Professional Documents

Culture Documents

98 pl725

98 pl725

Uploaded by

Blmjdb Abdelhafid0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

98-pl725

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 page98 pl725

98 pl725

Uploaded by

Blmjdb AbdelhafidCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

THIRD ANGLE PROJECTION REVISIONS

REV] ECN No. DESCRIPTION. DATE | DR JAUTH

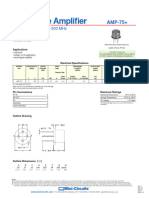

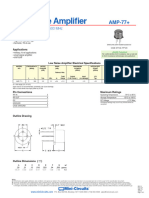

SUGGESTED MOUNTING CONFIGURATION FOR

KEEP—OUT ZONE, .030X.030, DQ1225 CASE STYLE

INDER OF BOTTOM SIDE OF N/c FOR GROUND

COMPONENT C8

‘COPLANAR WAVEGUIDE:

.021 TRACE WIDTH &

.015 GAP, 2 PL.

(SEE NOTE 2)

PACKAGE

OUTLINE TOP VIEW

‘COMPONENT | SIZE ‘SOLDER MASK (SM1)

IMMERSION GOLD (0.025um~0.075um)

ELECTROLESS NICKEL (3um—6um)

Li COPPER: 0.5 OZ (0.7mll)

SERA BASE: RO«350B (10mil)

L2 COPPER: 0.5 07 (0.7mil)

BASE: FR& (2.0mm)

LB COPPER: 0.5 02 (0.7mil)

ELECTROLESS NICKEL (3um=6um)

IMMERSION GOLD (0.025um~0.075um)

‘SOLDER MASK (SM2)

cr..08 [0402

Laz | 0402

mi __[ovoe emer

.090"+.002”

(2.3040.05]mm

NOTES:

1. PCB IS MULTILAYER PCB, SEE STACK-UP DIAGRAM.

2. TRACE WIDTH & GAP PARAMETERS ARE SHOWN FOR ROGERS RO4350B

WITH DIELECTRIC THICKNESS .010"+.001"; COPPER: 1/2 OZ.

FOR OTHER MATERIALS TRACE WIDTH AND GAP MAY NEED TO BE MODIFIED.

3. CHIP COMPONENT FOOT PRINTS SHOWN FOR REFERENCE.

FOR COMPONENT VALUES REFER TO TB-PMA3—14LN+ OR TB~TSS-14LN+.

4. COPPER LAYERS L2 & L3 OF THE PCB ARE CONTINUOUS GROUND PLANES.

[| DENOTES PoB COPPER LAYOUT WITH sMoBC

(SOLDER MASK OVER BARE COPPER)

DENOTES COPPER LAND PATTERN FREE OF SOLDER MASK

UNLESS OTHERWISE SPECIFIED] Tals [__DaTE

ae

cee eee ee [! Mini—Circuits sanrwis

TRESS: [See |e wae

Res PL, DQ1225, TB-PMA3(TSS)-14LN+

anc

rere

Se Ree R CRS RRERE REE wenn | A | 15542 98-PL-725 B

[amerarowe ma omens |" 9BPL725 MF Bl [1 OF 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Les 100 Verbes Les Plus Utilises en Anglais PDFDocument2 pagesLes 100 Verbes Les Plus Utilises en Anglais PDFtaffy192100% (1)

- Ava 183P DG+Document6 pagesAva 183P DG+Blmjdb AbdelhafidNo ratings yet

- EHC-24LDocument5 pagesEHC-24LBlmjdb AbdelhafidNo ratings yet

- AMP-75Document2 pagesAMP-75Blmjdb AbdelhafidNo ratings yet

- CMA-62Document5 pagesCMA-62Blmjdb AbdelhafidNo ratings yet

- Ava 24a D+Document6 pagesAva 24a D+Blmjdb AbdelhafidNo ratings yet

- AMP-77Document2 pagesAMP-77Blmjdb AbdelhafidNo ratings yet

- AVA-183MPDocument9 pagesAVA-183MPBlmjdb AbdelhafidNo ratings yet

- Spice 0402dfDocument2 pagesSpice 0402dfBlmjdb AbdelhafidNo ratings yet

- Amp 15Document2 pagesAmp 15Blmjdb AbdelhafidNo ratings yet

- PMA3-14LNDocument4 pagesPMA3-14LNBlmjdb AbdelhafidNo ratings yet

- Fahad 2019Document5 pagesFahad 2019Blmjdb AbdelhafidNo ratings yet

- Ms Tel Cherifi+MiraouiDocument130 pagesMs Tel Cherifi+MiraouiBlmjdb AbdelhafidNo ratings yet

- TELKOMNIKA Journal PaperDocument9 pagesTELKOMNIKA Journal PaperBlmjdb AbdelhafidNo ratings yet

- LAB 5 - Implementing An ALU: GoalsDocument9 pagesLAB 5 - Implementing An ALU: GoalsBlmjdb AbdelhafidNo ratings yet

- طلب خطي لاجتياز مباراة الأمن الوطني PDFDocument1 pageطلب خطي لاجتياز مباراة الأمن الوطني PDFBlmjdb AbdelhafidNo ratings yet

- Commande PCB - FILTRE PDFDocument256 pagesCommande PCB - FILTRE PDFBlmjdb AbdelhafidNo ratings yet

- 65nm CMOS Process Data SheetDocument1 page65nm CMOS Process Data SheetBlmjdb Abdelhafid0% (1)