Professional Documents

Culture Documents

Blower Manual PDF

Uploaded by

Datta DoifodeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blower Manual PDF

Uploaded by

Datta DoifodeCopyright:

Available Formats

SHRI VILE PARLE KELAVANI MANDAL’S

Institute of Technology, Dhule.

Dist. Dhule (M.S.).

www.svkm-iot.ac.in

CENTRIFUGAL AIR BLOWER TEST RIG

Aim: - To determine the overall efficiency of a centrifugal blower.

.

Apparatus Required:-

Stop watch

Spanner

DESCRIPTION:-

Centrifugal blower is a non-positive displacement or a steady flow machine. It

discharges high volume air with a comparatively low pressure with respect to the positive

displacement type’s machines. Centrifugal blowers are widely used in industrial

applications where there is a requirement for constant flow of larger volumes of air such

as in ventilation, combustion, transporting materials, cooling and heating systems, dust

control, air conveyor systems, and industrial vacuum applications. The two most common

types of Centrifugal Blowers are Pressure Blowers and Volume Blowers. Pressure

Blowers are designed to draw or push air at high pressures, rated in static pressure water

gauge (SPWG). Volume Blowers are designed to draw or push larger volumes of air, rated

in cubic feet of air per minute (CFM), at lower static pressures than Pressure Blowers.

Centrifugal Blowers are typically made of fabricated steel, stainless steel or cast aluminum.

Blower consist of motor, impeller and its body. Three impellers are provided with

setup are forward curved, backward curved, radial curved vane. These are interchangeable

and may be one of them can be fixed on motor shaft. An electric motor is used to run the

blower. Blower vanes are directly mounted on the motor shaft. The rotating part of

centrifugal blower is called impeller. It consist of series of vanes. The impeller is mounted

on a shaft which is connected to shaft of electric motor. The casing of Centrifugal Blower

Department of Mechanical Engineering SVKM’S Iot, Dhule.

is vortex casing (increasing cross sectional area).It surrounds the impeller and is designed

in such a way that kinetic energy of impeller is transferred to air gets converted into

pressure energy before the air leaves the casing and enters the delivery pipe. Pitot tube is a

cylindrical tube used in the delivery pipe and its one end is connected to manometer to

measure the differential pressure and hence to measure the flow rate of air delivered. A

gate valve is used to control the flow rate of the delivered air in delivery pipe.

WORKING OF CENTRIFUGAL BLOWER:-

The centrifugal blower works on the principle of forced vortex flow, which means

that when an external torque rotates certain mass of fluid ,the rise in pressure head of the

rotating fluid takes place. The rise in pressure head any point of the rotating fluid is

proportional to the square of the tangential velocity (rise in pressure head is v2/2g) of the

liquid at that point. Thus at the out let of impeller where radius is more, the rise is pressure

head will be more, and fluid (air) will be discharged at outlet with a high pressure head.

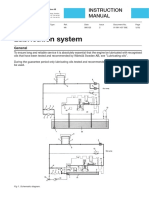

The Centrifugal Blower Test Rig gives the study of a universal blower in which

different type of impeller’s can be interchanged in the casing one by one. The air pressure

is measured with the help of a manometer. Discharge is measured with the help of an orifice

meter. An energy meter is provided to measure the power input. Thus the overall efficiency

of the blower can be found out.

Fig. 2 Shapes of vanes of centrifugal blower

Department of Mechanical Engineering SVKM’S Iot, Dhule.

DIAGRAM OF CENTRIFUGAL BLOWER TEST RIG:-

SPECIFICATIONS :-

1. Motor – 2 H.P., 3 Ph., 2800 rpm Induction motor.

2. Impeller’s – Daimeter 370 mm a) Radial b) Forward & c) Backward.

3. Orificemeter -- to measure the flow rate of blower having Ø 70 mm.

4. Energymeter – to measure the power input (Energy meter constant = 1600

imp./Kw/hr.)

5. Valve – to control the flow rate of blower. ( at the end of the discharge pipe)

6. Pitot Tube : Pitot tube is used to measure fluid flow velocity

Department of Mechanical Engineering SVKM’S Iot, Dhule.

PROCEDURE : –

01. Fill up clean water in all the 2 manometers up to half of its length.

02. Mount any selected impeller in the casing properly. See that after clamping the

impeller, it rotates freely in the casing.

03. Initially, open the gate valve at the end of piping completely.

04. Switch ‘ON’ blower. See that the Impeller rotates in a proper direction.

Note.- If the motor rotates in opposite direction, interchange any two phases in

supply line. See that the blower is completely stopped before switching ‘ON’.

05. After starting the blower, wait for 2 to 3 minutes, till the impeller is set to a steady

speed. Note down the manometer difference of orifice meter, blower pressure, pitot

tube & time required for 10 impulse of the energy meter.

06. Change the gate valve position & take down all the readings.

07. Repeat the procedure for different impellers.

OBSERVATION TABLE :-

Sr. Impeller Impeller Position Blower Orificemeter Time for 10 imp. of

No. Type Head Manometer energymeter ‘t’ (sec)

’H’(mm) ‘hw’ (mm)

1 Radial Half opening

2 Radial 3/4 opening

3 Radial Full opening

Department of Mechanical Engineering SVKM’S Iot, Dhule.

CALCULATIONS:

1. Blower Head 1000

H = ‘hw’ in mtr. X -------- = …. m. of air.

þa

where, þa = Density of air 1.17 kg/m3 at NTP.

2. Discharge of blower

Q = cd x /4 x d2 x 2g. [ hw. (1000/ þa )]

= 0.64 x /4 x (0.07)2 x 2 x 9.81. [ hw (1000/ 1.17 ) ]

Q = …….. m3 / sec

hw = Manometer head in mtr.

3. Input power

10 x 3600 10 x 3600

I.P. = ---------------- Kw. = -------------- = ------------- Kw.

t x 1600 ------ x 1600

4. Shaft power

S.P. = I.P. x 0.75 Watt. (Motor efficiency = 0.75)

= I.P. x 1000 x 0.75

= Watt.

Department of Mechanical Engineering SVKM’S Iot, Dhule.

5. Out put power

O.P. = P. Q . H (where, P= 11.477 N/m3 )

= 11.5 x ______ x _____

= Watt.

6. Overall efficiency-

Output power

= ------------------ x 100

Shaft power

RESULT TABLE:

Sr. Impeller Impeller Position Discharge of Blower Overall Efficiency of Blower

No. Type

1 Radial Half opening

2 Radial 3/4 opening

3 Radial Full opening

CONCLUSION:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Department of Mechanical Engineering SVKM’S Iot, Dhule.

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Centrifugal Blower Test Rig PDFDocument7 pagesCentrifugal Blower Test Rig PDFGurmeet Mehma100% (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- 6 Centrifugal BlowerDocument7 pages6 Centrifugal BlowerdhundterahoNo ratings yet

- Centrifugal Air BlowerDocument3 pagesCentrifugal Air BlowermuralidharanNo ratings yet

- Centrifugal BlowerDocument3 pagesCentrifugal BlowerVicy gostNo ratings yet

- Performance Test On Single Stage Axial Flow FanDocument3 pagesPerformance Test On Single Stage Axial Flow FanAkhil Jaiswal100% (1)

- Design of A Centrifugal Blower For A 400kg Rotary Furnace.Document6 pagesDesign of A Centrifugal Blower For A 400kg Rotary Furnace.AJER JOURNALNo ratings yet

- Centrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Document9 pagesCentrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Sandeep SainiNo ratings yet

- Radial Blower Performance TestDocument2 pagesRadial Blower Performance Test17044 AZMAIN IKTIDER AKASHNo ratings yet

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33No ratings yet

- Hydraulic & Pneumatic MotorsDocument14 pagesHydraulic & Pneumatic MotorsJogi Oscar SinagaNo ratings yet

- Ojeda, Khen Mehko C. - Me 417-Bsme 4aDocument8 pagesOjeda, Khen Mehko C. - Me 417-Bsme 4akhinojidaNo ratings yet

- Department of Mechanical Engg. Semester IvDocument4 pagesDepartment of Mechanical Engg. Semester IvVicy gostNo ratings yet

- Multistage Centrifugal Pump Test RigDocument13 pagesMultistage Centrifugal Pump Test Rigأشرف علي100% (1)

- Design and Performance Analysis of Centrifugal PumpDocument8 pagesDesign and Performance Analysis of Centrifugal Pumpsudhirm16No ratings yet

- FLUID MACHINERY Sessional GalibDocument14 pagesFLUID MACHINERY Sessional Galibnehar shubheschaNo ratings yet

- IMPULSE TURBINE TESTDocument10 pagesIMPULSE TURBINE TESTzaxiondlNo ratings yet

- Axial Fan Laboratory ReportDocument11 pagesAxial Fan Laboratory ReportAbenezer TasewNo ratings yet

- Centrifugal Pump Test RigDocument4 pagesCentrifugal Pump Test RigSameer Tamboli100% (1)

- Axial Fan Testing EquipmentsDocument8 pagesAxial Fan Testing EquipmentsVijay ShetNo ratings yet

- Lab 5 - Operating Characteristics of A Centrifugal PumpDocument9 pagesLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaNo ratings yet

- Air BlowerDocument7 pagesAir BlowerShiva YadavNo ratings yet

- Lab Test Set Up of Pelton Wheel and TestDocument7 pagesLab Test Set Up of Pelton Wheel and TestHimansu GoswamiNo ratings yet

- TP Turbomachine1 Pelton Wheel Lab SheetDocument7 pagesTP Turbomachine1 Pelton Wheel Lab SheetAbdelwahab.gfNo ratings yet

- Components and Operation Op Power HouseDocument45 pagesComponents and Operation Op Power Housesensiblesakshi_21939100% (1)

- Centrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Document9 pagesCentrifugal Pump Test Rig (With A.C Motor, 3 Speed With Step Cone Pulley)Sandeep SainiNo ratings yet

- Centrifugal Pump Report CompletedDocument24 pagesCentrifugal Pump Report CompletedMohamad Fareez Roslan100% (1)

- Centrifugal Pump2Document15 pagesCentrifugal Pump2limakupang_matNo ratings yet

- Axial Fan Experiment SheetDocument8 pagesAxial Fan Experiment Sheetpranesh0% (1)

- Pump CharacteristicsDocument8 pagesPump CharacteristicsgeocaustasNo ratings yet

- Centrifugal Pump FullDocument25 pagesCentrifugal Pump FullMohamad FaizNo ratings yet

- ME415 6 Turbomachines - 221215 - 074849Document44 pagesME415 6 Turbomachines - 221215 - 074849Gaurav MehtaNo ratings yet

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningDocument3 pagesPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- Khulna University of Engineering & TechnologyDocument9 pagesKhulna University of Engineering & Technology17044 AZMAIN IKTIDER AKASHNo ratings yet

- LAB: TWO STAGE AIR COMPRESSOR TESTDocument4 pagesLAB: TWO STAGE AIR COMPRESSOR TESTAmit Singh DehuryNo ratings yet

- Centrifugal FansDocument19 pagesCentrifugal FansMark John Santos60% (5)

- TLT Industrial FansDocument42 pagesTLT Industrial FansNguyen Thanh TrungNo ratings yet

- Reciprocating PumpDocument8 pagesReciprocating PumpGurmeet Mehma50% (4)

- Industrial Fans: Delivery ProgramDocument42 pagesIndustrial Fans: Delivery ProgramKvvPrasadNo ratings yet

- Aerodynamics Lab Manual (PCT)Document21 pagesAerodynamics Lab Manual (PCT)pgkaero80% (5)

- Hiren Sem II (180111203)Document22 pagesHiren Sem II (180111203)hirenNo ratings yet

- Francis Turbine Test 1. TurbinesDocument5 pagesFrancis Turbine Test 1. TurbinesSerhat GüvenNo ratings yet

- Centrifugal PumpDocument21 pagesCentrifugal PumpIzzul Hazim B. IbrahimNo ratings yet

- Centrifugal Pump Test RigDocument5 pagesCentrifugal Pump Test RigAlbert AinstineNo ratings yet

- FLUID MACHINERY - CENTRIFUGAL PUMP LAB REPORTDocument31 pagesFLUID MACHINERY - CENTRIFUGAL PUMP LAB REPORTHarizx SaufixNo ratings yet

- Impulse TurbineDocument15 pagesImpulse TurbineHazwan JamhuriNo ratings yet

- Test On A Centrifugal Pump: CE 371 1 - Pumps and Open Channel Flow - Laboratory AssignmentDocument5 pagesTest On A Centrifugal Pump: CE 371 1 - Pumps and Open Channel Flow - Laboratory AssignmentTinaaTinyNo ratings yet

- Engine Testing TechniqueDocument8 pagesEngine Testing TechniqueNur YakhinNo ratings yet

- Fluid Mechanics Lab ManualDocument37 pagesFluid Mechanics Lab ManualMohith MarripatiNo ratings yet

- Kaplan TurbineDocument7 pagesKaplan TurbinenidhidarklordNo ratings yet

- Reciprocating - Pump - Lab Manual Ms WordDocument10 pagesReciprocating - Pump - Lab Manual Ms WordSandeep SainiNo ratings yet

- Class: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2Document2 pagesClass: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2santhosh bandariNo ratings yet

- Turbine Lab ReportDocument11 pagesTurbine Lab ReportIzzul Hazim75% (8)

- AXIAL FLOW FAN TEST RIG PERFORMANCEDocument4 pagesAXIAL FLOW FAN TEST RIG PERFORMANCERajath ShettyNo ratings yet

- Design of Hydropower Plant : Mohammed ADocument18 pagesDesign of Hydropower Plant : Mohammed AMymanNo ratings yet

- 02 05 01 MB OkDocument35 pages02 05 01 MB OkdadrahimNo ratings yet

- Workover Operations Workover Rigs Workover RigsDocument2 pagesWorkover Operations Workover Rigs Workover RigsASIF SADARNo ratings yet

- Rotor turning gear operation guideDocument10 pagesRotor turning gear operation guideVinod Varadan SNo ratings yet

- BDocument11 pagesBDany MedinaNo ratings yet

- Pipe friction loss calculation sheetDocument9 pagesPipe friction loss calculation sheetNghiaNo ratings yet

- Form For Solar Pumping Cy 2023 Proposed Cy 2024Document11 pagesForm For Solar Pumping Cy 2023 Proposed Cy 2024fitz lagoNo ratings yet

- US Legal Binding Document for ASTM F1139 Steam Trap StandardDocument6 pagesUS Legal Binding Document for ASTM F1139 Steam Trap StandardRamesh-NairNo ratings yet

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass ValvesadehriyaNo ratings yet

- Reference Venturi & Orifice 1Document22 pagesReference Venturi & Orifice 1luqmanhazkymNo ratings yet

- Simplex Agss: Complies Fully With All Relevent StandardsDocument2 pagesSimplex Agss: Complies Fully With All Relevent Standardsumair186No ratings yet

- PHQC 3036 - Pull Part Manual 2016 1010Document9 pagesPHQC 3036 - Pull Part Manual 2016 1010VladimirNo ratings yet

- Installation, Operation and Maintenance Manual: 3AV 1 To 3AV 430Document21 pagesInstallation, Operation and Maintenance Manual: 3AV 1 To 3AV 430KevinNo ratings yet

- Impulse Turbine: Description Learning Objectives/experimentsDocument3 pagesImpulse Turbine: Description Learning Objectives/experimentsbeshirNo ratings yet

- Alfa Laval Separartor s937 System DescriptionDocument14 pagesAlfa Laval Separartor s937 System DescriptionIgors VrublevskisNo ratings yet

- Service Manual Danfoss Burner ComponentsDocument107 pagesService Manual Danfoss Burner ComponentsBala PrabuNo ratings yet

- Kenco - Installation Instructions Model KLCE Oil Level ContrDocument4 pagesKenco - Installation Instructions Model KLCE Oil Level ContrJorge ContrerasNo ratings yet

- Flow Through Pipes LabDocument15 pagesFlow Through Pipes LabLauren MNo ratings yet

- Refill 1lb Propane Bottles Completely for 50 CentsDocument6 pagesRefill 1lb Propane Bottles Completely for 50 CentsNatalia NelsonNo ratings yet

- Wärtsilä lubrication system manualDocument10 pagesWärtsilä lubrication system manualLIVIANo ratings yet

- v20 - GE-1019 Turbofan and Turbojet Engines Database Handbook-27-34Document8 pagesv20 - GE-1019 Turbofan and Turbojet Engines Database Handbook-27-34MoyiNo ratings yet

- Industrial Valve Manufacturer in India - SpecialityvalveDocument5 pagesIndustrial Valve Manufacturer in India - SpecialityvalvespecialityvalveNo ratings yet

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFDocument5 pagesLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerNo ratings yet

- Hydro Test Method for Yanbu 2 Power Project PipingDocument20 pagesHydro Test Method for Yanbu 2 Power Project PipingGodwin A.udo-akanNo ratings yet

- Pumps and Filters: 345D and 349D Excavator Hydraulic System - AttachmentDocument2 pagesPumps and Filters: 345D and 349D Excavator Hydraulic System - AttachmentRodrigo EvaristoNo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Propulsive Efficiency Factors in Gas Turbine EnginesDocument21 pagesPropulsive Efficiency Factors in Gas Turbine EngineskousikkumaarNo ratings yet

- Aircraft Propulsion Lecture - 2Document16 pagesAircraft Propulsion Lecture - 2tbfhlwNo ratings yet

- Crankcase Pressure RegulatorDocument10 pagesCrankcase Pressure RegulatorKhaldoun BayazidNo ratings yet

- Tata 1618 Eii 24 V 5200 LPT V200904Document286 pagesTata 1618 Eii 24 V 5200 LPT V200904Bheema SolankeNo ratings yet

- Start Two Stage Ammonia Plant Et 2015-02-23Document80 pagesStart Two Stage Ammonia Plant Et 2015-02-23dachoko8750% (2)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismFrom EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo ratings yet