Professional Documents

Culture Documents

Wayang Windu Unit-2 CDM Program

Uploaded by

Rizki GeovaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wayang Windu Unit-2 CDM Program

Uploaded by

Rizki GeovaniCopyright:

Available Formats

WAYANG WINDU UNIT-2 CDM PROGRAM

Hariyanto.srl@starenergy.co.id

Star Energy Geothermal (Wayang Windu) Ltd.

The 2019 IERE - PLN Bali Workshop, March 2019

Abstract

This paper describes Wayang Windu team experience to manage CDM monitoring process in line with the requirement of Operational Performance

field personnel and validation purpose. Clean Development Mechanism (CDM) is one of the incentive for renewable

Generation (GWh) Availabilty Factor (%)

energy developer including geothermal energy. CDM process is strictly following standard rule starting from CDM

registration process by applicant, verification and validation process by auditor as required till process of approval as CDM 2,500

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

99.9

99.8

99.7

99.6

%

99.0

98.8

97.1

97.1

96.3

project. Wayang Windu (WW) Unit-1 is not registered as CDM project because WW Unit-1 was developed and

96.1

95.5

95.0

100

1,921 1,878 1,870 1,880 1,924 1,907 1,895

2,000 1,846

commissioned in 2000 before CDM program existed. With the opportunity of CDM incentive, WW Unit-2 was registered as 1,814

90

CDM project. 1,500

80

1,111

961

976

964

960

948

The process was started from WW Phase 2 Geothermal Power Construction Project which was the construction project of

891

958

953

932

910 921 937 922 938 956

3

1,000 888 856

65.4

65.0

70

117 MW geothermal power station. This project constructed and installed WW Power Plant Unit-2 as additional new unit

961

952

948

943

938

937

935

932

923

922

921

920

917

913

910

547

888

856

507

added to an existing grid started in 2007 and commissioned in 2009. This project installed steam gathering system from 500

564

60

507

various well pads which had interface connection with Unit-1 steam supply so both units are possible to be operated by

using other wells units. With this condition, selected position of metering system is really essential to verify the accurate 0

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

50

2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

data for CDM verification purpose. Total Net Gen WW1 (GWh) Total Net Gen WW2 (GWh) CombineNet (GWh) Availability Factor WW1 Availability Factor WW2

Note: Operational record in 2015 was affected by landslide incident

WW CDM project development process involved field personnel from the beginning phase of CDM project registration. The

team was consisting of multi discipline team which should consistently follow the process and put high commitment to

support WW Unit-2 validation process during verification by UNFCCC official parties. Since 2 December 2010, WW Unit-2

had been certified for five times and achieved 2,933,000 TCO2e, and in status awaiting issuance request periode 1 CDM Process

January 2015 – 1 December 2017 with Certified Emission Reduction (CER) estimation 1,678,445 TCO2e. Currently,

renewal CDM credit for 2 Dec 2017 until 1 Dec 2024 is on progress.

SE & SCB agreed to develop unit-2 as CDM project, 6th Nov 2008

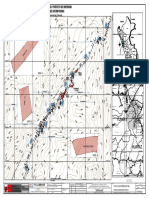

Wayang Windu Geothermal Power Plant January 2009, PDD submitted to UNFCCC

5th December 2008

8th May2009

Completeness check 4th May 2010

Request for registration 05 May - 01 July 2010, Registered

on 2nd December 2010

Star Energy owns and operates one of the largest geothermal power plants in Indonesia, located in West Java

Star Energy has sole rights to explore and develop geothermal resources in the Wayang Windu contract area as

Pertamina Geothermal Energy’s contractor

Currently SEGWWL plant has a gross installed generation capacity of 227MW, and we have the exclusive right to sell

up to 400MW of geothermal energy generated from the contract area to PLN on a “take-or-pay” basis

We have 26 production wells and 4 injection wells Organization

Current Geothermal Assets Managed by Star Energy Group

Wayang Windu (100%)

PRODUCTION

Stage: Production Hamiding

EXPLORATION

Capacity: 227 MW Stage: Exploration

Unit 1: June 2000 (110 MW) Resource Size: 220 - 400 MW

3rd Party

Unit 2: March 2009 (117 MW)

Sekincau Selatan

EXPLORATION

Stage: Exploration What Star Energy does now ?

Resource Size: 300 - 500 MW

Darajat (95%) 1. Monitoring & Reporting

PRODUCTION

Salak (100%)

Production data collecting, archiving, analysing

PRODUCTION

Stage: Production

Stage: Production

Capacity: 377 MW

Capacity: 271 MW

Flow measurement verification, calibration and personil certification

Unit 1: 1994 (55 MW)

Unit 1/2: 1994 (120 MW)

Unit 2: 2000 (95 MW)

Laboratory analysis

Unit 3/4/5/6: 1997 (257 MW)

Unit 3: 2007 (121 MW) 2. Verification and Re-certification

Star Energy manages and operates geothermal power plant and steam field with gross capacity of 875 MW :

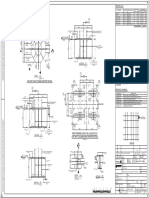

Wayang Windu geothermal power plant with gross installed generation capacity of 227 MW. Monitoring Process

Salak geothermal power plant with gross installed generation capacity of 197MW and steam sales capacity of

180MW

Darajat geothermal power plant with gross installed generation capacity of 216MW and steam sales capacity of Point of Monitoring :

55MW 1. Steam Production (MSO : Main Steam Orifice), include

Steamfield Above 3

NCG (CH4 & CO2)

Star Energy has right to match the best tender offer for the license in Hamiding concession and Sekincau Selatan Ground System

concession to develop the resource area. 2. Brine Reinjection (Msb)

4

3. Steam to Turbine (Msv : Main Steam Ventury)

4. Electricity Generation Net (EGv)

5. CO2 emissions from fossil fuel Combustion (Genset diesel

5

Where Star Energy Stands Now & Fire pump)

1

Ranked 3rd as World’s Largest Geothermal Operator 2 CER = Project Emission – Baseline Emission – Leakage

Ranked 1st as the Biggest Geothermal Operator in Indonesia 1,400

Wells

1,200 1,159 Wells

1,000 Wells

875 1,031

900

1,000

800 875 Project Emission

Capacity (MW)

839

700

800

Steam Produce MSO or MSV Which is higher + Brine produce

Capacity (MW)

577 725

600

500 600

400

Baseline Emission

400

300

Project Emission * NCG content (CH4, CO2) – (Combustion fuel EDG & Fire pump * Carbon content)

200 120 110 200

100

Leakage

0 0

Star Energy Pertamina Geodipa Sarulla

Energy

Development

ENEL Green Power Star Energy Comision Federal de Calpine Corporation

Electricadad Steam leakage on system

Geothermal Consortium Corporation

Energy

Source: Pertamina & EBTKE 2017 Source: World Energy Council Publication: World Energy Resources 2016

Certified Emission Reduction (CER) – Credit Sales

Certified Emissions Reduction Up to 2018

2,343,324

Production Process

2,500,000

1,475,207

2,000,000

T CO2e

Power Plant

1,500,000

1. Steam and hot water are extracted from production wells

Steamfield Above 1,000,000 Issued

435,370

435,370

393,462

393,462

372,178

372,178

2. Water is separated from the steam in the separator and

354,240

Ground System

323,167

323,167

Sold

2 then injected back into the reservoir through injection wells 500,000

To be issued

4

3. The steam is further cleaned in the scrubber, then goes 0

12/2/2010 - 05/23/2011 - 11/01/2011 - 06/01/2012 - 01/01/2013 - 01/01/2015 -

direct to the turbine 05/22/2011 10/31/2011 05/31/2012 12/31/2012 12/31/2014 06/30/2018

Period 2010 - 2018

4. The steam turns the turbine which turns the generator to

5 produce electricity which is then sold directly to PLN

3

5. The steam through the turbine is condensed into water,

1 then cooled in the cooling tower and then reinjected back Refferences

to the reservoir • https://unfccc.int/kyoto_protocol/mechanisms/clean_development_mechanism/items/2718.php

Wells • http://cdm.unfccc.int/Projects/DB/TUEV-SUED1260194062.48/view

Wells Wells

• http://en.wikipedia.org/wiki/Carbon_credit

www.postersession.com

www.postersession.com

You might also like

- CDU Overhead Multiple CorrosionDocument7 pagesCDU Overhead Multiple Corrosionrvkumar61100% (1)

- Apple's CSAM Detection MechanismDocument12 pagesApple's CSAM Detection MechanismMike WuertheleNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Java Mind Maps PDFDocument1 pageJava Mind Maps PDFgceramesh100% (1)

- ICCT Annual Report, 2022Document35 pagesICCT Annual Report, 2022D'Errah ScottNo ratings yet

- Planning For EV Charging Infrastructure A Toolkit June 2013Document38 pagesPlanning For EV Charging Infrastructure A Toolkit June 2013Melecio Jesus Leano Jr.No ratings yet

- Sustainable Development Project Class 10th PDFDocument14 pagesSustainable Development Project Class 10th PDFSD P90% (21)

- LCCF Book Version 2 2017Document116 pagesLCCF Book Version 2 2017IkhwanNo ratings yet

- Notes:: CheniereDocument1 pageNotes:: CheniereMonse LNo ratings yet

- Statement of Purpose CSDocument2 pagesStatement of Purpose CSashwin100% (1)

- EXERSRCISEbtugasDocument4 pagesEXERSRCISEbtugasRizki GeovaniNo ratings yet

- Digitalization in Shipping in Lieu of Upcoming IMO DCSDocument61 pagesDigitalization in Shipping in Lieu of Upcoming IMO DCSSohan MishraNo ratings yet

- Corona Kavach Insurance BrochureDocument5 pagesCorona Kavach Insurance Brochurekishore2648No ratings yet

- Cardenas Norte battery construction project status reportDocument7 pagesCardenas Norte battery construction project status reportPorfirio Ruiz GascaNo ratings yet

- Crepes and Waffles Corporate Strategy AnalysisDocument1 pageCrepes and Waffles Corporate Strategy AnalysisOladayo AyodejiNo ratings yet

- Dhemaji District Income CertificateDocument1 pageDhemaji District Income CertificateBoishal Bikash BaruahNo ratings yet

- Thesis BoardsDocument1 pageThesis BoardsJames ConleyNo ratings yet

- Dhemaji: Dhemaji District (Assam E-District Project)Document1 pageDhemaji: Dhemaji District (Assam E-District Project)Boishal Bikash BaruahNo ratings yet

- Chi Ti: Produced by An Autodesk Educational ProductDocument1 pageChi Ti: Produced by An Autodesk Educational ProductNam TranNo ratings yet

- Java Technology Concept MapDocument1 pageJava Technology Concept Mapkostas.karis100% (2)

- Cable Track Sizing and Locations PDFDocument1 pageCable Track Sizing and Locations PDFiqbal husseinNo ratings yet

- Layout Current Drg-ModelDocument1 pageLayout Current Drg-ModelMuzzammil ShaikhNo ratings yet

- PG 5 A1 - PmaDocument1 pagePG 5 A1 - Pmamoreno chinchayNo ratings yet

- Sittwe Township - Rakhine State: Myanmar Information Management UnitDocument1 pageSittwe Township - Rakhine State: Myanmar Information Management UnitAung MwinNo ratings yet

- Part III 2019Document72 pagesPart III 2019yilunzhangNo ratings yet

- WA Deming 20170308 TM GeoDocument1 pageWA Deming 20170308 TM Geoidentitytheft23No ratings yet

- Federal Child Welfare Grant Program Matrix TableDocument2 pagesFederal Child Welfare Grant Program Matrix TableBeverly TranNo ratings yet

- Split RingDocument4 pagesSplit RingIlaiarajaNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNo ratings yet

- Sector2 PT PanchpakhadiDocument1 pageSector2 PT PanchpakhadiAksh RdNo ratings yet

- Area M Mass KG Grade Length Section QTY Item: W801 UC152 152 30 S355JR 0.36 1 12.1 400Document1 pageArea M Mass KG Grade Length Section QTY Item: W801 UC152 152 30 S355JR 0.36 1 12.1 400RITONo ratings yet

- 60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendDocument1 page60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendSohail SurveNo ratings yet

- Online Insurance Sales WorkflowDocument1 pageOnline Insurance Sales WorkflowFaisal AzizNo ratings yet

- Roberts - arvo10.StKitts - raceSpecificMRA Vs QRADocument1 pageRoberts - arvo10.StKitts - raceSpecificMRA Vs QRAPaul H ArtesNo ratings yet

- Agamoni: Dhubri District (Assam E-District Project)Document1 pageAgamoni: Dhubri District (Assam E-District Project)Abu Sayed MandalNo ratings yet

- Traffic Assignment Algorithm ComparisonDocument36 pagesTraffic Assignment Algorithm ComparisonSiervo Andrés Aguirre BenavidesNo ratings yet

- GIIRS Company Report YARETANOL ProgramDocument6 pagesGIIRS Company Report YARETANOL ProgramIvaneth Silva PernaletteNo ratings yet

- 2021 RoadmapDocument2 pages2021 RoadmapSathia ShekarNo ratings yet

- Os00002 e Bw31.za3.um02&ez18445Document1 pageOs00002 e Bw31.za3.um02&ez18445Gopalakrishnan DhandapaniNo ratings yet

- Inspection - PC SlopeDocument1 pageInspection - PC SlopeAbdelrhman M. El SaftyNo ratings yet

- Edwards Aquifer SystemDocument1 pageEdwards Aquifer SystemIvan HerreraNo ratings yet

- Produced by An Autodesk Student Version: Universidad Privada Del NorteDocument1 pageProduced by An Autodesk Student Version: Universidad Privada Del NorteNuria CandelaNo ratings yet

- LMCPL-P2023-02-COS-43 - Working Platform - Service Rack Zone 2Document8 pagesLMCPL-P2023-02-COS-43 - Working Platform - Service Rack Zone 2Ali md YounusNo ratings yet

- I 0417 - Muelle Yemaya (Noga) - Es-01Document1 pageI 0417 - Muelle Yemaya (Noga) - Es-01Ariana ZamoraNo ratings yet

- Carnegie: State Vehicular Recreation AreaDocument1 pageCarnegie: State Vehicular Recreation AreabradalbiNo ratings yet

- Waterbox 900Document28 pagesWaterbox 900cem jakartaNo ratings yet

- @COA 2024 - LIA ALIYANIDocument54 pages@COA 2024 - LIA ALIYANISuryadi YadiNo ratings yet

- STATEMENT OF APPROPRIATIONS FOR PUBLIC WORKS DEPTDocument32 pagesSTATEMENT OF APPROPRIATIONS FOR PUBLIC WORKS DEPTKenneth Cyrus OlivarNo ratings yet

- Value TreeDocument1 pageValue TreeMaisaa NajiNo ratings yet

- KFL - Hydrant - 100 PSIDocument11 pagesKFL - Hydrant - 100 PSITanay KarmokarNo ratings yet

- F-212 Ad08 PDFDocument13 pagesF-212 Ad08 PDFVictor JimenezNo ratings yet

- Ronkonkoma Go201Document2 pagesRonkonkoma Go201Sylvia SmithNo ratings yet

- Creating HTML Reports in PowershellDocument1 pageCreating HTML Reports in PowershellAjay Kumar DwivediNo ratings yet

- Vendor & Customer Setup: Login To Opsdog To Purchase The Full Workflow Template (Available in PDF, VisioDocument1 pageVendor & Customer Setup: Login To Opsdog To Purchase The Full Workflow Template (Available in PDF, VisioLIGAYA SILVESTRENo ratings yet

- Reports-Sector Studies-Somaliland - Sector Functional Assessment - FINAL TECHNICAL MASTER - Geopolicity - April 19 2012 - Reduced SizeDocument189 pagesReports-Sector Studies-Somaliland - Sector Functional Assessment - FINAL TECHNICAL MASTER - Geopolicity - April 19 2012 - Reduced SizeMubarak Maal100% (1)

- D9T Electrical SystemDocument4 pagesD9T Electrical SystemPablo PorrasNo ratings yet

- CH 1 Text SolutionsDocument14 pagesCH 1 Text SolutionsElvis wuNo ratings yet

- Perlove Medical Cataloge - NewDocument18 pagesPerlove Medical Cataloge - NewEngr kunleNo ratings yet

- CGK063 BBCS Mechanical BinderDocument110 pagesCGK063 BBCS Mechanical BinderBack to SumateraNo ratings yet

- ReportDocument1 pageReportskyswiftapartmentsNo ratings yet

- QSC-PL1.8 Pwramp XtalDocument12 pagesQSC-PL1.8 Pwramp XtalAkhmad GuiNo ratings yet

- StarHealthAssureInsurancePolicy BrochureDocument13 pagesStarHealthAssureInsurancePolicy Brochurepradosh002No ratings yet

- Insurance BillDocument13 pagesInsurance BillSureshKarnanNo ratings yet

- Project Schedule (Full)Document2 pagesProject Schedule (Full)atunacNo ratings yet

- FLR A9sn Ep 3810 PD Is 5605 03Document1 pageFLR A9sn Ep 3810 PD Is 5605 03Brandon C LoyolaNo ratings yet

- Wayang Windu Geothermal Power Station - Reinstatement of Landslide Damaged Geothermal Fluid Supply PipelinesDocument8 pagesWayang Windu Geothermal Power Station - Reinstatement of Landslide Damaged Geothermal Fluid Supply PipelinesRizki GeovaniNo ratings yet

- PRD-3.0-PGD Managing Power GenerationDocument18 pagesPRD-3.0-PGD Managing Power GenerationRizki GeovaniNo ratings yet

- Surat LamaranDocument1 pageSurat LamaranRizki GeovaniNo ratings yet

- GeomorphologyDocument21 pagesGeomorphologyRizki GeovaniNo ratings yet

- WawanDocument7 pagesWawanRizki GeovaniNo ratings yet

- 19 - 01 - 18 Efektivitas Serat Jerami English JournalDocument47 pages19 - 01 - 18 Efektivitas Serat Jerami English JournalRizki GeovaniNo ratings yet

- My NounDocument24 pagesMy NounReski0% (1)

- Relevance of Social, Economic, and Environmental Impacts On Residents' Satisfaction With The Public Administration of TourismDocument15 pagesRelevance of Social, Economic, and Environmental Impacts On Residents' Satisfaction With The Public Administration of TourismDeer ViianNo ratings yet

- LUKOIL's HSE Policy for 21st CenturyDocument1 pageLUKOIL's HSE Policy for 21st CenturyHedi Ben MohamedNo ratings yet

- An Overview of Porsche's Supply Chain & OperationsDocument16 pagesAn Overview of Porsche's Supply Chain & OperationsMaria LoghinNo ratings yet

- FulltextDocument18 pagesFulltexttu260122No ratings yet

- The Potential of E-Fuels To Decarbonise Ships & Aircraft (OECD-ITF - 2023)Document56 pagesThe Potential of E-Fuels To Decarbonise Ships & Aircraft (OECD-ITF - 2023)Ioannis BoukisNo ratings yet

- Our Path To Net Zero Real EstateDocument10 pagesOur Path To Net Zero Real EstateDanielle Yanwen JiangNo ratings yet

- 2016 Full NAMA Concept Jeepney NAMADocument116 pages2016 Full NAMA Concept Jeepney NAMAP MarieNo ratings yet

- EIA of Versova-Bandra Sea Link ProjectDocument30 pagesEIA of Versova-Bandra Sea Link ProjectSaakshi KariaNo ratings yet

- practice-unit-5Document6 pagespractice-unit-5Vương BíchNo ratings yet

- AssignmentDocument12 pagesAssignmentMd. Fahim Shahriar MozumderNo ratings yet

- Environmental Law NotesDocument11 pagesEnvironmental Law NotesAmita SinwarNo ratings yet

- Carbon Pricing MethodologyDocument9 pagesCarbon Pricing MethodologydjaaaamNo ratings yet

- Call Fiche - Life 2023 Cet - enDocument80 pagesCall Fiche - Life 2023 Cet - enmmsymeonidouNo ratings yet

- Make 10 Content Ideas For Blog On Solar Panels and Inverter TechnologyDocument2 pagesMake 10 Content Ideas For Blog On Solar Panels and Inverter TechnologyHajra BatoolNo ratings yet

- The Role of Carbon Capture and Storage in The Energy TransitionDocument23 pagesThe Role of Carbon Capture and Storage in The Energy TransitionEsperanza MorenoNo ratings yet

- How Can India Scale Lithium Ion Battery Manufacturing Sector and Supply ChainDocument36 pagesHow Can India Scale Lithium Ion Battery Manufacturing Sector and Supply ChainJack ReacherNo ratings yet

- Environmental Issues LessonDocument108 pagesEnvironmental Issues LessonMich KidNo ratings yet

- Pilot-Scale Hydrogen Energy Utilization System Demonstration: A Commercial Building Case Study On On-Site Green Hydrogen Production and UseDocument10 pagesPilot-Scale Hydrogen Energy Utilization System Demonstration: A Commercial Building Case Study On On-Site Green Hydrogen Production and Usedidavaran tejaratNo ratings yet

- Renewables Atlas FinalDocument128 pagesRenewables Atlas FinalOrtegaYONo ratings yet

- Negative Effects of Excessive Meat Eating-ARGUMENTATIVE ESSAYDocument2 pagesNegative Effects of Excessive Meat Eating-ARGUMENTATIVE ESSAYJune PinedaNo ratings yet

- The Harmonized National Research and Development (R&D) AgendaDocument32 pagesThe Harmonized National Research and Development (R&D) AgendaPrince SanjiNo ratings yet

- XI FABC PA Final DocumentDocument21 pagesXI FABC PA Final DocumentLiju PJNo ratings yet

- BC Hydro - North Montney Region ElectrificationDocument2 pagesBC Hydro - North Montney Region ElectrificationAlaskaHighwayNewsNo ratings yet