Professional Documents

Culture Documents

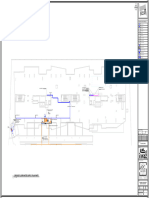

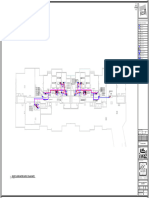

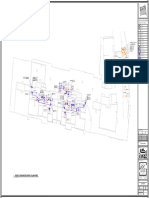

Ar 006

Ar 006

Uploaded by

orisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ar 006

Ar 006

Uploaded by

orisCopyright:

Available Formats

MAINTENANCE PROCEDURE NO. IN-AR-096-PM REV.

01 DATE: 17-11-01

TITLE/TAG FUNCTION CHECK BTEX ANALYZER

EQUIPMENT TYPE BTEX ANALYZER

INTERVAL 1 YEARLY

PRECAUTIONS

Note: Tick boxes to indicate completion.

1. Obtain an approved Work Permit before commencing activities.

PREPARATION/ISOLATION

2. Check that the equipment tags are as detailed on work order sheet/work permit.

CAUTION: ONLY QUALIFIED PERSONS ARE AUTHORISED TO PERFORM THIS

PROCEDURE. REFER TO WARNINGS AND PRECAUTIONS IN VENDOR

MANUAL.

MAINTENANCE ACTIVITY

3. Make a complete system check of the analyzer.

4. Check the status of the analyzer control panel.

5. Check the condition of emitter, receiver & optical-fibre.

6. Check the quality of test gas (used for reference and span calibration).

7. Check the calibration history of the analyzer.

8. Check and adjust as necessary reference and span calibration of the analyzer. (Refer to vendor’s manual

Sections 5.2 and 5.3 respectively)

9. Check the accuracy after calibration of the analyzer. (Refer to vendor’s manual Sections 5.4.1)

10. Check the availability of calibration standard samples of the analyzer.

11. Gas cylinders used for analyzer should be stored in ventilated, storage areas.

12. Keep maintenance records of the analyzer at the monitoring station.

13. Sign off the work permit.

REPAIR WORK

14. Is repair work or corrective action required? YES NO

15. Has a Work Order been raised? YES NO

REFERENCE INFORMATION

Opto-Analyzer for Air Quality Monitoring Hardware Operating Manual

Appendix D & E of Document Number 5-A-AA-EC-E-0001

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Vdocuments - MX Mechanicalmechanical Pe Study Guidestudy Guide As A Professional Engineer You WillDocument90 pagesVdocuments - MX Mechanicalmechanical Pe Study Guidestudy Guide As A Professional Engineer You WillorisNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Biblical MeditationDocument33 pagesBiblical Meditationoris100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fire Protection Parameters - Proposed CPU CateringDocument1 pageFire Protection Parameters - Proposed CPU CateringorisNo ratings yet

- Ground Floor HVAC-Drain Part 3: Issue StatusDocument1 pageGround Floor HVAC-Drain Part 3: Issue StatusorisNo ratings yet

- FF 20 RF 01Document1 pageFF 20 RF 01orisNo ratings yet

- GWP Expected Sewage FlowsDocument3 pagesGWP Expected Sewage FlowsorisNo ratings yet

- CGN BDF 002 - 02Document2 pagesCGN BDF 002 - 02orisNo ratings yet

- Ar-001 02Document2 pagesAr-001 02orisNo ratings yet

- FF 20 Ur 00Document1 pageFF 20 Ur 00orisNo ratings yet

- FP PCW 002 - 02Document2 pagesFP PCW 002 - 02orisNo ratings yet

- DS 40 Ur 00Document1 pageDS 40 Ur 00orisNo ratings yet

- Ground Floor Water Supply Plan-Part1 1: Issue StatusDocument1 pageGround Floor Water Supply Plan-Part1 1: Issue StatusorisNo ratings yet

- CGN BDF 001 - 02Document2 pagesCGN BDF 001 - 02orisNo ratings yet

- FP Pde 001 - 02Document2 pagesFP Pde 001 - 02orisNo ratings yet

- WS 30 RF 01Document1 pageWS 30 RF 01orisNo ratings yet

- WS 30 RF 02Document1 pageWS 30 RF 02orisNo ratings yet

- LT-23 - SPL - (G-1) - MED-Home Work - Work Energy Power-16-09-21Document7 pagesLT-23 - SPL - (G-1) - MED-Home Work - Work Energy Power-16-09-21orisNo ratings yet

- LT-23 - SPL - (G-1) - MED-Home Work - States of Matter - 09-09-21Document5 pagesLT-23 - SPL - (G-1) - MED-Home Work - States of Matter - 09-09-21orisNo ratings yet

- Ground Floor Water Supply Plan-Part3 1: Issue StatusDocument1 pageGround Floor Water Supply Plan-Part3 1: Issue StatusorisNo ratings yet

- DiDocument1 pageDiorisNo ratings yet

- FP PCW 001 - 02Document2 pagesFP PCW 001 - 02orisNo ratings yet

- UntitledDocument1 pageUntitledorisNo ratings yet

- External Wall DetailDocument1 pageExternal Wall DetailorisNo ratings yet

- LT-23 SPL (G-1) Morphology of Animals - 04-09-21Document6 pagesLT-23 SPL (G-1) Morphology of Animals - 04-09-21orisNo ratings yet

- LT-23 SPL G-1 - NEET - Motion in A Straight Line - 19-06-21Document8 pagesLT-23 SPL G-1 - NEET - Motion in A Straight Line - 19-06-21orisNo ratings yet

- 5 Building Envelope: Table 5.5-0 Building Envelope Requirements For Climate Zone 0 (A, B)Document1 page5 Building Envelope: Table 5.5-0 Building Envelope Requirements For Climate Zone 0 (A, B)orisNo ratings yet

- LT-23 - SPL - GP1-MED-Home Work - Structure of Atom 29-07-21Document7 pagesLT-23 - SPL - GP1-MED-Home Work - Structure of Atom 29-07-21orisNo ratings yet

- LT-23 SPL (G-1) - States of Matter-11-09-21Document8 pagesLT-23 SPL (G-1) - States of Matter-11-09-21orisNo ratings yet

- LT-23 SPL G 1&2 - MED-Home Work-Biological Classification - 22-07-21Document7 pagesLT-23 SPL G 1&2 - MED-Home Work-Biological Classification - 22-07-21orisNo ratings yet

- Vdocuments - MX Commercial Air Conditioning Industrial VentilationDocument38 pagesVdocuments - MX Commercial Air Conditioning Industrial VentilationorisNo ratings yet