Professional Documents

Culture Documents

Comparative Study of The Energy Absorption Capacities of XPS and XPE

Uploaded by

suresh puranic mathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Study of The Energy Absorption Capacities of XPS and XPE

Uploaded by

suresh puranic mathCopyright:

Available Formats

International Journal of Engineering Research ISSN:2319-6890)(online),2347-5013(print)

Volume No.4, Issue No.7, pp : 368-372 01 July 2015

Comparative Study of the Energy Absorption Capacities of XPS and XPE

Foam Filled Aluminium Square Tubes under Quasi-Static Axial Compression

Suman Bargav. R1, Venkataswamy K. S.2, Dr. Suresh P. M.3

1

Research Scholar VTU Regional Resource Centre, Belgaum

2

PG Student, KSIT, Bangalore

3

Professor and Head, Department of Mechanical Engineering, KSIT, Bangalore

*Corresponding Email: suman.bargav@gmail.com

Abstract:Quasi-static compression tests were performed on other hand, there is a continuous attempt to decrease the value of

empty and foam filled Aluminium square tubes. Two different Pmax. Accordingly, CFE is defined (J. Marzbanrad 2014) as the

foam types: Extended Polystyrene (XPS) and Extended ratio of the mean force to the initial peak force.

Polyethylene (XPE) were used to fill the empty tubes. In this

paper experimental and numerical simulations were performed There have been ongoing attempts to increase the energy

to investigate the effect of foam filling on crashworthiness absorption capability of tubular structures. Methods such as

parameters. frusta, Multi-corner columns, Sandwich plates, Honeycomb cells,

Tube inversion and tube splitting have been investigated with this

Keywords: XPS, XPE, Specific Energy absorption, Crush regard (Alghamdi 2001). Methods to reduce peak load by

Force efficiency introducing Grooves (S.J. Hosseinipour 2003) and slots (Amir

Radzi Ab. Ghani 2012) have been studied.

I. Introduction

In last few decades, foam- filled tubes are given much attention in

The impact of transport vehicles is undesirable but occurs now crashworthiness applications. Aluminium foam and Polyurethane

and then. Hence, it is important to design the transport structures foam have gained popularity due to their high specific strength,

to withstand impacts and crashes. There is a continuous demand cost and ease of manufacturing. Foam-like lattices are often used

for the design of light weight structures which puts greater for cushioning, packaging or to protect against impact, utilizing

demands on the designer since more aspects of design become the long, flat plateau of their stress–strain curves (Ashby 2006).

critical as the working stresses become closer to the ultimate The increased number of lobes created by introducing foam filler

strengths of the material. These light weight structures causes the force level of the foam-filled tubes to be significantly

eventually improve fuel economy and emissions along with higher than that of the combined effect of empty tube and foam

reduced cost. separately (Hong-Wei Song 2005).

A typical Load-displacement response during an impact of Many investigations have been carried out on tube structures

tubular structures shows an initial peak load which is usually filled with Polyurethane foams (K. A. Kamarudin 2008), (Nirut

much higher than the calculated mean load. Ideally the load must Onsalung 2010), (REID 1993).

rise to a threshold value that will cause no harm to passengers

and remain constant for the subsequent deformation (Faris In this paper, the energy absorption capacities of Polystyrene and

Tarlochan 2014). The initial high peak load is caused by the Polyethylene foams are studied.

formation of the first plastic fold. Depending on the specimen or

component geometry, subsequent folds begin to form after or II. Specimen Preparation

during the formation of the first fold. Each subsequent smaller

peak represents one fold. 6063-T6 Aluminium alloy tubes are available in lengths of 12 feet

for commercial use. The square tubes of dimension 2inch X 2inch

There are several parameters that are significant in any crash and of thickness 3 mm were selected for the study. Nine test

analysis. They include: Peak Load, Energy absorption, Crush samples were cut from these tubes and machined to a length of

Load efficiency (CFE), Specific Energy Absorption (SEA), and 150 mm each. Out of these nine samples, three were filled with

Mean Load (Pm). These are important parameters for comparing XPS foam, three with XPE foam and the remaining three were

the effectiveness of the energy absorber. left empty. The XPS and XPE foams are available in the form of

50 mm thick sheets and these were cut and inserted into the tubes.

Energy absorption is calculated as the area under the load- Each foam is of density 46 kg/m3.

displacement curve during impact process and SAE is the energy

absorbed per unit weight of the absorber The dimensions were measured using a digital Vernier calliper of

0.01 mm least count. The weights of each sample are measured

Pm and Pmax are used to describe the characteristics of an absorber. using digital weighing scale PRITECH (Model No, KL-Z-030)

The larger value of Pm corresponds to larger value of the energy with least count of 0.1 g. The lateral dimension of the tube varied

absorbed and the goal of the design is to maximize it. On the from 51.09 mm to 52.10 mm. However, the thickness of the tube

IJER@2015 Page 368

International Journal of Engineering Research ISSN:2319-6890)(online),2347-5013(print)

Volume No.4, Issue No.7, pp : 368-372 01 July 2015

varied from 3.02 mm to 3.24 mm and height of the specimen Figure 2. It shows that XPS foam has a considerable elastic

varied from 149.5 mm to 151.44 mm over the entire specimen region while, XPE has negligible elastic region. However, the

samples. All dimensions are measured at room temperature. plateau regions for XPS and XPE foams are spread till the strain

Details of the test specimen are shown in the Table 1 of 0.6-0.75 from where it starts densifying.

Table 1: Specimen details

Tube dimensions (mm) Tube weight (g)

Ref No Foam

W B t H Empty Filled

EE5A - 51.09 51.74 3.24 151.44 243.1 -

EE5B - 51.87 52.00 3.11 150.12 241.0 -

EE5C - 51.99 52.10 3.10 150.76 242.0 -

EF4G XPS 52.04 51.96 3.23 150.41 241.1 255.3

EF4H XPS 51.95 51.86 3.10 152.02 243.4 257.8

EF4J XPS 51.61 51.69 3.23 149.50 240.8 255.0

EF4K XPE 52.10 51.78 3.18 150.21 239.8 254.1

EF4L XPE 51.71 51.99 3.02 150.63 241.6 256.5

EF4M XPE 51.72 51.96 3.04 150.62 241.6 255.8

III. Material Properties

Standard tensile test specimen was machined out from the tube

made out of Aluminium 6063-T6. The test specimen was Figure 2: Engineering Stress-Strain curves for XPS and XPE

machined from the same tube that was subjected to compression- foams

load test in the present experimental study.

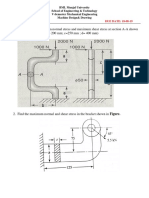

IV. Experiment

Tensile test was conducted on TUE-C-1000 tensile test machine

as per Test reference IS 1608-2005. The extensometer of 50 mm Each of the nine test specimen were subjected to load test under

gauge length was used to obtain stress-strain diagram for the compression on a UTM (Model No: TUE-C-1000) of 100 tonne

tensile test specimen. capacity. The test was carried out under Quasi-Static condition

with the loading rate of 0.6 kN/s. The experiments were

The Figure 1 shows the stress-strain curve for the material of the terminated manually when the specimens have crushed to

tube. The Aluminium alloy shows tensile strength of 148.2 MPa, beyond 100 mm from its initial length. The deformation pattern

while its yield strength is 116.8 MPa. It showed elongation of is observed. The load versus displacement curves is plotted and

about 12.64%. The young’s modulus and the tangent modulus the energy absorbed during the compression process is

were then estimated to be respectively 60 GPa and 550 MPa. calculated. The comparison is made between the empty and

foam filled tubes.

V. Experimental Results

From the experiments carried out, it was observed that all

specimens underwent systematic progressive folding forming 2-

3 lobes. This type of crushing mode is known in literature as

Diamond mode or non-Axisymmetric sequential folding.

The crushing modes of the empty tubes, XPS foam filled tubes

and XPE foam filled tubes are shown respectively in Figure 3,

Figure 4 and Figure 5

Figure 1: Engineering Stress-Strain curves for Aluminium

alloy

The stress-strain curves for XPS and XPE foams were obtained

from the compression test. The specimen each of densities 46

kg/m3 were cut in the form of 50 mm cube and tested under Figure 3: Crushing modes of the empty tubes

compression. The stress strain curve for the foams is shown in

IJER@2015 Page 369

International Journal of Engineering Research ISSN:2319-6890)(online),2347-5013(print)

Volume No.4, Issue No.7, pp : 368-372 01 July 2015

The Figure 7 and Figure 8 show the variation with respect to

displacement of energy and mean load during the compression

process. It shows that there is no significant improvement in

energy absorption by foam filling.

Figure 4: Crushing modes of the XPS foam filled tubes

Figure 5: Crushing modes of the XPE foam filled tubes Figure 7: Experimental Energy curves

The Figure 6 shows the load versus displacement curve. From

the plot, it is observed that there is no effect of the foam filling

on the peak load.

Figure 8: Experimental Mean Load Curves

The details of the crashworthiness parameters are shown in the

Table 2

Figure 6: Experimental Load versus displacement curves Table 2: Crashworthiness parameters

Expt Pm Ea Deformation Pmean

SEA CFE

No. (kN) (kJ) (mm) (k N)

EE5A

84.4 4.5 110 41 18.7 49

EE5B

83.2 4.7 100 47 19.5 56

EE5C

84.1 4.5 103 44 18.7 52

EF4G

84.2 4.0 92 44 15.7 52

EF4H

87.3 4.9 105 47 19.1 54

EF4J

84.1 4.8 104 46 18.8 55

EF4K

82.5 4.4 97 45 17.3 55

EF4L

84.4 4.6 102 45 17.9 53

IJER@2015 Page 370

International Journal of Engineering Research ISSN:2319-6890)(online),2347-5013(print)

Volume No.4, Issue No.7, pp : 368-372 01 July 2015

EF4M

84.4 4.8 103 46 18.6 55

VI. FE Modelling

The finite element commercial software LS DYNA R971 is used

to study the numerical simulations. The tubes were modelled in

Hypermesh using 4-noded shell elements with 2 integration

points along the thickness of the tube and are of element size 2

mm. The foams were modelled using Hex element of size 4 mm.

Thematerialmodel MAT_PIECEWISE_LINEAR_PLASTICITY

(MATL24)was used to model Aluminium tubes and Figure 10: Deformation Pattern

MAT_LOW_DENSITY_FOAM (MATL57) was used to model

foam behaviour. A-Empty; B- XPS filled; C-XPE filled tubes

The contact behaviour was modelled using the cards

The Figure 11 shows the Load versus displacement curve during

AUTOMATIC_GENERAL and CONTACT_INTERIOR the compression process. From the plot, it is observed that there

respectively between Tube-Foam interface and self interacting

is no significant effect of the foam filling on curve.

surfaces (internal behaviour of the foam).

The rigid wall was created at bottom of the tube to constrain the

motion of the tube along the direction of loading. A prescribed

motion defined to a rigid wall created at the top of the tube that

crushed the tube quasi-statically. The simulation was terminated

after the rigid walled crushed the tube for about 120 mm.

The FE model with Boundary Conditions is shown in the Figure

9

Figure 11: FEM Load versus displacement curve

The Figure 12 and Figure 13 show the variation with respect to

displacement of energy and mean load during the compression

process. It shows that there is no improvement either in the

energy or in the mean load curve by foam filling.

Figure 9: FE model showing the BC

VII. FE Results

Three sets of simulations were performed to simulate the

crushing of Empty tube, XPS foam filled tube and XPE foam

filled tube. The results were post processed in LS-PrePost 4.0

From the simulations carried out, it was observed that the tubes

underwent crushing in the same pattern as was found in the

experiments.

The crushing modes of the empty tubes, XPS foam filled tubes

and XPE foam filled tubes are shown in Figure 10

Figure 12: FEM Energy versus displacement curves

IJER@2015 Page 371

International Journal of Engineering Research ISSN:2319-6890)(online),2347-5013(print)

Volume No.4, Issue No.7, pp : 368-372 01 July 2015

Figure 13: FEM Mean Load Curves

VIII. Conclusion

The effect of foam filling on the impact characterization (SEA,

CFE etc.) of XPS and XPE foam filled aluminium tubes are

investigated in this paper. The study shows that the low density

foams with lower plateau stress offer less or no resistance to

deformation. Hence its participation during energy absorption

process is insignificant and therefore it cannot be used in the

energy absorption application.

From the present results, it is proposed that a future study can be

carried out with the use of higher density foams with higher

plateau stress. It is also recommended to make a comparative

study between the PU, XPS and XPE foam filled tubes by

increasing the densities.

Acknowledgement

The authors remain thankful for the encouragement and support

received throughout this research work to Kammavari Sanga

group of Institutions, The principal Dr. T. V. Govindaraju and

Raghavendra Spectro Metallurgical Laboratories.

References

vi. J. Marzbanrad, A. Keshavarzi. "A Numerical and

i. Alghamdi, A.A.A. "Collapsible impact energy absorbers-an experimental study on the crash behavior of the extruded aluminum

overview." Thin-Walled Structures, 2001: 189-213. crash box with elastic support." Latin American Journal of Solids and

ii. Amir Radzi Ab. Ghani, M.A. Hassan, Zahari Taha, M. Hamdi. Structures 11 (2014): 1329-1348.

"Effect of Slot Geometry on the Impact Response of Square Column." vii. K. A. Kamarudin, S. Kanthasamy, A. E. Ismail. "Crushing

Advanced Science Letters 13 (2012): 1-7. Characteristics of Foam-Filled Columns." ICCBT, 2008.

iii. Ashby, M.F. "The properties of foams and lattices." Phil. viii. Nirut Onsalung, Chawalit Thinvongpituk, Kulachate

Trans. R. Soc (Royal Society publishing) 364 (2006): 15-30. Painthong. "The Influence of Foam Density on Specific Energy

iv. Faris Tarlochan, S.V. Perumal, Khalifa Al-Khalifa, Abdel Absorption of Rectangular Steel Tubes." Energy Research Journal

Magid Hamouda. "A Novel Design of Lightweight Aluminum Tubular (Science Publications) 1, no. 2 (2010): 135-140.

Crash-Box for Crashworthiness Application." Proc. of the Intl. Conf. on ix. REID, S. R. "Plastic Deformation Mechanisms in Axially

Advances in Mechanical and Robotics Engineering (Institute of Compressed Metal Tubes used as Impact Energy Absorbers." Int. J.

Research Engineers and Doctors), 2014. Mech. Sci. 35, no. 12 (1993): 1035-1052.

v. Hong-Wei Song, Zi-Jie Fan, Gang Yu, Qing-Chun Wang, A. x. S.J. Hosseinipour, G.H. Daneshi. "Energy absorbtion and

Tobota. "Partition energy absorption of axially crushed aluminum mean crushing load of thin-walled grooved tubes under axial

foam-filled hat sections." International Journal of Solids and Structures compression." Thin-Walled Structures 41 (2003): 31-46.

(Elsevier) 42 (2005): 2575-2600.

IJER@2015 Page 372

You might also like

- Optimal Design of Flexural Systems: Beams, Grillages, Slabs, Plates and ShellsFrom EverandOptimal Design of Flexural Systems: Beams, Grillages, Slabs, Plates and ShellsNo ratings yet

- Mechanics of Materials 2: The Mechanics of Elastic and Plastic Deformation of Solids and Structural MaterialsFrom EverandMechanics of Materials 2: The Mechanics of Elastic and Plastic Deformation of Solids and Structural MaterialsRating: 4 out of 5 stars4/5 (14)

- 1 PB PDFDocument5 pages1 PB PDFMaazNo ratings yet

- A Comparative Study of Energy Absorption Characteristics of Foam-Filled and Multi-Cell Square Columns (2007)Document14 pagesA Comparative Study of Energy Absorption Characteristics of Foam-Filled and Multi-Cell Square Columns (2007)naveed6069No ratings yet

- Research Paper Sample 1-1Document4 pagesResearch Paper Sample 1-1Abidul IslamNo ratings yet

- High-Strain-Rate Compressive Behavior of A Rigid Polyurethane Foam With Various DensitiesDocument9 pagesHigh-Strain-Rate Compressive Behavior of A Rigid Polyurethane Foam With Various DensitiesATISH KUMAR DASNo ratings yet

- Crushing Performances of Winding Square Kenaf Fiber Reinforced CompositesDocument5 pagesCrushing Performances of Winding Square Kenaf Fiber Reinforced CompositesGarett MasterNo ratings yet

- AMME - Volume 18 - Issue 18th International Conference On Applied Mechanics and Mechanical Engineering. - Pages 1-15Document15 pagesAMME - Volume 18 - Issue 18th International Conference On Applied Mechanics and Mechanical Engineering. - Pages 1-15Valentina DiamanteNo ratings yet

- Zhang, Zhang, Wang - 2016 - Bending Collapse of Square Tubes With Variable ThicknessDocument10 pagesZhang, Zhang, Wang - 2016 - Bending Collapse of Square Tubes With Variable ThicknessMuhammad Khairul SNo ratings yet

- Acara MultiobjectivecrashworthinessoptimizationDocument12 pagesAcara MultiobjectivecrashworthinessoptimizationELDHO JACOB JOYNo ratings yet

- Energy Absorption Capacity of Composite BeamsDocument6 pagesEnergy Absorption Capacity of Composite BeamsvijayapandimNo ratings yet

- Analysis of The Properties and Microstructure of Ultra-ThinDocument7 pagesAnalysis of The Properties and Microstructure of Ultra-Thinmohammadreza hajialiNo ratings yet

- Zhang 2016Document10 pagesZhang 2016arif usmanNo ratings yet

- Energy Absorption and Crushing Behaviour of Foam-Filled Aluminium TubesDocument4 pagesEnergy Absorption and Crushing Behaviour of Foam-Filled Aluminium TubesSMITINo ratings yet

- Fatigue Life Assessment of Orthotropic Steel Deck With UHPC PavementDocument7 pagesFatigue Life Assessment of Orthotropic Steel Deck With UHPC PavementGuilherme AlencarNo ratings yet

- SANDWICH BEAM FLEXURE BEHAVIOUR REPORT E3.4Document15 pagesSANDWICH BEAM FLEXURE BEHAVIOUR REPORT E3.4Wang Yi DanNo ratings yet

- 14.Stress-Strain Relationship in Axial Compression For EPS ConcreteDocument7 pages14.Stress-Strain Relationship in Axial Compression For EPS ConcreteManuel GutarraNo ratings yet

- 663 Ea0076Document4 pages663 Ea0076anon_629908933No ratings yet

- The Effect of Hydrostatic Pressure On The Mechanical Properties of Glass Fibre/epoxy Unidirectional CompositesDocument11 pagesThe Effect of Hydrostatic Pressure On The Mechanical Properties of Glass Fibre/epoxy Unidirectional CompositesMartín KunuschNo ratings yet

- A Nonlinear FE Method For The Prediction of Slabs On Grade BehaviourDocument7 pagesA Nonlinear FE Method For The Prediction of Slabs On Grade BehaviourJuan BravoNo ratings yet

- Test 6451654751351Document10 pagesTest 6451654751351uvezfGRNo ratings yet

- Oshkovr 2012Document6 pagesOshkovr 2012Sait Ozan YılmazNo ratings yet

- 2000 Experimental Study On The Effect of Tension For RubberDocument8 pages2000 Experimental Study On The Effect of Tension For Rubberarnold.r.mendoNo ratings yet

- BFRPConfinedCylinders AK ERTDocument4 pagesBFRPConfinedCylinders AK ERTMahmoud HamadaNo ratings yet

- Design of Elastomeric Bearing System and AnalysisDocument11 pagesDesign of Elastomeric Bearing System and Analysisabdelrahman emadNo ratings yet

- Paper Svoboda Machacek 002Document10 pagesPaper Svoboda Machacek 002loc nguyenNo ratings yet

- Mechanical Properties of Polyurethane FoamsDocument7 pagesMechanical Properties of Polyurethane FoamsRégis OngolloNo ratings yet

- Özkaynak2016 Article ACapacityCurveModelForConfinedDocument30 pagesÖzkaynak2016 Article ACapacityCurveModelForConfinedTariqul IslamNo ratings yet

- Wen-Yea Jang, Stelios Kyriakides and Andrew M. Kraynik - On The Compressive Strength of Open-Cell Metal Foams With Kelvin and Random Cell StructuresDocument39 pagesWen-Yea Jang, Stelios Kyriakides and Andrew M. Kraynik - On The Compressive Strength of Open-Cell Metal Foams With Kelvin and Random Cell StructuresFlaoeramNo ratings yet

- Thin-Walled Structures: Niyazi Tanlak, Fazil O. SonmezDocument11 pagesThin-Walled Structures: Niyazi Tanlak, Fazil O. SonmezFelipe Dornellas SilvaNo ratings yet

- Experimental Studies On The Impact Characteristics of Seamless Fibremetal Laminate (FML) TubesDocument5 pagesExperimental Studies On The Impact Characteristics of Seamless Fibremetal Laminate (FML) TubesNurlia HanimNo ratings yet

- Compression Testing of BambooDocument12 pagesCompression Testing of BamboomavessNo ratings yet

- Modulus of Elasticity of Low Strength Concrete: Conference PaperDocument7 pagesModulus of Elasticity of Low Strength Concrete: Conference PaperDiana VazquezNo ratings yet

- Compressive Strength Assessment of Concrete Structures From Small Core by Point Load TestDocument8 pagesCompressive Strength Assessment of Concrete Structures From Small Core by Point Load Testzacoeb_a1669No ratings yet

- Fatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressDocument17 pagesFatigue Capacity of Plain Concrete Under Fatigue Loading With Constant Confined StressVicente Bergamini PugliaNo ratings yet

- Polymer Testing: Kedar S. Pandya, Lokesh Dharmane, Jayaram R. Pothnis, G. Ravikumar, N.K. NaikDocument6 pagesPolymer Testing: Kedar S. Pandya, Lokesh Dharmane, Jayaram R. Pothnis, G. Ravikumar, N.K. NaikBhasker RamagiriNo ratings yet

- Carbon EpoxyDocument26 pagesCarbon EpoxyAdrià Borrego OrpinellNo ratings yet

- Fracture Energy of Steel Fiber-Reinforced ConcreteDocument18 pagesFracture Energy of Steel Fiber-Reinforced ConcreteMilanNo ratings yet

- Fatigue Crack Growth of Filament Wound GRP Pipes With A Surface Crack Under Cyclic Internal PressureDocument6 pagesFatigue Crack Growth of Filament Wound GRP Pipes With A Surface Crack Under Cyclic Internal PressureNarayanan KharthiNo ratings yet

- Experimental Simulation For Load Reduction Techniques On Underground Utilities Using GeofoamDocument9 pagesExperimental Simulation For Load Reduction Techniques On Underground Utilities Using GeofoamIEREKPRESSNo ratings yet

- @@CITE - IDES Hay@@ A Crushing Analysis and Multi-Objective Optimization of Thin-Walled Five-Cell StructuresDocument18 pages@@CITE - IDES Hay@@ A Crushing Analysis and Multi-Objective Optimization of Thin-Walled Five-Cell StructuresNhanNo ratings yet

- Strengthening of Reinforced Concrete Stepped Beam Using Cotton BeltDocument11 pagesStrengthening of Reinforced Concrete Stepped Beam Using Cotton BeltAbdulkhaliq AbdulyimahNo ratings yet

- Fatigue Behaviour of Rail Steel - A Comparison BetDocument8 pagesFatigue Behaviour of Rail Steel - A Comparison BetnehaJSPLNo ratings yet

- Modeling Large Deformation and Failure of Expanded Polystyrene Crushable Foam Using Ls DynaDocument8 pagesModeling Large Deformation and Failure of Expanded Polystyrene Crushable Foam Using Ls DynaNguyễn TúNo ratings yet

- A New Bending Test Method of Advanced CompositesDocument6 pagesA New Bending Test Method of Advanced CompositesMinhazul Abedin RiadNo ratings yet

- Point Load Test 2Document12 pagesPoint Load Test 2Rajitha ShehanNo ratings yet

- Use of Split-Disk Tests For The Process Parameters-Kaynak2005Document8 pagesUse of Split-Disk Tests For The Process Parameters-Kaynak2005houcinejNo ratings yet

- 10.1007@s40870 019 00192 0Document11 pages10.1007@s40870 019 00192 0vinhtungbkNo ratings yet

- CompositeDocument11 pagesCompositelikith333No ratings yet

- Study of A Uniaxial Tension Test MethodologyDocument28 pagesStudy of A Uniaxial Tension Test MethodologyJuan Diego Vargas MendozaNo ratings yet

- FEM of UHPC Beams Under Pure TorsionDocument5 pagesFEM of UHPC Beams Under Pure TorsionHHTNo ratings yet

- W6 Design Optimization Case Study Car StructuresDocument10 pagesW6 Design Optimization Case Study Car StructuresMartin PedrozaNo ratings yet

- Prediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie ModelsDocument4 pagesPrediction of Shear Strength of PPFRC Moderate Deep Beams Using Strut-and-Tie Modelschetan2042No ratings yet

- Experimental, Theoretical and Numerical Study On Thin Walled Steel Single and Compound Channel Sections in Axial CompressionDocument12 pagesExperimental, Theoretical and Numerical Study On Thin Walled Steel Single and Compound Channel Sections in Axial Compressionخوێندن لە ئەوروپاNo ratings yet

- Transmission Loss 1Document6 pagesTransmission Loss 1Chirlly UlaiNo ratings yet

- 1-S2.0-S0308016116301843-Main Application of Small Punch Testing On The Mechanical andDocument9 pages1-S2.0-S0308016116301843-Main Application of Small Punch Testing On The Mechanical andRamesh EthirajanNo ratings yet

- Experimental Determination of Dynamic Young's Modulus and Damping of An Aramid-Fabricpolyester Composite MaterialDocument4 pagesExperimental Determination of Dynamic Young's Modulus and Damping of An Aramid-Fabricpolyester Composite MaterialAzeNo ratings yet

- Assessing The Tensile Capacity of Cold-Formed Steel ConnectionsDocument8 pagesAssessing The Tensile Capacity of Cold-Formed Steel ConnectionsSang NguyenNo ratings yet

- Plastic Theory of Structures: In SI/Metric UnitsFrom EverandPlastic Theory of Structures: In SI/Metric UnitsRating: 5 out of 5 stars5/5 (3)

- Design and Analysis of A Frame For Roller Hemming CellDocument5 pagesDesign and Analysis of A Frame For Roller Hemming Cellsuresh puranic mathNo ratings yet

- A Review On Plastic Deformation in EcapDocument6 pagesA Review On Plastic Deformation in Ecapsuresh puranic mathNo ratings yet

- 15me82-Module 4-Am Full PDFDocument78 pages15me82-Module 4-Am Full PDFsuresh puranic mathNo ratings yet

- Conf Journal ICETEISM 29Document4 pagesConf Journal ICETEISM 29suresh puranic mathNo ratings yet

- Developments of Robotic TechnologyDocument20 pagesDevelopments of Robotic Technologysuresh puranic mathNo ratings yet

- Developments of Robotic TechnologyDocument13 pagesDevelopments of Robotic Technologysuresh puranic mathNo ratings yet

- Arch - Dam - EM - 36 - 10-19-2012 - Final Draft PDFDocument98 pagesArch - Dam - EM - 36 - 10-19-2012 - Final Draft PDFGligor JakovleskiNo ratings yet

- Composite Materials Project: Tomescu Ioana-Claudia Fils Iii Amanat, Group 1Document9 pagesComposite Materials Project: Tomescu Ioana-Claudia Fils Iii Amanat, Group 1Ioana TomescuNo ratings yet

- Kerto Manual LVL Mechanical PropertiesDocument6 pagesKerto Manual LVL Mechanical PropertiesVinnieTranNo ratings yet

- Siemens Data Center Whitepaper Aluminium Versus CopperDocument9 pagesSiemens Data Center Whitepaper Aluminium Versus CopperlongplNo ratings yet

- Flat Spiral SpringsDocument2 pagesFlat Spiral SpringsBharani DaranNo ratings yet

- Assignment 1Document4 pagesAssignment 1p KumarNo ratings yet

- Hydro en Aw 6082Document3 pagesHydro en Aw 6082Velissarios DemetriouNo ratings yet

- SC-1060U DatasheetDocument2 pagesSC-1060U DatasheetAgus IrawanNo ratings yet

- Strength and Protective Coatings On Steel Industrial Fence FrameworkDocument7 pagesStrength and Protective Coatings On Steel Industrial Fence FrameworkDarwin DarmawanNo ratings yet

- Manual of Steel DesignDocument158 pagesManual of Steel DesignSajoyan Haque100% (1)

- Latbsdc CriteriaDocument53 pagesLatbsdc CriteriaMREFAATNo ratings yet

- Unconfined Compressive Strength of SoilDocument4 pagesUnconfined Compressive Strength of SoilJoshi DhvanitNo ratings yet

- Masonry DesignDocument7 pagesMasonry DesignedisonmalahitoNo ratings yet

- Ch9 Horizontally Curved Steel GirdersDocument43 pagesCh9 Horizontally Curved Steel GirdersErnie ErnieNo ratings yet

- PROJECT PROPOSA1-min PDFDocument48 pagesPROJECT PROPOSA1-min PDFomoshola ibrahimNo ratings yet

- Ratio of Undrained Shear Stress To Vertical Effective StressDocument5 pagesRatio of Undrained Shear Stress To Vertical Effective StressCarlos AcostaNo ratings yet

- Shear Force and Bending MomentDocument79 pagesShear Force and Bending MomentMadhu Sudhan TNo ratings yet

- The Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteDocument6 pagesThe Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteGladys Eras ValladolidNo ratings yet

- DESIGN CalculationDocument47 pagesDESIGN CalculationZayyan Romjon100% (2)

- Aerospace Engineering Sample Report PDFDocument4 pagesAerospace Engineering Sample Report PDFDuncan LeeNo ratings yet

- Strength of Materials 4th Edition by Pytel and SingerDocument5 pagesStrength of Materials 4th Edition by Pytel and SingerIan Jimbo Constantino82% (11)

- High-Temperature Tensile and Creep Data For Inconel 600Document13 pagesHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- Construction and Building Materials: Mohammad Karamloo, Moosa Mazloom, Gholamhasan PayganehDocument8 pagesConstruction and Building Materials: Mohammad Karamloo, Moosa Mazloom, Gholamhasan PayganehKevin SilvaNo ratings yet

- 718 Steel For PPR MouldDocument2 pages718 Steel For PPR MouldninhnhatNo ratings yet

- FDOT BDV25 977 01 RPTDocument306 pagesFDOT BDV25 977 01 RPTtecanasioNo ratings yet

- Engelhardt Steel Notes VI - Connections PDFDocument29 pagesEngelhardt Steel Notes VI - Connections PDFPauccar Rhp HpNo ratings yet

- MCEN3004 Advanced Strength of Materials Assignment (2024) : Problem StatementDocument2 pagesMCEN3004 Advanced Strength of Materials Assignment (2024) : Problem StatementAntonyNo ratings yet

- Compression Test em 327: Mechanics of Materials Laboratory: ObjectivesDocument5 pagesCompression Test em 327: Mechanics of Materials Laboratory: Objectivesrajenkoley88% (8)

- Rectangular Concrete BeamDocument6 pagesRectangular Concrete BeamRachid IdirNo ratings yet