Professional Documents

Culture Documents

HAT-UM-U1-V1.0 User Manual Hydraulic Assembly Tool en

Uploaded by

anilp12rOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAT-UM-U1-V1.0 User Manual Hydraulic Assembly Tool en

Uploaded by

anilp12rCopyright:

Available Formats

User Manual

Hydraulic assembly tool

Type HE; HF; HS; NE; NH; NS; NT; HC

for LOKRING® tube connections

Table of contents

Table of contents ......................................................................................................................... 2

1 About this user manual ................................................................................................... 4

1.1 Explanation of symbols ...................................................................................................... 4

1.2 Limitation of liability............................................................................................................ 5

1.3 Scope of delivery ............................................................................................................... 5

1.4 Warranty terms .................................................................................................................. 5

1.5 Manufacturer ..................................................................................................................... 6

2 Safety ................................................................................................................................ 6

2.1 Intended use ...................................................................................................................... 6

2.2 Misuse ............................................................................................................................... 6

2.3 Safety notices and accident prevention ............................................................................. 6

2.3.1 General .............................................................................................................................. 6

2.3.2 Operating personnel .......................................................................................................... 6

2.3.3 Work area .......................................................................................................................... 7

2.3.4 Residual risks and safety measures .................................................................................. 7

3 Description of product .................................................................................................. 10

3.1 Designation...................................................................................................................... 11

3.2 Models HE and NE .......................................................................................................... 11

3.3 Models HF, HS, NF, NS and NT ...................................................................................... 11

3.4 Technical data ................................................................................................................. 13

3.5 Operating conditions ........................................................................................................ 13

4 First start-up .................................................................................................................. 13

4.1 Connecting the tool .......................................................................................................... 13

4.2 Before first use ................................................................................................................ 13

5 Use .................................................................................................................................. 14

5.1 Operating principle........................................................................................................... 14

5.2 Assembly of a LOKRING tube connection ....................................................................... 15

6 Adjustment of the assembly tool ................................................................................. 18

7 Storage and transport ................................................................................................... 28

8 Maintenance and care ................................................................................................... 29

8.1 Cleaning .......................................................................................................................... 30

8.2 Lubrication ....................................................................................................................... 30

HAT-UM-U1-V1.0 2/33 10/22/2020

9 Troubleshooting ............................................................................................................ 32

10 Disposal.......................................................................................................................... 32

Appendix A: Declaration of conformity.................................................................................... 33

HAT-UM-U1-V1.0 3/33 10/22/2020

1 About this user manual

IMPORTANT!

Read the user manual carefully before using the machine and keep in a safe place for the

life of the product!

Also read and observe the user manual for the LOKRING® hydraulic aggregate for gener-

ating the required working pressure!

This user manual is part of the product. Illustrations in this manual are provided for general understanding and

can differ from the actual model. It is assumed that personnel are familiar with normal procedures such as the

use of suitable work clothing (e.g. work shoes, hearing protection, safety goggles, etc.). Subject to technical

modifications. In addition to carefully reading the user manual, we also recommend that you obtain training and

instruction in operation and handling of assembly tools from one of our qualified technicians. In case anything

is unclear, please contact the manufacturer.

1.1 Explanation of symbols

Safety notices in this manual are marked with symbols. The safety notices are introduced with signal words

that express the scope of the hazard. Always comply with safety notices and act with caution in order to pre-

vent accidents, personal injury and material damage.

DANGER!

indicates a hazard with a high degree of risk, which if not avoided will result in death or

severe injury.

WARNING!

indicates a hazard with a moderate degree of risk, which if not avoided can result in death

or severe injury.

CAUTION!

indicates a hazard with a low degree of risk, which if not avoided can result in minor or

moderate injury.

INFORMATION!

indicates special information for effective handling of the tool.

HAT-UM-U1-V1.0 4/33 10/22/2020

1.2 Limitation of liability

All information and notices in this manual were compiled taking into account the applicable standards and regu-

lations, in accordance with the state of the art, as well as our extensive knowledge and experience.

The manufacturer assumes no liability for damages arising from:

Failure to observe the user manual

Non-intended use

Deployment of untrained personnel

Unauthorized modifications

Technical changes

Use of non-approved spare parts

Use of the assembly tool in violation of regulations or unauthorized modifications to the machine will exempt

the manufacturer from liability and will invalidate the declaration of conformity! In this case the user will be lia-

ble for damages resulting from use of the machine.

In the case of special versions, the ordering of additional options, or on the basis of the latest technical chang-

es, the actual scope of delivery can deviate from the explanations and depictions described in this manual.

The following documents and/or regulations apply: the obligations stipulated in the delivery contract, the Gen-

eral Terms and Conditions and the manufacturer’s Terms of Delivery, and the applicable statutory regulations

at the time the contract is concluded.

1.3 Scope of delivery

The scope of delivery includes:

1 x hydraulic assembly tool

1 x user manual

1.4 Warranty terms

The warranty terms are included in the manufacturer's terms and conditions.

HAT-UM-U1-V1.0 5/33 10/22/2020

1.5 Manufacturer

The manufacturer of the hydraulic assembly tool is:

VULKAN Lokring Rohrverbindungen GmbH & Co. KG

Heerstrasse 66

D-44653 Herne

Tel.: +49 2325-922-155

Fax: +49 2325 51222

E-mail: info.Lok@vulkan.com

2 Safety

2.1 Intended use

This assembly tool is intended only for commercial use with hydraulic aggregates from VULKAN Lokring

Rohrverbindungen GmbH & Co. KG in accordance with the descriptions and safety information provided in this

user manual. Operation of the assembly tool is permitted only indoors.

2.2 Misuse

Any use of the product that deviates from the intended use is deemed misuse. Use of the machine with other

hydraulic aggregates, in particular those of other manufacturers, is prohibited.

2.3 Safety notices and accident prevention

2.3.1 General

The instruction in this user manual and the safety notices affixed to the unit with respect to operation, mainte-

nance and repairs must be observed and complied with for safety reasons.

2.3.2 Operating personnel

The use of tools can involve certain risks. Their operation and handling is therefore permitted by trained and

experienced personnel only. First startup, maintenance and repairs must be carried out by specially trained

personnel. Take advantage of the training measures offered by the manufacturer.

Operating personnel must wear close-fitting clothing and safety shoes. The minimum age for operation of the

tool is 18. However, it is permitted to allow persons age 16 and older to work with the tool if required for com-

pletion of an apprenticeship, under the supervision of a competent professional.

HAT-UM-U1-V1.0 6/33 10/22/2020

2.3.3 Work area

In order to ensure safe working conditions it is absolutely necessary that the work area be level and hard-

wearing, and that there is sufficient space for freedom of movement. The workplace must also be sufficiently

illuminated.

2.3.4 Residual risks and safety measures

It is strictly prohibited to disable, modify, block, remove, convert or supplement any components of safety and

protective devices of the hydraulic tool; failure to comply can result in defects and/or life-threatening injuries.

The manufacturer cannot be held liable for damage or injuries resulting from such negligence. Any instances of

negligence mentioned above will also immediately void any warranty entitlement.

CAUTION!

Danger of injury!

From unpacking, lifting or transport of the assembly tool

Minor injuries can result

Wear suitable safety shoes when unpacking, lifting or transporting the assembly tool!

DANGER!

Danger of injury!

Slipping, stumbling and falling

Severe injuries will result

Watch out for surfaces that have become slippery from use of the machine and also for

tripping hazards caused by the hydraulic hose.

DANGER!

Danger of injury!

From inadvertent startup of the machine

Severe injuries will result

Do not connect or disconnect tools to/from the hydraulic aggregate while the unit is con-

nected to the electric power grid. Inadvertent startup of the hydraulic aggregate can

cause serious injuries.

Unplug the plug!

HAT-UM-U1-V1.0 7/33 10/22/2020

DANGER!

Danger of injury!

Due to contact with hot surfaces

Severe injuries can result

Some parts of the hydraulic aggregate become very hot during operation. To avoid

burns, do not touch hot machine parts.

DANGER!

Danger of injury!

From closing jaws

Severe injuries will result

Do not reach into the danger zone between the assembly jaws!

This also applies in the event that the tool cannot be removed from the tube after

assembly, because the tube is jammed in the tool. In this case first pull the plug

and then release the tool manually.

Loose-fitting clothing, jewelry or long hair can be caught. It is also possible that

certain types of gloves can be caught. Therefore, wear only tight-fitting clothing

and no jewelry, and always ensure that hair is protected!

DANGER!

Danger of injury!

Due to explosion

Severe injuries will result

Use of the tool in explosive areas is not permitted.

WARNING!

Danger of injury!

Severe injuries will result

When working on the hydraulic assembly tool and when connecting the tool to the hy-

draulic aggregate, always comply with the applicable safety regulations, especially the

accident prevention regulations of the trade associations.

HAT-UM-U1-V1.0 8/33 10/22/2020

WARNING!

Danger of injury!

Severe injuries will result

Always disconnect hydraulic hoses from the hydraulic aggregate when no assembly tool

is connected!

WARNING!

Danger of injury

Severe injuries will result

If there are indications of irregular function and performance, stop using the tool immedi-

ately and service or repair the tool!

CAUTION!

Danger of injury

Minor injuries will result

When handling the tool, be aware of the danger that can arise from uncontrolled move-

ments of pressurized hoses. For example, separation of the hydraulic hose from the tool.

Conduct daily inspections of hydraulic hoses and hydraulic connections for damage or

wear, and replace if necessary.

CAUTION!

Danger of injury

Minor injuries will result

Never exceed the maximum operating pressure of 300 bar. Otherwise, this can result in

destruction of the assembly tool and danger to other people.

HAT-UM-U1-V1.0 9/33 10/22/2020

3 Description of product

The hydraulic assembly tool is used only for assembly of LOKRING tube connections on tubes intended for this

purpose. The required working pressure is generated by a hydraulic aggregate, which is also available from

VULKAN Lokring.

Figure 1

a. Start button

b. Jaw constant

c. Jaw variable

d. Clamping jaws

e. Control pin

f. Protective plate

g. Jaw housing

HAT-UM-U1-V1.0 10/33 10/22/2020

3.1 Designation

The name of the assembly tool is composed of the following properties:

HAT-A-BB-CC,CC-LRDD+EE-XF (Example: HAT-L-HE-03,00-LR07-10)

HAT: Hydraulic Assembly Tool

A: Tool size (S, M, ML, L, XL or XXL)

BB: Model (based on clamping jaws)

CC,CC: Clamping jaw size

LRDD: Outer diameter of the LOKRING tube connection

EE: Recess of the jaw constant for the LOKRING tube connection

XF: Special tool

3.2 Models HE and NE

The HE and NE tools are for tube connections in which the outer tube is flared. The clamping jaws (d) are

smooth and engage behind the flared area. When the tool closes, they slide over the non-flared area until they

press against the flared area. This stabilizes the flared area.

3.3 Models HF, HS, NF, NS and NT

These models are for tube connections in which the fixed clamping jaw has to clamp on the outer tube. The

outer tube is not flared or is only slightly flared. In this models the overlapping of the LOKRING tube connection

can be adjusted.

Figure 29

HAT-UM-U1-V1.0 11/33 10/22/2020

The following table shows the information on the type plates of the assembly tools:

VULKAN Lokring

MANUFACTURER Rohrverbindungen GmbH & Co. KG

Heerstraße 66

(Manufacturer) DE-44653 Herne, Germany

www.vulkan.com

TYPE

HAT

(Type)

BUILT

YYYY

(Year of manufacture)

PMAX

300 bar / 30 MPa

(Rated pressure)

Qnominal

2.5 l/min.

(Flow rate)

DOCUMENT

HAT-UM-U1-V1.0

(Drawing no. of documentation)

SERIAL NO. HAT-YY-XXX

(Serial number) (YY = year of manufacture / XXX = serial number)

Table 1

HAT-UM-U1-V1.0 12/33 10/22/2020

3.4 Technical data

Max. outer diameter of tube: 28 mm*

Max. tube wall thickness: 1.5 mm*

Max. operating pressure: 300 bar

Assembly time: approx. 2 sec.

A-weighted sound pressure level LpA:** 75.8 dB (expanded uncertainty U = +3 dB)

Total vibration value: 1.93 m/s² (expanded uncertainty U = 1.14 m/s²)

Weight: approx. 3 kg

Dimensions: approx. 315 x 80 x 50 mm

*other dimensions on request

**with VULKAN Lokring hydraulic aggregate model HA

3.5 Operating conditions

Permissible ambient temperature: 0°C to 40°C

Permissible relative humidity: ≤ 90% (non condensing)

4 First start-up

4.1 Connecting the tool

Remove packaging and check tool for damage. Before connecting the tool, check to ensure that threaded joints

are firmly seated and the tool guides are smooth running. If necessary, lubricate the guides with a universal

lubricating spray. Connect the assembly tool to the hydraulic hoses of the VULKAN Lokring hydraulic aggre-

gate (Attention: Switch off hydraulic aggregate!). For correct connection, refer to the user manual for the hy-

draulic aggregate.

4.2 Before first use

To ensure that the assembly tool is functioning properly, after correctly connecting the assembly tool to the

hydraulic aggregate, press the start button (a) several times, without assembling a tube connection.

HAT-UM-U1-V1.0 13/33 10/22/2020

5 Use

Conduct the following inspection before use:

Assume a stable position and hold the tool correctly: Be ready to counteract normal or sudden movements.

Check tool for possible damage prior to use.

WARNING!

Danger of injury

Severe injuries will result

If there are indications of irregular function and performance, stop using the tool immedi-

ately and service or repair the tool!

INFORMATION!

The operating pressures on the hydraulic aggregate are set at the factory and should not

be changed.

INFORMATION!

The following description is based on the assembly of a LOKRING® tube connection with

a flared outer tube. There are different connection types for LOKRING ® tube connec-

tions, and therefore different tube geometries. Always consult the Best Practice docu-

ment for the application.

5.1 Operating principle

Press and hold the start button (a) on the tool to activate the motor of the hydraulic aggregate so that the pump

generates the set pressure. The tool is activated by the hydraulic pressure. Once the set pressure is reached

and the work process of the tool is completed, the hydraulic aggregate is deactivated. If the start button (a) is

released during operation, the hydraulic aggregate is deactivated and the tool returns to starting position.

HAT-UM-U1-V1.0 14/33 10/22/2020

5.2 Assembly of a LOKRING tube connection

DANGER!

Danger of injury!

From closing jaws

Severe injuries will result

Do not reach into the danger zone between the assembly jaws!

This also applies in the event that the tool cannot be removed from the tube after

assembly, because the tube is jammed in the tool. In this case first pull the plug

and then release the tool manually.

Loose-fitting clothing, jewelry or long hair can be caught. It is also possible that

certain types of gloves can be caught. Therefore, wear only tight-fitting clothing

and no jewelry, and always ensure that hair is protected!

Proceed as follows to assemble the LOKRING tube connection:

1. Assembly direction

Push the LOKRING onto the inner tube, with the end having the Smallest

Chamfer

diameter

smallest diameter first.

2. Place the LOKRING on the inner tube

Place the LOKRING with the chamfer on the inner tube in the

Chamfer

assembly direction.

HAT-UM-U1-V1.0 15/33 10/22/2020

3. Push the LOKRING onto the inner tube

Push the LOKRING onto the inner tube.

4. Insert inner tube

Push tubes at least the length of the LOKRING + 3 mm, or in the

case of flared tubes, all the way to the stop.

5. Apply LOKPREP

> Always use the included pipettes to apply LOKPREP.

MIN 120°

> Apply LOKPREP at least in an area of 120° of the tube cir-

cumference.

> Capillary action ensures the even distribution of LOKPREP.

6. Position the LOKRING

Push the LOKRING in the direction of the outer tube until the

chamfer touches the outer tube.

HAT-UM-U1-V1.0 16/33 10/22/2020

7. Position the tool

Position the assembly tool at a slight angle so that the LOKRING

is firmly in the jaw constant (b).

8. Clamp outer tube

> Press the outer tube against the clamping jaws (d) until the

tube locks into place; in the case of a flared tube, clamp be-

hind the flared area.

> Align the assembly tool perpendicular to the connection.

9. Check the position of the LOKRING

> The LOKRING must be flush within the jaw constant (b).

> The LOKRING must be in contact with the outer tube.

10. Check tubes

Make sure that the inner tube is inserted far enough into the outer

tube; in case of flared tubes, all the way to the stop.

HAT-UM-U1-V1.0 17/33 10/22/2020

11. Carry out assembly

> Press and hold the start button (a) on the assembly tool until

assembly is complete.

> Afterwards, the assembly tool opens automatically.

12. Done

> The outer tube must be visible at least 1 mm and in the full

MIN. 1 mm, 360°

circumference behind the smallest inner diameter of the LO-

KRING.

> The LOKRING must never be mounted beyond the end of

the flared area.

6 Adjustment of the assembly tool

For models HE and NE, adjustment of the assembly tool is not possible. If the LOKRING is pushed too short or

too far over the outer tube, check the length of the flared area of the outer tube for compliance with the applica-

tion drawing. If the LOKRING is still not correctly pushed on, contact the customer service department.

For all other models, adjustment of the overlapping length is possible.

The assembly tools are pre-adjusted for standard connections at the factory. Depending on the connection, it

may be necessary to readjust the assembly tool. To adjust the hydraulic assembly tools so that the ring is

pushed far enough over the outer tube, the control pin (e) must be adjusted accordingly. To facilitate adjust-

ment, the following theoretical formula can be used as a guide. However, readjustment of the control pin (e)

may still be necessary.

HAT-UM-U1-V1.0 18/33 10/22/2020

A Tube connection B Jaw constant with control pin

Table 2

This formula can be used:

𝐿1 = 𝐿2 + 𝐿3 + 8 𝑚𝑚

L3 of 3 mm results in the following rule of thumb:

𝑳𝟏 = 𝑳𝟐 + 𝟏𝟏 𝒎𝒎

HAT-UM-U1-V1.0 19/33 10/22/2020

Proceed as follows to adjust the control pin length:

1. Switch off the hydraulic aggregate

and disconnect the assembly tool

from the hydraulic hose.

2. Use a hexagon key to remove the

protective plate (f) from the tool.

3. Remove circlips from the jaw bolt of

the jaw constant (b).

HAT-UM-U1-V1.0 20/33 10/22/2020

4. Remove the jaw bolt.

5. Remove the jaw constant (b) from

the tool.

6. Measure and note the length of the

control pin (e) L1.

HAT-UM-U1-V1.0 21/33 10/22/2020

7. Loosen the setscrew that secures

the control pin (e).

8. Loosen the nut.

9. Unscrew the screw all the way.

HAT-UM-U1-V1.0 22/33 10/22/2020

10. Adapt the length of the control pin

(e).

11. Drive out the control pin (e) with a

pin punch.

12. Check the control pin (e). If signs of

wear are visible on the cylindrical

surface, it must be replaced. Tap the

control pin (e) into the jaw constant

(b) to the desired length.

Note: If the LOKRING tube connection is

not pushed far enough over the outer

tube, the control pin (e) must protrude

out of the jaw constant (b) by the desired

length.

HAT-UM-U1-V1.0 23/33 10/22/2020

13. Check the adjusted length.

14. Tighten the locking screw.

15. Carefully screw in the screw as far

as the control pin (e) and fix with the

lock nut.

HAT-UM-U1-V1.0 24/33 10/22/2020

16. Insert the jaw constant (b) with the

guide pin into the jaw variable (c).

17. Align the holes in the jaw constant

(b) and the jaw housing (g).

18. Push Teflon washers on both sides

into the gap between the jaw con-

stant (b) and the jaw housing (g).

HAT-UM-U1-V1.0 25/33 10/22/2020

19. Push the jaw bolt through the jaw

housing (g) and jaw constant (b).

20. Fasten circlips on the jaw bolt.

21. The jaw constant (b) is now mount-

ed. The distance between the jaw

constant (b) and the jaw variable (c)

still has to be adjusted.

HAT-UM-U1-V1.0 26/33 10/22/2020

22. Loosen the nut and turn the screw in

or out to adjust the distance between

the jaw variable (c) and the jaw con-

stant (b).

Note: When the control pin (e) is just

before the clamping jaws (d), the dis-

tance between the jaws is correct. The

radius at the front of the control pin (e)

can be used for orientation. When the

run-out of the radius is still slightly visi-

ble, the tool is correctly adjusted.

23. Adjustment of the tool is complete.

24. Mount protective plate (f).

HAT-UM-U1-V1.0 27/33 10/22/2020

25. Connect the tool to the hydraulic

hose and conduct a test assembly.

Readjust the tool as necessary.

7 Storage and transport

Store the tool in the following conditions:

Do not store outdoors

Store in a dry and dust-free location

Do not expose to aggressive media

Protect from direct sunlight

Avoid mechanical shocks

Storage temperature: 15°C to 35°C

Relative humidity: ≤ 60%

When stored longer than 1 month:

o Preserve tool (lightly oil or grease metal parts) and wrap airtight in foil

o Check the general condition of all parts regularly

o If necessary, refresh or repeat the preservation

Clean all parts before storing the tool again.

HAT-UM-U1-V1.0 28/33 10/22/2020

8 Maintenance and care

The following sections describe the maintenance tasks that are necessary for optimal and trouble-free opera-

tion.

DANGER!

Danger of injury!

From inadvertent startup of the machine

Severe injuries can result

For cleaning, repairs and maintenance, and whenever leaving the workplace, de-

pressurize the tool and unplug the power plug from the power supply. It is not sufficient to

switch off the power by setting the switch to the OFF position.

If increased wear is detected as a result of regular inspections, shorten the required maintenance intervals

according to the actual signs of wear, and replace any defective parts (use only original VULKAN Lokring

replacement parts!).

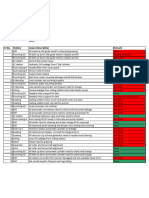

Maintenance schedule:

after after after

daily weekly 20,000 40,000 120,000

assemblies assemblies assemblies

Cleaning and visual inspection X

Cleaning and lubrication of moving

X

parts near the screw head

Complete cleaning (dismantle all mov- at least

every 2

ing parts) months

Inspect and, if necessary, replace the

X X X

springs

Visual inspection of control pin (e) and

X X X X X

replace, if necessary

If you have any questions regarding maintenance tasks and intervals, please contact the customer service

department. If necessary, a general refurbishing can be arranged with the manufacturer.

HAT-UM-U1-V1.0 29/33 10/22/2020

8.1 Cleaning

Periodic cleaning is necessary due to the ambient conditions and the use of the tool.

After extended use of the tool, LOKPREP can accumulate especially in the front area of the tool.

Remove LOKPREP manually. Wipe off any impurities with a lint-free cloth. To remove stubborn impurities,

LOKCLEAN (article no. L14004152) is recommended.

Never use solvents or acids, esters (organic compounds consisting of acids and alcohol), acetone (ketone),

chlorinated hydrocarbons or oils containing nitrocarbonates. Do not use chemicals with a low flash point.

8.2 Lubrication

Lubrication is very important and should be carried out carefully. Lubricate all pins, joints and springs, as well

as the piston movement, by hand only.

Lubrication of the piston is achieved by the hydraulic system.

Since lubrication is done manually, the tool should be inspected regularly. Also check the oil tank of the hydrau-

lic aggregate and add oil as necessary.

The following illustration shows the points that require special attention:

HAT-UM-U1-V1.0 30/33 10/22/2020

HAT-UM-U1-V1.0 31/33 10/22/2020

9 Troubleshooting

No. Fault Remedy

Switch off hydraulic aggregate!

Carefully pull the tool out of the tube connection. If

blocked, use a hammer to carefully tap the guide pin

protruding from the jaw variable (c).

1 Tool jams or does not open

The tool will now open again. Check for possible

damage to components.

If the fault occurs again, contact the customer service

department.

For models HE and NE:

Check tube diameters, flared section is too short.

All other models:

LOKRING tube connection is not pushed on

2 1. Check the outer tube for slipping of the clamping

far enough.

jaws (d). Replace the clamping jaws (d) if neces-

sary.

2. Control pin (e) not set correctly. Set control pin (e)

again.

LOKRING tube connection is pushed on too For models HE and NE:

far. Check tube diameters, flared section is too long.

All other models:

Control pin (e) not set correctly. Set control pin (e)

again.

3 Oil drips from the front of the tool head. Seals are leaking. Contact customer service depart-

ment.

10 Disposal

Ensure compliance with the national regulations for recycling according to material type.

If no take-back or disposal agreement was made, dispose of the dismantled components by recycling. The

local authorities or specialized disposal companies can provide information on environmentally compatible

disposal. If necessary, the tool can be sent back to the manufacturer with a request for disposal.

HAT-UM-U1-V1.0 32/33 10/22/2020

Appendix A: Declaration of conformity

HAT-UM-U1-V1.0 33/33 10/22/2020

You might also like

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Econom 0 - 01 - 1 - 2 - Operating Instruction - Active Facades - Industrial UseDocument34 pagesEconom 0 - 01 - 1 - 2 - Operating Instruction - Active Facades - Industrial UseMarcio SantosNo ratings yet

- Mark PumpDocument71 pagesMark Pumpmartin.rubenNo ratings yet

- 02 Service Manual PDFDocument37 pages02 Service Manual PDFramiNo ratings yet

- AOV Operating ManualDocument40 pagesAOV Operating ManualThanh Tung NguyenNo ratings yet

- Operating Manual: For Hydraulic CylindersDocument41 pagesOperating Manual: For Hydraulic CylindersErdinc SenmanNo ratings yet

- Junior 1 - 1S - 2 - Operating Instruction - Industrial UseDocument33 pagesJunior 1 - 1S - 2 - Operating Instruction - Industrial UseVegard SømliøyNo ratings yet

- Birotor Plus 2" Single Case: Installation & Operation ManualDocument26 pagesBirotor Plus 2" Single Case: Installation & Operation ManualFaiz FaizNo ratings yet

- Flujometro Batch Flux 5500Document24 pagesFlujometro Batch Flux 5500sergio fuerteNo ratings yet

- SO Safety Manual F300K DLT7663 19 AEN 003Document22 pagesSO Safety Manual F300K DLT7663 19 AEN 003Ali JamaliNo ratings yet

- 4325e Contoil VzoDocument28 pages4325e Contoil VzoChristian Believers' Assembly BorivaliNo ratings yet

- Installation, Operating and Maintenance Instructions: HADEF Monorail Trolley Type 18/16VADocument11 pagesInstallation, Operating and Maintenance Instructions: HADEF Monorail Trolley Type 18/16VAGuillermo ManchayNo ratings yet

- Active: Manual - Crane DrivesDocument29 pagesActive: Manual - Crane DrivesSAGETS ExploitRMNo ratings yet

- QS WATERFLUX3000 en 180307 4002400902 R07Document24 pagesQS WATERFLUX3000 en 180307 4002400902 R07ZAHID HOSSAINNo ratings yet

- 4365e Contoil vzfIIDocument48 pages4365e Contoil vzfIIChristian Believers' Assembly BorivaliNo ratings yet

- 4601en 0119fleDocument40 pages4601en 0119fleHpnoteNo ratings yet

- DMB Manual en 201002Document17 pagesDMB Manual en 201002Shesharam ChouhanNo ratings yet

- Original Operating ManualDocument21 pagesOriginal Operating ManualKolakaluri MadhuNo ratings yet

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- 4600en 0119fleDocument40 pages4600en 0119fledeni jakaNo ratings yet

- Sim Q Mkii Installation Instructions 4189330024 UkDocument17 pagesSim Q Mkii Installation Instructions 4189330024 UkPrakash VNo ratings yet

- Instruction Manual - Unique To Mixproof Tank Outlet Valve - Ese00156enDocument62 pagesInstruction Manual - Unique To Mixproof Tank Outlet Valve - Ese00156enNguyễn Tuấn VũNo ratings yet

- Bronkhorst Manual EL FLOW SelectDocument51 pagesBronkhorst Manual EL FLOW SelectcccirmusNo ratings yet

- Install, Operate and Maintain Monorail Trolley GuideDocument18 pagesInstall, Operate and Maintain Monorail Trolley GuideNenad PetrovicNo ratings yet

- Dressta-Servis Manual PDFDocument595 pagesDressta-Servis Manual PDFanto banaš100% (3)

- Flender CouplingsDocument60 pagesFlender CouplingscakhokheNo ratings yet

- Washer-Extractors: Pocket Hardmount Variable-SpeedDocument19 pagesWasher-Extractors: Pocket Hardmount Variable-SpeedHomeroPerezNo ratings yet

- Manual EL FLOW SelectDocument51 pagesManual EL FLOW SelectCarlos BNo ratings yet

- 1.Comprehensive HPU User ManualDocument65 pages1.Comprehensive HPU User ManuallearningzabatNo ratings yet

- Hs-3400 Manual m9252 - r1 - Ms3400 STD XPDocument109 pagesHs-3400 Manual m9252 - r1 - Ms3400 STD XPrlcc1984100% (5)

- Dresta TD-20MDocument632 pagesDresta TD-20MDragan100% (9)

- QS OPTIFLUX2000 en 110815 7309842400 R04Document24 pagesQS OPTIFLUX2000 en 110815 7309842400 R04Fabio UnruhNo ratings yet

- Smtd15mex08 3eDocument707 pagesSmtd15mex08 3eFredy VelazquezNo ratings yet

- CM2 Att082 2001Document126 pagesCM2 Att082 2001Dimas Agil Roeseno KambunaNo ratings yet

- 320 01 HADEF Manual Wall Mounted Jib CraneDocument12 pages320 01 HADEF Manual Wall Mounted Jib CraneMatej AndrašekNo ratings yet

- Hydraulik: Jahns-Regulatoren GMBHDocument12 pagesHydraulik: Jahns-Regulatoren GMBHLake HouseNo ratings yet

- MIG ManualDocument24 pagesMIG Manualvladyslav.kuzykNo ratings yet

- 230V Gas-Gasless Mig WeldersDocument24 pages230V Gas-Gasless Mig WelderssjenicakNo ratings yet

- Operators Manual L20Document96 pagesOperators Manual L20SMM ENTREPRISENo ratings yet

- SJHS0 5BDocument76 pagesSJHS0 5BDavid CordovaNo ratings yet

- Operation Manual ADG-EnglischDocument230 pagesOperation Manual ADG-Englischashish gautamNo ratings yet

- Modbus GBDocument48 pagesModbus GBhernangycNo ratings yet

- KGZX NBOSmzg AHl Abt 7 S WGQFP 6Document30 pagesKGZX NBOSmzg AHl Abt 7 S WGQFP 6ankarthik11No ratings yet

- Um Front Load Washers and Washer DryersDocument84 pagesUm Front Load Washers and Washer DryersBobby PrimaNo ratings yet

- K-Two: User ManualDocument35 pagesK-Two: User ManualErvin PintoNo ratings yet

- FlowmeterDocument28 pagesFlowmeterJuan RamondNo ratings yet

- Sump PumpDocument35 pagesSump PumpPrashant VanjariNo ratings yet

- Bizhub - c360 Service ManualDocument1,150 pagesBizhub - c360 Service ManualRudyNo ratings yet

- Bretec c2 OperationDocument88 pagesBretec c2 OperationSerkanAlNo ratings yet

- Bizhub C220 Service Manual PDFDocument114 pagesBizhub C220 Service Manual PDFDon LeNo ratings yet

- Ewm PDFDocument86 pagesEwm PDFDenis ImamovicNo ratings yet

- Edan Sonotrax ManualDocument47 pagesEdan Sonotrax ManualDaniel GalindoNo ratings yet

- BFBP Maintenance Instruction For HZB200-430 PDFDocument30 pagesBFBP Maintenance Instruction For HZB200-430 PDFJuan Jose Mendez GarciaNo ratings yet

- 08 - Hydraulic Dismounting Device For Roll UnitsDocument53 pages08 - Hydraulic Dismounting Device For Roll UnitsCHRISTIAN ROJAS VALENZUELANo ratings yet

- Shinova DM8D Defibrillator - User ManualDocument63 pagesShinova DM8D Defibrillator - User Manualhüseyin vururNo ratings yet

- 8706en 0119fleDocument64 pages8706en 0119fledeni jakaNo ratings yet

- 11-1506 880PL_HD_ManualDocument37 pages11-1506 880PL_HD_Manualalejandro.ruizgNo ratings yet

- EB 9519 EN: Translation of Original InstructionsDocument44 pagesEB 9519 EN: Translation of Original InstructionsChristian H OrtizNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Geda Manual EngDocument18 pagesGeda Manual Enganilp12rNo ratings yet

- Recdatatjv Manual EngDocument21 pagesRecdatatjv Manual Enganilp12rNo ratings yet

- Operating Manual: For Lokring Single Ring Tube JoiningDocument11 pagesOperating Manual: For Lokring Single Ring Tube Joininganilp12rNo ratings yet

- Operating Manual: For Lokring Single Ring Tube JoiningDocument11 pagesOperating Manual: For Lokring Single Ring Tube Joininganilp12rNo ratings yet

- L13003483 HA-TF 23 R25 380-400V 3phasen 2xM ENDocument19 pagesL13003483 HA-TF 23 R25 380-400V 3phasen 2xM ENanilp12rNo ratings yet

- Maintainance Activitys For Production Deptt. Machinery - Xls - 0Document20 pagesMaintainance Activitys For Production Deptt. Machinery - Xls - 0anilp12rNo ratings yet

- Assembling Tool 8mm 4L08HE1552 - L13002758Document11 pagesAssembling Tool 8mm 4L08HE1552 - L13002758Ahmad MuhammadNo ratings yet

- F-MNT-02 Log BookDocument2 pagesF-MNT-02 Log Bookanilp12rNo ratings yet

- Maintainance Activitys For Production Deptt. Machinery - Xls - 0Document20 pagesMaintainance Activitys For Production Deptt. Machinery - Xls - 0anilp12rNo ratings yet

- Unilever Australia MSDSDocument5 pagesUnilever Australia MSDSarditNo ratings yet

- Risk Assessment For Working On Mobile TowerDocument5 pagesRisk Assessment For Working On Mobile Towerfaizan khanNo ratings yet

- Mod 5 Unit 30 International Safety Management CodeDocument12 pagesMod 5 Unit 30 International Safety Management CodeMc LiviuNo ratings yet

- I-002 - Safety and Automation System (SAS) Rev2, May2001Document24 pagesI-002 - Safety and Automation System (SAS) Rev2, May2001Dragoslav DzolicNo ratings yet

- MIN - Q1203 - v1.0 - Jumbo Drill Operator - 09.02.2022 PDFDocument43 pagesMIN - Q1203 - v1.0 - Jumbo Drill Operator - 09.02.2022 PDFBapi MondalNo ratings yet

- 1-Water Safety Plan For Water Quality Management - PUB SingaporeDocument33 pages1-Water Safety Plan For Water Quality Management - PUB SingaporeJason LimNo ratings yet

- Presented By: Sandeep Yadav MSC Nursing1St YearDocument35 pagesPresented By: Sandeep Yadav MSC Nursing1St YearAlmas100% (1)

- DEKRA Process Safety Experts for Risk Management and Safety ComplianceDocument8 pagesDEKRA Process Safety Experts for Risk Management and Safety ComplianceNishir Shah100% (1)

- MSDS - REINZOSIL - 70 31414 10 - (v11 GB EN) PDFDocument5 pagesMSDS - REINZOSIL - 70 31414 10 - (v11 GB EN) PDFJuju JusmanNo ratings yet

- Chapter 7Document2 pagesChapter 7Yhel TrinidadNo ratings yet

- Permit To Work Policy ProcedureDocument7 pagesPermit To Work Policy ProcedureChristian Auditor RiveraNo ratings yet

- Ansi B11.23-2002 (R2007)Document64 pagesAnsi B11.23-2002 (R2007)Moataz MashhourNo ratings yet

- Inspection Test Plan, Inspection Checklist, Work Safety Procedure REFERENCEDocument174 pagesInspection Test Plan, Inspection Checklist, Work Safety Procedure REFERENCEJeff JiaNo ratings yet

- Fosroc Thioflex 600 Pouring Grade Base: Safety Data SheetDocument7 pagesFosroc Thioflex 600 Pouring Grade Base: Safety Data SheetAlves EdattukaranNo ratings yet

- Working at Heights Practical ModuleDocument2 pagesWorking at Heights Practical ModuleMadalina FoteaNo ratings yet

- Turning Up The Heat - Full Service Fire Safety Engineering For Concrete StructuresDocument3 pagesTurning Up The Heat - Full Service Fire Safety Engineering For Concrete StructuresKin ChenNo ratings yet

- MSDS EonDocument5 pagesMSDS EonIndieNo ratings yet

- Implementation of Labor Law in RMG Sector: Investigating The Scenario of Health, Safety and Welfare Issues in Dhaka, BangladeshDocument17 pagesImplementation of Labor Law in RMG Sector: Investigating The Scenario of Health, Safety and Welfare Issues in Dhaka, BangladeshA FCNo ratings yet

- Eam 2/gui 6 Establishment of Just Culture' Principles in Atm Safety Data Reporting and AssessmentDocument51 pagesEam 2/gui 6 Establishment of Just Culture' Principles in Atm Safety Data Reporting and AssessmentHANSA blogNo ratings yet

- Inspection and Maintenance of Mechanical Power Presses: National Safety Council Data Sheet 603 Rev. July 2004Document9 pagesInspection and Maintenance of Mechanical Power Presses: National Safety Council Data Sheet 603 Rev. July 2004Emrah AkcayNo ratings yet

- Corrosion Inhibitor-Az8104-Msds-SuezDocument9 pagesCorrosion Inhibitor-Az8104-Msds-SuezMaximiliano Vandee C. MitakdaNo ratings yet

- Boost pressure up to 4 times with no-power air boosterDocument20 pagesBoost pressure up to 4 times with no-power air boosterCarlos Andres Rodriguez SolarteNo ratings yet

- Method of Statement - Pa SystemDocument15 pagesMethod of Statement - Pa SystemashifNo ratings yet

- Gavin Chui: Professional ProfileDocument3 pagesGavin Chui: Professional ProfileMarkoNo ratings yet

- Ronald ThaeleDocument2 pagesRonald ThaelerthaelehotmailcomNo ratings yet

- Firex MSDS Be 020518Document8 pagesFirex MSDS Be 020518Eng.Ibrahim OthmanNo ratings yet

- ST001 - A4 Overheads - Duty of Care Domestic Rev 0Document6 pagesST001 - A4 Overheads - Duty of Care Domestic Rev 0Teodoro EsquilloNo ratings yet

- TETRA Steel 1200 BrochureDocument4 pagesTETRA Steel 1200 BrochureQingming MaNo ratings yet

- Cold CuttingDocument9 pagesCold CuttingChristopher uche100% (1)

- CWP Cert PDFDocument4 pagesCWP Cert PDFmurtazagulzar3No ratings yet