Professional Documents

Culture Documents

Cymel-1158 en A4

Uploaded by

vikram.iitkgpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cymel-1158 en A4

Uploaded by

vikram.iitkgpCopyright:

Available Formats

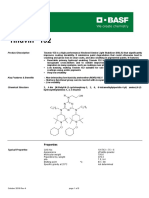

CYMEL® 1158

Technical Datasheet

PRODUCT DESCRIPTION BACKBONE POLYMER SELECTION

CYMEL® 1158 resin is an n-butylated, high imino melamine crosslinker CYMEL® 1158 resin is an effective crosslinker for backbone polymer

which combines the excellent compatibility of a conventional butylated resins containing hydroxyl, carboxyl, and amide functional groups, such

melamine resin with the fast, low temperature cure response of CYMEL® as those found on alkyd, polyester or acrylic resins. Although the

325 resin. Like other high imino melamine resins, CYMEL® 1158 has a optimum level of CYMEL® 1158 resin should be determined

high tendency to self-condense resulting in films with high film hardness experimentally, ratios of 25 to 35% based on resin solids are typically

that can be adjusted based on loading. Its hydrophobic nature improves most effective.

substrate wetting, flow and leveling, and humidity and salt spray

x

resistance making it suitable for a wide range of applications including

automotive topcoats and general industrial finishes.

CATALYSIS

x CYMEL® 1158 resin may not require the addition of an acid catalyst to

BENEFITS the formulation to obtain effective cure. In many instances, the acidity of

the backbone polymer in the formulation is sufficient to catalyze the

· Fast cure response reaction under normal baking conditions (15 - 20 minutes at 120 -

· Substrate wetting 150°C). If catalyst addition is required, then 0.5 - 1.0% of CYCAT® 296-9

· Low formaldehyde release upon cure catalyst based on total resin solids is recommended.

· Humidity and salt spray resistance

x

x FORMULATION STABILITY

APPLICATION AREAS

The stability of solvent-borne systems containing CYMEL® 1158 resin can

· Automotive coating formulations be enhanced by the addition of primary alcohols, amines, or a

· General industrial coatings combination of these. Low molecular weight primary alcohols such as

ethanol or n-butanol are most effective. Recommended amines are TEA

x

or DMEA at a concentration of 0.5 - 1.0% on total binder solids.

PHYSICAL PROPERTIES

x

Property Range Method STORAGE STABILITY

Appearance Clear Liquid ASTM E284

Non-volatile by DIN 55671 (Foil, 45 CYMEL® 1158 resin has a shelf life of 720 days from the date of

78-82% manufacture when stored at temperatures below 32°C. Although low

wt. min/45°C)

temperatures are not detrimental to stability, its viscosity will increase,

4000 – 7000

Viscosity, 23°C DIN EN ISO 3219 possibly making the resin difficult to pump or pour. The viscosity will

mPa·s

reduce again on warming, but care should be taken to avoid excessive

Free local heat as this can cause an irreversible increase in viscosity.

< 0.5% BS-EN-1243-2011

formaldehyde

Color, APHA ≤ 70 DIN EN ISO 6271

x

SOLUBILITY

Alcohols Complete

Esters Complete

Ketones Complete

Aromatic hydrocarbons Complete

Aliphatic hydrocarbons Partial

Water Insoluble

x

COMPATIBILITY

Acrylic resins Very good

Alkyd resins Very good

Polyester resins Very good

Epoxy resins Very good

3.1 / 20.09.2022 (replaces all previous versions) Worldwide Contact Info: www.allnex.com Page 1/1

Disclaimer: allnex Group companies ('allnex') exclude all liability with respect to the use made by anyone of the information contained herein. The information contained herein represents allnex's best

knowledge but does not constitute any express or implied guarantee or warranty as to the accuracy, the completeness or relevance of the data set out herein. Nothing contained herein shall be construed as

conferring any license or right under any patent or other intellectual property rights of allnex or of any third party. The information relating to the products is given for information purposes only. No guarantee

or warranty is provided that the product and/or information is suitable for any specific use, performance or result. Any unauthorized use of the product or information may infringe the intellectual property

rights of allnex, including its patent rights. The user should perform his/her own tests to determine the suitability for a particular purpose. The final choice of use of a product and/or information as well as the

investigation of any possible violation of intellectual property rights or misappropriation of trade secrets of allnex and/or third parties remain the sole responsibility of the user.

Notice: Trademarks indicated with ® , TM or * as well as the allnex name and logo are registered, unregistered or pending trademarks of Allnex Netherlands B.V. or its directly or indirectly affiliated allnex Group

companies. ©2022 allnex Group. All Rights Reserved.

You might also like

- Cymel 1158Document2 pagesCymel 1158sidneidecarvalhoNo ratings yet

- Cymel-U-80 en A4Document1 pageCymel-U-80 en A4vikram.iitkgpNo ratings yet

- Setamine Us 138 BB 70 - en - A4Document1 pageSetamine Us 138 BB 70 - en - A4Akash BadwaikNo ratings yet

- Crayamid 115Document1 pageCrayamid 115ashfaq afzalNo ratings yet

- Cymel-Nf-2000a en A4Document2 pagesCymel-Nf-2000a en A4DidarNo ratings yet

- Cymel-Nf-3030 en A4Document1 pageCymel-Nf-3030 en A4DidarNo ratings yet

- Crayamid 115X - 70%Document2 pagesCrayamid 115X - 70%WALTER KLISSMANNo ratings yet

- Cymel-Nf-3041 en A4Document1 pageCymel-Nf-3041 en A4DidarNo ratings yet

- CYMEL 303 LF - EN - Letter 1Document2 pagesCYMEL 303 LF - EN - Letter 1Yousef LotfyNo ratings yet

- TDS - Glenium 114Document2 pagesTDS - Glenium 114Alexi ALfred H. TagoNo ratings yet

- Sabic PlaDocument4 pagesSabic PlavgciasenNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- EMULSION TECHNICAL DATA SHEET (7 Revised 1212)Document1 pageEMULSION TECHNICAL DATA SHEET (7 Revised 1212)kabiru isahNo ratings yet

- p190035 en Versalink-Brochure NR RZ WebDocument4 pagesp190035 en Versalink-Brochure NR RZ Webyilong luoNo ratings yet

- Petronas Disrol 120: Premium Quality 12 TBN Medium Speed Diesel Engine OilsDocument1 pagePetronas Disrol 120: Premium Quality 12 TBN Medium Speed Diesel Engine OilsHazrulnizam HassanNo ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- Cycat-4040 TDSDocument1 pageCycat-4040 TDSCao LongNo ratings yet

- Rrrrrnaa EF PDFDocument1 pageRrrrrnaa EF PDFHYDRAGUARDPLUS ANTIMICROBIAL NANO COATINGNo ratings yet

- Cytec Cymel ResinsDocument9 pagesCytec Cymel ResinsHarshad PorwalNo ratings yet

- Accelerator NL-64-100: Product Data SheetDocument3 pagesAccelerator NL-64-100: Product Data SheetAhmedNo ratings yet

- VMA Mastermatrix-110-Tds PDFDocument2 pagesVMA Mastermatrix-110-Tds PDFpavan6595No ratings yet

- Property Value: (1) Typical Properties, Not To Be Construed As SpecificationsDocument6 pagesProperty Value: (1) Typical Properties, Not To Be Construed As Specificationsvanhung68No ratings yet

- DSM Chemical Guide 2007 03.qDocument17 pagesDSM Chemical Guide 2007 03.qABHISEK BHATTACHARYANo ratings yet

- TDS Acronal 7079 PDFDocument3 pagesTDS Acronal 7079 PDFWahid Karol100% (1)

- Craymul 2145Document1 pageCraymul 2145jamesBTNo ratings yet

- Acronal 7079 PI EDADocument3 pagesAcronal 7079 PI EDAGokul Basker100% (2)

- ANCAMINE® 2422 Curing Agent: DescriptionDocument7 pagesANCAMINE® 2422 Curing Agent: DescriptionSastra MahachemNo ratings yet

- Cdeep-Mul Product Data SheetDocument1 pageCdeep-Mul Product Data SheetpaimanNo ratings yet

- Application Sheet: Consistent and Efficient Adjunct LiquefactionDocument5 pagesApplication Sheet: Consistent and Efficient Adjunct LiquefactionRiyanNo ratings yet

- Ebecryl-P115 en A4Document1 pageEbecryl-P115 en A4ichsan hakimNo ratings yet

- Viscopol-7788 en A4Document1 pageViscopol-7788 en A4Duodo NguyenNo ratings yet

- TDS AlKyd ResinDocument2 pagesTDS AlKyd ResinAji PradahNo ratings yet

- Silikoftal® HTL 1: Description SolubilityDocument1 pageSilikoftal® HTL 1: Description SolubilityWangYunNo ratings yet

- Formulating With Millathane Millable PolyurethanesDocument3 pagesFormulating With Millathane Millable PolyurethanesMichael WokurekNo ratings yet

- Shell Melina S 30 PDFDocument2 pagesShell Melina S 30 PDFbeu catalinNo ratings yet

- Dynasylan® 1124: Bis (Trimethoxysilylpropyl) AmineDocument3 pagesDynasylan® 1124: Bis (Trimethoxysilylpropyl) Aminebhisma.nugerahNo ratings yet

- Overview of ElastomersDocument2 pagesOverview of ElastomersRuilin TanNo ratings yet

- Risun 12000dDocument2 pagesRisun 12000dPranshu JainNo ratings yet

- Amicure 101 UsDocument4 pagesAmicure 101 Usmandy.chenxi1009No ratings yet

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocument2 pagesAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaNo ratings yet

- RisunDocument2 pagesRisunPranshu JainNo ratings yet

- Shell Tivela S 220: Advanced Synthetic Gear OilsDocument2 pagesShell Tivela S 220: Advanced Synthetic Gear OilsViruzfhmNo ratings yet

- SETALUX D A 870 BA - EN - LetterDocument2 pagesSETALUX D A 870 BA - EN - LetterFabio Enrique Gomez RamirezNo ratings yet

- Versamid 125: Technical Data SheetDocument3 pagesVersamid 125: Technical Data SheetAMIT HALDERNo ratings yet

- Eastman Coatings: Formulating Acid-Catalyzed Wood Coatings: What You Need To SucceedDocument3 pagesEastman Coatings: Formulating Acid-Catalyzed Wood Coatings: What You Need To SucceedmanojNo ratings yet

- Comparison Between Dry Lamination and Extrusion LaminationDocument26 pagesComparison Between Dry Lamination and Extrusion LaminationRicardo PratiwiharjaNo ratings yet

- Setalux D A 160 X - en - A4Document2 pagesSetalux D A 160 X - en - A4Juan Sebastián Fernández RamírezNo ratings yet

- Setalux D A 870 Ba - en - A4Document1 pageSetalux D A 870 Ba - en - A4Fabio Enrique Gomez RamirezNo ratings yet

- Whitmore Det-900 GreaseDocument1 pageWhitmore Det-900 GreaseDon HowardNo ratings yet

- NACURE For Amino Crosslinked Systems USDocument8 pagesNACURE For Amino Crosslinked Systems USClayton EliasNo ratings yet

- Super Gelkyd 6006 Wda 55Document2 pagesSuper Gelkyd 6006 Wda 55monrmNo ratings yet

- MR-2125 PDSDocument2 pagesMR-2125 PDSMark WuNo ratings yet

- DS - 1090 FRT - 25.09.2012Document4 pagesDS - 1090 FRT - 25.09.2012McFlyNo ratings yet

- Oilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDocument10 pagesOilfield Emulsion Control: A Major Issue During Heavy Crude Oil ProductionDaniel DamboNo ratings yet

- H85929Document16 pagesH85929dhavaleshNo ratings yet

- Shell Helix HX8 Synthetic 5W-30 (SN CF A3 B4 MB229.3) (AU)Document2 pagesShell Helix HX8 Synthetic 5W-30 (SN CF A3 B4 MB229.3) (AU)YandiNo ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- 06 - Nitrogen Compounds (Level) Module-5Document14 pages06 - Nitrogen Compounds (Level) Module-5Raju SinghNo ratings yet

- CHEM1920 Lecture 10Document22 pagesCHEM1920 Lecture 10Kahelia CampbellNo ratings yet

- Reagent ListDocument9 pagesReagent ListArka MukhopadhyayNo ratings yet

- Parishram (2024) : Alcohol, Phenol and EtherDocument2 pagesParishram (2024) : Alcohol, Phenol and Etherpayeb14656No ratings yet

- Alcohols, Phenols and EthersDocument3 pagesAlcohols, Phenols and EthersCJ's Music GalleryNo ratings yet

- Us 5700768Document10 pagesUs 5700768sanjeev guptaNo ratings yet

- 1 - Intro To Organic ChemistryDocument144 pages1 - Intro To Organic ChemistryDANIEL ORTAÑEZNo ratings yet

- 4.6 Organic Chemistry 2Document30 pages4.6 Organic Chemistry 2caroprinters01No ratings yet

- Ank Import Data Clean v1Document618 pagesAnk Import Data Clean v1siyengar1447No ratings yet

- Aep - CPP - 1Document9 pagesAep - CPP - 1ayesha sheikhNo ratings yet

- Carbonyl Compounds-I S-1Document8 pagesCarbonyl Compounds-I S-1sciencewing rbiNo ratings yet

- CBSE Class 12 Chemistry Syllabus 2023 24Document7 pagesCBSE Class 12 Chemistry Syllabus 2023 24IbinNo ratings yet

- Organic ChemistryDocument1 pageOrganic ChemistryHarshit SharmaNo ratings yet

- Alcohol Phenol and Ether PYQ Solution - 18290254 - 2023 - 06 - 20 - 12 - 09Document3 pagesAlcohol Phenol and Ether PYQ Solution - 18290254 - 2023 - 06 - 20 - 12 - 09telate6613No ratings yet

- 2018 Nitrogen Compounds Tutorial AnswersDocument24 pages2018 Nitrogen Compounds Tutorial AnswersAmelia WongNo ratings yet

- Alcohols & Carboxylic Acids 2 QPDocument11 pagesAlcohols & Carboxylic Acids 2 QPDia GadaNo ratings yet

- SME Chemistry Topic 10 Organic Chemistry NotesDocument69 pagesSME Chemistry Topic 10 Organic Chemistry Notessiqi daiNo ratings yet

- AlcoholsDocument74 pagesAlcoholsSmit PatelNo ratings yet

- عضوية١Document10 pagesعضوية١مصطفى ابراهيم سعيدNo ratings yet

- Lab Report Experiment 5 Hydroxy CompoundsDocument5 pagesLab Report Experiment 5 Hydroxy CompoundsYe Woon LimNo ratings yet

- Listado Inertes EPADocument77 pagesListado Inertes EPAToSTADA RoyonNo ratings yet

- Alcohol Ether and PhenolsDocument43 pagesAlcohol Ether and Phenolswadhwaniakansha9No ratings yet

- Organic Chemistry 12 Cheat SheetDocument25 pagesOrganic Chemistry 12 Cheat SheetVanessa MurphyNo ratings yet

- Lecture 4 IR Spectrum AnalysisDocument43 pagesLecture 4 IR Spectrum AnalysiskhadijahhannahNo ratings yet

- 6.1-S - Organic C 30 - Naming BookletDocument50 pages6.1-S - Organic C 30 - Naming Bookletk.7330167No ratings yet

- AlcoholsDocument15 pagesAlcoholsNikolina RajkovačaNo ratings yet

- Manual Amali Sko3023 Sem A222Document27 pagesManual Amali Sko3023 Sem A222nadiaNo ratings yet

- Alcohols Phenols and EthersDocument1 pageAlcohols Phenols and EthersNitisha GuptaNo ratings yet

- (Xii) Alcohol, Phenol, EtherDocument10 pages(Xii) Alcohol, Phenol, EtherAbhishek SharmaNo ratings yet

- Dwnload Full Biochemistry 4th Edition Mathews Test Bank PDFDocument12 pagesDwnload Full Biochemistry 4th Edition Mathews Test Bank PDFmahoutcawk.cn3ec8100% (14)