Professional Documents

Culture Documents

Tds Polybit-Polypoxy-Ct en Mea

Uploaded by

khaleejdubai jubailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds Polybit-Polypoxy-Ct en Mea

Uploaded by

khaleejdubai jubailCopyright:

Available Formats

Polypoxy CT

Bitumen Modified Epoxy Coating

characteristics

► Excellent chloride & sulphate resistance

► High build coating, no primer required

► Excellent long term corrosion protection

► Abrasion resistant

► Seam less finish

► Easy to apply – can be applied by brush, roller or spray.

TDS_Polypoxy CT_GCC_0519

► Economical

abrasion

resistant

DESCRIPTION

Polypoxy CT is a two component bitumen modified liquid

epoxy resin coating. Polypoxy CT is a high build, dense, 1

coating designed to protect concrete and metal structures.

FIELDS OF APPLICATION prepared substrate to achieve a uniform coating with

To provide protection to concrete and metal minimum wet film thickness of 200 microns. Subsequent

structures such as:- coats shall be applied after the coating achieves its initial

– concrete foundation cure.

– steel pipes & ferrous metals COVERAGE

– off shore and marine structures

4m2/lt./coat will give a Dry Film Thickness of 200

APPLICATION INSTRUCTIONS micron.

Surface preparation CLEANING

Surface to be coated with Polypoxy CT should be Clean all equipments with Polysolvent immediately after

structurally sound, dimensionally stable, clean and free use. Hardened materials can be removed mechanically

from laitance, oil or any other contaminants. Grit blasting only.

is recommended for complete removal of deleterious

materials and other contaminants which will affect the STORAGE & SHELF LIFE

adhesion from the substrate. Store in a cool, dry place and keep away from all sources

Mixing of heat and sunlight. In tropical climates, store in air

Mix part A and part B separately for a minute and then condition rooms. The shelf life is up to 6 months in un-

transfer Part B (reactor) to Part A (base) and mix thoroughly opened conditions and if stored as per recommendations.

for 2 –3 minutes to get a uniform homogenous consistency. excessive exposure to sunlight, humidity and UV will result

Use a slow speed electric drill with a proprietary mixing in the deterioration of the quality of the product and reduce

paddle. its shelf life.

Application HEALTH & SAFETY

Polypoxy CT can be applied by brush, short hair roller As with all construction chemical products, caution should

or airless spray. Apply the mixed material to a properly always be exercised. Protective clothing such as gloves

and goggles should be worn. Treat any splashes to the TECHNICAL SPECIFICATION

skin or eyes with fresh water immediately. Should any of

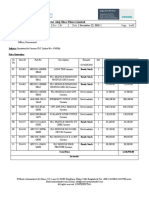

PRoPeRTieS VAlUeS

the products be accidentally swallowed, do not induce

vomiting, but call for medical assistance immediately. Appearance Black

ensure the container is available for the medical attendant Mixed Density, [g/cc] 1.2±0.05

to examine any relevant instructions and contents details. Pot life @ 25°C [mins] 60

Reseal all containers after use and ensure product is stored

Pull out strength, [n/mm²] >1.5

as instructed on the safety section of the labeling.

Tack free time [hrs] 2

SUPPLY inital cure

Polypoxy CT 20 lt. kit @ standard conditions [hrs] 24

Polysolvent 5 lt. & 20 lt. pail Full cure

@ standard conditions [days] 7

Water permeability

@ 5 bar pressure, [mm] nil

Over coating interval,

@ 25°C, [hrs] 24

All values given are subject to 5-10% tolerance

Apart from the information given here it is also important to observe the relevant

guidelines and regulations of various organisations and trade associations as

well as the respective standards. The aforementioned characteristics are based

TDS_Polypoxy CT_GCC_0519

on practical experience and applied testing. Warranted properties and possible

uses which go beyond those warranted in this information sheet require our

written confirmation. All data given was obtained at an ambient and material

temperature of +23°C and 50 % relative air humidity at laboratory conditions

unless specified otherwise. Please note that under other climatic conditions

hardening can be accelerated or delayed.

The information contained herein, particularly recommendations for the

handling and use of our products, is based on our professional experience.

As materials and conditions may vary with each intended application, and

thus are beyond our sphere of influence, we strongly recommend that in each

case sufficient tests are conducted to check the suitability of our products

for their intended use. Legal liability cannot be accepted on the basis of the

contents of this data sheet or any verbal advice given, unless there is a case

2 of wilful misconduct or gross negligence on our part. This technical data sheet

supersedes all previous editions relevant to this product.

Henkel Polybit Industries Ltd.; PO Box: 293, Umm Al Quwain, UAE

Tel:+971(6)76 70 777; Fax:+971(6)76 70 197; henkelpolybit@henkel.com

Henkel Polybit Industries Ltd.; PO Box: 5911, Dammam-31432, KSA

Tel:+96613808 4061 / 62, Fax: +966 13 812 1164; polybitdammam@henkel.com

www.henkelpolybit.com

You might also like

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Polycoat RTLDocument2 pagesPolycoat RTLniaz05288No ratings yet

- Polypoxy EC: Epoxy Based Cementitious Repair SystemDocument2 pagesPolypoxy EC: Epoxy Based Cementitious Repair SystemAlexi ALfred H. TagoNo ratings yet

- 6 2 3 6 4 Polybond Ep PDFDocument2 pages6 2 3 6 4 Polybond Ep PDFHtun ZarniNo ratings yet

- Polyprime AC: Acrylic Modified PrimerDocument2 pagesPolyprime AC: Acrylic Modified PrimerVaittianathan MahavapillaiNo ratings yet

- Polypoxy BF: Epoxy Repair Putty and Blow Hole FillerDocument2 pagesPolypoxy BF: Epoxy Repair Putty and Blow Hole FillerAlexi ALfred H. TagoNo ratings yet

- Eur Val Tectyl502c CTG Tec enDocument2 pagesEur Val Tectyl502c CTG Tec ennathansta61No ratings yet

- Polycure AC: Acrylic Based Concrete Curing CompoundDocument2 pagesPolycure AC: Acrylic Based Concrete Curing Compoundmohamed ayadNo ratings yet

- Polycure W Polycure W: Water Based Curing CompoundDocument2 pagesPolycure W Polycure W: Water Based Curing CompoundMuhsin KhanNo ratings yet

- Tectyl 502CDocument2 pagesTectyl 502Cmoinu85No ratings yet

- Tectyl 502c c2 TdsDocument2 pagesTectyl 502c c2 TdspokleNo ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexSasi KumarNo ratings yet

- Mea Polybit Tds Polybit Polyrepair FC 20 en MeaDocument2 pagesMea Polybit Tds Polybit Polyrepair FC 20 en MeaVaittianathan MahavapillaiNo ratings yet

- Poly ZincDocument2 pagesPoly ZincMahinda GamageNo ratings yet

- Hydroseal P: Hydrophilic Rubber Based On PolyurethaneDocument2 pagesHydroseal P: Hydrophilic Rubber Based On PolyurethaneVaibhav GoyalNo ratings yet

- Produktinformation Tectyl 506 G TE033 01Document2 pagesProduktinformation Tectyl 506 G TE033 01HDSC ChemicalsNo ratings yet

- 7 2 1 1 6 1 Polyflex 10 PDFDocument2 pages7 2 1 1 6 1 Polyflex 10 PDFFourier MakambioNo ratings yet

- Recegrout Sl10: Product Data SheetDocument2 pagesRecegrout Sl10: Product Data SheetAmira RamleeNo ratings yet

- Bituprime SB: Solvent Based Bitumen PrimerDocument2 pagesBituprime SB: Solvent Based Bitumen Primerfaisal nadeemNo ratings yet

- Polyshield: (Bituminous Damp Proof Membrane)Document31 pagesPolyshield: (Bituminous Damp Proof Membrane)Mathikumar Melur MelurNo ratings yet

- POLYCOATDocument2 pagesPOLYCOATGeorge TsiamtsourisNo ratings yet

- DR - Fixit Cipoxy 16DDocument3 pagesDR - Fixit Cipoxy 16DKiran KumarNo ratings yet

- 196 DR Fixit BitufixDocument3 pages196 DR Fixit BitufixMohiuddin MuhinNo ratings yet

- 229 - Dr. Fixit PU Plain InjectionDocument3 pages229 - Dr. Fixit PU Plain InjectionZephyr HBNo ratings yet

- EUR Val TectylMultiPurpose506 CTG TEC ENDocument2 pagesEUR Val TectylMultiPurpose506 CTG TEC ENbouwersNo ratings yet

- Product Information: Tectyl™ 502-CDocument2 pagesProduct Information: Tectyl™ 502-CnicusebpNo ratings yet

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidNo ratings yet

- Polypoxy CR PDFDocument2 pagesPolypoxy CR PDFsudhialakkal0% (1)

- Polyfoam SS45Document71 pagesPolyfoam SS45BavishNo ratings yet

- Cray Coat: Product Data SheetDocument1 pageCray Coat: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Armix Hyye Crete PC30Document3 pagesArmix Hyye Crete PC30Devinder SokhiNo ratings yet

- 7 2 1 1 4 1 Bituboard 30Document2 pages7 2 1 1 4 1 Bituboard 30PRAJITH PREMKUMARNo ratings yet

- Product Information: Tectyl™ 121-LVDocument2 pagesProduct Information: Tectyl™ 121-LVRavi GurugeNo ratings yet

- Dr. FixIt Fastflex (Crown Paints) PDFDocument3 pagesDr. FixIt Fastflex (Crown Paints) PDFBarrack O MNo ratings yet

- Watertite CL 51Document2 pagesWatertite CL 51Alexi ALfred H. TagoNo ratings yet

- Polyglass: 2/23 A Polyglass VEF 5th June 2007Document3 pagesPolyglass: 2/23 A Polyglass VEF 5th June 2007Saradhi MedapureddyNo ratings yet

- Watertite BB 30Document2 pagesWatertite BB 30Alexi ALfred H. TagoNo ratings yet

- Polyguard PEDocument2 pagesPolyguard PEabcd1860100% (1)

- Data Sheet - Durobuild FCDocument2 pagesData Sheet - Durobuild FCVaittianathan MahavapillaiNo ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- Blue SealDocument3 pagesBlue Sealpandey7108767% (3)

- POLYTEXDocument2 pagesPOLYTEXDon AlexNo ratings yet

- Polyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinDocument2 pagesPolyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinVaittianathan MahavapillaiNo ratings yet

- Polyprime PS: Primer For Porous JointsDocument2 pagesPolyprime PS: Primer For Porous JointsaahtagoNo ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Watertite TS 15Document2 pagesWatertite TS 15Alexi ALfred H. TagoNo ratings yet

- Loctite 7232 High Temperature Wear Resistant Putty: Product Description SheetDocument1 pageLoctite 7232 High Temperature Wear Resistant Putty: Product Description SheetjohnNo ratings yet

- DR Fixit Bathseal WaterproofingDocument3 pagesDR Fixit Bathseal WaterproofingreshmitapallaNo ratings yet

- Flexseal PU440 TDSDocument2 pagesFlexseal PU440 TDSkumaraguruNo ratings yet

- Polyglass: Page 1 of 2Document2 pagesPolyglass: Page 1 of 2whyme_bNo ratings yet

- Pioneer Pro Water Tite 102 Technical Spec SheetDocument2 pagesPioneer Pro Water Tite 102 Technical Spec SheetGerald Ordoñez Delos ReyesNo ratings yet

- 112 Dr. Fixit Pidifin 2KDocument3 pages112 Dr. Fixit Pidifin 2KmcgNo ratings yet

- 113 Dr. Fixit FastflexDocument3 pages113 Dr. Fixit FastflexNaing Ye Htun100% (1)

- Mycoflex 488 MS: Single-Component MS-Polymer Sealer in Accordance With DIN 18450Document2 pagesMycoflex 488 MS: Single-Component MS-Polymer Sealer in Accordance With DIN 18450Rodrigo Felicio AdrianoNo ratings yet

- Loctite 595-EN PDFDocument2 pagesLoctite 595-EN PDFDhananjay LimayeNo ratings yet

- Protectosil CIT PDFDocument3 pagesProtectosil CIT PDFFrancois-No ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- Dr. Fixit USPRO Foam: Single Component Expanding Multi-Purpose Polyurethane FoamDocument3 pagesDr. Fixit USPRO Foam: Single Component Expanding Multi-Purpose Polyurethane FoamDeep GandhiNo ratings yet

- EmulsioDerma HDDocument2 pagesEmulsioDerma HDkhaleejdubai jubailNo ratings yet

- Aluminum Reflector For Guard RailDocument1 pageAluminum Reflector For Guard Railkhaleejdubai jubailNo ratings yet

- Aramco - Mot Guardrail - Al OmaierDocument3 pagesAramco - Mot Guardrail - Al Omaierkhaleejdubai jubailNo ratings yet

- Sika Bitumen 60Document27 pagesSika Bitumen 60khaleejdubai jubailNo ratings yet

- Ambitions Arabia-1Document1 pageAmbitions Arabia-1khaleejdubai jubailNo ratings yet

- Anchorage DetailsDocument1 pageAnchorage Detailskhaleejdubai jubailNo ratings yet

- 9 Row Fencing SystemDocument1 page9 Row Fencing Systemkhaleejdubai jubailNo ratings yet

- Part 6Document175 pagesPart 6khaleejdubai jubailNo ratings yet

- Safety Rolling BarrierDocument2 pagesSafety Rolling Barrierkhaleejdubai jubailNo ratings yet

- Hcis FenceDocument2 pagesHcis Fencekhaleejdubai jubailNo ratings yet

- RK ROAD SAFETY Profile Dec 2019 - CompressedDocument20 pagesRK ROAD SAFETY Profile Dec 2019 - Compressedkhaleejdubai jubailNo ratings yet

- Khaleej Dubai UpdatedDocument78 pagesKhaleej Dubai Updatedkhaleejdubai jubailNo ratings yet

- Quality Plan - Guard RailDocument1 pageQuality Plan - Guard Railkhaleejdubai jubailNo ratings yet

- Swaging Procdure Wire HSD004Document8 pagesSwaging Procdure Wire HSD004khaleejdubai jubailNo ratings yet

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Document7 pagesMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimNo ratings yet

- Multiple Choice Practice Questions For Online/Omr AITT-2020 Instrument MechanicDocument58 pagesMultiple Choice Practice Questions For Online/Omr AITT-2020 Instrument Mechanicمصطفى شاكر محمودNo ratings yet

- EPW, Vol.58, Issue No.44, 04 Nov 2023Document66 pagesEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseNo ratings yet

- Six Sigma PresentationDocument17 pagesSix Sigma PresentationDhular HassanNo ratings yet

- Bring Your Gear 2010: Safely, Easily and in StyleDocument76 pagesBring Your Gear 2010: Safely, Easily and in StyleAkoumpakoula TampaoulatoumpaNo ratings yet

- "Tell Me and I Forget, Teach Me and I May Remember, Involve MeDocument1 page"Tell Me and I Forget, Teach Me and I May Remember, Involve MeBesufkad Yalew YihunNo ratings yet

- Taylor Series PDFDocument147 pagesTaylor Series PDFDean HaynesNo ratings yet

- Table of Reinforcement Anchorage Length & Lap Length - Eurocode 2Document7 pagesTable of Reinforcement Anchorage Length & Lap Length - Eurocode 2NgJackyNo ratings yet

- KK AggarwalDocument412 pagesKK AggarwalEnrico Miguel AquinoNo ratings yet

- Mahindra&mahindraDocument95 pagesMahindra&mahindraAshik R GowdaNo ratings yet

- Structural Design Basis ReportDocument31 pagesStructural Design Basis ReportRajaram100% (1)

- There Will Come Soft RainsDocument8 pagesThere Will Come Soft RainsEng ProfNo ratings yet

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 pagesDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNo ratings yet

- .IAF-GD5-2006 Guide 65 Issue 3Document30 pages.IAF-GD5-2006 Guide 65 Issue 3bg_phoenixNo ratings yet

- Digital Systems Project: IITB CPUDocument7 pagesDigital Systems Project: IITB CPUAnoushka DeyNo ratings yet

- Hofstede's Cultural DimensionsDocument35 pagesHofstede's Cultural DimensionsAALIYA NASHATNo ratings yet

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuNo ratings yet

- TM Mic Opmaint EngDocument186 pagesTM Mic Opmaint Engkisedi2001100% (2)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Installation Instructions INI Luma Gen2Document21 pagesInstallation Instructions INI Luma Gen2John Kim CarandangNo ratings yet

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- JO 20221109 NationalDocument244 pagesJO 20221109 NationalMark Leo BejeminoNo ratings yet

- 2007 ATRA Seminar ManualDocument272 pages2007 ATRA Seminar Manualtroublezaur100% (3)

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- SievesDocument3 pagesSievesVann AnthonyNo ratings yet

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)

- Types of Chemical Reactions: Synthesis and DecompositionDocument3 pagesTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínNo ratings yet

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADODocument782 pages.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusNo ratings yet

- Stress Management HandoutsDocument3 pagesStress Management HandoutsUsha SharmaNo ratings yet

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)