Professional Documents

Culture Documents

Application of Statistical Process Contr

Uploaded by

osadik696Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Statistical Process Contr

Uploaded by

osadik696Copyright:

Available Formats

Communication

Brazilian Journal of

Pharmaceutical Sciences

Short

http://dx.doi.org/10.1590/s2175-97902018000217499

Application of statistical process control for spotting compliance

to good pharmaceutical practice

Mostafa Essam Eissa1*, Ahmedy Mahson Abid2

1

Quality Unit, Quality Compliance Section, HP, Giza, Egypt, 2Quality Unit, Quality Assurance Section, BP Pharmaceutical,

East Cairo, Egypt

For the release of pharmaceutical products into the drug market; most of the pharmaceutical companies

depend on acceptance criteria - that are set internally, regulatory and/or pharmacopeially. However,

statistical process control monitoring is underestimated in most quality control in cases; although it

is important not only for process stability and efficiency assessment but also for compliance with all

appropriate pharmaceutical practices such as good manufacturing practice and good laboratory practice,

known collectively as GXP. The current work aims to investigate two tablet inspection characteristics

monitored during in-process control viz. tablet average weight and hardness. Both properties were assessed

during the compression phase of the tablet and before the coating stage. Data gathering was performed

by the Quality Assurance Team and processed by Commercial Statistical Software packages. Screening

of collected results of 31 batches of an antibacterial tablet - based on Fluoroquinolone -showed that all

the tested lots met the release specifications, although the process mean has been unstable which could

be strongly evident in the variable control chart. Accordingly, the two inspected processes were not in

the state of control and require strong actions to correct for the non-compliance to GXP. What is not

controlled cannot be predicted in the future and thus the capability analysis would be of no value except

to show the process capability retrospectively only. Setting the rules for the application of Statistical

Process Control (SPC) should be mandated by Regulatory Agencies.

Keywords: Statistical process control (SPC). In-process control. GXP. Film coated tablet. Fluoroquinolone.

Capability analysis. Pharmaceutical practice.

INTRODUCTION the consequences on the impacted products would be

devastating (Asotra, Cossin, Yacobi, 2012).

The core value around which pharmaceutical For any firm to work with high‑quality standards

industry is basically centered is the delivery of medicinal level, an efficient Quality Control (QC) system must be

products which fulfill five criteria namely: Safety - implemented (Spiridonică, 2011). Since achieving highest

Identity -Strength - Purity - and Quality (SISPQ) (Welty, levels of quality standards are hindered by the extent of

2009). The deficiencies in products quality delivered to variability, thus, the main value of Statistical Process

final customer may not be obvious to the consumer, so Control (SPC) resides in reducing the variability in the

the Quality Team is a crucial defense line that protects manufacturing process (Spiridonică, 2011). The concept

both patients and manufacturers from consequences of the continuous improvement in any organization by

of delivering non-conforming drug products to the reducing variability is critical for both SPC and overall

market. However, the problem exacerbation may be due Quality Management (Ciobanu, Schreiner, 2002).

to its effect(s) on employees’ morals and attitudes due Due to above-mentioned challenges, present

to deficiency in quality. Thus, if the quality concept is work aims to investigate the current state of control

not communicated efficiently within the organization, for a pharmaceutical product manufactured in a new

pharmaceutical firm. Furthermore, monitoring the

*Correspondence: M. E. Eissa. Quality Unit, Quality Compliance Section,

process stability would provide assurance on future

HP, Giza, Egypt. E-mail: mostafaessameissa@yahoo.com process yield consistency. The study also focused on

Braz. J. Pharm. Sci. 2018;54(2):e17499 Page 1 / 5

M. E. Eissa, A. M. Abid

detecting the compliance of manufactured product to best analysis was performed as described in software manual

pharmaceutical practice which may be referred to, here, guide (GraphPad Prism User Guide, 2015). Distribution

as GXP through SPC. The study scope will cover two identification and analysis was conducted using XLSTAT

inspection properties of a pharmaceutical product viz. the Version 2014.5.03 (Eissa, 2016b).Box-and-Whisker

average weight and hardness of tablet. By using SPC, the Plots and control charts were constructed using Minitab®

current state of manufacturing control can be evaluated Version 17.1.0 (Minitab 17, 2013).

for monitoring of both characteristics. Moreover, the

current state of the process stability would determine the RESULTS AND DISCUSSION

consistency and steadiness of inspected characteristic.

This is considered a crucial integral part of product SPC tools and techniques have become an essential

manufacturing good practices. Accordingly, the product part of quality monitoring and improvement system

value could be evaluated through the degree of compliance in many industries including the pharmaceutical

with GXP. manufacturing field. The first step involved an overview

on results, its pattern and data homogeneity. Analysis

MATERIAL AND METHODS of results during data mining showed that the average

tablet weight in the 20 th batch was exceedingly high

A non-sterile manufacturing pharmaceutical plant outlier (although not Out‑Of‑Specification (OOS)) value

was established in the Industrial Zone at South Delta “692.13 mg” by Robust regression and Outlier removal

region in Egypt. The plant has begun launching products method (ROUT) (Q = 1.0%) test during trending average

of class D production area for solid dosage forms (Eissa, weight results(GraphPad Prism User Guide, 2015). This

2016a). During 2016, 31 batches of film coated tablets unexpected result highlighted the need to further analyze

based on Fluoroquinolone - as an active pharmaceutical to elucidate reason for such observation. On the other

ingredient (API) - were manufactured, tested and released hand, hardness test results did not show any outliers

according to the specifications in Ministry of Health preliminarily using GraphPad Prism. On the same line,

(MoH) product registration. Box-and-Whisker diagrams illustrated in Figure 1

The current study is part of a large project covering confirmed the absence of outliers (indicated by absence

different inspection characteristics of a variety of the of asterisks “*”). Moreover, they showed the pattern of

firm’s medicinal dosage forms. The product is a film data distribution with a little degree of skewness towards

coated tablet that is composed of Levofloxacin (API: the lower side (Lane, 2017). Minimum, 25% percentile,

Broad spectrum antibiotic of Fluoroquinolone class median, 75% percentile and maximum values for average

(Briggs, Freeman, Yaffe, 2012; levoflaxin, 2017), hydroxy weight and hardness were 644, 654, 660, 665, 669 and 15,

propyl methyl cellulose (Disintegrant), crospovidone 16, 16, 17, 18.

(Disintegrant), Avicel PH 102 (Filler), sodium stearyl The second step focused on the determination of

fumarate (Lubricant) and coating material (Coating film) the data distribution and degree of normality which was

(Eissa, Mahmoud, 2015; Sodium Stearyl Fumarate, 2017). important in the interpretation of the trending charts in the

The manufacturing process includes the following study. Removal of abnormally high result from average

steps: dispensing and weighing components from weight data has improved normality by Anderson-Darling

warehouse, blending, compaction followed by last (AD) test from P =0.023 to P =0.110 (Support.minitab.

blending step then compression, coating, blistering and com, 2016). Interestingly, distribution fitting test showed

packaging finally in secondary package to be transferred that Weibull (2) distribution is the closest with P =0.982

to the finished products warehouse. A process that is very (The Weibull Distribution, 2017). In contrast, hardness

common in solid oral dosage forms manufacturing and data still demonstrated that normal distribution is the

similar aspects have been discussed before by some field closest fit with P =0.9692. The Mean Value ± Standard

experts (Harbir, 2012; Mulla, 2015). Deviation (SD), skewness and kurtosis of average weight

Two inspection characteristics were assessed in and hardness were 659±6.2 mg, 16±0.82 Kilopond (Kp),

the production process during tablet core compression ‑0.65, ‑0.20 and ‑0.31, ‑0.88, respectively. The coefficient

phase, namely: average weight and hardness. Results of variation and the geometric mean were 0.94%, 659

were collected from In-Process Control (IPC) monitoring and 5.11%, 16, respectively. Figure 2 and 3 demonstrated

logs and arranged batch‑wise in Microsoft Office Excel normality of both average weight and hardness visually,

2007. Data were subjected to statistical analysis using respectively, using normal probability plot (The Anderson-

GraphPad Prism Version 6.01 software for Windows. The Darling Statistic, 2017). Thirdly, capability histogram was

Page 2 / 5 Braz. J. Pharm. Sci. 2018;54(2):e17499

Application of statistical process control for spotting compliance to good pharmaceutical practice

variation stability. Surprisingly, none of the inspected

parameters showed acceptable stability, consistency or

efficiency in the process (Smartersolutions.com, 2017).

Interestingly, although the process variation (from MR

charts) was stable (except for one point in hardness), the

process center (I charts) was in “Out-of-Control” state

especially in average weight. The assignable causes of

fluctuations (indicated by batches represented in red

dots) should be isolated from normal processes with

common cause variations (Martz, 2013). Moreover, both

processes are not centered and showed drifts toward either

of the border specification limits with possible future

excursions. This case was especially evident with hardness

in capability analysis. Accordingly, capability plots have

no value and may indicate past performance only but

cannot provide future prediction unless the processes

instability factors were corrected by Corrective Action

and Preventive Action (CAPA) (Qimacros.com, 2017).

Since there was no subgroups for each point, the last 25

observations in Figure 2 and 3 are the same as in the last

ones in I charts. Further investigation is required to figure

out and correct the source of non-GXP activities which

might stem from the manufacturing and/or IPC activities.

The current study demonstrated the need to establish

an official requirement for SPC in pharmaceutical

monitoring as a part of routine quality system through

Regulatory bodies to solve the non-compliant activities

concurrently and immediately rather than retrospectively.

SPC provides strong control and verification of newly

established operation efficiency and the needed

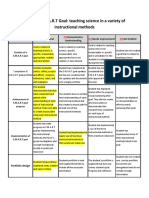

FIGURE 1 - Box Plot diagram showing the pattern of data adjustments if the process is not working satisfactorily.

distribution for average weight and hardness as part of IPC tests To conclude, the pharmaceutical dosage forms may meet

during the compression process. the specification limits required for the product release,

while hiding signs of future excursions that may turn into

interpreted for both of the inspection properties in order true OOS. Moreover, SPC provides visual evidence of

to determine the location of normally distributed process process stability accompanied with GXP.

between specification limits (SLs). In addition, histograms Accordingly, it could be concluded from previous

were not centered within SLs and data was found to be study that the inspection characteristics monitoring of

shifted towards the lower average weight limit. While pharmaceutical products should take into consideration

results of hardness strongly shifted towards the upper limit each of the following:

(Minitab 17, 2013). 1. SPC could provide a visual measure of specific

Examination of the constructed process behavior procedure compliance with GXP.

(control) chart was inspected - after histograms 2. The importance of official regulatory enforcements

examination to monitor the process. Shewhart charts were for implementation of SPC within pharmaceutical

constructed for different types of data with a certain degree industry especially in developing countries.

of normality using Individual-Moving Range (I-MR) chart 3. Monitoring overall manufacturing cycle perfor-

as demonstrated in Figure 2 and 3. Normality assumption mance of product rather than reliance on product re-

was confirmed to avoid errors in alarm detection while lease specifications only may show the gap between

constructing Shewhart charts. I-MR is actually composed delivered into market product, its true manufacturing

of two charts: I chart that determined the process state of quality conditions and the environment within which

control mean and MR chart which showed the process it has been manufactured.

Braz. J. Pharm. Sci. 2018;54(2):e17499 Page 3 / 5

M. E. Eissa, A. M. Abid

FIGURE 2 - Statistical control monitoring of average weight test showing out-of-control points as red dots.

FIGURE 3 - Statistical control monitoring of hardness test showing out-of-control points as red dots.

Page 4 / 5 Braz. J. Pharm. Sci. 2018;54(2):e17499

This is an open-access article distributed under the terms of the Creative Commons Attribution License.

Application of statistical process control for spotting compliance to good pharmaceutical practice

4. The application of the current method is simple and Minitab 17: Getting started with Minitab 17. Minitab Inc.; 2013.

saves time using a statistical software package, yet

its full potential in product quality process monitor- Mulla A. Tablet manufacturing process created by Asadulla

ing is crucial. Mulla [Internet].Slideshare.net. 2015. [cited 19 March 2017].

Available from: https://www.slideshare.net/akmulla/tablet-

REFERENCES manufacturing-process.

Asotra S, Cossin A, Yacobi A. Costs of failure in product quality. Qimacros.com. Stability analysis versus capability analysis

Pharm Technol. 2012;36(4):110‑118. [Internet].Qimacros.com. 2017. [cited 19 March 2017].

Available from: https://www.qimacros.com/lean-six-sigma-

Briggs GG, Freeman RK, Yaffe SJ. Drugs in pregnancy and articles/stability-analysis-vs-capability-analysis/.

lactation: a reference guide to fetal and neonatal risk. London:

Lippincott Williams & Wilkins; 2012. Smartersolutions.com. Transforming individuals control chart

data [Internet]. Smartersolutions.com. 2017 [cited 19 March

Ciobanu RC, Schreiner C. Calitatea in industriesiservicii.Iasi: 2017]. Available from: https://www.smartersolutions.com/

Fides;2002. resources/transforming-individuals-control-chart-data.

Eissa ME, Mahmoud AM. Development of methods for Sodium Stearyl Fumarate (Inactive Ingredient) - Drugs.com

microbial recovery: pharmaceutical dosage forms including [Internet]. Drugs.com. 2017. [cited 19 March 2017]. Available

drugs with antimicrobial properties (Study III). Eur Pharm Med from: https://www.drugs.com/inactive/sodium-stearyl-

Res(EJPMR).2015;2(4):537‑549. fumarate-320.html.

Eissa ME. microbiological assessment of compressed air Spiridonică AM. The use of statistical process control

at a pharmaceutical industry: statistical process control. J in pharmaceuticals industry. In: Proceedings of the 54th

ApplPharmlSci(JAPHAC). 2016b;3(1):23‑28. international scientific conference, Durable Agriculture

‑Development Strategies. 2011 Jun 1; Iaşi.LucrăriStiinţifice.

Eissa ME. Novel rapid method in ecological risk assessment p271‑275.

of air‑borne bacteria in pharmaceutical facility.Mahidol Univ J

Pharm Sci. 2016a,43(3):115-126. Qimacros.com. Stability analysis versus capability analysis

[Internet].Qimacros.com. 2017. [cited 19 March 2017].

GraphPad Prism User Guide [Internet]. Graphpad.com. 2015. Available from: https://www.qimacros.com/lean-six-sigma-

[cited 19 March 2017]. Available from: https://www.graphpad. articles/stability-analysis-vs-capability-analysis/.

com/guides/prism/6/user-guide/index.htm?.

The Anderson-Darling statistic - Minitab [Internet].Support.

Harbir K. Processing technologies for pharmaceutical tablets: minitab.com. 2016. [cited 19 March 2017]. Available from:

A review. Int Res J Pharm. 2012;3(7):20‑23. http://support.minitab.com/en‑us/minitab/17/topic‑library/

basic-statistics-and-graphs/introductory-concepts/data-

Lane D. Box Plots [Internet]. Onlinestatbook.com. 2017. [cited concepts/anderson-darling/.

19 March 2017]. Available from: http://onlinestatbook.com/2/

graphing_distributions/boxplots.html. The Weibull Distribution - ReliaWiki [Internet].Reliawiki.org.

2017. [cited 19 March 2017]. Available from: http://reliawiki.

Levofloxacin Monograph for Professionals - Drugs.com org/index.php/The_Weibull_Distribution.

[Internet].Drugs.com. 2017. [cited 19 March 2017]. Available

from: https://www.drugs.com/monograph/levofloxacin.html. Welty G. Framework for continuous improvement.JGXP

Compliance. 2009;13(1):79‑89.

Martz E. How to create and read an I-MR control chart

[Internet].Blog.minitab.com. 2013. [cited 19 March 2017]. Received for publication on 18th August 2017

Available from: http://blog.minitab.com/blog/understanding- Accepted for publication on 14th November 2017

statistics/how-create-and-read-an-i-mr-control-chart.

Braz. J. Pharm. Sci. 2018;54(2):e17499 Page 5 / 5

You might also like

- Importance of Quality Control in Pharmaceutical ManufacturingDocument4 pagesImportance of Quality Control in Pharmaceutical ManufacturingventurefostergroupNo ratings yet

- Pharmaceutics 13 00919 v2Document45 pagesPharmaceutics 13 00919 v24n4n4sNo ratings yet

- 19.Md. Sahab Uddin Et Al., IAJPS 2016, 3 (12), 1624-1638Document15 pages19.Md. Sahab Uddin Et Al., IAJPS 2016, 3 (12), 1624-1638Abdul RahimNo ratings yet

- Process Capability EngDocument11 pagesProcess Capability EngApoloTrevinoNo ratings yet

- Haccp Water PurificationDocument13 pagesHaccp Water PurificationClifton JuraNo ratings yet

- Design Space 1Document9 pagesDesign Space 1Mohammad Syahrul Bin BoonieNo ratings yet

- The Duty for Sponor Oversight in Clinical Trials: Practical Guide: 2nd Edition Clinical Data ReviewFrom EverandThe Duty for Sponor Oversight in Clinical Trials: Practical Guide: 2nd Edition Clinical Data ReviewNo ratings yet

- Quality by Design (QBD) A Comprehensive Understanding of ImplementationDocument7 pagesQuality by Design (QBD) A Comprehensive Understanding of Implementationiabureid7460No ratings yet

- Which Batch Size For Validation and Stability StudiesDocument1 pageWhich Batch Size For Validation and Stability StudieskushalNo ratings yet

- Quality by Design (QBD) : A Comprehensive Understanding of Implementation and Challenges in Pharmaceuticals DevelopmentDocument8 pagesQuality by Design (QBD) : A Comprehensive Understanding of Implementation and Challenges in Pharmaceuticals DevelopmentmcamilaarredondovelezNo ratings yet

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Pauli2019 PDFDocument11 pagesPauli2019 PDFIkram Abi HamzahNo ratings yet

- Pauli2019 PDFDocument11 pagesPauli2019 PDFIkram Abi HamzahNo ratings yet

- New Challenges For Biopharmaceutical Process DevelopmentDocument4 pagesNew Challenges For Biopharmaceutical Process DevelopmentAmgad_SNo ratings yet

- 2010 Article 9566Document5 pages2010 Article 9566Shimul HalderNo ratings yet

- Multi Attribute Method Implementation Using A High Resolution Mass Spectrometry PlatformDocument22 pagesMulti Attribute Method Implementation Using A High Resolution Mass Spectrometry Platformyun baiNo ratings yet

- Some Quality Control Analysis Parameters For Parenteral FormulationsDocument5 pagesSome Quality Control Analysis Parameters For Parenteral FormulationsEditor IJTSRDNo ratings yet

- QBT To QBDDocument7 pagesQBT To QBDshelfinararaNo ratings yet

- FBP Formulation parametricQbDRAPSR-05Document21 pagesFBP Formulation parametricQbDRAPSR-05Sartha KumarNo ratings yet

- Quality by Design: Lower Cost of QualityDocument5 pagesQuality by Design: Lower Cost of QualityNarendrakumarNo ratings yet

- An Overview of Pharmaceutical Process Validation and Process Control Variables of Tablets Manufacturing Processes in IndustryDocument16 pagesAn Overview of Pharmaceutical Process Validation and Process Control Variables of Tablets Manufacturing Processes in Industrynsk79in@gmail.comNo ratings yet

- QBD Dry PowdersDocument13 pagesQBD Dry PowdersTausif AlamNo ratings yet

- ReviewDocument11 pagesReviewNoonNo ratings yet

- QBD ... Plackett Burman...Document12 pagesQBD ... Plackett Burman...cabeto124211No ratings yet

- An Integrated Approach by FMEA Fuzzy PrioritizatioDocument16 pagesAn Integrated Approach by FMEA Fuzzy PrioritizatiobrotodhegdoNo ratings yet

- ISO-GUM and Supplements Are Utilized For QA of BCA Data: Yasuo IwakiDocument31 pagesISO-GUM and Supplements Are Utilized For QA of BCA Data: Yasuo IwakiKemo TufoNo ratings yet

- GMP ManualDocument303 pagesGMP ManualShrinivas TamaskarNo ratings yet

- Development Knowledge QBDDocument6 pagesDevelopment Knowledge QBDNarendrakumarNo ratings yet

- Aksu 2019 Chapter 2Document23 pagesAksu 2019 Chapter 2Angel GarciaNo ratings yet

- Control Strategy For Process Development of High Shear Wet Granulation and Roller Compaction To Prepare A Combination Drug Using Integrated Quality by DesignDocument27 pagesControl Strategy For Process Development of High Shear Wet Granulation and Roller Compaction To Prepare A Combination Drug Using Integrated Quality by Designiloveit52252No ratings yet

- Section VIIIDocument96 pagesSection VIIISri RahayuNo ratings yet

- Journal of Pharmaceutical Sciences: Naseem Ahmad Charoo, Mark Durivage, Ziyaur Rahman, Mohamad Haitham AyadDocument6 pagesJournal of Pharmaceutical Sciences: Naseem Ahmad Charoo, Mark Durivage, Ziyaur Rahman, Mohamad Haitham Ayadmehrdarou.qaNo ratings yet

- Process Analytical Technology Concepts and Principles PDFDocument8 pagesProcess Analytical Technology Concepts and Principles PDFhdmnauNo ratings yet

- Quality by Design: Review ArticleDocument13 pagesQuality by Design: Review ArticleIjupbs IjupbsNo ratings yet

- Technology Transfer 1Document5 pagesTechnology Transfer 1Android modded gamesNo ratings yet

- Process Analytical Technology: A ReviewDocument23 pagesProcess Analytical Technology: A ReviewAbbas Syed100% (2)

- Multivariate Statistical Process Control in Product Quality Review Assessment - A Case StudyDocument10 pagesMultivariate Statistical Process Control in Product Quality Review Assessment - A Case Studyd1360sdfggfbdmllNo ratings yet

- Microsoft Word 2007 Keyboard ShortcutsDocument8 pagesMicrosoft Word 2007 Keyboard ShortcutsKumar GalipellyNo ratings yet

- CPGM 7345.848 - Inspection of Biological Drug ProductsDocument20 pagesCPGM 7345.848 - Inspection of Biological Drug ProductsKisho RamNo ratings yet

- CPV Case Study Interactive VersionDocument102 pagesCPV Case Study Interactive VersionMinh LeNo ratings yet

- Basic Concept of Process Validation in Solid Dosage Form (Tablet) : A ReviewDocument10 pagesBasic Concept of Process Validation in Solid Dosage Form (Tablet) : A Reviewqc jawaNo ratings yet

- Implementation of QBD AQbD Approach in Pharmaceutical Formulation and Analytical Method Development A Comprehensive Research Review Ijariie18342 PDFDocument32 pagesImplementation of QBD AQbD Approach in Pharmaceutical Formulation and Analytical Method Development A Comprehensive Research Review Ijariie18342 PDFrbmoureNo ratings yet

- QBD Application For The Pharmaceutical Development ProcessDocument34 pagesQBD Application For The Pharmaceutical Development Processsooho32No ratings yet

- QBD in API ManufacturingDocument78 pagesQBD in API ManufacturingManivannan KathirvelNo ratings yet

- KB002839-MRK1609-01 Pharma Manufac Set Effective SpecsDocument14 pagesKB002839-MRK1609-01 Pharma Manufac Set Effective SpecsMiguel Zuniga MarconiNo ratings yet

- State of Total Quality Management in Pharmaceutical Industry Literature ReviewDocument4 pagesState of Total Quality Management in Pharmaceutical Industry Literature ReviewwoeatlrifNo ratings yet

- A Review On Analytical Method DevelopmenDocument8 pagesA Review On Analytical Method DevelopmenJaydeep PawarNo ratings yet

- Process Analytical Technology PAT in Pharmaceutical DevelopmentDocument9 pagesProcess Analytical Technology PAT in Pharmaceutical DevelopmentMaria CutajarNo ratings yet

- BFS-FRIEDMAN - Contamination Case Studies Paper PDFDocument9 pagesBFS-FRIEDMAN - Contamination Case Studies Paper PDFipatoffNo ratings yet

- The FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsFrom EverandThe FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsNo ratings yet

- A Roadmap For The Implementation of Continued Process VerificationDocument13 pagesA Roadmap For The Implementation of Continued Process VerificationzombiecorpNo ratings yet

- Pharmaceutical Process Validation ThesisDocument8 pagesPharmaceutical Process Validation Thesisafkogftet100% (1)

- Getting Scientific About Cleaning ValidationDocument2 pagesGetting Scientific About Cleaning ValidationOuss AmaNo ratings yet

- Analysis of Wet Granulation Process With Plackett-Burman Design Ñ Case StudyDocument9 pagesAnalysis of Wet Granulation Process With Plackett-Burman Design Ñ Case StudyAnnwary SiregarNo ratings yet

- 制药连续生产过程操作管理的状态维护框架设计+ OcrDocument43 pages制药连续生产过程操作管理的状态维护框架设计+ OcrYUHANGNo ratings yet

- Quality by Design in Pharmaceutical Manufacturing: A Systematic Review of Current Status, Challenges and Future PerspectivesDocument19 pagesQuality by Design in Pharmaceutical Manufacturing: A Systematic Review of Current Status, Challenges and Future PerspectivesArturo T. Sánchez-MoraNo ratings yet

- BJSTR Ms Id 001662considerationsDocument4 pagesBJSTR Ms Id 001662considerationsDrkrishnasarma pathyNo ratings yet

- Continuous Pharmaceutical Manufacturing: PharmaceuticsDocument2 pagesContinuous Pharmaceutical Manufacturing: PharmaceuticsneproxenNo ratings yet

- Miranda2018 PDFDocument38 pagesMiranda2018 PDFDiana LeonNo ratings yet

- Developing IT Security Risk Management PlanDocument5 pagesDeveloping IT Security Risk Management PlanKefa Rabah100% (3)

- 6 - Designing Manufacturing Processes - Hill - Product ProfilingDocument20 pages6 - Designing Manufacturing Processes - Hill - Product ProfilingLalit S KathpaliaNo ratings yet

- ReDocument3 pagesReSyahid FarhanNo ratings yet

- T3 Rapid Quantitative Test COA - F2311630AADDocument1 pageT3 Rapid Quantitative Test COA - F2311630AADg64bt8rqdwNo ratings yet

- Scheps Omni Channel PDFDocument41 pagesScheps Omni Channel PDFaaronweNo ratings yet

- ENG18Document2 pagesENG18Lef RJNo ratings yet

- Newtom 3G ManualDocument154 pagesNewtom 3G ManualJorge JuniorNo ratings yet

- Smart Goals Rubric 2Document2 pagesSmart Goals Rubric 2api-338549230100% (2)

- PDFs/Sprinker NFPA 13/plan Review Sprinkler Checklist 13Document5 pagesPDFs/Sprinker NFPA 13/plan Review Sprinkler Checklist 13isbtanwir100% (1)

- Selenium Question and AnswerDocument35 pagesSelenium Question and AnswerManas Jha50% (2)

- 18 Kadek Devy Crisna S - Emcee ScriptDocument6 pages18 Kadek Devy Crisna S - Emcee ScriptSugar HoneyTheoryNo ratings yet

- Technical Sheet Azud Watertech WW EngDocument2 pagesTechnical Sheet Azud Watertech WW EngMiguel Torres ObrequeNo ratings yet

- Dissertation Bowden PDFDocument98 pagesDissertation Bowden PDFmostafaNo ratings yet

- Purposeful InnovationDocument6 pagesPurposeful InnovationKeith Tanaka MagakaNo ratings yet

- Algebra 1 Vocab CardsDocument15 pagesAlgebra 1 Vocab Cardsjoero51No ratings yet

- Case Study: The Firm Wide 360 Degree Performance Evaluation Process at Morgan Stanley SummaryDocument1 pageCase Study: The Firm Wide 360 Degree Performance Evaluation Process at Morgan Stanley SummaryMehran MalikNo ratings yet

- Safety Data Sheet: Armohib Ci-28Document21 pagesSafety Data Sheet: Armohib Ci-28SJHEIK AbdullahNo ratings yet

- Melissas ResumeDocument2 pagesMelissas Resumeapi-329595263No ratings yet

- Progress Test 3Document7 pagesProgress Test 3Mỹ Dung PntNo ratings yet

- Trade Secrets Lawsuit V ReebokDocument17 pagesTrade Secrets Lawsuit V ReebokDarren Adam HeitnerNo ratings yet

- LECTURE 11-Microalgal Biotechnology-Biofuels N BioproductsDocument16 pagesLECTURE 11-Microalgal Biotechnology-Biofuels N BioproductsIntan Lestari DewiNo ratings yet

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocument2 pagesSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNo ratings yet

- Impact of Child Labour On School Attendance and Academic Performance of Pupils in Public Primary Schools in Niger StateDocument90 pagesImpact of Child Labour On School Attendance and Academic Performance of Pupils in Public Primary Schools in Niger StateJaikes100% (3)

- Product Information Flyer: CIMSTAR® 10-570-HFP With FACT™Document2 pagesProduct Information Flyer: CIMSTAR® 10-570-HFP With FACT™sobheysaidNo ratings yet

- Evolution of Human Resource ManagementDocument13 pagesEvolution of Human Resource Managementmsk_1407No ratings yet

- Pre Int Work Book Unit 9Document8 pagesPre Int Work Book Unit 9Maria Andreina Diaz SantanaNo ratings yet

- Case Study-Hain Celestial: Student Name Institution Affiliation DateDocument5 pagesCase Study-Hain Celestial: Student Name Institution Affiliation DategeofreyNo ratings yet

- Sendik's Oconomowoc Press AnnouncementDocument2 pagesSendik's Oconomowoc Press AnnouncementTMJ4 NewsNo ratings yet

- Caso Contra Ángel Pérez: Respuesta de La Fiscalía A Moción de La Defensa Sobre Uso de FotosDocument8 pagesCaso Contra Ángel Pérez: Respuesta de La Fiscalía A Moción de La Defensa Sobre Uso de FotosEl Nuevo DíaNo ratings yet

- Brand Trust, Customer SatisfacDocument21 pagesBrand Trust, Customer SatisfacJar JarNo ratings yet