of heat treatment is ageing. Is consists of re- 0 0 148,4 55 48,8 34

heating and air cooling. Ageing aims at precipitation of Cr from 1 0,8 332,6 98 26,8 12,6

2 1,3 360,1 132 14,6 10,1

supersaturated solution in the form of precipitates, which

3 1,7 420,6 145 9,6 9

significantly increase alloy strength. The process in conducted in 4 2,2 355,8 164 6 6,5

the temperature of 450-510°C. The heating takes from 1,5 to 4 h.

82 ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84

The microstructure was assessed on the basis of the chosen a) b)

micro sections. A coarse-grained macro-structure of equiaxial

grains was established, with clearly seen dendritic heterogeneity,

without any gas or shrinkage porosity.

For further investigations the CuNi2Si0,8 alloy was chosen.

The samples to be investigated were cast into metal and sand

moulds. The chosen samples were heat-treated, in order to

establish the possibility of dispersive strengthening of the cast

structure. The exemplary research results of macro-and

microstructures are collated in Figures 5 and 6.

a) b)

c) d)

c) d)

Fig. 6. The microstructure CuNi2Si0,8 after the heat treatment,

sand moulds (a, b), metal moulds (c,d). Etched with Mi21,

Magnification 50x (a,c), 500x (b,d)

Table 7.

Mechanical properties of the CuNi2Si0,8 alloy

Alloy Conductivity, Rm,

No. A5, % HV

state MS MPa

1 Lp 9,5 235 7,6 80

2 Lk 15 380 15,2 91

3 Lp-R6 16 320 3,2 118

Fig. 5. The microstructure CuNi2Si0,8 sand moulds (a, b), metal 13

4 Lk-R6 600 2,5 148

moulds (c,d). Etched with Mi21, Magnification 50x (a,c), 500x

(b,d)

Based on the microscopic analysis it can be ascertained that

increasing the chromium content above 0.8% brings about

The microstructure of the alloys researched has dendritic

appearing the intermetallic phase precipitates, especially at the

character with small precipitates of intermetallic phases in

boundary of intercrystalline grains. According to the data, it is the

interdendritic regions. In the case of metal moulds a greater size

original chromium phase. The addition of silicon and nickel

reduction of primary structure is visible, and clearly compact

causes the fact that in the microstructure there is a clear, dendritic,

structure of the solid state. In the sand moulds slow solidification

reduced in size structure of solid state, and in the interdendritic

is conducive to microporosity appearing at places.

region there may appear Ni2Si phases (Fig 5).

After the heat treatment the heterogeneity disappears. There

The results of a microstructure (Fig. 7), research conducted

are only grain outlines of solid state visible in the microstructure,

with the help of scanning microscope Hitachi S-4200 coupled

without the intermetallic phase precipitates from the interdendritic

with the system detecting and analysing EDS type of X-ray,

regions. The changes in microstructure cause changes in strength

properties. The exemplary results of strength tests are collated in registered at the 15kV accelerating voltage showed - Table 8.

Table 7.

ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84 83

pollution of the bath. An important element of refining

chromium copper is the deoxidation process conducted most

easily with deoxidizing master alloys, such as CuP, CuB2.

− applying modifying treatments causes slight improvement

in the degree of grain size-reduction,

− there is a clear increase in strength parameters and electrical

conductivity after the heat treatment of chromium copper,

− the research confirmed the engineering difficulties present

during the melting process – during the melting and pouring

the liquid metal into the moulds, the parameters must be

strictly observed,

− silicon additions in multicomponent materials on copper

matrix, also with chromium and nickel, clearly improve

technological properties, and, at the same time, their

strength properties.

Fig. 7. The microstructure CuNi2Si0,8 References

Table 8. [1] Górny, Z. (1995). Non-ferrous metals and their casting

The microanalysis of phases results for CuNi2Si0.8 alloy (Fig.8) alloys – melting, casting, structures and properties. Krakow:

Element Int. c/s Atomic, % Conc, % Ed. Foundry Research Institute.

Si 11.69 13.721 6.623 s1mar1 [2] Górny, Z. & Sobczak, J. (2001). Modern casting materials

Mn 0.30 0.171 0.161 based on non-ferrous metals. Krakow: Ed. Foundry Research

Institute.

Fe 0.98 0.552 0.530

[3] Dies, K. (1967). Copper and copper alloys in technique.

Ni 10.68 7.123 7.185 Berlin: Springer Verlag ed.

Cu 62.52 78.211 85.409 [4] Kurski, K. (1967). Copper and copper technical alloys.

Si 26.95 27.673 15.041 s2mar2 Katowice: Silesian ed.

Mn 0.49 0.275 0.293 [5] Rdzawski, Z. (2009). Alloyed copper. Gliwice: Ed. Silesian

Fe 2.60 1.481 1.600 Univ. of Technology.

Ni 38.85 35.818 40.685 [6] Rdzawski, Z., Ducki, K., Jabłońska, M. & Śmiglewicz, A.

(2010). Properties and microstructure of CuNi2Si1 alloy.

Cu 28.56 34.283 42.160

Rudy i Metale NieŜelazne. 55(2), 78-83.

Si 3.45 4.325 1.964 s2mar3 [7] Rzadkosz, S., Kranc, M., Nowicki, P. & Piękoś, M. (2009).

Mn 0.00 0.000 0.000 Refining processes of selected copper alloys. Archives of

Fe 0.62 0.289 0.261 Foundry Engineering. 9(2), 29-34.

Ni 2.00 0.940 0.892 [8] Rzadkosz, S., Kozana, J. & Kranc, M. (2013). Researching

Cu 73.24 94.200 96.78 the influence of chemical composition and technological

parameters on the quality of copper alloys. Archives of

Foundry Engineering. 13(spec. 1), 153-158.

[9] Rzadkosz, S., Garbacz-Klempka, A. & Kranc, M. (2010).

4. Conclusions Structural examinations of selected copper castings. Archives of

Foundry Engineering. 10(spec. 1), 435-440.

In the course of our research it was established that: [10] Rzadkosz, S., Kranc, M., Garbacz-Klempka, A., Kozana, J.

− the most important element in copper and alloyed copper & Piękoś, M. (2013). Investment casting technology applied

casting is creating the optimal conditions of melting and to copper alloys. Archives of Foundry Engineering. 13 (spec.

efficient impurities extraction with the help of oxygen and 3), 143-148.

hydrogen. During melting, the possibility of contact of the [11] Rzadkosz, S., Kranc, M., Nowicki, P. & Piękoś, M. (2009).

bath with any sources of impurities should be limited, Influence of refining operations on a structure and properties

through applying proper protective atmosphere and of copper and its selected alloys. Archives of Metallurgy and

protective-refining slags. Materiale. 54(2), 299-304.

− as stock materials pure kinds of copper should be used, [12] Drápala, J., Kubíček, P., Kostiuková, G. & Jopek, P. (2013).

electrolytic copper and CuCr12 master alloy. The furnaces Study of interaction between copper and melt of lead-free

used should enable fast melting of the metal stock, limiting solders. Metalurgija. 52(4), 509-511.

the possibility of polluting the metal. One of the ways of

checking the alloy quality is measuring electrical

conductivity of copper. Lower conductivity may indicate

84 ARCHIVES of FOUNDRY ENGINEERING Volume 14, Issue 2/2014, 79-84

You might also like

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- Refining Processes in The Copper Casting Technology: S. Rzadkosz, M. Kranc, A. Garbacz-Klempka, J. Kozana, M. PiękośDocument4 pagesRefining Processes in The Copper Casting Technology: S. Rzadkosz, M. Kranc, A. Garbacz-Klempka, J. Kozana, M. PiękośエリタノアンソネーNo ratings yet

- Kho Swinbourne10 mpm188 EAFDocument9 pagesKho Swinbourne10 mpm188 EAFRICCO LauwisNo ratings yet

- High-Strength Aluminium Alloys and Their Use in Foundry IndustryDocument7 pagesHigh-Strength Aluminium Alloys and Their Use in Foundry Industryferhat aydoganNo ratings yet

- Iwcc Cu-Vortrag AldDocument16 pagesIwcc Cu-Vortrag Aldhadjlarbi-h100% (1)

- Kho Swinbourne10 Mpm188 EAFDocument9 pagesKho Swinbourne10 Mpm188 EAFalilounahdisteNo ratings yet

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringDocument6 pagesCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringAgil SetyawanNo ratings yet

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringDocument6 pagesCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringSaif UllahNo ratings yet

- Metalurgia Física ModernaDocument20 pagesMetalurgia Física ModernaMariliaFrancoNo ratings yet

- Morphology and Frictional Characteristics Under Electrical Currents of Al2O3 Cu Composites Prepared by Internal OxidationDocument8 pagesMorphology and Frictional Characteristics Under Electrical Currents of Al2O3 Cu Composites Prepared by Internal Oxidationmohamed aliNo ratings yet

- Tribological Properties of Cu Based Composite Materials Strengthened With Al O ParticlesDocument4 pagesTribological Properties of Cu Based Composite Materials Strengthened With Al O ParticlesNoura Nour ElshamsNo ratings yet

- pp58-64 MS09 PDFDocument7 pagespp58-64 MS09 PDFBagičan KrivuľkosNo ratings yet

- A Comprehensive Review of Recent Advances in Magnesia Carbon RefractoryDocument9 pagesA Comprehensive Review of Recent Advances in Magnesia Carbon RefractorySoumya MukherjeeNo ratings yet

- Impact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CDocument9 pagesImpact Toughness of The Duplex Stainless Steel SAF 2304, With HeatinG 1100-1300 CwiNo ratings yet

- Simko SiCcorrosionDocument10 pagesSimko SiCcorrosionJarmilaMlynárikováNo ratings yet

- Journal of Manufacturing Processes: Mingfeng Li, Yanjun Wang, Shanglu Yang, Wu Tao, Guotao ZhangDocument12 pagesJournal of Manufacturing Processes: Mingfeng Li, Yanjun Wang, Shanglu Yang, Wu Tao, Guotao Zhangfara latifaNo ratings yet

- Comparison of Methods For Determining The Ferrite Content in Duplex Cast SteelsDocument6 pagesComparison of Methods For Determining The Ferrite Content in Duplex Cast SteelsDaniel Esteban Barra MuñozNo ratings yet

- Influence of ZN and MG Alloying On The Corrosion Resistance Properties of Al Coating Applied by Arc Thermal Spray Process in Simulated Weather SolutionDocument13 pagesInfluence of ZN and MG Alloying On The Corrosion Resistance Properties of Al Coating Applied by Arc Thermal Spray Process in Simulated Weather SolutionMarlon Steven PerazaNo ratings yet

- Copper and Copper AlloysDocument19 pagesCopper and Copper AlloysYousef Adel HassanenNo ratings yet

- Surface Conformed Approach For Mechanical Property Analysis Using Ultrasonic Welding of Dissimilar MetalsDocument20 pagesSurface Conformed Approach For Mechanical Property Analysis Using Ultrasonic Welding of Dissimilar Metals林哲宇No ratings yet

- Comparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessDocument7 pagesComparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessIJAR JOURNALNo ratings yet

- Crystals 11 01091 v2Document12 pagesCrystals 11 01091 v2Gian Luca Riva RiquelmeNo ratings yet

- Muhammad 2021 IOP Conf. Ser. Mater. Sci. Eng. 1173 012061Document10 pagesMuhammad 2021 IOP Conf. Ser. Mater. Sci. Eng. 1173 012061joydip1990xNo ratings yet

- Copper-AlloysDocument9 pagesCopper-AlloysRm OtNo ratings yet

- Aalco Datasheet Cu SpecificationsDocument13 pagesAalco Datasheet Cu SpecificationsKhushal NakadeNo ratings yet

- Effect of Heat Treatment and Bath Composition of Electroless Nickel-Plating On Cavitation Erosion ResistanceDocument23 pagesEffect of Heat Treatment and Bath Composition of Electroless Nickel-Plating On Cavitation Erosion ResistanceSantiago TuestaNo ratings yet

- Toughness of 2,25Cr-1Mo Steel and Weld Metal: Articles You May Be Interested inDocument8 pagesToughness of 2,25Cr-1Mo Steel and Weld Metal: Articles You May Be Interested inNathalieHemmelmannNo ratings yet

- The Importance of Interlayers in Diffusion Welding - A ReviewDocument5 pagesThe Importance of Interlayers in Diffusion Welding - A Review2022353017No ratings yet

- Oh2020-Enhanced Stability and Electrocatalytic Activity of Graphene On Coppernickel Alloys For Hydrogen Production From WastewaterDocument9 pagesOh2020-Enhanced Stability and Electrocatalytic Activity of Graphene On Coppernickel Alloys For Hydrogen Production From WastewaterK A ThomasNo ratings yet

- Manpreet Et Al 2010Document12 pagesManpreet Et Al 2010manpreetNo ratings yet

- Experimental Analysis of Aluminium Alloy Reinforced With Rare Earth MetalsDocument12 pagesExperimental Analysis of Aluminium Alloy Reinforced With Rare Earth MetalsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Artigo 8 (2016)Document10 pagesArtigo 8 (2016)vianaufgNo ratings yet

- Weldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. SmithDocument7 pagesWeldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. Smithนรวิชญ์ กาญจนามัยNo ratings yet

- Effect of Steel Composition and Slag ProDocument5 pagesEffect of Steel Composition and Slag ProAbhinandan ChatterjeeNo ratings yet

- Electroplating: Applications in The Semiconductor Industry: Jivaan Kishore Jhothiraman, Rajesh BalachandranDocument23 pagesElectroplating: Applications in The Semiconductor Industry: Jivaan Kishore Jhothiraman, Rajesh BalachandranSharan KumarNo ratings yet

- 59 - 1 - Begic HadzipasicDocument10 pages59 - 1 - Begic HadzipasicGéssica PalaoroNo ratings yet

- Resisting Metal Dusting CorrosionDocument2 pagesResisting Metal Dusting CorrosionRonald MesinaNo ratings yet

- Afe2019 2 Kozana Lead-FreeDocument6 pagesAfe2019 2 Kozana Lead-FreeGennady KozyukinNo ratings yet

- Evaluation of The Electrical Properties of Carbon Electrodes Developed With Bio-Material Additions As A Sacrificial Anode in Cathodic ProtectionDocument12 pagesEvaluation of The Electrical Properties of Carbon Electrodes Developed With Bio-Material Additions As A Sacrificial Anode in Cathodic ProtectionFrancisco Javier Dominguez De Los SantosNo ratings yet

- Geometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingDocument15 pagesGeometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingMathews LimaNo ratings yet

- Welding Feasibility of Copper and Mild Steel Using TIG WeldingDocument3 pagesWelding Feasibility of Copper and Mild Steel Using TIG WeldingselavilizationNo ratings yet

- 2014Atabaki.MM焊接综述-强度损失Welding of aluminum alloys to steels an overviewDocument20 pages2014Atabaki.MM焊接综述-强度损失Welding of aluminum alloys to steels an overview1643150672No ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- A Comparative Electro-Mechanical Characterization of Tin-Lead Solder With Equal ProportionDocument6 pagesA Comparative Electro-Mechanical Characterization of Tin-Lead Solder With Equal ProportionAmitav BaruaNo ratings yet

- SMAW ArticuloDocument14 pagesSMAW ArticuloLuis RiveraNo ratings yet

- The Assessment of Modification of High-Zinc Aluminium Alloy: Archives of Foundry EngineeringDocument4 pagesThe Assessment of Modification of High-Zinc Aluminium Alloy: Archives of Foundry EngineeringPhung Tuan AnhNo ratings yet

- Corrosion Brass, Steel and Brass Coated WiresDocument13 pagesCorrosion Brass, Steel and Brass Coated WiresMichaela JoanidisovaNo ratings yet

- Effect of Cerium and Lanthanum On The Microstructurea ND Mechanical Properties of AISID 2 Tool SteelDocument6 pagesEffect of Cerium and Lanthanum On The Microstructurea ND Mechanical Properties of AISID 2 Tool SteelMatheus BoligonNo ratings yet

- 07 Copper and Copper AlloysDocument10 pages07 Copper and Copper Alloysdesi oktaviaNo ratings yet

- Application and Use of Different Aluminium AlloysDocument10 pagesApplication and Use of Different Aluminium AlloysSimon RečnikNo ratings yet

- The Electrodeposition of Ternary Fe-Cr-Ni AlloysDocument28 pagesThe Electrodeposition of Ternary Fe-Cr-Ni AlloysMariianiita SalvatoreNo ratings yet

- Research On Corrosion Mechanism of Overhead ConductorDocument4 pagesResearch On Corrosion Mechanism of Overhead ConductorJALIR ANDRE HUAYLLAS SOTONo ratings yet

- Materials 15 01621 v2Document14 pagesMaterials 15 01621 v2Ricardo GordilloNo ratings yet

- Project DeepakDocument36 pagesProject DeepakSuneesh ENo ratings yet

- Metals 12 01314 v2Document11 pagesMetals 12 01314 v2aa999666aaaNo ratings yet

- Effect of Shielding Gases On Austenitic Stainless Steel Overlay by FCAW Process On Low Alloy SteelDocument7 pagesEffect of Shielding Gases On Austenitic Stainless Steel Overlay by FCAW Process On Low Alloy SteelAdam Al AufaNo ratings yet

- Manikandan 2016 IOP Conf. Ser.: Mater. Sci. Eng. 149 012020Document13 pagesManikandan 2016 IOP Conf. Ser.: Mater. Sci. Eng. 149 012020Sayiram GNo ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- 0476Document4 pages0476Minette PacisNo ratings yet

- Raman, 1998Document10 pagesRaman, 1998Luan CaetanoNo ratings yet

- Effect of Preheating Temperature On The Microstructure and Corrosion Resistance of Tic-Ni Coating by Cs/PhipDocument11 pagesEffect of Preheating Temperature On The Microstructure and Corrosion Resistance of Tic-Ni Coating by Cs/Phipชลธิชา โยชาลีNo ratings yet

- (Archives of Foundry Engineering) Al-Si and Al-Si-Mg Cast Alloys Shrinkage Porosity EstimationDocument8 pages(Archives of Foundry Engineering) Al-Si and Al-Si-Mg Cast Alloys Shrinkage Porosity EstimationSaeid MirNo ratings yet

- Qin 2021 J. Phys. Conf. Ser. 1798 012013Document7 pagesQin 2021 J. Phys. Conf. Ser. 1798 012013Ramoul ChamseddineNo ratings yet

- Metals 13 01138Document23 pagesMetals 13 01138ชลธิชา โยชาลีNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Melting PracticeDocument17 pagesMelting PracticeAshish Kumar Jha100% (1)

- Foundry Tech Lesson Plan 8a 2014 2015Document3 pagesFoundry Tech Lesson Plan 8a 2014 2015Manjunatha EikilaNo ratings yet

- Copper e FinalDocument12 pagesCopper e FinalgoranNo ratings yet

- Ppce Unit VDocument35 pagesPpce Unit VVignesh vikiNo ratings yet

- Application of Waste Foundry Sand For Evolution of Low-Cost ConcreteDocument6 pagesApplication of Waste Foundry Sand For Evolution of Low-Cost ConcreteseventhsensegroupNo ratings yet

- Inventory ManagementDocument122 pagesInventory ManagementSahil Goutham100% (1)

- CarriersDocument28 pagesCarriersferdockmNo ratings yet

- Programme Book-IMMC2016Document76 pagesProgramme Book-IMMC20165085546100% (1)

- History of Metal CastingDocument17 pagesHistory of Metal CastingMobaraz KhokharNo ratings yet

- Bentonite For FoundriesDocument4 pagesBentonite For FoundriesSiddharth GuptaNo ratings yet

- Poster 2021 MM 33Document4 pagesPoster 2021 MM 33Hassan bhattiNo ratings yet

- Literature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Document115 pagesLiterature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Patricia BrandNo ratings yet

- Tesda Courses OfferedDocument18 pagesTesda Courses OfferedRyann Zandueta ElumbaNo ratings yet

- HMT Training Report PDFDocument40 pagesHMT Training Report PDFMohammedNo ratings yet

- c311316a-f4ce-4ddf-b262-c91d2b9f1c32Document13 pagesc311316a-f4ce-4ddf-b262-c91d2b9f1c32Ciro Antonio Zuñagua LLanosNo ratings yet

- Visvesvaraya Technological University: Government Engineering CollegeDocument8 pagesVisvesvaraya Technological University: Government Engineering CollegeSHARATH KMNo ratings yet

- Foundry MechanizationDocument15 pagesFoundry MechanizationShaaf Amjad100% (2)

- 2005 AFS - Metallurgical Comparisons Between Operating Conditions, Inoculant Types and Fade Effects in Grey IronDocument12 pages2005 AFS - Metallurgical Comparisons Between Operating Conditions, Inoculant Types and Fade Effects in Grey Irondemiancito06No ratings yet

- Beneficial Use of Foundry By-Products in Highway ConstructionDocument9 pagesBeneficial Use of Foundry By-Products in Highway ConstructionPauloDyerNo ratings yet

- Lecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal AhmadDocument99 pagesLecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal Ahmadjawad khalidNo ratings yet

- Badger Alloys NextGenTraditionalProcess EbookDocument8 pagesBadger Alloys NextGenTraditionalProcess Ebookmakdeep2012No ratings yet

- Found AryDocument30 pagesFound AryKawish TamourNo ratings yet

- Vacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000Document8 pagesVacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000sureshkumar908No ratings yet

- 03 TPJ - Qatalum - The Aluminium Company in QatarDocument42 pages03 TPJ - Qatalum - The Aluminium Company in QatarFelipe SineiderNo ratings yet

- ABI Group Presentation PDFDocument69 pagesABI Group Presentation PDFRangaswamy DoraiswamyNo ratings yet

- MCP Rapid ToolingDocument14 pagesMCP Rapid ToolingsferrandNo ratings yet

- BBA ProjectDocument54 pagesBBA ProjectAffy LoveNo ratings yet

- Us Army CC It0674 Analyze Fabrication Industries On Aerial ImageryDocument54 pagesUs Army CC It0674 Analyze Fabrication Industries On Aerial Imageryernst1978100% (1)

- Foundry BasicsDocument30 pagesFoundry BasicsDr. B. Ramesh100% (1)