Professional Documents

Culture Documents

1M Check 2

1M Check 2

Uploaded by

HsunamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1M Check 2

1M Check 2

Uploaded by

HsunamiCopyright:

Available Formats

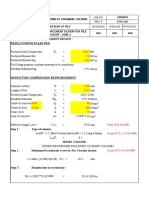

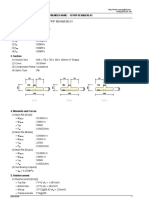

midas Gen Steel Checking Result

Company Project Title

Author User File Name C:\...\RAILING 1.0M LENGTH R1.mgb

z

1. Design Information

Design Code : AISC(15th)-LRFD16

Unit System : kN, m

Member No : 134 y

Material : A304 (No:1) 0.0015

(Fy = 205000, Es = 200000000)

Section Name : PIPE 25x1.5mm (No:2)

(Built-up Section).

0.025

Member Length : 0.09000

2. Member Forces Outer Dia. 0.02500 Wall Thick 0.00150

Axial Force Fxx = 1.59657 (LCB: 2, POS:J) Area 0.00011 Asz 0.00006

Bending Moments My = -0.1101, Mz = 0.00170 Qyb 0.00014 Qzb 0.00014

Iyy 0.00000 Izz 0.00000

End Moments Myi = -0.1040, Myj = -0.1101 (for Lb) Ybar 0.01250 Zbar 0.01250

Syy 0.00000 Szz 0.00000

Myi = -0.1040, Myj = -0.1101 (for Ly) ry 0.00833 rz 0.00833

Mzi = 0.00986, Mzj = 0.00170 (for Lz)

Shear Forces Fyy = 0.09072 (LCB: 2, POS:1/2)

Fzz = 0.06807 (LCB: 1, POS:J)

3. Design Parameters

Unbraced Lengths Ly = 0.09000, Lz = 0.09000, Lb = 0.09000

Effective Length Factors Ky = 1.00, Kz = 1.00

Moment Factor / Bending Coefficient

Cmy = 1.00, Cmz = 1.00, Cb = 1.00

4. Checking Results

Slenderness Ratio

KL/r = 10.8 < 200.0 (Memb:124, LCB: 1)................................... O.K

Axial Strength

Pr/Pc = 1.5966/20.4317 = 0.078 < 1.000 ...................................... O.K

Bending Strength

Mry/Mcy = 0.11007/0.15304 = 0.719 < 1.000 ................................... O.K

Mrz/Mcz = 0.00170/0.15304 = 0.011 < 1.000 ................................... O.K

Combined Strength (Tension+Bending)

Pr/Pc = 0.08 < 0.20

Rmax = Pr/(2*Pc) + SQRT[(Mry/Mcy)^2 + (Mrz/Mcz)^2] = 0.758 < 1.000 ................ O.K

Shear Strength

Vry/Vcy = 0.015 < 1.000 ...................................................... O.K

Vrz/Vcz = 0.011 < 1.000 ...................................................... O.K

Modeling, Integrated Design & Analysis Software Print Date/Time : 03/28/2024 11:29

You might also like

- CAT 345 B AGS 01 Up Hydraulic SchematicDocument7 pagesCAT 345 B AGS 01 Up Hydraulic SchematicGanapati Hegde100% (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 02-ToE-C945-111 - Service Manual Motoman K6S K10SDocument36 pages02-ToE-C945-111 - Service Manual Motoman K6S K10SBayron López CastilloNo ratings yet

- Calculation Check Temporary Tower - LG SlidingDocument9 pagesCalculation Check Temporary Tower - LG Slidingสายัญ บุญพาNo ratings yet

- HEB200Document1 pageHEB200giulioNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Diagonal Web Member PDFDocument1 pageDiagonal Web Member PDFJohn Edrick TanNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design InformationWidi NugrahaNo ratings yet

- Midas Gen: 1. Design InformationDocument6 pagesMidas Gen: 1. Design InformationChristian Jeremiah TevesNo ratings yet

- Web Members PDFDocument2 pagesWeb Members PDFJohn Edrick TanNo ratings yet

- Check Dam Cau Dan SinhDocument2 pagesCheck Dam Cau Dan SinhKhải TrươngNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Double Angle BarDocument1 pageDouble Angle BarShadin Asari ArabaniNo ratings yet

- DB16 MMDocument1 pageDB16 MMGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Envolvente ColumnaDocument1 pageEnvolvente ColumnaOrlando EnriqueNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationMikeNo ratings yet

- Project Job Number EngineerDocument2 pagesProject Job Number Engineerroan sthaNo ratings yet

- Midas Gen: 1. Design InformationDocument56 pagesMidas Gen: 1. Design InformationNyx Phoebe WPNo ratings yet

- Csec (U) LTD.: 1. General InformationDocument4 pagesCsec (U) LTD.: 1. General InformationCSEC Uganda Ltd.No ratings yet

- Project Title: Exercise 1Document2 pagesProject Title: Exercise 1tfvnjyNo ratings yet

- Agitator - Ag-C8-102Document4 pagesAgitator - Ag-C8-102uttam prabhuNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number EngineeronuroztkNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design InformationErwin d'AdventuraNo ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- Memoria VigaDocument1 pageMemoria VigaKarina Manjarres VergaraNo ratings yet

- Buat Linkset A60Document1 pageBuat Linkset A60nudewaNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- C1 W12x65 Full CalculationDocument5 pagesC1 W12x65 Full CalculationShadin Asari ArabaniNo ratings yet

- Midasit: 1. General InformationDocument4 pagesMidasit: 1. General InformationJefferd PaetNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerRooking Ewondo SfuutNo ratings yet

- Project Title:: Company ClientDocument36 pagesProject Title:: Company ClientArvin Torres GuintoNo ratings yet

- Analysis 1Document2 pagesAnalysis 1Việt QuốcNo ratings yet

- Fallacon 15Document1 pageFallacon 15Roma99No ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerbenjipaulNo ratings yet

- Appendix 5 DoneDocument36 pagesAppendix 5 Donearnoldleorenz17No ratings yet

- Csec (U) LTD.: 1. General InformationDocument6 pagesCsec (U) LTD.: 1. General InformationCSEC Uganda Ltd.No ratings yet

- Slab Design 3BHKDocument14 pagesSlab Design 3BHKharshNo ratings yet

- ABS Hull Calculation Rev 12-17-2004Document10 pagesABS Hull Calculation Rev 12-17-2004Anonymous gfR3btyUNo ratings yet

- Proposal Stressing JBT Preservasi Jalintim Sumatera Utara H.125 CM - L.16.0 M - CTC.185CmDocument12 pagesProposal Stressing JBT Preservasi Jalintim Sumatera Utara H.125 CM - L.16.0 M - CTC.185CmShetty SyabellaNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number EngineeronuroztkNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- Csec (U) LTD.: Member Name: - 1strip Beam (638) - 01Document40 pagesCsec (U) LTD.: Member Name: - 1strip Beam (638) - 01CSEC Uganda Ltd.No ratings yet

- Round HSS Design LRFDDocument4 pagesRound HSS Design LRFDklynchelleNo ratings yet

- Midasgen: 1. Design InformationDocument31 pagesMidasgen: 1. Design Informationduchoang5000No ratings yet

- DocumentDocument1 pageDocumentBurim ZeqiriNo ratings yet

- Steel Design - SAP 2000Document5 pagesSteel Design - SAP 2000Nayolle CoelhoNo ratings yet

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- c250 FootingDocument3 pagesc250 FootingSharmaine Anyayahan BalaoingNo ratings yet

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- Insert Plate Design - LugsDocument8 pagesInsert Plate Design - Lugsnavneet3bawaNo ratings yet

- Buckling ExampleDocument3 pagesBuckling ExampleSrdjan KosoricNo ratings yet

- View PrintDocument1 pageView PrintHenry GutierrezNo ratings yet

- MIDAS/Gen: 1. Design InformationDocument1 pageMIDAS/Gen: 1. Design InformationHenry GutierrezNo ratings yet

- Input Echo, Leg & Lug Item 1, Description: GuideDocument4 pagesInput Echo, Leg & Lug Item 1, Description: GuideSiri SiriNo ratings yet

- Tepo Sole Co., LTD: 1. General InformationDocument3 pagesTepo Sole Co., LTD: 1. General InformationAlpha ScimathNo ratings yet

- TS 500-2000 (R2018) Example 001 PDFDocument4 pagesTS 500-2000 (R2018) Example 001 PDFHenry TuganoNo ratings yet

- Ultimate List of ISO Standards For Medical Devices-1Document34 pagesUltimate List of ISO Standards For Medical Devices-1Sridharan PadmanabhanNo ratings yet

- Sist en 13819 2 2021Document9 pagesSist en 13819 2 2021souma nyarNo ratings yet

- What Are Fossil FuelsDocument8 pagesWhat Are Fossil Fuels03. Thu AnhNo ratings yet

- Strongest Quarter Helped by Low Base: 3Q FY07 Results PreviewDocument24 pagesStrongest Quarter Helped by Low Base: 3Q FY07 Results PreviewIndushekhar JhaNo ratings yet

- Determinants of Green Competitive AdvantageDocument23 pagesDeterminants of Green Competitive AdvantageInsiya AbbasNo ratings yet

- Pricomm FinalsDocument8 pagesPricomm FinalsAllyza Marie BalaneNo ratings yet

- Parameters Farmtrac 6090 Pro 4Wd EngineDocument1 pageParameters Farmtrac 6090 Pro 4Wd Enginepp1560078No ratings yet

- RAN17.1 Basic Feature DescriptionDocument234 pagesRAN17.1 Basic Feature Descriptiondonia77No ratings yet

- Written Assignment Unit 2Document4 pagesWritten Assignment Unit 2Hasnaa SeyaghaNo ratings yet

- Letra 'Always' 'It'S My Life'Document1 pageLetra 'Always' 'It'S My Life'César Cabrejos AlvaradoNo ratings yet

- Astm d1747Document4 pagesAstm d1747Shreyansh KaushikNo ratings yet

- M Tech 2 Sem SyllbusDocument14 pagesM Tech 2 Sem Syllbusnchandrasekhar418No ratings yet

- Moses' Mother in EXODUS 2:1-10 AND Mothers in Personal Names Among The Igbo People, South-East NigeriaDocument19 pagesMoses' Mother in EXODUS 2:1-10 AND Mothers in Personal Names Among The Igbo People, South-East NigeriaAllistair MatthysNo ratings yet

- General Psychology 4: THE Physiological Basis OF Behavior: Prepared By: Mark Fredderick R. Abejo RN, MANDocument7 pagesGeneral Psychology 4: THE Physiological Basis OF Behavior: Prepared By: Mark Fredderick R. Abejo RN, MANMariel EfrenNo ratings yet

- Microsoft Word - Starship Troopers Miniatures Game SupplementDocument17 pagesMicrosoft Word - Starship Troopers Miniatures Game SupplementThomas Bartholomew100% (2)

- Pet Reading Practice 3Document10 pagesPet Reading Practice 3Jugador FelizNo ratings yet

- Diseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Document2 pagesDiseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Uriel Vélez OrejuelaNo ratings yet

- g3500c and G3500e Generator Electrical System PDFDocument4 pagesg3500c and G3500e Generator Electrical System PDFСергей Шевченко0% (1)

- Static Pneumatic Tired RollerDocument2 pagesStatic Pneumatic Tired RollerricsnikNo ratings yet

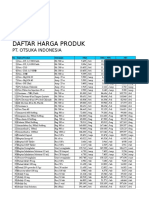

- OtsukaDocument9 pagesOtsukaklinik ikhtiar insaniNo ratings yet

- Acoustics Notes M1Document11 pagesAcoustics Notes M1ANNA PAULA R. DULAYNo ratings yet

- Feludar Goendagiri by Satyajit RoyDocument41 pagesFeludar Goendagiri by Satyajit RoyArup RoyNo ratings yet

- Range Rover Evoque BrochureDocument2 pagesRange Rover Evoque BrochureParantap SinghNo ratings yet

- Solutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartDocument7 pagesSolutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartBassel AlshamiNo ratings yet

- PT124B 121 (英文)Document2 pagesPT124B 121 (英文)Jose Villalobos CoralNo ratings yet

- Who Is Katherine JohnsonDocument2 pagesWho Is Katherine JohnsonKHADİGA ELMANEANo ratings yet

- 2022 Utility Master Plan and Wastewater Treatment Plant Capacity Evaluation and Capital UpgradesDocument191 pages2022 Utility Master Plan and Wastewater Treatment Plant Capacity Evaluation and Capital UpgradesGregNo ratings yet

- Design Calculation or Analysis Cover Sheet SSC: Iz!-E-GfDocument20 pagesDesign Calculation or Analysis Cover Sheet SSC: Iz!-E-GfPawan TiwariNo ratings yet