Professional Documents

Culture Documents

Recdatatjv Manual Eng

Uploaded by

anilp12rCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recdatatjv Manual Eng

Uploaded by

anilp12rCopyright:

Available Formats

RECDATA TJ V

Vacuum Macro Stations Software System

Management

USER’S MANUAL

Code: 8.003.7.032_rev.08 pag. 1/21

GALILEO TP

PROCESS EQUIPMENT

Via del Pantano 73

50018 SCANDICCI (Firenze)

All product names are trademarks which belong to

their respective companies. They are used in a confidential manner only for

illustrative purposes and for the benefit of those companies.

All rights reserved. No part of this book may be reproduced

or transmitted in any form or by any means, electronic

or mechanical, including photocopying, recording or by any information

storage retrieval system, without permission from

Galileo TP - Process Equipment.

Code: 8.003.7.032_rev.08 pag. 2/21

TABLE OF CONTENTS

INTRODUCTION ...................................................................................................................... 4

1.1 GENERAL INFORMATION ............................................................................................................ 4

1.2 SYMBOLISM .............................................................................................................................. 4

INSTALLATION AND TEST LINES CONFIGURATION ............................................................... 5

2.1 TEST LINE WITH STATIONS IN FIXED POSITION ......................................................................... 5

2.2 TEST LINE WITH MOVING STATIONS AND FIXED DISTANCES....................................................... 6

2.3 TEST LINE WITH MOVING STATIONS AND VARIABLES DISTANCES ............................................... 6

2.4 WIFI CONNECTION .................................................................................................................... 7

SOFTWARE INSTALLATION ..................................................................................................... 8

3.1 MINIMUM HARDWARE REQUIREMENTS ...................................................................................... 8

3.2 SOFTWARE REQUIREMENTS....................................................................................................... 8

3.3 INSTALLATION PROCEDURE ....................................................................................................... 8

PROGRAM USE ...................................................................................................................... 10

4.1 FIRST START ........................................................................................................................... 10

4.2 MAIN WINDOW ....................................................................................................................... 11

4.3 TEST CYCLES PROGRAMMING .................................................................................................. 12

4.3.1 GENERALS PARAMETERS ................................................................................................... 12

4.3.2 REFERENCE CURVES DEFINITION ...................................................................................... 13

4.4 HOW TO MAKE ASSOCIATION BETWEEN A TEST CYCLE AND A BARCODES FAMILY ...................... 15

4.5 RESULTS ANALYSIS ................................................................................................................. 15

4.6 ACCESSORIES FUNCTIONS ....................................................................................................... 16

4.6.1 (A) NEW CONFIGURATION ................................................................................................ 16

4.6.2 (B) USER ACCESS MODE ................................................................................................... 16

4.6.3 (C) ADMINISTRATOR PASSWORD MODIFICATION .............................................................. 16

4.6.4 (D) BARCODE MASK MANAGEMENT ................................................................................... 16

4.6.5 (E) TEST CYCLES MANAGEMENT ........................................................................................ 16

4.6.6 (F) BARCODE READING RULES MANAGEMENT .................................................................... 16

4.6.7 (G) RESULTS ANALYSIS..................................................................................................... 17

4.6.8 (H) DATABASE BACKUP MANAGEMENT .............................................................................. 17

4.6.9 (I) LOG FILE VISUALIZATION ............................................................................................ 17

4.6.10 (J) PRINTER MANAGEMENT............................................................................................ 18

4.6.11 (K) DEVICES RESET AND DEVICE OFFLINE MANAGEMENT ............................................... 18

HOW TO ACCESS RECDATA DATABASE FROM OTHER SYSTEMS .......................................... 19

MODBUS COMMUNICATION PROTOCOL ............................................................................... 20

6.1 SEQUENCE OF INTERACTION ................................................................................................... 21

Code: 8.003.7.032_rev.08 pag. 3/21

INTRODUCTION

1.1 GENERAL INFORMATION

RecDATA TJ V is a specialized software in the Vacuum Test of the cooling circuits, and has been

designed and built specifically to be used in industrial production lines. The Vacuum Test is

performed on the basis of a vacuum signal.

At the end of the Test, RecDATA TJ V immediately sends the result to the testing station, in

addition to displaying the result also in the main screen.

In addition, RecDATA TJ V stores data relatives to test carried out within its own database, making

it possible to analyze tests in offline mode.

In the remainder of this manual we will see in detail all the types of tests that can be programmed

with RecDATA TJ V, especially by providing guidelines in order to achieve the maximum

performance from the system.

RecDATA TJ V is connectable to GEDA software, software system developed by Galileo TP to meet

the needs of production statistics, traceability and production documentation printing.

1.2 SYMBOLISM

This symbol identifies operations that, if executed, might cause an

anomalous system performance. In these cases Galileo TP will not be held

responsible and the eventual malfunction will be only due to an improper use

of the system.

This symbol identifies an information which is supplied to the user as an

advice for an optimal use of the system.

Code: 8.003.7.032_rev.08 pag. 4/21

INSTALLATION AND TEST LINES CONFIGURATION

A Functional Test LINE consists of several test stations. All testing stations of a single line are

connected to RecDATA TJ V through a communication network, that for example, if the acquiring

device is the Galileo model Captor, will be based on a RS485 serial line.

In general we distinguish between static test lines or moving test lines (carousels). The examples

described in section 2.1 and 2.2 are two possible configurations with the device Captor.

When connected through the RS485 serial line, the maximum number of connected stations per

line is 128.

For the automatic management of the line, it is needed a barcode reader. To start a test cycle

automatically through the barcode reader, the operator will read the barcode relative to the station

(typically a number that identifies the station) and the barcode of the product to be tested. This

double bar code will be received by RecDATA TJ V, which will automatically send to the device all

the parameters needed to perform the test.

In the absence of the barcode reader, it is possible to start the test cycles in manual way, by

inserting the necessary codes directly from the user interface of the program.

For a correct installation of the test lines is needed to rely on experienced

staff.

2.1 TEST LINE WITH STATIONS IN FIXED POSITION

In this kind of configuration, typically the adopted connection is fully "wired", always to be

preferred for performance and reliability compared to a "wireless" connection. In Figure 1 is shown

an example concerning this type of configuration.

VG 402/502

Figure 1 – Static line test configuration example.

Code: 8.003.7.032_rev.08 pag. 5/21

2.2 TEST LINE WITH MOVING STATIONS AND FIXED DISTANCES

When is needed to install a testing line moving but the distances between the various test stations

are fixed, the most efficient solution is to provide a single "bridge" that puts in wireless

communication RecDATA TJ V and the line (see Figure 2). In this way is possible to combine the

flexibility of wireless with the performance of wired.

VG 402/502

Figure 2 – Moving test line with fixed distances between stations.

2.3 TEST LINE WITH MOVING STATIONS AND VARIABLES DISTANCES

In this case the only possible installation is a completely wireless data transmission line. This kind

of line can be implemented only with the "Captor K" device in WIFI mode. Examples of these

installations are when the carousel has the "fast return".

CAPTOR

VG 502 K

Figure 3 - Moving test line with variables distances between stations. This kind of configuration is

allowable only with “VG 502” device.

Code: 8.003.7.032_rev.08 pag. 6/21

2.4 WIFI CONNECTION

When RecDATA TJ V is connected to VG 502 device, you can use WIFI standard for a wireless

connection. The connection is made through an access point connected to RecDATA TJ V PC by an

Ethernet cable.

In this case the VG 502 devices must be equipped with the kit with 2.505.0.125 code. The access

point provided by Galileo TP must also be used, configured and tested specifically to work with the

VG 502.

The two prerequisites in order to guarantee adequate performance for industrial use are listed

below in case of WIFI installation:

In order to achieve the maximum in term of performance we recommend a

maximum distance between the access point and VG 502 of not more than 40

meters. It will also be necessary to position the access point in a central

position respect to the carousel itself. In case of carousels with greater

distances, or with the presence of physical obstacles that may cause

attenuation or the total disappearance of the signal, you will need to install more

access points.

In order to achieve the maximum in term of performance and reliability,

RecDATA WIFI system must use an exclusive channel. If this cannot be

guaranteed, the overall performance of the system will degrade

proportionally to data traffic present on the used channel, and the Real Time

constraints will not always be guaranteed.

PC

RecDATA

TJ V

VG 502 VG 502 VG 502

Uart Uart Uart Uart Uart Uart

Socket

Modem Modem Modem

RS485 RS485 RS485

ETH WiFi WiFi WiFi

11.0.1.1 11.0.1.2 11.0.1.3

11.0.0.250

255.255.0.0

Wi-Fi Access Wi-Fi Access

Point Point

ETH ETH

11.0.0.251 11.0.0.252

VG 502 VG 502 VG 502

Uart Uart Uart Uart Uart Uart

Modem Modem

RS485 WiFi RS485

Modem RS485

WiFi WiFi

11.0.2.1 11.0.2.2 11.0.2.3

Figura 4 - WI-FI modality configuration.

Code: 8.003.7.032_rev.08 pag. 7/21

SOFTWARE INSTALLATION

Once the installation and configuration of the test lines are done, you are ready to install the

software. Before proceeding with the installation, make sure your PC meets the minimum

hardware and software requirements listed below. Some of the software requirements are,

however, included in the installation package RecDATA TJ V.

3.1 MINIMUM HARDWARE REQUIREMENTS

• Processor: Intel Core i5 or superior.

• Memory: 8 Gb or superior.

• Screen resolution: 1280 x 1024 or superior.

• I/O: RS232/RS485 serial interfaces, network board 10/100 Mbit, plus eventual second

network board 10/100 Mbit for connection to GEDA independent network..

• Peripherals: CD-ROM reader, network or local printer.

3.2 SOFTWARE REQUIREMENTS

• Operative system: Microsoft Windows 7 64-bit , Microsoft Windows 10 Pro .

• Database managing system: Microsoft SQL Server 2008 Express R2 SP1 , Microsoft

SQL Server 2014 Express SP3 (included in the installation package).

• Environment: Framework .NET 4.0 (included in the installation package) and

Framework .NET 3.5 (eventually to enable and to install separately).

The PC should be connected to an UPS in order to avoid systems

malfuctionings due to sudden power supply drops.

Modify the following Windows properties:

• Set the “Power Options” so that the PC does not turn off automatically.

• Allow RecDATA TJ V to run with Administrator privileges in all PC

system.

• Disable “Automatic Windows Update” in order to avoid undesirable PC

restart.

3.3 INSTALLATION PROCEDURE

The RecDATA TJ V installation procedure is very simple as all the necessary operations are

completed automated. It will take a few minutes to complete the installation as most of the time is

used to install and configure the Microsoft SQL Server and Microsoft .NET .

The RecDATA TJ V installation package is composed by two executable files:

1. RecDATASqlServer.exe

2. RecDATATJVSetup.exe

For a correct installation, it is necessary to execute first RecDATASqlServer.exe: this application

will install and configure the database managing system and it will install the empty RecDATA TJ V

Code: 8.003.7.032_rev.08 pag. 8/21

database. Should the installation package include an USB key, it will be only necessary to insert

the key, make double click with the mouse on the file. NOTE: database can be installed on a

dedicated Server also, but in order to perform this kind of installation, ask to Galileo TP Service

department.

Once the installation and configuration of Microsoft SQL Server is terminated, execute at the

same way the file RecDATATJVSetup.exe: at first, this application will check that Microsoft .NET

4.0 is installed inside the system; shouldn’t it be present, it will be installed.

Afterwards, it will be automatically started the RecDATA TJ V installation.

During RecDATA TJ V installation, following folders will be created:

1. “C:\RecDATA_DB”: it is the folder used by RecDATA TJ V to manage the

database. Inside, there will be a subfolder called “Backup”, used as default path

for the system backup.

2. “C:\Program Files(x86)\Galileo TP\RecDATA TJ V”: it is the programme main

folder. Inside there will be following subfolders:

a. “conf”: subfolder with the XML configuration files.

b. “images”: subfolder containing images and icons used by the system.

c. “log”: subfolder containing the log file for the system monitoring.

d. “logo”: subfolder containing the logo image files used for printer

operations.

e. “doc”: subfolder containing the programme documentation.

For the system correct functioning, it is mandatory not to modify neither the

structure of the folders created during the installation process, nor the

content of the files stored inside.

To start the program, make double click on the Desktop icon or execute the application from

Windows “Start” menu.

To uninstall the programme enter the normal function offered by Windows systems and select

RecDATA TJ V from the list of the installed programs. The uninstalling will only regard RecDATA TJ

V, while if you need to uninstall Microsoft SQL Server or Microsoft .NET , they will have to be

uninstalled separately.

Before starting GEDA, be sure you have correctly inserted the hardware USB

key supplied with the application.

Code: 8.003.7.032_rev.08 pag. 9/21

PROGRAM USE

Have the PC with the RecDATA TJ V working in front of you in order to easily understand this

paragraph.

RecDATA TJ V has two operation modality, User and Administrator. When used in Administrator

mode, RecDATA TJ V provides all possible functionality while in User mode, it is restricted only to

certain functions.

To access in Administrator mode Password is required. During installation temporary password is

set. The temporary password is: RecDATA.

It is advisable to change the temporary password at first start.

4.1 FIRST START

RecDATA TJ V has distributed with its USB HW key. Without inserting USB key into the PC where

you installed RecDATA TJ V, the following operations will be denied:

1. Start the program.

2. Perform remote programming of the machines.

3. Perform query relatives.

In order to access the test lines configuration screens and those related to the creation of the test

cycles, you need to log in as Administrator.

When RecDATA TJ V is started for the first time, it shows the screen configuration for test lines.

The user must enter all the necessary informations for the configuration of lines and the

composing stations.

RecDATA TJ V is able to manage up to 4 test lines, for a total of 512 stations. Each line may be

composed of a maximum of 128 stations. In the configuration screen of the lines you have to

enter the number of test lines and the number of stations for each per line.

When the total number of stations is large, the stations should be split over

multiple lines. In this way RecDATA TJ V manages the various lines in

'parallel', obtaining considerable advantages in terms of performance.

The required informations for each test line are:

1. Number of Stations: the number of stations composing the test line.

2. Line Description: the name of the test line, for example: “Line 1”.

3. Device type: is the device type for the test line. The correct device must be

chosen from a well-defined list that will appear in a drop down menu.

4. Protocol: is the type of protocol communication through which RecDATA TJ V will

communicate with the devices selected in the previous step. The choice will be

made from a list of a dropdown menu, and this list will depend on the particular

device selected in the previous step.

Code: 8.003.7.032_rev.08 pag. 10/21

5. N° COM (Stations): the serial port for communication with all the stations

composing the test line.

6. Protocol (Barcode Reader): communication protocol to select in order to read

Barcode, the possible choices are:

a. Serial (RS232).

b. ModBus RTU.

c. ModBus TCP.

d. TCP/IP.

7. N° COM (Barcode Reader): the serial COM port where to connect Barcode

Reader in case of Serial protocol.

8. TCP port (Barcode Reader): the TCP/IP port to insert in case TCP/IP or

ModBus TCP protocol is selected.

Once all the information have been input, press button OK to start the application again and, after

the start, the RecDATA TJ V main window will be shown.

4.2 MAIN WINDOW

The functions offered by RecDATA TJ V main window are:

• Real time monitoring of the stations: the process lines and the stations input during the

configuration step, are represented in a graphic mode in the window central part. The

stations are represented by buttons which could have different colors according to the

current status:

o : the station is in STAND BY status, so it is ready to work.

o White: the station is in WORK status, but it has not sent any “sample” yet.

o : the station is in WORK status, so it is running a test cycle.

o : the station is in PROGRAMMING mode, or it is performing GASBALLAST

operation.

o : the station has communication problems (NO COMM status).

o : the station was disabled by the user (OFFLINE status), RecDATA TJ V will

not receive data from this station until it will be enabled again through the

specific function (refer to paragraph 4.6.11).

Pressing the buttons relative to the stations you get different functionality, depending on

the current status of the station:

• STAND BY: in this case the opened screen is that where you can enter the barcode

of the test unit, and start the test cycle for that unit.

• WORK: in this case the opened screen is that where you can see the real time

curves relative to all signals acquired during test (the station must have sent at

least one sample).

• Real time monitoring of the running test:

o The remaining test time will be showed through the specific Bargraph.

o The result of the last test cycle or the status of the running test cycle will be

showed through the colour of the specific Bargraph:

▪ : if the test is running, it is signaled that the result will be PASS. If the

test is finished, it is signaled that the last test result has been PASS.

▪ : it is signaled that the last test result has been FAIL.

▪ : the running test result will be FAIL.

• Display of the test results: The main screen allows you to view real-time results and details

of the last finished test. You can also view a list of all the latest tests completed, and from

this list is also possible go to the screen that allows detailed analysis of the particular test.

• Statistics: it is possible to see “pass” or “fail” statistics.

Code: 8.003.7.032_rev.08 pag. 11/21

From the main screen it is possible to access all the optional functionality of the program. These

functions will be described in section 4.6.

When a station on the main screen has a status of "NO COMM" (

color), you may lose data if you do not resolve the possible problem, before

the machine is out of memory responsible of storage of "packets" to be sent.

If the symbol “ ” appears while going with the mouse on any graphic

interface component, GEDA advises the user that additional functions are

available; they can be entered by a double click of the mouse or by pressing

the mouse right button and by selecting the desired operation from the

menu.

4.3 TEST CYCLES PROGRAMMING

The screen that allows you to create a new test cycle is divided into two sections, one section

where you have to enter the general parameters, while the other section is dedicated to the

creation of the Reference Curve.

4.3.1 GENERALS PARAMETERS

This screen allows the insert of the following parameters:

• Cycle description: description of the test cycle.

• Curves Rejection Criteria: this section is concerning the rejection criteria for the analysis

of acquired curves:

o Curves Range: the curves of the acquired signals must be within the range defined

by the Upper Reference Curve and Lower Reference Curve.

▪ Range tolerance: maximum number of points in terms of a percentage that

can go out of the defined range.

o Distance: it is considered the distance in mathematical terms between the acquired

signal curve and the main reference curve.

▪ Distance tolerance: distance value over the maximum allowable distance,

expressed as a percentage.

• Signals: through the specific table, it is possible to select the signals for test.

• Cycle Type:

o Evacuation: set a cycle only with Evacuation phase.

o Evacuation + Leak Test: set a cycle with both Evacuation and Leak Test phases.

• Sampling time: sampling time both for Evacuation and Leak Test.

• Evacuation’s time: Evacuation time length.

• Leak Test Time: Leak Test time length.

• Set Point: Evacuation threshold and Leak Test threshold.

• Device Parameters:

o Start pressure set point: vacuum threshold below which the device starts to send

the samples to RecDATA TJ V.

o Start timeout: time within which the vacuum should be under the "Start pressure

set point."

o Cycle start modality: the selectable start cycle modalities are:

Code: 8.003.7.032_rev.08 pag. 12/21

▪ Automatic: the cycle starts immediately after that device (for example VG

402) receives the cycle parameters from RecDATA TJ V.

▪ Automatic + Start set point: before to start the cycle, the device waits until

the vacuum drops below the "Start pressure set point".

▪ Start Button: the cycle will start only after pressing the button 'Start'.

4.3.2 REFERENCE CURVES DEFINITION

For each selected signal, the user can define the reference curves. The reference curves allow the

definition of a comparison "model". In practice, all tested units are compared with the model

defined by the curve created.

It is not mandatory to define the reference curves for all signals of the test cycle, and the user can

also create a test cycle without defining any reference curves. In the latter case, all the tested

units will be judged "Pass".

In the case of the vacuum test, the reference curves may be useful to detect "abnormal" trends of

the vacuum curve. When the vacuum curve has an anomalous trend in most cases this would

indicate the presence of water or moisture in the circuit.

Once the Main Reference Curve is defined, you must set at least one between the Upper

Reference Curve and the Lower Reference Curve, this allows RecDATA TJ V to calculate correctly

the value of "maximum distance" for the reject criteria based on distance. The value of maximum

distance allows a mathematical normalization of the distance itself. In this way when the distance

calculated during the cycle test is a value between 0 and 1, then the tested unit is considered

"Pass", while for all values greater than 1, the testes unit is considered "Fail".

4.3.2.1 SET POINT

RecDATA TJ V allows the insertion of specific set point at any point on the graph. The set point

can be defined in both the Upper Reference Curve and the Lower Reference Curve. For example,

when the user defines a upper set point, if at that point the acquired value is greater than the

upper set point, then the tested unit is considered "Fail", regardless of the trend of the test for all

other samples.

The set point must be placed directly on the table to the right of the screen. First of all, the user

must click on the “Set Point” column in correspondence at the interested point. The set point value

must be inserted directly in the cell table, in the "Lower" and/or "Upper" columns. In Figure 3 is

shown an “Upper” set point.

Figura 3 – “Upper” Set Point.

4.3.2.2 MANUAL CREATION OF REFERENCE CURVES

Code: 8.003.7.032_rev.08 pag. 13/21

RecDATA TJ V allows the definition of the Reference Curves by manually inserting related values

directly in the table on the left of the screen.

The user can also draw the Reference Curves directly on the chart. In this case, first of all it is

advisable to draw the Main Reference Curve, and then apply the “top” and “bottom” offset

pressing the appropriate button.

After defining the Reference Curves, the user can also insert all the desired set point, thus

combining the reject criteria.

Figure 4 – Reference Curves drawn directly on chart.

4.3.2.3 AUTO-CREATION OF REFERENCE CURVES

After performing a certain number of tests for a given unit, in production line or in laboratory, it is

possible to recreate the reference curves by selecting a subset from acquired curves.

Once we have chosen the acquired curves that best fit our target “quality” model, we proceed with

an automatic calculation of the new reference curves. This process is called Auto-creation.

The Auto-creation can be performed for all signals defined in the test cycle. In order to be possible

to use the Auto-creation for a given signal, it is necessary that in the RecDATA TJ V Database is

stored at least one compatible curve. The compatibility must be related to test cycle that user is

creating or editing. The basic compatibility requirements to be met are:

• The curves related to the selected signal must be stored in Database.

• The stored curves must have the same length and the same total sampling time of the test

cycle that user is creating or editing.

If one of these requirements is not met, an error message will inform the user that there are no

compatible curves stored in Database, and therefore it is not possible to make the Auto-creation.

After opening the Auto-creation screen, the user can select a subset from the acquired curves set

for the calculation of the new Reference Curves.

All selectable curves meet the compatibility requirements listed above.

For the calculation of the new curves, the user can select the following criteria:

• Min – Max criteria: the new Upper Reference Curve is the set of maximum points while the

new Lower Reference Curve is the set of minimum points. The maximum and minimum are

calculated for each sampling instant, considering all the values of the selected curves. The

Main Reference Curve is calculated for each sampling instant by an arithmetic mean of all

values belonging to all selected curves.

• Mean - Variance criteria: the Main Reference Curve is calculated for each sampling instant

by an arithmetic mean of all values belonging to the selected curves. The Upper Reference

Code: 8.003.7.032_rev.08 pag. 14/21

Curve and the Lower Reference Curve is calculated in terms of the variance. The variance

value may be regulated by a "delta" value inserted from the user’s interface.

The Min - Max criteria is to be preferred in case you want to make sure that

all the curves selected (so the product units) for the calculation are

considered "Pass" in a hypothetical test. The Mean – Variance criteria is more

suitable for to emphasize the "trend" represented by the selected curves.

To make the newly-created curves effective, simply exit the Auto-creation screen.

4.4 HOW TO MAKE ASSOCIATION BETWEEN A TEST CYCLE AND A

BARCODES FAMILY

In order to automate the testing process through a Barcode Reader, it is necessary to associate

the test cycle to a family of barcodes.

The family of barcodes representing a given model can be identified with a "mask". The mask is a

code identifying the set of fixed characters together with their position, while the other characters

out of the mask are variable.

RecDATA TJ V allows the creation of masks with max 32 characters length.

Figure 5 – Mask example. The inserted characters (‘123’ e ‘ABCD’) identifies the fix part of the barcode.

Once the user has created the mask, RecDATA TJ V will display the full set of test cycles stored on

Database for the selection.

4.5 RESULTS ANALYSIS

RecDATA TJ V stores all test data in its own Database. This allows the visualization and analysis of

all tests in offline mode. Selecting the relevant function from the main screen (see par. 4.6.9), the

screen for the construction of the query is shown, then the screen for analysis that will show all

the test retrieved from Database.

The screen for the creation of the query allows user to retrieve tests from Database based on

various criteria:

• Barcode Mask.

• Barcode.

• Model description.

• Date and hour intervals.

• Line description.

• Station number.

• Test result.

The number of tests recovered from Database will depend on the criteria entered in the query.

Code: 8.003.7.032_rev.08 pag. 15/21

The Analysis screen is composed by three parts:

• The table with all the tests retrieved from the Database.

• The list of signal buttons for all of the signals included in the test cycle selected from the

table.

• The graph where are displayed all test curves. In this part are available all the necessary

commands to interact with the graphics, and also are displayed all the informations needed

to understand the reasons for any "Fail".

The Analysis screen allows to compare the Reference Curves created in test cycles with the curves

acquired during the tests. It is also possible to print the curves.

4.6 ACCESSORIES FUNCTIONS

From the main window it is possible to enter the RecDATA TJ V accessories functions. This

paragraph describes in general all the functions which can be entered from the main window.

Figure 7 shows the functions list as they are shown on the main window.

A B C D E F G H I J K

Figure 6 – Accessories functions

4.6.1 (A) NEW CONFIGURATION

The management window of the test lines configuration is shown to the user once RecDATA TJ V

is started for the first time. Afterwards, it is possible to enter this window in order to modify the

configuration.

4.6.2 (B) USER ACCESS MODE

From this screen user can change the access mode of the program. The choice is between User or

Administrator.

4.6.3 (C) ADMINISTRATOR PASSWORD MODIFICATION

With this function, it is possible to change the password for the Administrator user.

4.6.4 (D) BARCODE MASK MANAGEMENT

This is the function that allows the creation, modification and deletion of all barcode masks for the

association of test cycles to barcodes.

4.6.5 (E) TEST CYCLES MANAGEMENT

This is the function that allows the creation, modification and deletion of the test cycles.

4.6.6 (F) BARCODE READING RULES MANAGEMENT

This screen allows you to set the reading rules for multiple barcodes. You can set the lengths of

the different barcodes to be read, and you can set the fill character also. This feature allows you to

handle the reading of maximum 5 barcodes for test cycle selection.

Code: 8.003.7.032_rev.08 pag. 16/21

4.6.7 (G) RESULTS ANALYSIS

With this function, user can retrieve all tests stored in the Database, and perform a complete test

analysis, comparing the acquired curves with the Reference Curves defined in the test cycle (see

section 4.5).

4.6.8 (H) DATABASE BACKUP MANAGEMENT

The screen allows the RecDATA TJ V database backup configuration. The frequency parameter has

to be input and the possible options are:

1. Hourly.

2. Daily (Default).

3. Weekly.

4. Manual.

Another parameter to be set is the time in which the backup has to be performed, so it must be

set a time in which your PC is turned on.

With the manual option the user is totally responsible for making the backup, through the

appropriate button present on the window.

Another important parameter is the one related to the path and/or device where the backup needs

to be physically written. The backups are not “destructive” types; the data of the working

database will remain there even after the backup.

RecDATA TJ V continuously monitors the size of the Database, and if its size risks of exceeding the

set limit (this limit cannot be changed by the user), RecDATA TJ V will shows a message saying

that user should perform the operation of "cleaning", in which the user can select the oldest data

for deletion.

As default set up RecDATA TJ V writes the backup in the folder “C:\RecDATA_DB\Backup”.

It is advisable to make the backup on a device which is different from the

one where RecDATA TJ V is installed. Should be RecDATA TJ V PC be present

inside a LAN domain, it would be advisable to save the backup on a safe

server accessible from the network (in this case you will need to set a path

like “\\servername\foldername”). As an alternative, use a removable

support such as an external HD.

"Hourly" backup is an incremental backup, so it requires a “base” full backup

type performed each day. It is therefore necessary to ensure that full

backup is performed each day, setting a time backup in which the PC is

turned on.

4.6.9 (I) LOG FILE VISUALIZATION

This feature is useful to investigate the cause of malfunctions in communication.

When this feature is enabled, RecDATA TJ V keeps track of all messages that are sent/coming

to/from the stations. This information is written to the log file.

This feature is normally disabled because the amount of data that can be written in the log file is

considerable, then user should enable this feature only in case of problems. The log file is written

to the log subfolder in the root folder of the program.

The log function must be enabled by modifying directly the XML configuration file.

Code: 8.003.7.032_rev.08 pag. 17/21

4.6.10 (J) PRINTER MANAGEMENT

The screen allows user to insert the company logo in the header of the Report to be printed.

The logo has to be a PNG image in with a maximum size of 200x50 pixels.

User can also set the automatic printing of the final report, and can also specify the type of

printer.

4.6.11 (K) DEVICES RESET AND DEVICE OFFLINE MANAGEMENT

This feature allows user to reset the status of one or more devices. Such operation may be

necessary in case of restart of a WORK state Captor, because for RecDATA TJ V this Captor

continues to be in WORK while the new status, after restart, is STAND BY.

In practice, the operation of "reset" will force the Captor state to become STAND BY also for

RecDATA TJ V.

Through this function is also possible to set one or more devices in OFFLINE state. This operation

could be necessary in case of stop production of a set of devices, for example for maintenance. In

this way it is possible to preserve the performance of the system.

User should perform “Reset” operation or “Offline” operation only when he

has the absolute certainty that this operation will not lead in a loss of data.

In case a WORK device is reset, the interrupted cycle cannot be recovered.

Code: 8.003.7.032_rev.08 pag. 18/21

HOW TO ACCESS RECDATA DATABASE FROM OTHER SYSTEMS

The RecDATA TJ V database is accessible by anyone through an account with read-only

permissions. To access the database you need to make a connection to the SQL Server instance

installed on the same PC where installed RecDATA TJ V. Access can be made with the following

credentials:

• Username: RDReader

• Password: GTP000

The database name is “RECDATA”. The instance of SQL Server used by RecDATA TJ V cannot be

used for management of other databases. In case you need to install other databases on the same

PC where RecDATA TJ V is installed, these databases will necessarily have to be installed on a new

instance of SQL Server.

For installation and configuration of SQL Server, refer to the appropriate Microsoft documentation.

The instance of SQL Server used by RecDATA TJ V cannot be used for

management of other databases. If you need to install other databases on

RecDATA TJ V PC, you have to install and configure another instance of SQL

Server. Changing the configuration of the SQL Server used by RecDATA TJ V

may cause malfunction of the entire system.

Code: 8.003.7.032_rev.08 pag. 19/21

MODBUS COMMUNICATION PROTOCOL

In order to manage the movement of the functional test line automatically, for example through a

Conveyor, RecDATA TJ V has to be able to exchange data information without the operator, such

as the barcode.

Since version 2.0 RecDATA TJ V is able to use ModBus industrial protocol. There are two kinds of

registers, the General Registers Area and the Specific Registers Area. In General Registers Area

the registers are not specific for any connected device, they are used for miscellaneous data

exchange between Master and Slave, while in Specific Registers Area the registers are used to

exchange data pertaining to specific VG. Each VG is assigned 50 registers, beginning with address

#50. This means VG number 2 registers begin at address #100, VG number 3 at address #150,

and so on.

RecDATA TJ V will act as Slave, so it will wait for the ModBus Master data and commands (see

paragraph 6.1 for the command sequence).

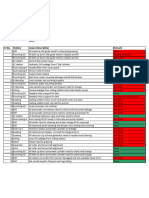

Table 1 - General Registers

Register Alias Data type Permitted Description

Address Values

#0 SLAVE_REBOOTED Unsigned 0, 1 RecDATA TJ V will set this register to

Integer (16 “1” when it boots. Default value is 0.

bits) No other values are permitted.

#1-49 - - - Not used, reserved for future generic

data.

Table 2 - Specific Registers

Register Alias Data Permitted Description

Address type Values

#50-89 BARCODE Char Any UNICODE These 40 registers contain the 40

UNICODE char (but only (or less) characters that make up

those that can the serial number string. Each

be converted register contains one character in

to ASCII char). ASCII decimal value. For ‘test’

barcode:

• #50 = ‘116’

• #51 = ‘101’

• #52 = ‘115’

• #53 = ‘116’

#94 OUT1 Unsigned 0, 1 Test Cycle PASSED

Integer

(16 bits)

Code: 8.003.7.032_rev.08 pag. 20/21

#95 OUT2 Unsigned 0, 1 Test Cycle FAILED

Integer

(16 bits) Note: only one of the two registers

94 and 95 will be set to 1, never

both.

#96 OUT3 Unsigned 0, 1 Test Cycle IN PROGRESS

Integer

(16 bits)

#97 START_TEST Unsigned 0, 1 The Modbus master sets this field

Integer to 1 to signal RecDATA TJ V to start

(16 bits) the test cycle.

#98 STATION_READY Unsigned 0, 1 The Modbus master must check

Integer the value of this register before

(16 bits) setting the value of the

START_TEST register.

#99 - - - Not used, reserved for future use.

6.1 SEQUENCE OF INTERACTION

Reported here is the sequence of commands, or the protocol, between Master and Slave to

automate the execution of Test Cycles:

1. Once booted up, Slave (RecDATA) sets the value of register 0 SLAVE_REBOOTED to 1.

2. Once the connection between VG and RecDATA is made, Slave sets the value of register 98

STATION_READY to 1.

3. Master writes registers 50 to 89 (BARCODE). Slave stays idle.

4. Master writes the value 0 to registers 94 OUT1 (PASS) and 95 OUT2 (FAIL). Slave stays idle.

5. Master writes the value 1 to register 96 OUT3 (cycle in progress). Slave stays idle.

6. Master checks that the value of register 98 STATION_READY is 1. Slave stays idle. If the value of

this register is 0, Master waits.

7. Master writes the value 1 to register 97 START_TEST. If the value of register 98 is 1, Slave starts

extracting data from registers 50-89 and preparing the test cycle to be executed based on the

Barcode read. Otherwise, Slave ignores the START_TEST request.

8. Slave writes the value 0 to register 98. Master stays idle.

9. Slave executes the vacuum test cycle. Master stays idle.

10. Slave writes the value 1 to either 94 OUT1 or 95 OUT2. Master stays idle.

11. Slave writes the value 0 to register 97 START_TEST. Master stays idle.

12. Slave writes the value 0 to register 96 OUT3 (meaning the cycle is finished). Master can now get

the test result by reading registers 94 e 95 (only one of them will be set to 1).

13. Slave writes the value 1 to register 98. Master stays idle.

Code: 8.003.7.032_rev.08 pag. 21/21

You might also like

- Recdatatj Manual EngDocument22 pagesRecdatatj Manual Enganilp12rNo ratings yet

- User Manual PCI 9113A Rev1.30Document91 pagesUser Manual PCI 9113A Rev1.30iman wahyudinNo ratings yet

- LMTDocument53 pagesLMTneeraj kumarNo ratings yet

- Harsh Environment Acquisition Terminal (H.E.a.T.) System Evaluation Kit (Rev. C)Document24 pagesHarsh Environment Acquisition Terminal (H.E.a.T.) System Evaluation Kit (Rev. C)jat_scribdNo ratings yet

- DeepSea 8620 User GuideDocument40 pagesDeepSea 8620 User GuideMTU650100% (1)

- Mecg2 ManualDocument32 pagesMecg2 ManuallauguicoNo ratings yet

- User's Manual: 0HJD3L (HO3R (3OXV 6Shhg'Rph, Qwhuqhw&DphudDocument109 pagesUser's Manual: 0HJD3L (HO3R (3OXV 6Shhg'Rph, Qwhuqhw&DphudMahmoud AhmedNo ratings yet

- Ge Fanuc Automation: Tcp/Ip Ethernet Communications For Pacsystems™Document136 pagesGe Fanuc Automation: Tcp/Ip Ethernet Communications For Pacsystems™jimenezhnNo ratings yet

- 3G8F7-CLK12-E3G8F7-CLK52-E3G8F7-CLK21-E Controller Link Support Boards for PCI Bus Installation GuideDocument46 pages3G8F7-CLK12-E3G8F7-CLK52-E3G8F7-CLK21-E Controller Link Support Boards for PCI Bus Installation GuideMD SAIFULNIZAM ABDUL HALIMNo ratings yet

- m07508207 XXXXXXXX 0 enDocument424 pagesm07508207 XXXXXXXX 0 enStefan BusoiNo ratings yet

- Remote Terminal Unit With 8203 - Dual RS-485 Communications ModulesDocument220 pagesRemote Terminal Unit With 8203 - Dual RS-485 Communications ModulesАлександрNo ratings yet

- 5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGDocument200 pages5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGzinebNo ratings yet

- Wago-I/O-System 750: ManualDocument368 pagesWago-I/O-System 750: ManualMircea AndoneNo ratings yet

- L-PRO 4500: Transmission Line Protection RelayDocument478 pagesL-PRO 4500: Transmission Line Protection RelaycacobecoNo ratings yet

- IOTService User Manual 20181211Document62 pagesIOTService User Manual 20181211Anonymous yugocxnNo ratings yet

- L PRO 2100 ManualDocument306 pagesL PRO 2100 ManualEduardo ZamoranoNo ratings yet

- Project Ref No.: PSE/TZ/T19005Document86 pagesProject Ref No.: PSE/TZ/T19005Luis MaalihanNo ratings yet

- Differential Pressure Transmitter PAD ManualDocument75 pagesDifferential Pressure Transmitter PAD ManualAbid HameedNo ratings yet

- 1sdh000891r0002 PDFDocument42 pages1sdh000891r0002 PDFrajasekar thangarajNo ratings yet

- Allen Bradley Power Monitor 3000 Manual PDFDocument356 pagesAllen Bradley Power Monitor 3000 Manual PDFAndrewcaesar100% (1)

- EDG-4508 4516 Manual Ed6Document108 pagesEDG-4508 4516 Manual Ed6amineNo ratings yet

- OSCOP P V6.60 E50417-H1076-C170-A5 enDocument402 pagesOSCOP P V6.60 E50417-H1076-C170-A5 enRinda_RaynaNo ratings yet

- Mobility PC Programmer DealerDocument15 pagesMobility PC Programmer DealerMiguel GonzalezNo ratings yet

- WAGO-TO-PASS® 761: ManualDocument126 pagesWAGO-TO-PASS® 761: ManualbgtNo ratings yet

- 1761 Device NetDocument100 pages1761 Device NetJorge MontanoNo ratings yet

- Operating Manual: Signal Converter SSI - Analog / SerialDocument30 pagesOperating Manual: Signal Converter SSI - Analog / SerialDiana MIND AmayaNo ratings yet

- Functions 840DDocument290 pagesFunctions 840DRogel Rios100% (2)

- Ducati Energia Dat Manual 140128 1813 Datpiu User Manual Eng PDFDocument60 pagesDucati Energia Dat Manual 140128 1813 Datpiu User Manual Eng PDFPiero AguilarNo ratings yet

- Ancortek Manual V1.0 20150601Document21 pagesAncortek Manual V1.0 20150601Wesley GeorgeNo ratings yet

- Protocol Converter For PROFIBUS-DP Slave: PKV 30-DpsDocument17 pagesProtocol Converter For PROFIBUS-DP Slave: PKV 30-DpsMoumene Djafer BeyNo ratings yet

- Prolinx Modbus Ethernet ManualDocument135 pagesProlinx Modbus Ethernet ManualZuñiga AntonioNo ratings yet

- 6MD663 64 ManualDocument224 pages6MD663 64 Manualdilipeline100% (1)

- E870-L915LG12 Usermanual ES v1.2Document32 pagesE870-L915LG12 Usermanual ES v1.2javierk38No ratings yet

- Minor Project ReportDocument29 pagesMinor Project ReportHiteshNo ratings yet

- WP CHARM CommissioningDocument30 pagesWP CHARM Commissioningand1975No ratings yet

- Technical Communication Omnipcx Enterprise: Date: 13 October 2009Document98 pagesTechnical Communication Omnipcx Enterprise: Date: 13 October 2009locuras34No ratings yet

- Pac Rx3i Cpu Manual - Gfk2222hDocument580 pagesPac Rx3i Cpu Manual - Gfk2222htarco systemsNo ratings yet

- Trane RT-SVP06A-EN 05062008Document125 pagesTrane RT-SVP06A-EN 05062008Elias Garcia JerezNo ratings yet

- E3/T3 Interface Plug-In Card For Loop-O9400R or Loop-O9400R-XCU16Document46 pagesE3/T3 Interface Plug-In Card For Loop-O9400R or Loop-O9400R-XCU16Nguyễn Văn HưngNo ratings yet

- Flowmeter D184b059u02-04-05 - 2006Document52 pagesFlowmeter D184b059u02-04-05 - 2006jebisiNo ratings yet

- Workstationst Alarm Viewer: Instruction GuideDocument118 pagesWorkstationst Alarm Viewer: Instruction GuideMARIO OLIVIERINo ratings yet

- 7SA522x Manual A3 v043003 UsDocument592 pages7SA522x Manual A3 v043003 UsDrastaru ValentinNo ratings yet

- W 3000Document30 pagesW 3000sarokihNo ratings yet

- WaveLight Allegretto Wave Eye-Q - User Manual PDFDocument232 pagesWaveLight Allegretto Wave Eye-Q - User Manual PDFVitaliy INo ratings yet

- Startup-Basic: User ManualDocument16 pagesStartup-Basic: User ManualVA MaintNo ratings yet

- Quectel EM12EG12EG18 at Commands Manual V1.0Document231 pagesQuectel EM12EG12EG18 at Commands Manual V1.0suppoNo ratings yet

- 4230 ManualDocument204 pages4230 Manualterios77No ratings yet

- Wago To-Pass 761 761-xxx: ManualDocument24 pagesWago To-Pass 761 761-xxx: ManualbgtNo ratings yet

- User Manual: HGM6400 Automatic Genset Controller (With J1939 Interface)Document37 pagesUser Manual: HGM6400 Automatic Genset Controller (With J1939 Interface)nhocti007No ratings yet

- GFK2314CDocument654 pagesGFK2314CEzz NadiNo ratings yet

- 7UM61x Manual PDFDocument424 pages7UM61x Manual PDFJavier Valencia MurilloNo ratings yet

- EDG-4508 4516 Manual Ed.3Document112 pagesEDG-4508 4516 Manual Ed.3JulivanNo ratings yet

- Data Acquisition IntroductionDocument204 pagesData Acquisition IntroductionRafael FloresNo ratings yet

- Manual Part 2 Engineering & Technical References: REF 542 PlusDocument248 pagesManual Part 2 Engineering & Technical References: REF 542 PlusHatem HusseinNo ratings yet

- Ethernet ManualDocument282 pagesEthernet ManualjimenezhnNo ratings yet

- Firmware Update User ManualDocument53 pagesFirmware Update User ManualSamdan NamhaisurenNo ratings yet

- Teles - Gate Manager 14.0Document33 pagesTeles - Gate Manager 14.0Surenhobsd50% (2)

- Practical E-Manufacturing and Supply Chain ManagementFrom EverandPractical E-Manufacturing and Supply Chain ManagementRating: 3.5 out of 5 stars3.5/5 (4)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Geda Manual EngDocument18 pagesGeda Manual Enganilp12rNo ratings yet

- HAT-UM-U1-V1.0 User Manual Hydraulic Assembly Tool enDocument33 pagesHAT-UM-U1-V1.0 User Manual Hydraulic Assembly Tool enanilp12rNo ratings yet

- L13003483 HA-TF 23 R25 380-400V 3phasen 2xM ENDocument19 pagesL13003483 HA-TF 23 R25 380-400V 3phasen 2xM ENanilp12rNo ratings yet

- Operating Manual: For Lokring Single Ring Tube JoiningDocument11 pagesOperating Manual: For Lokring Single Ring Tube Joininganilp12rNo ratings yet

- Assembling Tool 8mm 4L08HE1552 - L13002758Document11 pagesAssembling Tool 8mm 4L08HE1552 - L13002758Ahmad MuhammadNo ratings yet

- Operating Manual: For Lokring Single Ring Tube JoiningDocument11 pagesOperating Manual: For Lokring Single Ring Tube Joininganilp12rNo ratings yet

- Maintainance Activitys For Production Deptt. Machinery - Xls - 0Document20 pagesMaintainance Activitys For Production Deptt. Machinery - Xls - 0anilp12rNo ratings yet

- F-MNT-02 Log BookDocument2 pagesF-MNT-02 Log Bookanilp12rNo ratings yet

- Maintainance Activitys For Production Deptt. Machinery - Xls - 0Document20 pagesMaintainance Activitys For Production Deptt. Machinery - Xls - 0anilp12rNo ratings yet

- Itinerary For 3days and 2nights in Pangasinan, PhilippinesDocument5 pagesItinerary For 3days and 2nights in Pangasinan, PhilippinesKathleen Gail Arguelles ArcegaNo ratings yet

- Nesco Utility: Expression of InterestDocument14 pagesNesco Utility: Expression of InterestSanjayaNo ratings yet

- Westinghouse 191Document3 pagesWestinghouse 191Ali BalzaNo ratings yet

- ENGINE OVERHAUL 2.6 4cylDocument24 pagesENGINE OVERHAUL 2.6 4cylalbertoNo ratings yet

- Filing For ExtensionDocument5 pagesFiling For ExtensionTexas WatchdogNo ratings yet

- Export Promotion Capital Goods Scheme PresentationDocument32 pagesExport Promotion Capital Goods Scheme PresentationDakshata SawantNo ratings yet

- Nokia Help PDFDocument101 pagesNokia Help PDFTim GargNo ratings yet

- Swelab User ManualDocument2 pagesSwelab User Manualhayder FadelNo ratings yet

- Tut 1Document5 pagesTut 1foranangelqwertyNo ratings yet

- Iphone 14 Plus InvoiceDocument2 pagesIphone 14 Plus Invoicesubhashgidwani0099100% (1)

- What is Reliability Centered Maintenance and its principlesDocument7 pagesWhat is Reliability Centered Maintenance and its principlesRoman AhmadNo ratings yet

- Quality SND zones for big movesDocument4 pagesQuality SND zones for big movesAriel Gohoury100% (1)

- Reverse Traversal HomeworkDocument3 pagesReverse Traversal Homeworkabhi74No ratings yet

- Excel Basics1 ShortcutsDocument14 pagesExcel Basics1 ShortcutsJMFMNo ratings yet

- Yamaha Tdm900 2002-2007 Workshop Service ManualDocument5 pagesYamaha Tdm900 2002-2007 Workshop Service ManualAlia Ep MejriNo ratings yet

- My Little Pony: Friendship Is Magic #14 PreviewDocument10 pagesMy Little Pony: Friendship Is Magic #14 PreviewGraphic Policy100% (3)

- Harmonization and Standardization of The ASEAN Medical IndustryDocument75 pagesHarmonization and Standardization of The ASEAN Medical IndustryGanch AguasNo ratings yet

- Quick Refer Ence Guide Collection:: ST Armorstart and Armorstart ST ConnectivityDocument12 pagesQuick Refer Ence Guide Collection:: ST Armorstart and Armorstart ST ConnectivityYeltsin MuniveNo ratings yet

- BDM Programmer for MC32xxx ChipsDocument11 pagesBDM Programmer for MC32xxx ChipsMoisés Rosado GallardoNo ratings yet

- System Integration and Architecture - P2Document24 pagesSystem Integration and Architecture - P2percival fernandezNo ratings yet

- Waymo LetterDocument14 pagesWaymo LetterSimon AlvarezNo ratings yet

- Mining Gate2021Document7 pagesMining Gate2021level threeNo ratings yet

- Absent Father, Absent Mother: Its Effect in The Behavior and Academic Performance of The Senior High School in SPCCDocument3 pagesAbsent Father, Absent Mother: Its Effect in The Behavior and Academic Performance of The Senior High School in SPCCRendel PorlaresNo ratings yet

- Sachin Vinod Nahar: SVKM's Usha Pravin Gandhi College of ManagementDocument3 pagesSachin Vinod Nahar: SVKM's Usha Pravin Gandhi College of ManagementSachin NaharNo ratings yet

- Journal of Cleaner Production: Peide Liu, Baoying Zhu, Mingyan Yang, Xu ChuDocument12 pagesJournal of Cleaner Production: Peide Liu, Baoying Zhu, Mingyan Yang, Xu ChuccNo ratings yet

- Acramin Prefix KDocument3 pagesAcramin Prefix KB.M. RasheduzzamanNo ratings yet

- Slides 06 PDFDocument71 pagesSlides 06 PDFLoai MohamedNo ratings yet

- Neca Labor Factor Score SheetDocument1 pageNeca Labor Factor Score SheetEng Waseem SamsodienNo ratings yet

- Sgsoc Esia Oils Cameroon LimitedDocument299 pagesSgsoc Esia Oils Cameroon LimitedcameroonwebnewsNo ratings yet