Professional Documents

Culture Documents

2022 10 19 Odessa Grantville-S1

Uploaded by

Mary Gen ReynesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2022 10 19 Odessa Grantville-S1

Uploaded by

Mary Gen ReynesCopyright:

Available Formats

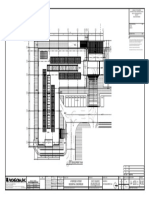

REPUBLIC OF THE PHILIPPINES

DEPARTMENT OF PUBLIC WORKS

CONSTRUCTION NOTES AND HIGHWAYS

OFFICE OF THE BUILDING OFFICIAL

A. GENERAL LAPU-LAPU CITY

1.

2.

CONSTRUCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE SHOWN OR NOTED.

IN THESE DRAWINGS INDICATED DIMENSIONS SHALL GOVERN AND DISTANCES OR SIZES SHALL NOT BE SCALED FOR

E. FOUNDATION RECOMMENDING APPROVAL:

CONSTRUCTION PURPOSES. STRUCTURAL SECTION:

1. FOOTING SHALL REST ON STIFF UNDISTURB SOIL STRATA, OR AN ENGINEERED (COMPACTED) FILL.

3. FOR ALL OTHER REQUIREMENTS, REFER TO ARCHITECTURAL, SANITARY, ELECTRICAL AND MECHANICAL WORKING DRAWINGS.

2. POURING OF CONCRETE SHALL NOT BE ALLOWED WHERE WATER IS PRESENT IN THE EXCAVATION DATE

4. SHOP DRAWING WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEEL, MISCELLANEOUS IRON, PRECAST WATER SHALL BE PUMPED OUT FIRST BEFORE POURING THE CONCRETE.

CONCRETE, ETC. SHALL BE SUBMITTED FOR ENGINEERINGS APPROVAL BEFORE FABRICATION.

3. BACK-FILLING SHALL BE DONE LAYER BY LAYER OF 200 mm FILL, THOROUGHLY COMPACTED 95 OF M.M.D.

5. CONTRACTOR SHALL VERIFY ALL DIMENSIONS BEFORE ALL WORK IS BEGUN, CHECK WITH MECHANICAL AND ELECTRICAL

6.

CONTRACTORS FOR CONDUITS, PIPE SLEEVES, ETC. TO BE EMBEDDED IN CONCRETE.

IT SHALL BE THE CONTRACTOR S RESPONSIBILITY TO PROVIDE ADEQUATE SHORINGS AND BRACING OF THE STRUCTURES

4.

UNTIL THEDESIRED ELEVATION IS ESTABLISHED.

SOIL BEARING CAPACITY 3,500 PSF A B C D APPROVED:

FOR ALL LOADS THAT MAY BE IMPOSED DURING CONSTRUCTION. 6909

ACI MINIMUM STRIPPING TIME MANUAL 2413 2861 1650 BUILDING OFFICIAL DATE

TIE BEAM/FOOTING f 2,500 s @ 28 DAYS, G1,S4 OF CONCRETE PRACTICE

WALLS* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 hr.

B. CONCRETE & REINFORCEMENTS WF1 WF1

ALL MATERIALS AND WORKMASHIP SHALL CONFORM WITH THE LATEST BUILDING CODE OF THE AMERICAN CONCRETE INSTITUTE

COLUMNS* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 hr.

SIDES OF BEAMS AND GIRDERS*. . . . . . . . . . . . . . . . . . . . . . .12 hr. 3

PAN JOIST FORMS C1F1 C1F1 C1F1 C1F1

( ACI 318-83 ). 30 IN. WIDE OR LESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 days

ALL CONCRETE SHALL DEVELOP A MINIMUM ULTIMATE COMPRESSIVE STRENGTH AT THE END OF 28 DAYS WITH CORRESPONDING OVER 30 IN. WIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 days

MAXIMUM SIZE OF AGGREGATES AND SLUMPS AS FOLLOWS:

WF1

2901

STRUCTURAL LIVE STRUCTURAL LIVE WF1

LOAD LESS THAN LOAD MORE THAN

MIN. 28 DAYS MAX. SIZE OF STRUCTURAL STRUCTURAL

LOCATION MAX. SLUMP DEAD LOAD DEAD LOAD

STRENGTH AGGREGATES

6051

FOOTING 20.7 M a 3,000 PSI 3/4 15.00 CM ARCH CENTERS

JOIST, BEAM, OR GIRDER SOFITS UNDER 10 ft. CLEAR SPAN 14 DAYS 7 DAYS

COLUMN 20.7 MPa 3,000 PSI 3/4 15.00 CM BETWEEN STRUCTURAL SUPPORTS 7 DAYS 4 DAYS

10 TO 20 ft. CLEAR SPAN BETWEEN STRUCTURAL SUPPORTS 14 DAYS 7 DAYS

BEAM 20.7 MPa 3,000 PSI 3/4 15.00 CM. OVER 20 ft. CLEAR SPAN BETWEEN STRUCTURAL SUPPORTS 21 DAYS 14 DAYS C1F1 C1F1 C1F1

SUS. SLAB 20.7 MPa 3,000 PSI 3/4 15.00 CM

ONE-WAY FLOOR SLABS

UNDER 10 ft. CLEAR SPAN BETWEEN STRUCTURAL SUPPORTS 4 DAYS 3 DAYS 2 WF1

WF1

10 TO 20 ft. CLEAR SPAN BETWEEN STRUCTURAL SUPPORTS 7 DAYS 4 DAYS

3150

3. MILD STEEL REINFORCEMENTS SHALL BE 16mm LARGER 414 MPa (G60) OVER 20 ft. CLEAR SPAN BETWEEN STRUCTURAL SUPPORTS 10 DAYS 7 DAYS

10mm 12mm 276 MPa (G40)

TWO-WAY SLAB SYSTEM . . . REMOVAL TIMES ARE CONTINGENT ON RESHORES WHERE

10mm SMALLER 228 MPa (G33)

REQUIRED, BEING PLACED AS SOON AS PRACTICABLE AFTER STRIPPING OPERATIONS ARE

AND SHALL BE FREE OF MILL SCALE OIL OR ANY OTHER SUBSTANCES WHICH TEND TO WEAKEN BOND STRENGTH. COMPLETE BUT NOT LATER THAN THE END OF THE WORKING DAY IN WHICH STRIPPING

4. IN GENERAL, THE LATEST EDITION OF ACI MANUAL OF STANDARD PRACTICE FOR DETAILING CONCRETE STRUCTURES SHALL OCCURS. WHERE RESHORES ARE REQUIRED TO IMPLEMENT EARLY STRIPPING WHILE

5.

BE ADHERED TO, UNLESS OTHERWISE SHOWN OR NOTED.

MAINTAIN MINIMUM CONC. COVER FOR REINFORCING STEEL AS FOLLOWS:

MINIMIZING SAG OR CREEP (RATHER THAN FOR DISTRIBUTION OF SUPERIMPOSED CONSTRUC-

TION LOADS AS COVERED IN SECTION 3.8), CAPACITY AND SPACING OF SUCH RESHORES 1 WF1 WF1

SHOULD BE SPECIFIED BY THE ENGINEER/ARCHITECT. C1F1 C1F1 C1F1 C1F1

WALL ABOVE GRADE 40 mm. SUSPENDED SLABS 20 mm.

BEAM STIRRUPS AND COLUMN TIES 40 mm.

WHERE CONCRETE IS EXPOSED TO EARTH

BUT POURED AGAINST FORMS 50 mm.

WHERE CONCRETE IS DEPOSITED DIRECTLY

AGAINST THE EARTH 75 mm.

S1-1 FOUNDATION PLAN 1:75M

6. SPLICES SHOULD BE SECURELY WIRED TOGETHER AND SHALL LAP OR EXTEND A MINIMUM OF 40 BAR DIAMETERS UNLESS

OTHERWISE SHOWN ON PLAN, SPLICES SHALL BE STAGGERED WHEREVER POSSIBLE.

7. PROVIDE DOWELS FOR ALL STRUTS AND COLUMNS, BEARING ON BEAMS AND WALLS, DOWELS SHALL BE EQUAL IN NUMBER

AND SIZE TO STRUT AND COLUMN REINFORCEMENTS, ALL DOWELS SHALL HAVE EMBEDMENT OF 40 BAR DIAMETERS. A B C D

8. ALL ANCHOR BOLTS, DOWELS AND OTHER INSERTS SHALL BE PROPERLY POSITIONED AND SECURED PRIOR TO PLACING OF

CONCRETE. A B C D 2413

6909

2861 1650

9. CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEOUS CURBS, SILLS, STOOLS, EQUIPMENTS AND MECHANICAL BASES 6909

THAT ARE REQUIRED BY THE ARCHITECTURAL, ELECTRICAL, AND MECHANICAL DRAWINGS.

2413 2861 1650

10. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF 7 CONSECUTIVE DAYS IMMEDIATELY AFTER POURING BY THE

USE OF A WET BURLAPS, FOG SPRAYING, CURING COMPOUNDS OR ANY OTHER APPROVED METHODS.

901

11. STRIPPING OF FORMS AND SHORES: SEE MINIMUM STRIPPING TIME (ACI MANUAL OF CONC. PRACTICE STANDARD)

C1

3

C. MASONRY, CONCRETE BLOCKS2L - 1 1/2 X 1 1/2 X 3.0mm THK ANGLE BAR

FOR WEB MEMBERS

2 X 3 1.2mm THK CEE PURLINS

SPACED @ 500mm O.C.

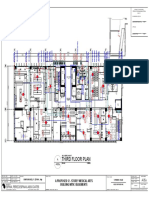

3 B1 B1

10MM DIA. ROUND

1. PROVIDE 1-12 mm DIA. BAR AT CORNERS, INTERSECTION, END OF WALLS AND EACH SIDE OF OPENINGS. BARS FOR SAG RODS

2. WALL REINFORCEMENT SHALL BE AS FOLLOWS UNLESS OTHERWISE NOTED:

C1 C1 C1

2901

S1 S1

2901

CHB WALL THICKNESS VERT. REINFORCEMENT HOR. REINFORCEMENT S1

600

B1 B2 B2 B1

6051

100 mm. 10 mm DIA. AT 40 m. 10 mm DIA. AT 60 m.

PROVIDE SWAT

150 mm. (EXT.) 10 mm DIA. AT 40 m. 1O mm DIA. AT 60 m. BRACE @ MIDSPAN

6051

(SEE DETAIL)

150 mm. (INT.) 10 mm DIA. AT 40 m. 10 mm DIA. AT 60 m.

TRUSS

TRUSS

TRUSS

TRUSS

B1 B1 C1

3. REINFORCING BARS SHALL BE LAPPED AT A MINIMUM OF 40 BAR DIAMETER. C1 C1 2 TRUSS: SEE DETAIL

3150

B1

D. STRUCTURAL STEEL

3150

S1 B2 S1 B2 B1

STAIRWELL

1. ALL MATERIALS AND WORKMANSHIP CONFORM WITH THE LATEST EDITION OF AMERICAN INSTIITUTE 2"X4" C-PURLINS

OF STEEL CONSTRUCTION (AISC) MANUAL UNLESS OTHERWISE NOTED. SPACED @ 600 O.C.

2.

3.

ALL STRUCTURAL STEEL INCLUDING THAT OF GUSSET PLATES SHALL BE ASTM A36 WITH YIELD STRENGTH Fy 248.22 MPa.

ALL BOLTS AND THREADED FASTENERS SHALL BE ASTM A 307.

1

1

900

4. ALL WELDS SHALL BE E 60 XX ELECTRODE AND SHALL DEVELOP AT LEAST 100 OF THE STRENGTH OF THE CONNECTED B1 B1

MEMBERS. C1 C1 C1 C1

TABLE OF LAP SPLICE 900

STANDARD HOOK (mm) TENSION LAP SPLICE (mm)

BAR ANCHORAGE BEAM COMP.

Ldh(mm) UNIT WT.

(mm) LENGTH (mm) SPLICE (mm) BEAM COLUMN

90 180 135 -90 LAP CLASS ( /m)

10 600 150 160 110 120 120 300

A

TOP BAR BOTTOM BAR

380 300

TIED

300

SPIRAL

300 0.616

S1-2 GF & 2F TYPICAL FRAMING PLAN 1:75M S1-3 ROOF FRAMING PLAN 1:75M

B 490 390

A 680 520

12 710 260 200 120 130 130 350 520 520 0.888

B 880 680

A 910 700

16 950 350 260 130 160 160 460 700 700 1.579

B 1180 910

A 1140 870

20 1180 440 320 160 200 320 580 870 870 2.466

B 1480 1130

A 1780 1370

25 1900 550 400 200 250 400 720 1370 1370 3.854

B 2310 1780

A 1990 1530

28 2190 620 480 260 810 1530 1530 4.833

B 2590 1990

A 2270 1750

32 2590 700 550 290 930 1750 1750 6.313

B 2950 2280

A 2560 1970

36 2990 790 650 360 1040 1970 1970 7.991

B 3330 2560

NOTES:

1. DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE, IN TENSION OR COMPRESSION, SHALL BE THAT FOR INDIVIDUAL BARS,

INCREASED 20 FOR THREE-BUNDLED AND 33 FOR FOUR-BUNDLED BARS.

2. FOR COLUMNS AT ANY LEVEL, NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED, NOTMORE THAN 33 OF THE BARS SHALL BE

SPLICED WITHIN THE REQUIRED LAP LENGTH, MINIMUM DISTANCE BETWEEN TWO ADJACENT SPLICED SHALL BE 600mm.

3. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm DEPTH OF CONCRETE CAST BELOW REINFORCEMENT.

4. LAP SPLICE SHALL BE CLASS B TENSION LAP SPLICE IF MORE THAN ONE HALF OF THE BARS WERE SPLICED AT ANY SECTION, WHILE CLASS A

TENSION LAP SPLICE IF HALF OR FEWER THAN HALF OF BARS WERE SPLICED.

FROM THE OFFICE OF: SEAL RA 9266 SEC. 4 ART. 33: PROJECT TITLE: OWNER: THIS DRAWING IS ISSUED FOR REVISIONS SHEET CONTENTS SHEET NO.

DRAWINGS, SPECIFICATIONS, AND OTHER CONTRACT DOCUMENTS, AS BUILT

ENGR.CIVIL

MARVIN PAVO AS INSTRUMENTS OF SERVICE, ARE THE INTELLECTUAL PROPERTY PROPOSED 2 STOREY RESIDENCE SPS. NEILBERT E. CASTILLO & OWNER'S APPROVAL

1

E.L. SUENYO + ASSOCIATES ENGINEER OF THE ARCHITECT, WHETHER THE OBJECT FOR WHICH THEY ARE

MADE IS EXECUTED OR NOT. IT SHALL BE UNLAWFUL FOR ANY

PERSON TO DUPLICATE OR TO MAKE COPIES OF SAID DOCUMENTS

ODESSA D. CASTILLO PRESENTATION

BIDDING

2

3

AS SHOWN S1

PRC NO.: 125884 PTR NO.: 3687462 FOR USE IN THE REPETITION OF OTHER PROJECTS OR BUILDINGS, ESTIMATE

AJOYA SUBDIVISION, GABI CORDOVA CEBU DATE: DECEMBER 6 2012 DATE: FEBRUARY 17 2022 WHETHER IN PART OR IN WHOLE, WITHOUT THE WRITTEN CONSENT DATE:

E.L. SUENYO + ASSOCIATES

DESIGN X CONSTRUCT X MANAGE OF THE ARCHITECT. GRANTVILLE II SUBDIVISION, MARIGONDON, LAPU-LAPU CITY BRGY. COGON PROPER, TUBURAN, CEBU BUILDING PERMIT

CONTACT: 0916 663 3267 edainsantos@gmail.com TIN.: 313-579-963 PLACE: CEBU CITY CONSTRUCTION / FABRICATION DRAWN BY: SC DD CD REV

You might also like

- Ce 35 Plate 8 PlumbingDocument2 pagesCe 35 Plate 8 PlumbingkbgainsanNo ratings yet

- A3-3 GF Doors & Windows Keyplan: ARCH264 - R7Document1 pageA3-3 GF Doors & Windows Keyplan: ARCH264 - R7reynesmarygen9No ratings yet

- Door and Window DetailDocument1 pageDoor and Window DetailkbgainsanNo ratings yet

- Agcg D - eDocument22 pagesAgcg D - eATMCI DavaoNo ratings yet

- Lighting Lay-Out Power Lay-Out: Fifth Floor Ground Floor Second Floor Third FloorDocument1 pageLighting Lay-Out Power Lay-Out: Fifth Floor Ground Floor Second Floor Third FloorMaycee PalenciaNo ratings yet

- Plan 1 BuildingDocument1 pagePlan 1 BuildingcimpstazNo ratings yet

- Perpective Facing Rizal Highway: Buenviaje MarceloDocument4 pagesPerpective Facing Rizal Highway: Buenviaje MarceloJohnvirgo CorpuzNo ratings yet

- Site Development Plan: C E F A G H J K L H'Document1 pageSite Development Plan: C E F A G H J K L H'anthony christian yangNo ratings yet

- Roof and Struc DetailsDocument1 pageRoof and Struc DetailskbgainsanNo ratings yet

- 13 ElectricalDocument1 page13 ElectricalUnknownNo ratings yet

- 2022 10 19 Odessa Grantville-A2Document1 page2022 10 19 Odessa Grantville-A2Mary Gen ReynesNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Front Elevation Right Side Elevation: A B C D E 5 4 3 2 1Document1 pageFront Elevation Right Side Elevation: A B C D E 5 4 3 2 1ArjelyNo ratings yet

- Legend:: S E W A G E Treatment Plant (P H A S E 2 & 3)Document1 pageLegend:: S E W A G E Treatment Plant (P H A S E 2 & 3)Ian Benedict congresoNo ratings yet

- Water Tank: LegendDocument1 pageWater Tank: LegendIan Benedict congresoNo ratings yet

- Legend:: Ulysses T. Arienza, UapDocument1 pageLegend:: Ulysses T. Arienza, UapIan Benedict congresoNo ratings yet

- TL - Sucat FinalDocument11 pagesTL - Sucat Finalven villanueva100% (1)

- Plumbing Plate 8Document1 pagePlumbing Plate 8kbgainsanNo ratings yet

- Archi-Struct 2Document14 pagesArchi-Struct 2The crypto GuyNo ratings yet

- Stadium Plans A1 SizeDocument21 pagesStadium Plans A1 SizeGerard Paul CusiNo ratings yet

- 3rd Floor VMAB Mechanical Plan ACUDocument1 page3rd Floor VMAB Mechanical Plan ACUWeeBooh Wit-aNo ratings yet

- Special and Different: The Autistic Traveler: Judgment, Redemption, & VictoryFrom EverandSpecial and Different: The Autistic Traveler: Judgment, Redemption, & VictoryNo ratings yet

- Strangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindFrom EverandStrangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindNo ratings yet

- Colonial Comics, Volume II: New England, 1750–1775From EverandColonial Comics, Volume II: New England, 1750–1775Rating: 3 out of 5 stars3/5 (1)

- What Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoFrom EverandWhat Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoNo ratings yet

- Concrete - Definition, Components, Grades, Manufacture, ConstructionDocument6 pagesConcrete - Definition, Components, Grades, Manufacture, Constructionadam dam jhegsNo ratings yet

- Trainer Training Programme in Construction Industry: Amman Technical Training Institute Karachi, PakistanDocument5 pagesTrainer Training Programme in Construction Industry: Amman Technical Training Institute Karachi, PakistanLokuliyanaNNo ratings yet

- Singly Reinforced Concrete Beam Design ExampleDocument16 pagesSingly Reinforced Concrete Beam Design Exampleyamen0% (1)

- Ductile Design of Column For Multistorey Building.Document4 pagesDuctile Design of Column For Multistorey Building.NikhilNo ratings yet

- Furniture ScheduleDocument2 pagesFurniture Schedulehenry jobsNo ratings yet

- Aedas A6 Architecture BrochureDocument37 pagesAedas A6 Architecture BrochureGordana SejfulovskiNo ratings yet

- Masters - Brief Rev01 - Low PDFDocument6 pagesMasters - Brief Rev01 - Low PDFJack GillbanksNo ratings yet

- Lightning Protection Calculation For Various Buildings (AS PER IS:2309-1989) Project: Plant AreaDocument3 pagesLightning Protection Calculation For Various Buildings (AS PER IS:2309-1989) Project: Plant AreaAmit GuptaNo ratings yet

- The Inspiration of Nature in Design Created A Movement of Organic Architecture Through Functionalism and Minimalism Since The 1800Document2 pagesThe Inspiration of Nature in Design Created A Movement of Organic Architecture Through Functionalism and Minimalism Since The 1800Carl Francis ArellanoNo ratings yet

- Mostafavi Ecological UrbanismDocument12 pagesMostafavi Ecological UrbanismIlse López GoveaNo ratings yet

- 17-19944 - 405 14th Street PDFDocument76 pages17-19944 - 405 14th Street PDFRecordTrac - City of OaklandNo ratings yet

- UK MKT DOC POR Porotherm Monolithic GuideDocument47 pagesUK MKT DOC POR Porotherm Monolithic GuideAlina TilekNo ratings yet

- Ubc 1982 PDFDocument778 pagesUbc 1982 PDFNguyen DuyNo ratings yet

- 1 No Province, Nepal Detail Estimate Cost Sheet: Office of The Rural Municipality ExecutiveDocument11 pages1 No Province, Nepal Detail Estimate Cost Sheet: Office of The Rural Municipality ExecutiveAPEX ENGINEERING CONSULTANCYNo ratings yet

- The Advantage and and Disadvantages of Living in A Block of FlatsDocument1 pageThe Advantage and and Disadvantages of Living in A Block of FlatsRichard DragomirNo ratings yet

- UPSIDA Rules and BylawsDocument107 pagesUPSIDA Rules and BylawsSOUMIL SENAPATINo ratings yet

- Long Span and High-Rise Steel ConstructionDocument89 pagesLong Span and High-Rise Steel Constructionကိုနေဝင်း100% (1)

- Data On PlanningDocument83 pagesData On PlanningVinodPotphodeNo ratings yet

- Formwork Inspection Check List: Rev - No. 0Document4 pagesFormwork Inspection Check List: Rev - No. 0Sahil SinghNo ratings yet

- UNIT13009Theory Reinforcing SteelDocument24 pagesUNIT13009Theory Reinforcing SteelThilan Senarathne100% (1)

- Ecotect PresentationDocument22 pagesEcotect PresentationMegha GolaNo ratings yet

- LH 1Document43 pagesLH 1Mario Torre DelgadoNo ratings yet

- Report On Thirunangur by JenniferDocument10 pagesReport On Thirunangur by JenniferJennifer PaulNo ratings yet

- Marketing at Vmeprecastproducts - Co M: Quotation: VME/CPW/580-A/22-23 Date:19th May, 2022Document3 pagesMarketing at Vmeprecastproducts - Co M: Quotation: VME/CPW/580-A/22-23 Date:19th May, 2022Nelson 2428No ratings yet

- 5 Storey Mixed Use BLDGDocument16 pages5 Storey Mixed Use BLDGElaine AsisNo ratings yet

- Soal Pas KLS 7 Sem 2 TH 2023 KunciDocument6 pagesSoal Pas KLS 7 Sem 2 TH 2023 Kuncisaniah_daniaNo ratings yet

- Irjet V6i12178 PDFDocument4 pagesIrjet V6i12178 PDFRadhika KhandelwalNo ratings yet

- SECTION 03200 Concrete ReinforcementDocument8 pagesSECTION 03200 Concrete ReinforcementSuranga ManuNo ratings yet

- GERMANDocument10 pagesGERMANMaryamNo ratings yet

- KDM Volume IIDocument252 pagesKDM Volume IICaroline LeblancNo ratings yet