Professional Documents

Culture Documents

CQR02-010 Control of Quality Records Procedure Rev 01

Uploaded by

rashidyousaf1992Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CQR02-010 Control of Quality Records Procedure Rev 01

Uploaded by

rashidyousaf1992Copyright:

Available Formats

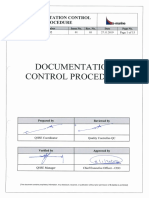

(ISO 17020:2012)

Control of Quality Records

Procedure

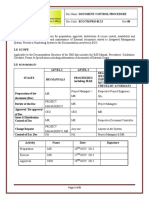

Document Origination, Revision & Amendment History:

Prepared By Reviewed By Approved By

Rev.

Issue Date

No.

Technical Manager Chief Executive Officer Chief Executive Officer

(TM) (CEO) (CEO)

01/01/2017 00

09/10/2023 01

*Authorized signatories are identified against the particular position on the “List of Staff, Services &

Competency” (Ref. LOS04-005).

Document Distribution List:

Copy No. 1 2 3

1 QMR/D-QMR **QMS Office File

*The document distribution status is available in the Master List of Documents and always the latest

revised (current version) copy is made available at the relevant point of use.** Accessible to the

employees mentioned in the “Master List of Documents” (Ref. MLD04-001).

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 1 of 6

(ISO 17020:2012)

CONTENTS

1. PURPOSE

2. SCOPE OF APPLICATION

3. DEFINITIONS

4. RESPONSIBILITY FOR APPLICATION

5. PROCESS

6. FILING, MAINTENANCE AND DISPOSAL OF RECORDS

7. ATTACHMENTS/ASSOCIATED DOCUMENTS

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 2 of 6

(ISO 17020:2012)

1. PURPOSE

The purpose of this procedure is to define an effective system for the control of

various quality records generated during implementation of quality system. These

records are subject to periodic analysis to understand the trend in the processes

and hence to implement improvement actions.

2. SCOPE OF APPLICATION

This procedure applies to all records within the ISO 17020 standards including

Internal and the External Origin, integrated / referred in this quality system as well as

their periodic analysis to understand trend in the processes. The scope of

application includes both hard copies and records maintained in electronic media.

3. DEFINITIONS

Statistical Analysis:

The process of compilation of data, their classification and analysis to project the

trend in the processes / system to identify any cause or to review the system

effectiveness regarding its implementation or any associated activity.

Records of External Origin:

If required, any previous version of the document(s) originated outside Tawasul; are

kept as record if still that has its importance for its previous use. This may be an

International Standards or any regulatory requirements etc.

Obsolete Copy:

These are out-dated copies of documents which are not in use anymore are kept as

record for a certain time.

4. RESPONSIBILITY FOR APPLICATION

The Quality Management Representative (QMR)/D-QMR, is responsible for

developing, implementing & maintaining of this procedure.

All the documents review, and approval is done by CEO/Managing Director of

Tawasul.

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 3 of 6

(ISO 17020:2012)

5. PROCESS

Form Origination as part

of Procedure /

Document

Data Collection/Form

Fillings

Not Ok

Review /

Approval

Ok

Filing

Preparation of Hard Disk

(If Required)

Archiving / Record

Keeping including

Obsolete Documents

6. PROCEDURE

This procedure provides details on filing, maintenance, and disposal of

records. A detailed description is given here below:

i. All the forms referred in various procedures are to be used by the

responsible personnel to record the activities and results. These records

shall be legible and shall indicate the processing conditions, traceability

links and the identity of person who prepared / verified them.

ii. All records shall be filed date wise or serial number wise whichever is easy

in retrievability.

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 4 of 6

(ISO 17020:2012)

iii. File all records as hard copies and/or in the computer as soft copies (e.g.

scanned or original soft data or software). All contractual or quality

related records on heat sensitive paper (Fax paper) shall be photocopied

to avoid fading, and file them accordingly. The record files are labelled in

a manner so can retrieve easily, effectively, and effectively.

iv. QMR/D-QMR is responsible for storing and maintaining of records

including their retention period is mentioned in the Master List Quality

Records and the documents records mentioned at the last part of

procedures/work instruction or wherever it requires. Person responsible for

storage of records shall ensure that they are maintained properly so that

over a period the records do not get spoiled or lost and information

remains legible.

v. Regular backups shall be taken for the records maintained in computer. If

necessary or required such records are maintained in on additional hard

disk to ensure protection from virus.

vi. Records required by the customer are made available, as per the terms

of contract or customer’s purchase order. (Generally, the, reports and

traceability records to national / international standards).

vii. Records Statistical Data is kept and maintained which may include any

non-conformance related to this QMS but not limited to audit

(internal/external) non-conformances, Customer complaints, Customer

Satisfaction Survey, Customer Feedback, Employee Satisfaction Survey,

etc.

viii. QMR/D-QMR prepares the “Quality Performance Analysis Report” based

on the statistical reports to discuss with all the concern team as well as for

the management review as per the Management Review Procedure.

The records and their related statistical data may include the followings

(refers to “Master List of Quality Records”: are kept and maintained, e.g.

which may include but not limited to:

▪ any non-conformance related to this QMS and related CPRs

✓ any non-conformance audit (internal/external)

✓ Customer complaints,

✓ Customer Satisfaction Survey,

✓ Customer Feedback,

✓ Etc.

▪ Performance on quality objectives

▪ Inspection performed in particular period and related issues etc.

ix. In case of record retention & storage period is required more or less than

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 5 of 6

(ISO 17020:2012)

three (03) years for the specific record(s), then this is specified or relevant

in the procedure/ work instructions/document and then will be

maintained accordingly. Records more than three (03) year old is

disposed-off appropriately including obsolete records. The documents are

stored and protected appropriately to avoid any damage and any

changes in contents of record/data.

x. All the records are issued with a particular number as per Document &

Data Control Procedure or this may be any system generated unique

number for its identification & retrieval. All calculations and data transfers

made by Tawasul are subjected for appropriate checks and this was

reviewed and verified by superior/senior officer/manager.

xi. The QMR/D-QMR will maintain all this Quality Management System

records current and up to date.

xii. Where records are stored in electronic media, the same shall be

password protected for access, periodic back-ups taken and installed

with virus shield.

xiii. The Quality Performance Analysis Report and statistical reports are

maintained for Three (03) years by the Management Representative.

Other records shall be maintained as stipulated in relevant procedures.

xiv. The record related to all the functions is maintained for the duration of the

order/contract or as a minimum period of Three (03) years along with all

contractual correspondence or otherwise specified. After that this can be

discarded (manual tear off or by any other appropriate means).

Tawasul assures that result of inspection/service(s) supplied by sub-

contractors in the inspection report(s) /certificate(s) is/are correct and

accurate. Any Correction/ Amendments in the report or certificate must

be in accordance with the established information shared/

communicated or sub-contracted by Tawasul. All records, reports/

certificate are properly maintained and archived for a period of Three

years (03) (7.4.4; 7.4.5) or unless or otherwise specified for any particular

document record internally or by any relevant regulatory agency /

authority or specified by any specific reference standards/schemes/

guidelines.

7. ATTACHMENTS/ASSOCIATED DOCUMENTS

a) Master List of Quality Records (LQR04-002)

b) Quality Performance Analysis Report (QRP04-026)

c) Document & Data Control Procedure (DDC02-009)

d) Management Review Procedure (MRP02-015)

All rights reserved. Unless otherwise specified, no part of this document may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and micro filming, without written permission from the Quality Management

Representative of the “TAWASUL”. This is a controlled document and not permitted to copy or print, if copied/printed shall be considered

as uncontrolled document, unless otherwise stamped as “Controlled Copy”.

Doc. No.: CQR02-010 Rev:01, TAWASUL TESTING & INPECTION SERVICES,

Effective Date: 09/10/2023 PO BOX 231586, Dubai, United Arab Emirates,

Issue Date: 01/01/2017 www.tawasulservice.com

Page No. Page 6 of 6

You might also like

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- 6.2document Control ProcedureDocument7 pages6.2document Control ProcedureStephen David Gozun100% (3)

- 01 4.2.3 4.4.5 Document Control ProcedureDocument8 pages01 4.2.3 4.4.5 Document Control ProcedureYousaf RichuNo ratings yet

- PRO-002 Record Control ProcedureDocument5 pagesPRO-002 Record Control Procedurealias brownNo ratings yet

- Document Control ProcedureDocument6 pagesDocument Control ProcedureLedo Houssien93% (15)

- 05 Documented Information ProcedureDocument3 pages05 Documented Information ProcedureZarai MaherNo ratings yet

- Internal Audit Findings Pcu 2022Document4 pagesInternal Audit Findings Pcu 2022ndayiragije JMVNo ratings yet

- 2.2.1 Quality Manual ProcedureDocument9 pages2.2.1 Quality Manual ProcedureStephen David GozunNo ratings yet

- Document Data Control ProcedureDocument5 pagesDocument Data Control ProcedureH. Nazeer Khan100% (1)

- So09-Qse-P1 Rev 0Document14 pagesSo09-Qse-P1 Rev 0Aung ThanNo ratings yet

- BCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageDocument15 pagesBCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageCarwell AbatayoNo ratings yet

- 1-Document Management ProcedureDocument9 pages1-Document Management ProcedureRohit SharmaNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- Material Handling and Preservation Procedure PDFDocument2 pagesMaterial Handling and Preservation Procedure PDFgali vidyasagar100% (1)

- Documented Information ProcedureDocument14 pagesDocumented Information ProcedureAnkurNo ratings yet

- SOP-02 Procedure For Control Documented InformationDocument3 pagesSOP-02 Procedure For Control Documented InformationMARYNOLD HACHERONo ratings yet

- L2-PIMS-002 - Documentation Control PDFDocument15 pagesL2-PIMS-002 - Documentation Control PDFsam walledNo ratings yet

- Sample - QMS-P001 Control-Of-Documented-InformationDocument8 pagesSample - QMS-P001 Control-Of-Documented-InformationCharmis TubilNo ratings yet

- Internal Audit Findings Pcu 2022Document4 pagesInternal Audit Findings Pcu 2022ndayiragije JMVNo ratings yet

- MD 010 Design Validation Sop 1 0 110905125013 Phpapp02Document1 pageMD 010 Design Validation Sop 1 0 110905125013 Phpapp02Omer ZiaNo ratings yet

- PR.13 Planning of AuditsDocument21 pagesPR.13 Planning of AuditsDaniel Jorge Da SilvaNo ratings yet

- Foi 090 1213 20Document19 pagesFoi 090 1213 20RobertoNo ratings yet

- 04 SCP Remote or Virtual Audit Checklist Rev 0 PDFDocument3 pages04 SCP Remote or Virtual Audit Checklist Rev 0 PDFQueenie Gallardo AngelesNo ratings yet

- IMI - Purchasing Maintenance Repair and Operations ProcedureDocument23 pagesIMI - Purchasing Maintenance Repair and Operations ProcedureRPM28XINo ratings yet

- SOP-HSE-001. Document Control Procedure (FINAL ENG)Document16 pagesSOP-HSE-001. Document Control Procedure (FINAL ENG)lulu silmiNo ratings yet

- IT Operations - Document Operating ProceduresDocument10 pagesIT Operations - Document Operating ProceduresAgung PrasetyoNo ratings yet

- 2.PR-GM 02 Document Control ProcedureDocument8 pages2.PR-GM 02 Document Control ProcedureFULGENCE RUHARARANo ratings yet

- Sop-Dc-02 - Control of RecordDocument7 pagesSop-Dc-02 - Control of Recordapi-278193171100% (1)

- Documented Process - Managing Documented InformationDocument8 pagesDocumented Process - Managing Documented Informationdhir.ankurNo ratings yet

- SOP 1, Document Control SOPDocument15 pagesSOP 1, Document Control SOPassfaw chekolNo ratings yet

- Lufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposeDocument11 pagesLufkin Middle East Document Control Procedure Doc ID Issue 1 Date 14/ 05/08 Prepared by Talaat Akader Approved by Anthony Beck PurposemohammedNo ratings yet

- Common Work Instructions For Directorate - 26082022Document12 pagesCommon Work Instructions For Directorate - 26082022snigdhaprajapati955No ratings yet

- 11-Management Review ProcessDocument2 pages11-Management Review ProcessDhinakaranNo ratings yet

- IMSP-01 Control of DocumentsDocument10 pagesIMSP-01 Control of DocumentsAbdul HadiNo ratings yet

- SHE-ECP-09-005 Building & Floor Procedure Rev02Document7 pagesSHE-ECP-09-005 Building & Floor Procedure Rev02grantNo ratings yet

- AMY-QMP-01 Procedure For Documented InformationDocument6 pagesAMY-QMP-01 Procedure For Documented InformationTauseef ShaukatNo ratings yet

- Integrated Management System: Quality Assurance ProcdeureDocument6 pagesIntegrated Management System: Quality Assurance ProcdeureLawzy Elsadig SeddigNo ratings yet

- UV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Document20 pagesUV - OQR - 1240 - 1600 - 1700 - 1900 - 2450 - 2550series (UV1700 - 1900 (With 7 WL)Fairuz Luthfa100% (1)

- Performing An Operational QualificationDocument9 pagesPerforming An Operational QualificationGowthamNo ratings yet

- 01 - F103-1 Audit PlanDocument2 pages01 - F103-1 Audit PlanHossam IbrahimNo ratings yet

- RMR-HSMS-P-007 Procedure For Control of HSEQ DocumentationDocument10 pagesRMR-HSMS-P-007 Procedure For Control of HSEQ DocumentationkamranNo ratings yet

- ISO 9001:2015 Procedure For Control of Documented InformationDocument9 pagesISO 9001:2015 Procedure For Control of Documented InformationQualtic Certifications100% (6)

- QO F 7.1 4 Ver 3.0 RDSO Inspection CertificateDocument4 pagesQO F 7.1 4 Ver 3.0 RDSO Inspection CertificatesanjaydeNo ratings yet

- Assessment ToolDocument13 pagesAssessment Toolal gulNo ratings yet

- Miles Document Control ProcedureDocument28 pagesMiles Document Control ProcedureAnold MedardNo ratings yet

- Process Manual MRDocument20 pagesProcess Manual MRaskannancvNo ratings yet

- SMS PRO 003 Procedure For The Control of Documented InformationDocument9 pagesSMS PRO 003 Procedure For The Control of Documented InformationpnagarajjNo ratings yet

- 01 - Documented InformationDocument20 pages01 - Documented Informationrc2834338No ratings yet

- MTP-PR-004-QUC Material Recieving Inspection (R0)Document5 pagesMTP-PR-004-QUC Material Recieving Inspection (R0)parwoto100% (1)

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of Documentsjamal nasirNo ratings yet

- SopDocument7 pagesSopSrinivasNo ratings yet

- IMS Procedures 2005 PrintDocument215 pagesIMS Procedures 2005 PrintGopal SudhirNo ratings yet

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of DocumentsMarjorie Dulay Dumol100% (1)

- Certification Procedure: Perry Johnson Registrars, Inc. Quality SystemsDocument25 pagesCertification Procedure: Perry Johnson Registrars, Inc. Quality SystemsPrashanth BNNo ratings yet

- Rules For Use of LogoDocument9 pagesRules For Use of LogoviratNo ratings yet

- Procedure For Control of Documented Information - TRACE INTERNATIONALDocument9 pagesProcedure For Control of Documented Information - TRACE INTERNATIONALISO SRCAS100% (1)

- SHE-ECP-09-017 Motorize Equipment Procedure Rev02Document7 pagesSHE-ECP-09-017 Motorize Equipment Procedure Rev02grantNo ratings yet

- ENP-00083 Rev05 Documentation and Record Management Procedure 20140506Document13 pagesENP-00083 Rev05 Documentation and Record Management Procedure 20140506jing zhangNo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- 0 IMS 10 - Document Control ProceduresDocument15 pages0 IMS 10 - Document Control Procedurestusharmitra12No ratings yet

- GS Mains PYQ Compilation 2013-19Document159 pagesGS Mains PYQ Compilation 2013-19Xman ManNo ratings yet

- Foundations of Special and Inclusive Education: A Learning ModuleDocument12 pagesFoundations of Special and Inclusive Education: A Learning ModuleDensiel Jude OrtegaNo ratings yet

- Invoice 961Document1 pageInvoice 961Imran KhanNo ratings yet

- Form I-129F - BRANDON - NATALIADocument13 pagesForm I-129F - BRANDON - NATALIAFelipe AmorosoNo ratings yet

- L1 Support-Windows Server Interview Question & AnswersDocument6 pagesL1 Support-Windows Server Interview Question & AnswersSmile Ever100% (3)

- Scupin and DeCorse Chapter 20Document29 pagesScupin and DeCorse Chapter 20Sana FarshbafiNo ratings yet

- 304 1 ET V1 S1 - File1Document10 pages304 1 ET V1 S1 - File1Frances Gallano Guzman AplanNo ratings yet

- Enrollment DatesDocument28 pagesEnrollment DatesEdsel Ray VallinasNo ratings yet

- Tmc521 Fundamentals of Marriage and Family - Lecture 1Document38 pagesTmc521 Fundamentals of Marriage and Family - Lecture 1Christian NwekeNo ratings yet

- Chapter 11 Accounting PrinciplesDocument45 pagesChapter 11 Accounting PrinciplesElaine Dondoyano100% (1)

- Sample OTsDocument5 pagesSample OTsVishnu ArvindNo ratings yet

- 2020 Macquarie University Grading and Credit Point System PDFDocument2 pages2020 Macquarie University Grading and Credit Point System PDFRania RennoNo ratings yet

- Business Finance: Quarter 2 - Module 6: Philosophy and Practices in Personal FinanceDocument2 pagesBusiness Finance: Quarter 2 - Module 6: Philosophy and Practices in Personal FinanceClemente AbinesNo ratings yet

- BPI Lesson 1 - Surveys & Investigation PDFDocument60 pagesBPI Lesson 1 - Surveys & Investigation PDFMayNo ratings yet

- Mercado v. Nambi FLORESDocument2 pagesMercado v. Nambi FLORESCarlos JamesNo ratings yet

- Solution and AnswerDocument4 pagesSolution and AnswerMicaela EncinasNo ratings yet

- A2 UNIT 2 Extra Grammar Practice RevisionDocument1 pageA2 UNIT 2 Extra Grammar Practice RevisionCarolinaNo ratings yet

- Completed Jen and Larry's Mini Case Study Working Papers Fall 2014Document10 pagesCompleted Jen and Larry's Mini Case Study Working Papers Fall 2014ZachLoving100% (1)

- Running Head: Problem Set # 2Document4 pagesRunning Head: Problem Set # 2aksNo ratings yet

- BibliographyDocument6 pagesBibliographyJpWeimNo ratings yet

- Wallem Philippines Shipping vs. SR Farms (2010)Document1 pageWallem Philippines Shipping vs. SR Farms (2010)Teff QuibodNo ratings yet

- Supplier Claim Flow ChecklistDocument1 pageSupplier Claim Flow ChecklistChris GloverNo ratings yet

- CPFContributionRatesTable 1jan2022Document5 pagesCPFContributionRatesTable 1jan2022ysam90No ratings yet

- The Lightworker's HandbookDocument58 pagesThe Lightworker's HandbookEvgeniq Marcenkova100% (9)

- Philo Week 8Document4 pagesPhilo Week 8Emiel Magante100% (1)

- Day1 - Session4 - Water Supply and Sanitation Under AMRUTDocument30 pagesDay1 - Session4 - Water Supply and Sanitation Under AMRUTViral PatelNo ratings yet

- Ciplaqcil Qcil ProfileDocument8 pagesCiplaqcil Qcil ProfileJohn R. MungeNo ratings yet

- DramaturgyDocument4 pagesDramaturgyThirumalaiappan MuthukumaraswamyNo ratings yet

- The Renaissance PeriodDocument8 pagesThe Renaissance PeriodAmik Ramirez TagsNo ratings yet

- Unit 7:: Intellectual PropertyDocument52 pagesUnit 7:: Intellectual Propertyمحمد فائزNo ratings yet