Professional Documents

Culture Documents

Avery Dennison T-6500

Avery Dennison T-6500

Uploaded by

n.basheerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avery Dennison T-6500

Avery Dennison T-6500

Uploaded by

n.basheerCopyright:

Available Formats

Report No.

: 220214-02G

TEST DATA SHEET

Project Name: Avery Dennison T-6500 Series High Intensity Performance

Retroreflective Sheeting (Type III/IV)

6.9 Adhesion

Requirement: ASTM D4956 6.9

Test Method: ASTM D4956 7.5

4 in. each of two (2) 1 in.x6 in. sheeting samples were bonded to

0.040 in. thick degreased and acid-etched 6061-T6 aluminum panels. After

conditioning for a minimum of 24 hours, a 0.79kg weight was hung from the

free end of sample 90° to the panel. After 5 minutes, the peel distance

was measured.

Peel Distance

Sample Maximum

#1 #2

T-6500 White 0.04 in. 0.04 in.

T-6501 Yellow 0.05 in. 0.07 in.

W-6504 Orange 0.07 in. 0.07 in.

T-6507 Green 0.06 in. 0.07 in. 2.0 in.

T-6508 Red 0.06 in. 0.06 in.

T-6505 Blue 0.08 in. 0.06 in.

T-6509 Brown 0.07 in. 0.09 in.

Samples meet Adhesion requirements.

6.10 Impact Resistance

Requirement: ASTM D4956 6.10

Test Method: ASTM D4956 7.11, D2794

3 in. x 5 in. samples mounted to 0.040 in. thick 6061-T6 aluminum were

subjected to a 10 in-lb impact from a mass with a steel ⅝ in. diameter

round tip.

Sample Results

T-6500 White No cracking or delamination outside impact area.

T-6501 Yellow No cracking or delamination outside impact area.

W-6504 Orange No cracking or delamination outside impact area.

T-6507 Green No cracking or delamination outside impact area.

T-6508 Red No cracking or delamination outside impact area.

T-6505 Blue No cracking or delamination outside impact area.

T-6509 Brown No cracking or delamination outside impact area.

Samples meet Impact Resistance requirements.

13

You might also like

- Zinc CoatingsDocument16 pagesZinc CoatingsShojikuriakoseT100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- Calcium Silicate TilesDocument8 pagesCalcium Silicate TilessivakumarNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Klingersil C-4430 DataDocument2 pagesKlingersil C-4430 DataangelelpedrosaNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Zinc Nickel PlatingDocument1 pageZinc Nickel PlatingSiripongTNo ratings yet

- Surface FinishesDocument8 pagesSurface FinishesasritaipNo ratings yet

- Plumbshield: For Use With Potable & Non-Potable Water ApplicationsDocument5 pagesPlumbshield: For Use With Potable & Non-Potable Water ApplicationsMychloesNo ratings yet

- Tedea-Huntleigh 355Document2 pagesTedea-Huntleigh 355jveraf_No ratings yet

- Insulators & TypesDocument48 pagesInsulators & Typesdilleh50% (2)

- Calcium Silicate False Ceiling TilesDocument6 pagesCalcium Silicate False Ceiling TilesDeepak ChandolaNo ratings yet

- Ficha Tecnica TermoencogibleDocument33 pagesFicha Tecnica TermoencogibleNACION001No ratings yet

- Profiled Sheeting Technical PDFDocument24 pagesProfiled Sheeting Technical PDFUmpahPah75No ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- Silicato de CalcioDocument2 pagesSilicato de Calciop_pr01No ratings yet

- Lead FreeDocument6 pagesLead FreeJithin Mathew0% (1)

- Cobalt Chromium Implant Grade TubingDocument2 pagesCobalt Chromium Implant Grade Tubingkunalkp88No ratings yet

- ROK ON SIS Specification Document 2020Document15 pagesROK ON SIS Specification Document 2020Tiffany Jacqueline Vázquez HernándezNo ratings yet

- Series 800 1000 TubularDocument6 pagesSeries 800 1000 TubularRatnesh GaurNo ratings yet

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- Sproule WR 1200 Perlite TDSDocument2 pagesSproule WR 1200 Perlite TDSnaseema1No ratings yet

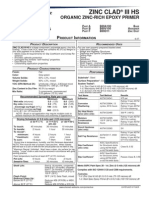

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- KS1000 KingzipDocument7 pagesKS1000 KingzipmrajansubramanianNo ratings yet

- Brochure AluPeb EnglishDocument8 pagesBrochure AluPeb EnglishThi PhamNo ratings yet

- Nylaflow Nylatron 2006Document4 pagesNylaflow Nylatron 2006Miguel GradeNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical MechanicalDocument1 pageABS (Acrylonitrile Butadiene Styrene) :: S.R. No. Propery ASTM Test Method Units ABS FR Physical Mechanicalshailesh284No ratings yet

- CORROSIONDocument40 pagesCORROSIONKrishnakant RaneNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- 2008 Lysaght Product Catalogue AccessoriesDocument0 pages2008 Lysaght Product Catalogue Accessorieskh88hmiNo ratings yet

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- Trusted Where Permanent Identification Is CriticalDocument2 pagesTrusted Where Permanent Identification Is Criticalsav33No ratings yet

- SB Drill CollarDocument51 pagesSB Drill CollarJeff ZhangNo ratings yet

- Perlite Sproule1200 Data SheetDocument2 pagesPerlite Sproule1200 Data Sheetkresimir.mikoc9765No ratings yet

- Spec 46311Document2 pagesSpec 46311DI Vlad Peña PrietoNo ratings yet

- Aerolite's Technical Data NewDocument4 pagesAerolite's Technical Data NewAr C KumarNo ratings yet

- Engineering Standard: Corrosion Protective Zinc Plating & Supplemental CoatingsDocument4 pagesEngineering Standard: Corrosion Protective Zinc Plating & Supplemental CoatingsCeliaNo ratings yet

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1No ratings yet

- PDS Nytro Bear ASTM EN PDFDocument2 pagesPDS Nytro Bear ASTM EN PDFP_sanchezNo ratings yet

- Steel Composition - SiliconDocument6 pagesSteel Composition - SiliconjaffliangNo ratings yet

- Aluminium 1100Document2 pagesAluminium 1100Anup DalalNo ratings yet

- Lesson 11 CorrosionDocument10 pagesLesson 11 CorrosionMAT-LIONNo ratings yet

- Calcium Silicate Data SheetDocument2 pagesCalcium Silicate Data Sheetkresimir.mikoc9765No ratings yet

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNo ratings yet

- LocDocument2 pagesLocCarlso Andres GuerreroNo ratings yet

- TDS 007 Hot Dip GalvanizingDocument4 pagesTDS 007 Hot Dip GalvanizingnicekhanNo ratings yet

- Impact: Wear Resistant SteelDocument6 pagesImpact: Wear Resistant SteelmazuckNo ratings yet

- Rolform 2-57Document28 pagesRolform 2-57Cw TanNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Deepwater Anode Data SheetsDocument18 pagesDeepwater Anode Data SheetsThaibinh NguyenNo ratings yet

- Cold Roll Lab ReportDocument14 pagesCold Roll Lab ReportSean BiseNo ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet

- Avery Dennison T-6500Document1 pageAvery Dennison T-6500n.basheerNo ratings yet