Professional Documents

Culture Documents

Contoh COA Turbidity

Uploaded by

Eko Waluyo JatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contoh COA Turbidity

Uploaded by

Eko Waluyo JatiCopyright:

Available Formats

page 1 of 2

Version1

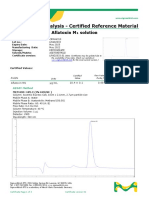

CERTIFIED REFERENCE MATERIAL

Turbidity Standard 0.5 NTU (Formazin)

Lot N: XXXXXX Ref N: TD0.5NTU.L1 Certification Date:XXXXXX

Barcode: XXXXXXXX

Certified Value* (NTU) Uncertainty** (NTU)

0.492 +/- 0.008

* The certified value was obtained using Turbidimeter calibration acc. to in-house procedure WQP 5.15.1/29

** The reported expanded uncertainty of measurement is stated as the standard uncertainty of measurement multiplied by the coverage factor k = 2, which for

a normal distribution corresponds to a coverage probability of approximately 95%. The standard uncertainty of measurement has been determined in

accordance with EA 4/02.

Metrological traceability:

The metrological traceability is assured through calibration on Turbidimeter. The calibration curve is drawn using standard solutions

prepared gravimetrically. All contributions in relation to the preparation of standard solutions are considered when evaluating the

uncertainty.

This certified reference material is produced by dissolving reagent grade Hydrazine Sulphate and Hexamethylenetetraamine in 18

MOhm deionized water (filtered through a 0.22 um filter).

The measurement results are traceable to SI. All analytical balances used for the preparation of the solution are calibrated yearly under

an in-house procedure with class E1 and class E2 analytical weights, traceable to DKD and are daily checked.

Class A laboratory glassware is used.

The results from temperature measurement are traceable to SI. The thermometers used for solution's calibration are calibrated from an

ISO 17025 accredited laboratory. The ambient conditions are controlled with a hygrometer calibrated from an ISO 17025 accredited

laboratory.

Expiry date: XXXXXX

Storage Conditions: Store in a refrigerator at temperatures between 2°C to 8°C

Intended use: For Laboratory Use Only

This CRM is intended for:

- Calibration of turbidimeters.

- Validation of analytical methods

- Preparation of "working reference samples"

- Detection limit and linearity studies

This standard also meets the requirements of the European Pharmacopoeia on a "2.2.1. Clarity and degree of opalescence of liquids"

and ISO 7027-1 "Water quality - Determination of turbidity - part 1: Quantitative methods"

This statement is not intended to restrict the use for other purposes.

Instructions for the correct use of this reference material:

page 2 of 2

Calibrate your instrument as directed by the manufacturer. After transportation, leave the bottle rest still for 24 hours. After removing

from the refrigerator, the solution is left at room temperature for several hours. Do not use heater to temper the solution!

Homogenization is done by tilting the bottle carefully from the bottom to the cap and avoiding the introduction of air into the solution. Do

not shake! Shaking adds air to the sample and may cause erroneous results. After pouring the sample into the cuvette, wait at least 20

minutes for the solution to stabilize and then perform the measurement.

Stability and storage:

This CRM is with a guaranteed stability until +/- 1% of the certified value within its shelf-life. Stability is guaranteed, provided that the

solution is kept in its original packaging, tightly closed stored, as written in the section: Storage Conditions. According to an in-house

procedure the producer will monitor this CRM at appropriate intervals and the purchasers will be notified of any significant changes

resulting in recertification or with withdrawal of the CRM during the state period of the validity of the certificate.

Hazardous situation:

The normal laboratory safety precautions should be observed when working with this RM. Further details for the handling of this RM are

available as safety data sheet.

Level of homogeneity:

This solution was mixed according to an in-house procedure and is guaranteed to be homogeneous.

To ensure sufficient homogeneity of the sample prior to use thoroughly mix by inversion.

Names of certifying officers:

Laboratory: Ognyan Todorov

Manager: Krassimira Taralova

This certificate has been computer generated and does not signated

This document is designed and the certified value(s) and uncertainty(ies) are determined in accordance with ISO Guide 31, ISO Guide

35,and Eurachem / CITAC Guides

This certificate relates solely to the lot number given above.

All processes (including generating of this certificate) are completely controlled by the specialized Computer-Aided-Manufacturing

(CAM) software.

This Certified Reference Material was produced under a quality management system that is:

- Registered to ISO 9001 Quality Management System (Lloyd's Register Quality Assurance Ltd Cert No 0039638)

- Accredited according to ISO/IEC 17025 – Testing (ANAB Cert No AT-1836)

- Accredited according to ISO 17034 - Reference Material Producer (ANAB Cert No AR-1835)

You might also like

- Wbi15 01 2024 Jan QPNDocument36 pagesWbi15 01 2024 Jan QPNfreemanNo ratings yet

- Act-1 SopDocument6 pagesAct-1 SopthomassreisNo ratings yet

- Autoclave Validation ProtocolDocument23 pagesAutoclave Validation ProtocolErum Manzoor100% (2)

- DKD-R 5-1-A-DKD-Guidelines-for-calibration-of-Digital-ThermometersDocument24 pagesDKD-R 5-1-A-DKD-Guidelines-for-calibration-of-Digital-ThermometersfarhanNo ratings yet

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Document12 pagesProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaNo ratings yet

- Sample Questions For API 570 EDocument14 pagesSample Questions For API 570 Eمبشر أحمدNo ratings yet

- Air Content in Concrete - Concrete Air Test - The Concrete NetworkDocument4 pagesAir Content in Concrete - Concrete Air Test - The Concrete NetworkPritha DasNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Temperature Mapping Protocol For RM QuarantineDocument20 pagesTemperature Mapping Protocol For RM Quarantinemehrdarou.qaNo ratings yet

- COA Buffer PH 4Document2 pagesCOA Buffer PH 4Jamilah Ghozy100% (1)

- Qualisteelcoat Technical Specifications Version21 31102013Document64 pagesQualisteelcoat Technical Specifications Version21 31102013Dino PedutoNo ratings yet

- Alat Vitek 2Document16 pagesAlat Vitek 2Ilma SyahrianNo ratings yet

- CoA - TD15NTU.L5 Turbidity Calibration Standard (Formazin)Document2 pagesCoA - TD15NTU.L5 Turbidity Calibration Standard (Formazin)Ahmad Atsari SujudNo ratings yet

- CoA OSM0300.L06Document2 pagesCoA OSM0300.L06Khalid JakirNo ratings yet

- CoA A059.20CP.L1Document2 pagesCoA A059.20CP.L1jimmytsangqaNo ratings yet

- Certified Reference Material: PH 3.776 at 25 C Potassium Dihydrogen CitrateDocument2 pagesCertified Reference Material: PH 3.776 at 25 C Potassium Dihydrogen CitrateLinh TONo ratings yet

- Con5-25 U2-Cond736343 McaDocument3 pagesCon5-25 U2-Cond736343 McanambiarnedumchalNo ratings yet

- CoA P873870Document3 pagesCoA P873870madalin danilNo ratings yet

- Certificado Material de Referencia PlomoDocument2 pagesCertificado Material de Referencia PlomoAyala MateoNo ratings yet

- Con2-25 R2-Cond696405 McaDocument3 pagesCon2-25 R2-Cond696405 McaclaudioNo ratings yet

- Triamcinolone AcetonideDocument12 pagesTriamcinolone Acetonideawais khanNo ratings yet

- SOP For Temperature Mapping Study - PharmaguidelineDocument2 pagesSOP For Temperature Mapping Study - PharmaguidelinedduraisamymanikandanNo ratings yet

- HbA1c (Whole Blood)Document8 pagesHbA1c (Whole Blood)aymanepocketNo ratings yet

- Aflatoxin m1 Crm46319 Lrad2033Document3 pagesAflatoxin m1 Crm46319 Lrad2033Irowati PurwaningsihNo ratings yet

- AA37N-5. Estándar Niquel. 29-12-2025Document2 pagesAA37N-5. Estándar Niquel. 29-12-2025calidadlaboratoriocgrNo ratings yet

- Afla B2 - TAS-M12LA1-10 220225-22187Document2 pagesAfla B2 - TAS-M12LA1-10 220225-22187Irowati PurwaningsihNo ratings yet

- Certificate of Analysis: Signal Word: DangerDocument2 pagesCertificate of Analysis: Signal Word: DangerMiguelNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4NO AZNo ratings yet

- WFP Shelf Life Study Protocol - Processed Food Products: Food Safety and Quality Assurance UnitDocument3 pagesWFP Shelf Life Study Protocol - Processed Food Products: Food Safety and Quality Assurance UnitĐăng LưuNo ratings yet

- H-046-000774-00 CK-MB CalibratorDocument19 pagesH-046-000774-00 CK-MB CalibratorJorge Stban PerezNo ratings yet

- CalciumDocument2 pagesCalciumAnil RawatNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4ROBINNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4alexisNo ratings yet

- Coa D-6428-BL 216071219Document2 pagesCoa D-6428-BL 216071219MiguelNo ratings yet

- H-046-002939-00 D-Dimer CalibratorDocument18 pagesH-046-002939-00 D-Dimer Calibratorteknisi bryanmedikalNo ratings yet

- QC 22 03Document12 pagesQC 22 03Yahia HassaanNo ratings yet

- HC28960088 Su enDocument2 pagesHC28960088 Su enMeilaDwiputriNo ratings yet

- AA13N-5. Estándar Cromo. 18-05-2026Document2 pagesAA13N-5. Estándar Cromo. 18-05-2026calidadlaboratoriocgrNo ratings yet

- Exhibit B3 GEN-03 Inspection - Edition No. 03 - Jan - 2019Document12 pagesExhibit B3 GEN-03 Inspection - Edition No. 03 - Jan - 2019Gagan Sai ReddyNo ratings yet

- Dac g1 Policy On Mui2r22011Document5 pagesDac g1 Policy On Mui2r22011Megame BakiNo ratings yet

- GBW08603 20160225 084902529 1238755Document3 pagesGBW08603 20160225 084902529 1238755OsmelNo ratings yet

- CodeDocument7 pagesCodesynojohnNo ratings yet

- Quality Certificate: VWR Conductivity Calibration StandardDocument4 pagesQuality Certificate: VWR Conductivity Calibration StandardPalacios Marina SandraNo ratings yet

- BISMUTODocument2 pagesBISMUTOLuis Castro HermozaNo ratings yet

- Contenido de Un MRCDocument3 pagesContenido de Un MRCSara RuizNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4Vũ Hoàng MaiNo ratings yet

- Araldite 252Document4 pagesAraldite 252HectorNo ratings yet

- ToluenDocument2 pagesToluenVũ Hoàng MaiNo ratings yet

- Certificate of Analysis: Signal Word: NoneDocument2 pagesCertificate of Analysis: Signal Word: Nonejoel0067No ratings yet

- Boldenone UndDocument2 pagesBoldenone UndAhmedNo ratings yet

- Aain1 S2-In682815rDocument3 pagesAain1 S2-In682815rlacastrohNo ratings yet

- Evonik Pharma Polymers News 2 2012Document8 pagesEvonik Pharma Polymers News 2 2012aryopoorNo ratings yet

- Sys Master - Pdfs - h03 - H5e - 10133532180510 - COA - DRE GS09010494 - ST WB CERT 2972235 1 1 1Document2 pagesSys Master - Pdfs - h03 - H5e - 10133532180510 - COA - DRE GS09010494 - ST WB CERT 2972235 1 1 1VerilisimaNo ratings yet

- Certificate of Analysis: 1.0 Description: CONOSTAN Single Element Standard, 0.001% SulfurDocument2 pagesCertificate of Analysis: 1.0 Description: CONOSTAN Single Element Standard, 0.001% SulfurIsrael LeviNo ratings yet

- Qci-054 - 092817Document2 pagesQci-054 - 092817Amanda NiedermaierNo ratings yet

- Sodium Chloride 1024060080 - 192406T 31 Dec 2024Document2 pagesSodium Chloride 1024060080 - 192406T 31 Dec 2024yulyansyah susantoNo ratings yet

- APQR (2ml) 2020Document5 pagesAPQR (2ml) 2020israel afolayan mayomiNo ratings yet

- D3954 152022 15 04 Standard Test Method For Dropping Point of WaxesDocument2 pagesD3954 152022 15 04 Standard Test Method For Dropping Point of WaxesBetsy WiedenfeldNo ratings yet

- PHR1001 Lrab7720Document6 pagesPHR1001 Lrab7720labanacabreraNo ratings yet

- D4758 Test de No VolatilesDocument2 pagesD4758 Test de No VolatilesMiguel Angel Lupaca BernalesNo ratings yet

- Flash Point by Small Scale Closed Cup Tester: Standard Test Methods ForDocument10 pagesFlash Point by Small Scale Closed Cup Tester: Standard Test Methods ForAbidin SyakirinNo ratings yet

- UIBC Control: Package Size Intended UseDocument19 pagesUIBC Control: Package Size Intended Usetech yuva cscNo ratings yet

- Certificate of Analysis: Sulfate IC CRM - 1000 MG/LDocument2 pagesCertificate of Analysis: Sulfate IC CRM - 1000 MG/LasanalyticalNo ratings yet

- Avoiding Errors in Electrochemichal MeasurementsDocument8 pagesAvoiding Errors in Electrochemichal MeasurementsSimon BruderNo ratings yet

- Chem 213 Chemical Analysis Final June 9, 2003Document10 pagesChem 213 Chemical Analysis Final June 9, 2003ramesh pokhrelNo ratings yet

- ImrulDocument5 pagesImrulJobaer ShaonNo ratings yet

- Xiameter OFX 8630 - TDSDocument2 pagesXiameter OFX 8630 - TDSyusuf fajar kurniawanNo ratings yet

- Dispex Ultra Fa 4480Document2 pagesDispex Ultra Fa 4480seydolackNo ratings yet

- Biochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesDocument33 pagesBiochemistry 09 - Class Notes - Shodh 2.0 Batch For CSIR NET - GATE Life SciencesSanjay Kumar RaoNo ratings yet

- 2.1 Chemical Bonds - Ionic, Covalent and Metallic QPDocument28 pages2.1 Chemical Bonds - Ionic, Covalent and Metallic QPADITI ShuklaNo ratings yet

- Lab Report_Ionic and Covalent BondsDocument7 pagesLab Report_Ionic and Covalent Bondsgbenga bolarinwaNo ratings yet

- Density (Multiple Choice) QPDocument15 pagesDensity (Multiple Choice) QPsarashehab678No ratings yet

- Dionex Ionpac As19 Columns: Product ManualDocument40 pagesDionex Ionpac As19 Columns: Product ManualDr.Vinod SrivastavaNo ratings yet

- CH312 - COD Experiment ReportDocument3 pagesCH312 - COD Experiment ReportNarelle IaumaNo ratings yet

- Grade 5 Q1 ScienceDocument3 pagesGrade 5 Q1 ScienceMaricris LangaNo ratings yet

- Materials Science and Engineering An Introduction Callister 8th Edition Solutions ManualDocument36 pagesMaterials Science and Engineering An Introduction Callister 8th Edition Solutions Manualwaiment.sphex7134100% (43)

- Peta Assessments in Science 9 Quarter 2.2Document19 pagesPeta Assessments in Science 9 Quarter 2.29 - Sampaugita - Christian RazonNo ratings yet

- The Effect of Z-Primer On The Shear Bond StrengthDocument4 pagesThe Effect of Z-Primer On The Shear Bond StrengthIsabella OrdoñezNo ratings yet

- Manual Baño Maria - VWRDocument12 pagesManual Baño Maria - VWRAsesoria tecnica Azul DiagnosticNo ratings yet

- Genchem q2 m8 Polymers Final LayoutDocument28 pagesGenchem q2 m8 Polymers Final LayoutReynaPolNo ratings yet

- PI e UREA 16Document2 pagesPI e UREA 16Moch Abdul RokimNo ratings yet

- H2S UOP 212-77 MethodDocument7 pagesH2S UOP 212-77 MethodPorfirio AguileraNo ratings yet

- Harmonized Guideline On Limit and Testing of Elemental Impurities in Pharmaceutical Substances - A ReviewDocument8 pagesHarmonized Guideline On Limit and Testing of Elemental Impurities in Pharmaceutical Substances - A ReviewNUR QURRATUAININo ratings yet

- Citric AcidDocument76 pagesCitric AcidHoàng TấnNo ratings yet

- Dynamics and Control System Design For Biodiesel TDocument7 pagesDynamics and Control System Design For Biodiesel TAverly Jerryl EscotoNo ratings yet

- Chemistry - Higher Level: Pre-Leaving Certificate Examination, 2020 Triailscrúdú Na Hardteistiméireachta, 2020Document12 pagesChemistry - Higher Level: Pre-Leaving Certificate Examination, 2020 Triailscrúdú Na Hardteistiméireachta, 2020Diaa SaberNo ratings yet

- Unit Operations: Multi Stage AbsorptionDocument23 pagesUnit Operations: Multi Stage AbsorptionVeshal Purshothama SeelanNo ratings yet

- Fermentation Kinetics For The Production of Ethanol by ImmobilizeDocument278 pagesFermentation Kinetics For The Production of Ethanol by ImmobilizeFitria Nur LailyNo ratings yet

- TDS S130Document2 pagesTDS S130Iridian Cano CeronNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet