Professional Documents

Culture Documents

GVS 8

GVS 8

Uploaded by

MohammedIrfan0 ratings0% found this document useful (0 votes)

9 views13 pagesOriginal Title

GVS-8

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views13 pagesGVS 8

GVS 8

Uploaded by

MohammedIrfanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

GVR, GVS 50Hz/60Hz

GYEMAX

P U M P Ss

LIGHT VERTICAL MULTISTAGE CENTRIFUGAL PUMPS

OPERATING INSTRUCTIONS

MULTISTAGE STAINLESS STEEL

CENTRIFUGAL PUMP

General Data

@ Performance scope

Q [IM.GPM]

ieee ae wy tt

Q (us.GpM)

f Sp ee pe ao mre BEE

tay ava] Lf

300 2900RPM_[- 984

{| LL Em

0 2

s SO N cs

i a

100, | 320

ny | 20

a iL ted is

el eH Er ST ElEVE ISN ELE] bie

40 = +] =| 131

Lis

7

7.

i

dwells) oe Lbs bwluraan anton wy

Q (mm)

= fugl @alitu wea

ota

gtmorna

sk wee ae oe es

Q CUS.GPM]

? {tea ww 6 ewe OES

hh Be

sl seis be

ze

»» oe

= oo

im os

& =

“ 2

‘i ss

-

7 a

sa

a.

m

0

06 08 112 163.253 4 5 47h IOiDIMI6 2024 30 40 S0.G0THH 100 130

Q Lm)

0204 O68 ORL 62 3 4 6 HO 6 30

Q tus)

@ Product range

Description cov | ave | ova | cvs | ove | ove] ov2e | ove | over | aves | ves

SOREN

Rated flow [m*/h] 1 2 x 4 8 6 | 20 32 a 6s 8S

Rated flow (1/8), 028 083 A 22 44 56 89 nt ww |

low ange") oa2 124 [13s | siz | ex | 102s | ew | 255s | 30a | soso

“How nngeisl —[vst-0s6] o2s097]03811[04222| 14332201 2078 [aati ao.isa]sszna|iaes0s

TMepenetey | a | 3 | 2 | 2 | af 2 |» | «| «| 2 | oo

Moworpovechw) | asr23] o373 [ osra | osra [ans73| 2243 [11183] 1530 | 3038 | 404s | a4

‘Temperature range [C} ~18~+120 -

Ma isieny Ps) % al«[e#[«[»|[w]a

i

Gk efelel[el[oel[el[oel[eoleleoeleo

GVReipe conection

DIN Fnge Daas [ oNz | bxas | px [ pnw [ DNvo | pnw | DNGS | Dxao [ Dxto0] DNiCo

__Oval Flange ot cH Gills | Gite L

35008

ated ow iw ‘[2]3]*]*][«[»][»[lele|s

Rated flow (lis), 028 056 oss | ia 22 4a 36 so | 7 18 4

ow age] 062 [as [iss [ase | se | i026 | 234 | aoe | an4s | ensoo| corm

iow ngs] 017036|o28128]oaz-14] 0225) 1939 | 2872 339435133] a3. fara e761

“Max pressure[bat] a [ons [oo |: Ez is

Moorpovertkw} | 0373 | oss | ora ts

Teperanve range)

Max. eficensy[%) aw [ w [os 1

= : -

evs ele] elelelelele

GVSPipe comes

“DIN Flange xas | omis Dx | pww | bwso | pws | bNeS | pnw [pwio0] DNIGo

Oval Flange a | a | ot [orm | ova lt

IeMAX

@ Pump

GVRIGNS is a kind of vertical non-self priming

‘multistage centrifugal pump, which is driven by a stan-

dard cleciric motor. The motor output shaft directly con-

nects with the pump shaft through a coupling. The pees-

sure-resistant cylinder and flow passage components are

fixed between pump head and inlet &outlet section with

tic-bar bolts. The inlet and outlet are located atthe pump

bottom at the same plane. This kind of pump can be equ-

ipped with an intelligent protector to effectively prevent

it from dry-running, out-of-phase and overload.

@ Motor

(@Full-enclosed air-blast two-pole standard motor

‘©Protection class: IPSS

Insulation class: F

‘@Standard voltage:S0Hz: 1 x 220-230 / 240V

3 x 200-220 /346-380V

3220-240 / 380-415V

3 380-415V

Standard voltsge:60Hz: 3 x 200-230 / 346-400V

3200-255 / 380-440V

3200-277 / 380-480V

©@ Definition of Model

GYRGVSI,2,3,4,8,16 and 20

GV OR 8 8o- 2 7 1

| L—

GVR/GVS32,42,65 and 85

Go oR oS 2

© Application

GYRIGYS is a kind of multifunctional products

It can be used to convey various medium from tap water

to industrial liquid at different temperature and with di-

‘ferent flow rate and pressure.

(© Water supply: Water filter and transport in Waterwor-

ks, boosting of main pipeline, boosting in high-rise bu-

ildings.

(© Industrial boosting: Process flow water system, cleani=

ng system, high-pressure washing system, fire fighting

system,

(© Industrial liquid conveying: Cooling and air-conditio-

ning system, boiler water supply and condensing system,

‘machine-associated purpose, acids and alkali

(© Water treatment: Ultrafiltration system, reverse osmo-

sis system, distillation system, separator, swimming pool

(© rrigation: Farmland irrigation, spray irrigation, drip-

ping inrigation.

@ Operation con ns

(© Thin, clean, non-flammable and non-explosive liquid

containing no solid granules and fibers.

@Liquid temperature:

‘Normal temperature type: -15'C~+70°C,

Hot water type: #70C~+120C

@ Ambient temperature: up to +40°C

@ Altitude:up to 100m

Number of impeller

Stage

Rated flow (mh)

60Ht2 only

SOHz only

GMAX Multistage series, V-Vertical

‘Number of small impeller

Stagex10

Rated flow (mh)

6OHz only

SoH2 only

GMAX Multistage series, V-Vertical

@ Max inlet pressure

‘The maximum inlet pressure is shown in the table

below. But the actual inlet pressure plus the valve close

pressure of the pump shall be lower than the max. all-

owable working pressure.

Model

3500RPM

‘Max inlet pressure

2900RPM_

ine oa

aie | 3235 “tbar]

ea | et

3H~ 3-36, 15fbar] GvS4

eee | : oa

43-410 ofa] orkie ‘sth

E |r

1 tes GVSI6

a am ‘s{bar)

1 10fbar] a

He mo

‘avraa a

42-10~42-20 4{bar] 42-20~42-40-2 Lofbar]

@ Max working pressure

Model Curve m Model Curve number

2000RPM —3500RPM

—— GYSL

‘GvRI 1207 7

oa 1191.25 2

12123 U

5 213-2418 2

a Gysi

22s fl 32-315 7

212.26 2 3.17~3-28 2

GYR3 Tee

323.03 1 =

3228-3:36 2

Gra 3

246 L “ieee

49422 2 16-7~16-10 3

GVS20

Guns 201~204 7

B2/~ B12 1 20-8~20-10 3

8148-20 3 2

—— 32-10-1=3ES0 T

GYRI6 32-80~32.00-2 ‘

16:2~168 u £

16:10~16-16 2 Tavs

a rs 210-1 2230 T

GYR20 42.40.2~42.60 4

SS 5

201-208 u

20-10~20417 3 7

“=z. 65-40.2~65-50-2 ‘

er GVS8S

32-10-1~32-70 t 85-10-1850 7

32-40.2~32-120 4 85.40-2 4

3213032140 5

Gra The following figure shows the limitation of pressure a-

nnd temperature, which shall be kept within the region as

42-10-1~42-60, 1 shown in the figure.

42:10.2~42.90 4

42100-2-42-130-2 s a

1 Py

GYROS ai

65-10:1~65-50 1 a

65-60.2~ 68-80. 4 %

GyRES ‘

85-10-1~85.8022 i 4

5-50-85-60 4 °

40 mm IT

@ Curve illustration

stage ip grryony

First umber

Stagexto 2 » o* me _ qiusary

Number of sat impr

ith

GVR32GVS32 | oe

Pump Que, thet

tokeaed ine prevents

“=

9 negrats impeller

ped and thetype wi

‘Wsmalipeter 23)

a corve presents ef

sone ofthe pm. For

‘hep eauiped wit

sal npele vee.

fency willbe 2% lower

‘han that shown bythe

oot ee we ww etal

wf ie [3 | Npstteurecrpresses

alls © | eheaverge vale ofall

‘hall be taken ino cone

‘ideation when making

ark? ‘i aa tetetion

‘The OH curve of exch stage, presenting integrate

impeller 23)

@ Performance curve

Following conditions are suitable for the performa-

rice eurves shown bellow:

1. All curves are based on the measured values of SOH2:

constant motor speed 2900r/min, 60Hz: constant motor

speed 3500 r/min;

2, Curve tolerance in conformity with 1809906 Annex A.

3, Measurement is done with 20°C air-free water, kine-

matic viscosity of Imm/see.

4, The operation of pump shal refer tothe performance

region indicated by the thickened curve to prevent over

Incating due to to0 small flow rate or overload of motor

due to t00 lange flow rate

@ Minimum inlet pressure NPSH

In ease that the pressure in pump is lower than the

steam pressure used to convey liquid, the cavitations will

occur. To avoid cavitations, a minimum pressure at the

inlet side ofthe pump shall be guaranteed. The maximum

suction stroke can be calculated with following formula:

H+Pbx 10.2-NPSH-Hr-Hy-Hs

Po~atmosphere pressure [bar]

(cam be set as Ibar)

Ina closed system, Pb means system pressure [bar]

[NPSH=Net positive suetion lead [m1]

(Itcan be read out from the point of possible max.

flow rate shown on NPSH curve)

‘Hé=Pipeline loss atthe inlet (m]

Hy=Steam pressure [m]

Hs=Safety margin=Minimum 0.5m delivery head

If the calculated result H is positive, the pump may run,

under the max. Suction stroke H.

In ease the calculated result H is negative, a delivery

head of min. Inlet pressure is necessary.

© Operation in parallel

Connecting several pumps i

efit much more than running single large pump.

© Applicable o different working states necessary ina

variable low system,

# increasing the possibility of water supply when the

pump is in failure. Because in case of pump failure, only

part of the system flow is effected

parallel running will ben-

oe wD Ow

‘Two pumps or more ean be connected in parallel runni-

ng ifnecessary.

ne

1 hay

cer | tm)

40

30 38

25

wos

1018,

“La

(Check and ensure that the pump is not at cavitations state

7

@ Section drawing GVR/GVS1,2,3,4

@ Material GVR/GVS 1,2,3,4

No Name Material AISUASTM NO Name Material | AISVASTM

1 | Motor ur | teaing Tungsten carbide

2 | Pump head castiron—fASTM2SR 15, | npr Saimeee’ | araoed

Seal base Staintess steel |arsi304 | gn suineoses | A1S!306

ol hates 14 | mptersheve Sainlesstel | alsi0s

5 | Top diffuser Swintess sect atsisos ys [aa bie ad [ARce

6 | pittuser Staintess steel A1S1304 46 | Coaping Siereed

Support diffuser | Stainless stee! | AISI304

8 | inducer Stainless stec! | AISI304

9 | Inland outer chamber| Cast iron | ASTM2SB

10 | Base plate cast iron ASTM25B

@ Section drawing GVR/GVS8,16,20

@ Material GVR/GVS 8,16,20

No Name Material |AISUASTM NO Name Material | AISVASTM

1 | Motor 11 | Bearing Tungsen cable

2 | Pump head Cast iron [ASTM2SB 2, | impor Suinlsssiet | aisto4

3. | Seat base Staintess stee! atsiz0a | go santeset | aISi308

4 [Mechanteal seal 14 | impo steve suinkessest | aIsi04

5 | Top gittuser Stainless see! [atsis0 5 | Ge Saiimasd | ABOH

6 | pitruser siaintess stee1 4151304 416. | captng exbomped

7 |Support dittuser | Stainless steel |A1s1304

8 | Inducer Stainless steel | A1SI304

9 | intend ouietchanber [Cast iron J ASTM2SB

10 | Base plate Cast icon | ASTM2SB

@ Section drawing GVR/GVS32,42,65,85

@ Material GVR/GVS 32,42,65,85

No Name Material atsuasrM NO Name Material | AISUASTAL

1 | Brecker casticon— fastoase 41 | tmpelier ainless steel | AISI304

2 | Pump head cast iron fastoase 5 | han less stee! [AISI316

| sua Hess steel | isi304

3. | Mechanical seat

15. | tatermediate bearing [Tungsten carbide

4 |Top diffuser Stainless stect | A1st308

14 | cytinder ainless steet | A1SI304

5 |Support aittuser |Staintess stect | A1SI308

Seer 15, | Coupling [Carbon steel

6 | Ditvuser Stainless steel | AISI308 Musee pata (eae

7 | Inducer Stainless stec! | AISI308

8 | Intond outlet chamber|Cast iron | ASTM25B

9. | Base plate cast iron J ASTMASB

0

Bottom bearing

Tungsten carbide

10

GVS8, 3500 RPM, 60 Hz

@ Performance curve 1S09906 Annex A

° 10 20 30 0 50_Q[IMGPM}

Ho 10 20 30 40 0 6 QUUSGPM]

[m] (fy)

GVS8

20

700

20

180 00

160

00

v0

20 400

100

300

0

oo 200

0

100

0

° 00

o 12 3 4 5 6 7 § 9 WH BB 4 Qlmn)

pp Eta

(hp 14[kW1 “1

m0 | 0 0

0.60 so

060 ] 048 40

036 30

030 | 024 0

uz 0

0.00 1 a.0- °

o 12 3 4 5 6 7 8 59 H 2 13 1 Qtmin]

H hese wpa

(fe) | Cm miLttt]

o-| as!|_QHisingied :

1s

44 2 4te

wi Bho

m+ 6 2h6

*y 3 rhs

oto —o lo

o 123 4 § 6 7 8 8 HH B13 4 Qtmim}

o 0s 19 15 20 as 3035 40 QT is]

3500 RPM, 60 Hz

@ Performance table

Power | Q

Model 3

fodel dew) | why | 7 5 9 0 " 2 B 1

t t t t

Gvsa2i | 075 Fo | oa us uo | 10s 0 95 °

t I

osss | a ”

oes | 3 a LS 0

T (mm) ~ -

cwses ) 0 @

avs 4 as 18 {

owes 3 | 101 | |

7 cis [we Doe [ee Toe De |

_| © * pep

18 ms | te) fase) |e | as | ns

| 7 Se cee eae ee |

oxen on m | im | ow fom | im |e | ow | os

@ Installation sketch @ Size and weight

Ph Size(mm) Weight

Model

Bi | m2 | Bip] Di | D2 | (kg)

sr [os seam | ear

cussa | as7 70 ass |

ao a0 | or | im | ass) oa

J] Cate fete joe T | lr,

7 ‘ ar fais | we | in| ws |

4 | |

evses ast fais) ma | an | es | ar

Fa | |_| |

TI] za: qvsee as7 | 33s | saz | a0 | ass | a2

t | _

f ser |0 | 997 | 260 |e] or

out . !

; je | tr | 2 |

tata]

|

| 260 | 208 | a7

det] ce [=|

Gussi4 | 838) 50328330 | ass) as

i coat l

(GS-10 8-14 subsconnection of pipeline without oval ange

‘The overall dimensions of the single-phase motor and explosion-proof moter area litle changed, Pls contact us for details

42

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Fire Extinguisher Product Catalog EnglishDocument20 pagesFire Extinguisher Product Catalog EnglishMohammedIrfanNo ratings yet

- 6 - BillDocument1 page6 - BillMohammedIrfanNo ratings yet

- PWR-Series DatasheetDocument2 pagesPWR-Series DatasheetMohammedIrfanNo ratings yet

- AtciDocument6 pagesAtciMohammedIrfanNo ratings yet

- اعتماد كيمكو LuluDocument1 pageاعتماد كيمكو LuluMohammedIrfanNo ratings yet

- Generic MTC Straight Lengths 2022Document1 pageGeneric MTC Straight Lengths 2022MohammedIrfanNo ratings yet

- ديار قريش عبد اللطيف جميلDocument1 pageديار قريش عبد اللطيف جميلMohammedIrfanNo ratings yet

- Certificate of Origin L 36314021 - C955 SADocument2 pagesCertificate of Origin L 36314021 - C955 SAMohammedIrfanNo ratings yet

- Fawaz LetterDocument2 pagesFawaz LetterMohammedIrfanNo ratings yet

- Certificate of Origin L 35647913 - OC 0020619090Document3 pagesCertificate of Origin L 35647913 - OC 0020619090MohammedIrfanNo ratings yet

- Certificate of Origin L 36419949 - C955 SA - 0020471918Document3 pagesCertificate of Origin L 36419949 - C955 SA - 0020471918MohammedIrfanNo ratings yet

- California Copper Tube and FittingDocument1 pageCalifornia Copper Tube and FittingMohammedIrfanNo ratings yet

- Fire Department ConnectionDocument1 pageFire Department ConnectionMohammedIrfanNo ratings yet

- Replacementpartslist Acc2 DecoderDocument1 pageReplacementpartslist Acc2 DecoderMohammedIrfanNo ratings yet

- Kitchenhood Suppression System With LIFECO LE-EXDocument17 pagesKitchenhood Suppression System With LIFECO LE-EXMohammedIrfanNo ratings yet

- Mar-M-053-01 - B - Mueller Copper Pipes - Fawaz - SampleDocument4 pagesMar-M-053-01 - B - Mueller Copper Pipes - Fawaz - SampleMohammedIrfanNo ratings yet

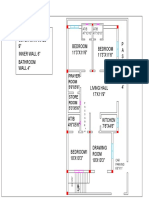

- Boundary Wall 6" Outer Main Wall 9" Inner Wall 6" Bathroom Wall 4"Document1 pageBoundary Wall 6" Outer Main Wall 9" Inner Wall 6" Bathroom Wall 4"MohammedIrfanNo ratings yet