Professional Documents

Culture Documents

Effect of Geometrical Parameters On The Coefficien

Uploaded by

Mohammed AbdelmoumeneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Geometrical Parameters On The Coefficien

Uploaded by

Mohammed AbdelmoumeneCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/323362529

Effect of Geometrical Parameters on the Coefficient of Performance of the

Ranque-Hilsch Vortex Tube

Article in Open Access Library Journal · January 2018

DOI: 10.4236/oalib.1104347

CITATIONS READS

6 489

2 authors:

Seifeldin Tarek Abdelghany Hamdy A. Kandil

The German University in Cairo The German University in Cairo (GUC)

10 PUBLICATIONS 67 CITATIONS 62 PUBLICATIONS 1,435 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Theory of Operation of the RHVT View project

Theory of Operation of the RHVT View project

All content following this page was uploaded by Seifeldin Tarek Abdelghany on 24 February 2018.

The user has requested enhancement of the downloaded file.

Open Access Library Journal

2018, Volume 5, e4347

ISSN Online: 2333-9721

ISSN Print: 2333-9705

Effect of Geometrical Parameters on the

Coefficient of Performance of the

Ranque-Hilsch Vortex Tube

Seif T. Abdelghany1, Hamdy A. Kandil2

Mechatronics Engineering Department, German University in Cairo, Cairo, Egypt

1

Mechanical Engineering Department, Faculty of Engineering, Alexandria University, Alexandria, Egypt

2

How to cite this paper: Abdelghany, S.T. Abstract

and Kandil, H.A. (2018) Effect of Geometrical

Parameters on the Coefficient of Performance The Ranque-Hilsch vortex tube is a simple device with no moving parts and

of the Ranque-Hilsch Vortex Tube. Open no mechanical operations. This tube separates the inlet air into two distinctive

Access Library Journal, 5: e4347. regions; an outward high temperature region and an inner low-temperature

https://doi.org/10.4236/oalib.1104347

one. A computational study of the vortex tube is presented in this article using

Received: January 17, 2018 the ANSYS Fluent® software whose results showed good agreement with the

Accepted: February 20, 2018 experimental measurements. The effects of different geometrical parameters

Published: February 23, 2018 such as the tube length to diameter ratio and the cold orifice size on the coef-

ficient of performance of the tube were investigated. The results showed that

Copyright © 2018 by authors and Open

Access Library Inc.

the coefficient of performance (COP) of the tube is highly affected by the tube

This work is licensed under the Creative length to diameter ratio ( L D ), and this effect varies when operating at dif-

Commons Attribution International ferent cold mass fractions where the maximum coefficient of performance

License (CC BY 4.0). occur at cold mass fraction of 0.64. The results also showed that the coefficient

http://creativecommons.org/licenses/by/4.0/

of performance of the tube is also affected by the cold orifice to tube diameter

Open Access

ratio ( d c D ) and that the maximum (COP) at any ( d c D ) ratio occurs also

at a cold mass fraction of 0.64.

Subject Areas

Mechanical Engineering

Keywords

Ranque-Hilsch Vortex Tube (RHVT), Cold Orifice, Maxwell’s Demon,

Refrigeration, Computational Fluid Dynamics (CFD), ANSYS Fluent

1. Introduction

The vortex tube (VT) is a device with a simple geometry without moving me-

DOI: 10.4236/oalib.1104347 Feb. 23, 2018 1 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

chanical parts [1] [2] [3] [4]. It enables the separation of hot and cold air vortices

from the inlet air, as it is supplied with compressed air that flows tangentially

through the inlet nozzles [5] [6] [7]. The Vortex tube was first discovered in

1933 by Georges J. Ranque [8], and in 1947 Rudolf Hilsch improved and mod-

ified the design of Ranque [9]. The vortex tube consists of many parts [10] [11]

including one or more inlet nozzles, a vortex chamber, a control valve that is lo-

cated at the hot outlet, a cold orifice and a working tube [12]. When compressed

air is injected tangentially through the inlet nozzles into the vortex chamber a

strong rotational flow (vortex) is formed at the periphery of the tube wall [13].

The vortex propagates till the end of the tube where some air leaves the tube via

the hot outlet. However, adjusting the control valve at the hot outlet forces the

rest of the air to reverse its direction and exit from the cold outlet along the cen-

terline of the tube. It is noted that two vortices occur inside the tube, one at the

periphery of the tube which exits at the hot outlet at a temperature much higher

than the inlet temperature and the other one at the core of the tube with oppo-

site flow direction which exits at the cold orifice with a temperature much lower

than the inlet temperature.

The VT is used in many applications such as cooling of airborne electronic

components, cooling of gas samples, and cooling of soldered parts including

spot welding and ultrasonic welding. It is also used in the separation of air into

nitrogen and oxygen rich fluid stream [14] [15]. The VT has many advantages

[16] [17] [18] [19] because of its low cost, light weight, reliability, compactness

and free maintenance as it has no moving parts. It has an adjustable temperature

range and cools without using any refrigerant or electricity.

The results presented in this paper show that the COP of the VT can be en-

hanced by adjusting the cold orifice to tube diameter ratio ( d c D ) and the

length to the tube diameter ratio while depending on the adjusted cold mass

fraction. This opens a new door to research on enhancing the performance of

the VT based on the requirements of the application.

2. Energy Separation inside the RHVT

An energy separation occurs in the vortex tube between the cold and hot streams

which causes the temperature changes between the inlet and exit streams. Many

researchers suggested various theories to explain the energy separation inside the

vortex tube. For example, Ahlborn [20] [21] suggested that the RHVT is a refrige-

ration device that can be modeled and analyzed as a classic thermodynamic refri-

geration cycle with significant temperature splitting, refrigerant and coolant loops,

expansion and compression loops and heat exchangers. A secondary circulation is

formed in the tube and acts as a refrigerant to transfer the energy from the cold

stream to the hot stream. Some researchers [1] [22] [23] [24] reported that the

energy separation inside the RHVT is due to work transfer caused by a torque

produced by viscous shear between inner and outer stream. Kurosaka [25] at-

tempted to explain the energy separation inside the VT by acoustic streaming. He

DOI: 10.4236/oalib.1104347 2 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

proposed that the energy separation is due to damping of acoustic streaming.

The effect of friction and turbulence in the VT has always been a major con-

cern of many researchers and was considered by some researchers as the reason

for energy separation. For example, using a simple vortex tube model with CFX

software and κ-ε turbulence model, Kazantseva et al. [26] attributed the energy

separation inside the VT to the energy and gas dynamic interaction of vortices

inside the VT. Behara et al. [27] modeled the RHVT using STAR-CD software

and concluded that the energy separation inside the VT exists due to the shear

work and heat transfer between the hot and cold streams. Bovand et al. [28] stu-

died a 3D model of the VT and concluded that a large portion of the energy

transfer inside the RHVT is due to the tangential viscous shear. Aljuwayehl et al.

[1] explained the operation inside the VT by the existence of viscous shear acting

on a control rotating surface separating the cold and hot flow regions. A torque

is produced which causes work transfer between the cold and hot flows. El May

et al. [29] reported the formation of a great amount of tangential shear stress of

the flow near the wall of the tube, and proposed that the tangential shear work can

be considered the most important mechanism of energy separation in the tube.

Abdelghany and Kandil [30] presented an operational theory for the vortex tube

such the mechanism inside the tube is in analogy to the gas refrigeration cycle (re-

versed Brayton cycle) where the inner vortex acts as a turbine and that outer vor-

tex acts as a compressor. They [30] concluded that a power transfer exist between

bother vortices in which the inner vortex loses energy and the outer vortex gains

energy based on the transfer of angular momentum between both vortices.

Some researchers noted the existence of secondary circulations in the vortex

tube. They attributed the energy separation to the secondary circulations. For

example, Behara et al. [31] confirmed the existence of secondary circulations in-

side the RHVT at small cold orifice to tube diameter ratio ( d c D ) and that such

circulations become weak as the d c D ratio increases and they disappear at

d c D ratios higher than 0.583. They used a CFD model of the RHVT and

showed that the total energy transfer was reduced by 21% due to the existence of

secondary circulation. Therefore, they concluded that it can be a performance

degrading mechanism. Such conclusion was confirmed by Farouk [32] [33] us-

ing a large eddy simulation (LES) technique on a CFD model of the VT which

showed that the secondary circulation resulted in enhancing the mixing between

cold and hot flow which increased the temperature of air exiting at cold outlet.

Also, Bovand et al. [28] confirmed that the secondary circulations are perfor-

mance degrading mechanism. Recently, Kandil and Abdelghany [34] investi-

gated the existence of secondary circulations in the vortex tube at different cold

orifice to tube diameter ratio ( d c D ) cases. It was confirmed [34] that operating

at high cold mass fraction doesn’t have any effect on the formation of secondary

circulations. Nevertheless, when operating at low d c D ratio secondary circu-

lations are formed near the cold outlet but only at low cold mass fraction. They

concluded that the secondary circulations have almost no effect in degrading the

DOI: 10.4236/oalib.1104347 3 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

performance of the vortex tube.

3. Performance Optimization of the RHVT

The performance of the RHVT is affected by geometrical properties such as the

length to tube diameter ratio ( L D ) and cold orifice to tube diameter ratio

( d c D ). The length to tube diameter ratio L D is a very important parameter

that attracted the interest of many researches s such as [1] [2] [35] [36] [37] [38]

[39]. For example, Bramo and Pourmahmoud [2] [35] [37] conducted a study on

the L D ratio effect on the performance of the VT at cold mass fraction of 0.3

(at the maximum cooling effect) and concluded that at L D ratio of 9.3 the VT

has the highest total temperature change. Almost all the other L D ratios have

the same performance and that the high performance at L D ratio of 9.3 is due

to the stagnation point along the centerline of the tube. Patel and Bartaria [38]

showed that as L D increases ΔTtotal increases to reach its maximum value at

L D ratio of 30 after which the performance of the VT decreases. They re-

ported that the performance of the tube in terms of maximum temperature dif-

ference between the hot and cold outlets, ∆T = Th − Tc , increases with increas-

ing L D ratio up to a critical value after which the performance degrades. Ay-

din and Baki [40] confirmed that there is an optimum value for the L D ratio

for the vortex tube. Maurya and Bhavsar [36] concluded that as the L D ratio

increases ΔTtotal increases to reach an asymptotic state, and to obtain the maxi-

mum energy separation effect the L D ratio should be greater than 10. Alju-

wayhel et al. [1] studied the L D ratio effect on the performance at cold mass

fraction of 0.3, near the maximum refrigeration point, and reported that as the

length increases the performance of the tube increases up to a certain length of

tube after which the effect of the L D ratio on the performance becomes neg-

ligible. Their results showed that there is a critical length of the VT over which

the majority of energy transfer takes place and exceeding this length doesn’t af-

fect the energy separation.

Kandil and Abdelghany [34] studied the effect of ( L D ) ratio on the performance

of the vortex tube at different cold mass fractions of 0.34, 0.4, 0.428, 0.5 and 0.72.

The effects of varying d c D on the performance of the VT was investigated

by Maurya and Bhavsar [36] by fixing the length and diameter of the tube at 120

mm and 10 mm, respectively, and changing the diameter of the cold orifice. The

best performance was achieved at the lowest cold temperature ( Tc ), which is the

temperature of air exiting at the cold outlet The cold temperature, Tc , decreased

with increasing d c till a critical diameter where the d c D = 0.583 then Tc

increased significantly. They suggested that the reduction of pressure gradient

due to increasing the cold orifice diameter ( d c ) is the reason behind the rise of

the cold exit temperature after reaching the critical d c . Andalibi et al. [41]

showed that maximum temperature separation occurs at d c D ratio of 0.45

and that operating at higher ratios will cause backflow at the cold outlet which

will degrade the tube’s performance. Nimbalkar and Muller [3] studied the effect

DOI: 10.4236/oalib.1104347 4 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

of the d c D ratio on the energy separation inside the tube and showed that

there is an optimum cold orifice diameter and operating at a lower diameter will

result in mixing the cold stream with the hot one and operating at a higher di-

ameter will result in mixing the hot stream with the cold one.

Recently, Kandil and Abdelghany [34] studied the effect of the d c D ratio

on the performance of vortex tube in terms of the cold temperature drop and the

hot temperature rise. Their results [34] showed that all the d c D ratio cases

exhibit similar behavior where the cold temperature drop increases when de-

creasing the cold mass fraction until a certain value of the cold mass fraction af-

ter which the cold temperature drop decreases significantly. They explained the

reason behind the decrease of the cold temperature drop after certain cold mass

fraction by the occurrence of back flow at the cold outlet

The results presented in this paper support and build on the research of Kan-

dil and Abdelghany [34] where the changes in the geometrical parameters of the

VT can be adjusted to enhance one parameter which is the COP.

4. Numerical Model

An Axisymmetric model of the RHVT was designed and simulated using ANSYS

Fluent® software. The model was validated using the experimental measure-

ments of Skye et al. [42]. ANSYS Fluent software solves the following compress-

ible turbulent flow conservation of mass, momentum and energy and state equa-

tion [43] (ANSYS Fluent Theory Guide):

Continuity equation in tensor notation:

∂ρ ∂

+

∂t ∂x j

( )

ρ u j + ρ ′u′j =0, j =1, 2,3 (1)

Momentum equations in tensor notations (all three components):

∂ ∂

∂t

(ρ ui + ρ ′ui′ + )∂x j

(

ρ ui u j + ui ρ ′u ′j )

(2)

∂p ∂

= − +

∂xi ∂x j

(

τ ij − u j ρ ′ui′ − ρ ui′u ′j − ρ ′ui′u ′j )

Where

∂u ∂u j 2 ∂u

τ ij= µ i

+ − δ ij k (3)

∂x j ∂xi 3 ∂xk

Energy Equation:

∂ ∂ ∂T

∂t

(

ρ H + ρ ′H ′ + ) ρ u j H + ρ u ′j H ′ + ρ ′u ′j H + ρ ′u ′j H ′ + u j ρ ′H ′ − k i

∂x j ∂x j

∂ρ ∂ 2 ∂u ∂u j ∂ui

=+ ui − µδ ij k + µ ui + (4)

∂t ∂x j 3 ∂xk

∂xi ∂x j

2 ∂u ′ ∂u ′j ∂u ′

− µδ ij ui′ k + µ ui′ + ui′ i , i, j , k = 1, 2,3

3 ∂xk ∂xi ∂x j

DOI: 10.4236/oalib.1104347 5 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Equation of State (ideal gas law)

p = ρ RT (5)

where δ ij is the Kronecker delta function ( δ ij = 1 if i = j and δ ij = 0 if

i ≠ j ); τ ij denotes viscous stress tensor; H represents the total enthalpy; T is

the static temperature, p is the pressure, ρ is the density and R is the universal

gas constant at standard conditions.

4.1. Turbulence Model

The results of the CFD model of the RHVT using the κ-ε Turbulence model

showed the best agreement with the experimental results of Skye et al. [42].

Therefore, the κ-ε Turbulence model was selected to simulate the turbulence in-

side the VT in this study.

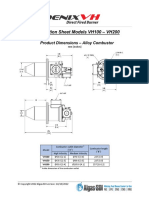

The geometry used in the current CFD model is based on the ExairTM 708

slpm vortex tube used by Skye et al. [42] as shown in Figure 1. The current

model shown in Figure 2 is an axisymmetric model of the tube with matching

geometrical properties to the VT used by Skye et al. [42], where the working tube

length is 106 mm, tube diameter is 11.4 mm and cold exit diameter is 6.2 mm.

The results of the CFD model of the VT became mesh independent when the

number of elements reached 17,000 elements. Due to the complexity and sensi-

tivity of the flow inside the VT, the time step of the solution had to be very small

Figure 1. Schematic of vortex tube used in the experiment [42].

Figure 2. Current CFD Model of the RHVT.

DOI: 10.4236/oalib.1104347 6 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

to allow converge such that the computation time of one simulation ranged from

12 to 48 hours using 8 processors on a 3.64 GHz HP workstation Z800 with 16

GB Ram.

4.2. Boundary Conditions

The experimental data from Skye et al. [42] provided some of the boundary con-

ditions for the inlet nozzles and both outlets while the rest of the data were ac-

quired from different previous CFD models [2] [35] which were implemented

based on the current configuration. The boundary conditions are summarized in

Table 1.

4.3. Numerical Model Validation

The current CFD model was validated by comparing its results with the experi-

mental measurements of Skye et al. [42] using the cold temperature drop ( ΔTc ),

and the hot temperature rise ( ΔTh ) defined as the difference in temperatures

between the outlet hot air and the inlet air.

Figure 3 shows the comparison of the cold temperature drop of the current

model with the experimental measurements and the computational results of

Skye et al. [42].

The results in Figure 3 show that the cold temperature drop increases as the

cold mass fraction ( µc ), which is the ratio between the cold air outlet mass flow

rate divided by the inlet mass flow rate, decreases up to a maximum ΔTc of

40.4 K at a cold mass fraction of 0.34 after which ΔTc decreases to reach a

temperature of 31.7 K at µc of 0.2099. The ΔTc reaches a minimum value of

20 K at µc of 0.87 which shows that as the cold mass fraction increases to a

maximum value the cold temperature drop decreases to its minimum value. It is

noted that the current model has better agreement with the experimental mea-

surements than that of Skye et al. [42] model.

Figure 4 shows the comparison between the hot temperature rise results of

the current study with the experimental measurements and the computational

results of Skye et al. [42].

The results show that the hot temperature rise increases as the cold mass frac-

tion increases to reach a maximum value of 86.7 K at cold mass fraction of 0.87.

Increasing the cold mass fraction further will be impractical due to the very low

Table 1. Boundary conditions used in the current study.

Boundary Condition Type and Parameter of boundary condition

Mass flow inlet boundary condition with mass flow rate of 8.35 g/s,

Inlet nozzles

total temperature of 294.2 K

Cold outlet Pressure outlet

Hot outlet Pressure outlet

Tube wall No slip boundary conditions with adiabatic wall

Tube axis Axisymmetric swirl conditions

DOI: 10.4236/oalib.1104347 7 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Figure 3. Comparison of the cold temperature drop results with the experimental mea-

surements and computational results of Skye et al. [42].

Figure 4. Comparison of the hot temperature rise results with the experimental mea-

surements and computational results of Skye et al. [42].

flow rate of air from the hot outlet. The results show also that at very low cold

mass fraction, the hot temperature rise decreases till it reaches a minimum value

of 11.4 K at cold mass fraction of 0.2099. The results show also that when oper-

ating at cold mass fractions from 0.2 to 0.45 the increase in temperature rise is

slow while as the cold mass fraction increases, the increase in temperature rise

DOI: 10.4236/oalib.1104347 8 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

becomes rapid especially at very high cold mass fractions. The comparison

shows that the current model has better agreement with the experimental mea-

surements than that of Skye et al. [42] model.

5. Performance Optimization of the RHVT

5.1. Effects of the Length to Tube Diameter Ratio on the Total

Coefficient of the Vortex Tube (COPtotal)

The performance of the VT was determined by Kandil and Abdelghany [34] in

terms of total temperature change. When studying the performance of the

RHVT, not only the hot temperature rise or the cold temperature drop should

considered but also the cold mass fraction, the pressure at the inlet and the

pressure at the cold outlet. The VT can be used for cooling as it may be used for

heating therefore a coefficient of performance (COP) for the two operations are

defined.

The coefficient of performance for the RHVT when it is used as a refrigerator

is the cooling power Q c divided by the input power P . The input power for

any refrigeration system is the input to the compressor. But for a RHVT system

a compressed air source is used which makes it difficult to define the input pow-

er. Fulton [44] proposed that the work used to compress the air through a re-

versible isothermal compression process from the exhaust pressure up to the

input pressure the input work is expressed as follows:

p

P = m in RmTin ln in (6)

pc

where

=Q c m c c p (Tin − Tc ) (7)

where Rm is the specific gas constant, pin is the input pressure and pc is the

cold exit pressure

Therefore the COP of the RHVT as a cooler is expressed as

γ µc (Tin − Tc )

COPc = (8)

γ −1 pin

Tin ln

pc

The COP for the RHVT when it is used as a heat pump is defined as the heat-

ing power Q divided by the input power P . The input power used by the

h

system takes the same from as the one used for the cooling RHVT

Therefore, the COP of the RHVT as a heat pump is expressed as

γ (1 − µc )(Th − Tin ) (9)

COPh =

γ −1 p

Tin ln in

pc

The total performance of the RHVT can be determined using the summation

of the COP as a cooler and as a heat pump which is expressed as:

DOI: 10.4236/oalib.1104347 9 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

=

COPtotal COPc + COPh (10)

Figure 5 shows the relationship between the COPtotal and different L D ra-

tios at cold mass fractions of 0.34, 0.4 and 0.43. The results in Figure 5 at cold

mass fraction of 0.34 show that at L D ratio of 2.8 the COPtotal is 0.3309 and

as the L D increases the COPtotal increases to reach a maximum value of

0.3746 at L D of 7.02 with a difference of 0.0437 from the COPtotal at the

lowest L D ratio of 2.8. After which any further increase in the L D ratio

will result in a decrease in the COPtotal and the performance of the VT to reach

a value of 0.3601 at L D ratio of 20.2.

The performance of the VT in terms of COPtotal at different L D ratios was

studied at different values of cold mass fraction. The results in Figure 5 and

Figure 6 at cold mass fraction of 0.4 show that the COPtotal at L D ratios

above 3.5 decreased significantly changing the trend of the curve. Increasing μ to

0.439 decreased the COPtotal even more such that the relation between the

COPtotal and the L D ratio at µ = 0.72 in Figure 6 shows a completely dif-

ferent pattern than that at µ = 0.34 shown in Figure 5 where the lowest L D

ratio of 2.8 has the highest COPtotal of 0.4936. As the L D ratio increases the

COPtotal decreases to reach an asymptotic value of 0.476 at L D ratio of 20.2.

These results show that the COPtotal at different L D ratios is dependent

upon the cold mass fraction, where at low cold mass fraction, as the L D in-

creases the COPtotal increases to reach a maximum value at a critical L D ra-

tio. Any further increase in the L D ratio will result in decreasing the COPtotal .

While as the cold mass fraction increases the difference between the maximum

and minimum COPtotal is reduced from 0.04 at µ = 0.34 to 0.0086 at µ = 0.5 .

Any further increase in the cold mass fraction will change the trend of the curve

Figure 5. Total COP of the VT at different L/D ratios at cold mass fractions of 0.34, 0.4

and 0.43.

DOI: 10.4236/oalib.1104347 10 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Figure 6. Total COP of the VT at different L/D ratios at cold mass fractions of 0.5, 0.64

and 0.72.

between the COPtotal and different L D ratios such that the lowest L D ra-

tio has the highest COPtotal and as the L D ratio increases the COPtotal de-

creases to reach asymptotic value at critical L D ratio.

In Figure 6, it is shown that the COPtotal at a cold mass fraction of 0.64 is

higher than that at any other cold mass fraction. Such results show that the best

COPtotal value will be achieved when operating the tube at a cold mass fraction

of 0.64 at any length to tube diameter ratio.

Such results don’t follow the same pattern of the results of total temperature

of Kandil and Abdelghany [34] where the best performance of the VT in terms

of total temperature is when operating at the maximum possible cold mass frac-

tion. This can be interpreted that the COPtotal depend not only on the cold and

hot temperature changes as the total temperature change but also on the cold

mass fraction and the pressure at the inlet and cold outlet.

5.2. Effects of the Cold Orifice to Tube Diameter Ratio on the

Performance of the Vortex Tube in Terms of COP

The cold orifice diameter is an important parameter that affects the performance

of the VT. Therefore, several trials were done to optimize the performance of the

tube of a diameter of 11.4 mm by varying the cold orifice diameter to pipe di-

ameter ratio, d c D .

5.2.1. Highest COP Cold (COPc)

When studying the performance of the RHVT taking into consideration not just

the highest temperature drop but also the cold mass fraction, the pressure at the

inlet and the pressure at the cold outlet, a new dimensionless parameter had to

be defined to combine the effect of all the previously mentioned parameters on

DOI: 10.4236/oalib.1104347 11 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

the performance of the vortex tube. This dimensionless parameter is the COPc

which was defined by Equation (8). Figure 7 shows the relationship between the

COPc and the cold mass fraction.

It is shown in Figure 7 that all d c D ratio cases follow a similar pattern

whereas the cold mass fraction increases the COPc increases till a critical cold

mass fraction which is almost the same in all cases of value of 0.64 after which

the COPc decreases with any further increase in cold mass fraction. The results

show that the d c D ratio of 0.6316 has the highest COPc of 0.319 at a cold

mass fraction of 0.64.

It is shown in Figure 7 that at cold mass fraction of 0.3 the COPc of the

d c D ratios above 0.5 drops to be lower than the COPc of the d c D ratios

below 0.5 but the pattern starts when the highest d c D ratio of 0.6316 drops at

cold mass fraction of 0.4. These results show that decreasing the cold mass frac-

tion beyond a threshold, especially for high d c D ratios, causes a drop in

COPc , resulting in an inversely proportional relationship beyond this threshold.

5.2.2. Highest COP Hot (COPh)

When studying the performance of the RHVT taking into consideration not just

the highest temperature rise but also the hot mass fraction, the pressure at the

inlet and the pressure at the cold outlet, a new dimensionless parameter had to

be defined to combine the effect of all the previously mentioned parameters on

the performance of the vortex tube. This dimensionless parameter is the COPh

which was defined by Equation (9). Figure 8 shows the relationship between the

COPh and the cold mass fraction.

It is shown in Figure 8 that all d c D ratio cases follow a similar pattern

whereas cold mass fraction increases the COPh increases up to a critical cold

Figure 7. Cold COP of the RHVT at different dc/D ratio.

DOI: 10.4236/oalib.1104347 12 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Figure 8. Hot COP of the RHVT at different dc/D ratio.

mass fraction which is almost the same value of 0.64 in all cases after which any

further increase in the cold mass fraction will result in decreasing the COPh .

The highest COPc of different d c D ratio cases existed at this exact cold

mass fraction as stated in the previous Section 5.2.1. The d c D ratio of 0.6316

has the highest COPh of 0.2145 at cold mass fraction of 0.64.

5.2.3. Highest COP Total (COPtotal)

From the previous sections, it was noted that the highest COPc and COPh

were at a cold mass fraction of 0.64 for all d c D ratio cases The COPtotal was

defined in Equation (10) as the summation of the COPc and COPh , therefore

when studying the performance of the RHVT in terms of the COPtotal , the

maximum COPtotal for all the different d c D ratio cases should exist at cold

mass fraction of 0.64 which is confirmed in Figure 9 which shows the relation-

ship between the COPtotal and the cold mass fraction. It is shown in Figure 9

that the d c D ratio of 0.6361 has the highest COPtotal of 0.534 at cold mass

fraction of 0.64.

It is noted from the results in Section 5.1 and Section 5.2 that the best perfor-

mance of the vortex tube in terms of COPtotal occurs when operating the vortex

tube at a cold mass fraction of 0.64 regardless of the length to tube diameter ratio

or the cold orifice to tube diameter ratio.

For Future research, these results can be more investigated in terms of flow

analysis using 3D modeling of the RHVT to gain more insights about what ac-

tually occurs at the cold mass fraction of 0.64. Building on these results, the flow

visualization at different d c D ratios at this cold mass fraction will also be very

beneficial.

DOI: 10.4236/oalib.1104347 13 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Figure 9. Total COP of the RHVT at different dc/D ratio.

6. Conclusions

The results of the current model are in good agreement with the available expe-

rimental measurements. Many geometrical parameters affect the performance of

the tube. In this study, the length to tube diameter ratio effect in terms of

COPtotal was investigated and the results showed that its effect on the perfor-

mance of the tube is different at different cold mass fractions where the maxi-

mum COPtotal at any length to tube diameter ratio occurs at cold mass fraction

of 0.64.

Also the effect of the cold orifice to tube diameter ratio on COPc , COPh and

COPtotal was investigated and the results showed that all the studied VTs at dif-

ferent d c D ratios have the maximum COPc and the maximum COPh at a

cold mass fraction of 0.64. The highest d c D ratio of 0.6361 has the highest

COPc and COPh .

It can be concluded that the best performance of the studied vortex tube at

any L D or d c D ratio occurs at a cold mass fraction of 0.64. Future inves-

tigation of the physical properties of the tube at such cold mass fraction and its

relation to other operating points of the vortex tube should be considered.

References

[1] Aljuwayhel, N.F., Nellis, G.F. and Klein, S.A. (2005) Parametric and Internal Study

of the Vortex Tube Using a CFD Model. International Journal of Refrigeration, 28,

442-450. https://doi.org/10.1016/j.ijrefrig.2004.04.004

[2] Bramo, A. and Pourmahmoud, N. (2010) A Numerical Study on the Effect of

Length to Diameter Ratio and Stagnation Point on the Performance of Counter

Flow Ranque-Hilsch Vortex Tubes. Australian Journal of Basic and Applied Sciences,

4, 4943-4957.

DOI: 10.4236/oalib.1104347 14 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

[3] Nimbalkar, S.U. and Muller, M.R. (2009) An Experimental Investigation of the Op-

timum Geometry for the Cold End Orifice of a Vortex Tube. Applied Thermal En-

gineering, 29, 509-514. https://doi.org/10.1016/j.applthermaleng.2008.03.032

[4] Rafiee, S.E. and Rahimi, M. (2013) Experimental Study and Three-Dimensional

(3D) Computational Fluid Dynamics (CFD) Analysis on the Effect of the Conver-

gence Ratio, Pressure Inlet and Number of Nozzle Intake on Vortex Tube Perfor-

mance-Validation and CFD Optimization. Energy, 63, 195-204.

https://doi.org/10.1016/j.energy.2013.09.060

[5] Dutta, T., Sinhamahapatra, K.P. and Bandyopdhyay, S.S. (2010) Comparison of

Different Turbulence Models in Predicting the Temperature Separation in a Ran-

que-Hilsch Vortex Tube. International Journal of Refrigeration, 33, 783-792.

https://doi.org/10.1016/j.ijrefrig.2009.12.014

[6] Aydin, O., Markal, B. and Avci, M. (2010) A New Vortex Generator Geometry for a

Counter-Flow Ranquee-Hilsch Vortex Tube. Applied Thermal Engineering, 30,

2505-2511. https://doi.org/10.1016/j.applthermaleng.2010.06.024

[7] Thakare, H.R. and Parekh, A.D. (2014) CFD Analysis of Energy Separation of Vor-

tex Tube Employing Different Gases, Turbulence Models and Discretisation

Schemes. International Journal of Heat and Mass Transfer, 78, 360-370.

https://doi.org/10.1016/j.ijheatmasstransfer.2014.06.083

[8] Ranque, G.J. (1933) Methods and Apparatus for Obtaining from a Fluid under

Pressure Two Currents of Fluids at Different Temperatures. Patent No. 1,952,281.

[9] Hilsch, R. (1947) The Use of the Expansion of Gases in a Centrifugal Field as Cool-

ing Process. The Review of Scientific Instruments, 18, 108-113.

https://doi.org/10.1063/1.1740893

[10] Xue, Y., Arjomandi, M. and Kelso, R. (2014) Energy Analysis within a Vortex Tube.

Experimental Thermal and Fluid Science, 52, 139-145.

https://doi.org/10.1016/j.expthermflusci.2013.09.004

[11] Xue, Y., Arjomandi, M. and Kelso, R. (2012) Experimental Study of the Flow Struc-

ture in a Counter Flow Ranque-Hilsch Vortex Tube. International Journal of Heat

and Mass Transfer, 55, 5853-5860.

https://doi.org/10.1016/j.ijheatmasstransfer.2012.05.081

[12] Dincer, K., Baskaya, S., Uysal, B.Z. and Ucgul, I. (2009) Experimental Investigation

and Exergy Analysis of the Performance of a Counter Flow Ranque-Hilsch Vortex

Tube with Regard to Nozzle Cross-Section Areas. International Journal of Refrige-

ration, 32, 87-94. https://doi.org/10.1016/j.ijrefrig.2008.06.002

[13] Bovand, M., Valipour, M.S., Dincer, K. and Eiamsa-ard, S. (2014) Application of

Response Surface Methodology to Optimization of a Standard Ranquee-Hilsch

Vortex Tube Refrigerator. Applied Thermal Engineering, 67, 545-553.

https://doi.org/10.1016/j.applthermaleng.2014.03.039

[14] Crocker, A.M., White, S.M. and Bremer, F. (2003) Experimental Results of a Vortex

Tube Air Separator for Advanced Space Transportation. In: Proceedings of the 39th

Joint Propulsion Conference and Exhibit, AIAA, Huntsville, 4451.

https://doi.org/10.2514/6.2003-4451

[15] Balepin, V. and Rosholt, D. (1999) Progress in Air Seperation with the Vortex Tube.

In: Proceedings of the 9th International Space Planes and Hypersonic Systems and

Technologies Conference, Norfolk, Virginia, 4884.

[16] Im, S.Y. and Yu, S.S. (2012) Effects of Geometric Parameters on the Separated Air

Flow Temperature of a Vortex Tube for Design Optimization. Energy, 37, 154-160.

https://doi.org/10.1016/j.energy.2011.09.008

DOI: 10.4236/oalib.1104347 15 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

[17] Zin, K.K., Hansske, A. and Ziegler, F. (2010) Modeling and Optimization of the

Vortex Tube with Computational Fluid Dynamic Analysis. Energy Research Jour-

nal, 1, 193-196. https://doi.org/10.3844/erjsp.2010.193.196

[18] Gao, C.M., Bosschaart, K.J., Zeegers, J.C.H. and de Waele, A.T.A.M. (2005) Expe-

rimental Study on a Simple Ranque-Hilsch Vortex Tube. Cryogenics, 45, 173-183.

https://doi.org/10.1016/j.cryogenics.2004.09.004

[19] Liu, X. and Liu, Z. (2014) Investigation of the Energy Separation Effect and Flow

Mechanism inside a Vortex Tube. Applied Thermal Engineering, 67, 494-506.

https://doi.org/10.1016/j.applthermaleng.2014.03.071

[20] Ahlborn, B.K. and Gordon, J.M. (2000) The Vortex Tube as a Classic Thermody-

namic Refrigeration Cycle. Journal of Applied Physics, 88, 3645-3653.

[21] Ahlborn, B.K., Keller, J.U. and Rebhan, E. (1998) The Heat Pump in a Vortex Tube.

Journal of Non Equilibrium Thermodynamics, 23, 159-165.

https://doi.org/10.1515/jnet.1998.23.2.159

[22] Gao, C. (2005) Experimental Study on the Ranque-Hilsch Vortex Tube. PhD Thesis,

Technische Universiteit Eindhoven, Eindhoven.

[23] Arbuzov, V.A., Dubnishchev, Y.N., Lebedev, A.V., Pravdina, M.K. and Yavorskii,

N.I. (1997) Observation of Large-Scale Hydrodynamic Structures in a Vortex Tube

and the Ranque Effect. Technical Physics Letters, 23, 938-940.

https://doi.org/10.1134/1.1261939

[24] Colgate, S.A. and Buchler, J.R. (2000) Coherent Transport of Angular Momen-

tum—The Ranque-Hilsch Tube a Paradigm. Annuals of the New York Academy of

Sciences, 898, 105-112. https://doi.org/10.1111/j.1749-6632.2000.tb06166.x

[25] Kurosaka, M. (1982) Acoustic Streaming in Swirling Flow and the Ranque-Hilsch

(Vortex-Tube) Effect. Journal of Fluid Mechanics, 124, 139-172.

https://doi.org/10.1017/S0022112082002444

[26] Kazantseva, O.V., Piralishvili, S.A. and Fuzeeva, A.A. (2005) Numerical Simulation

of Swirling Flows in Vortex Tubes. High Temperature, 43, 608-613.

https://doi.org/10.1007/s10740-005-0102-8

[27] Behera, U., Paul, P.J., Dinesh, K. and Jacob, S. (2008) Numerical Investigations on

Flow Behaviour and Energy Separation in Ranque-Hilsch Vortex Tube. Interna-

tional Journal of Heat and Mass Transfer, 51, 6077-6089.

https://doi.org/10.1016/j.ijheatmasstransfer.2008.03.029

[28] Bovand, M., Valipour, M.S., Eiamsa-ard, S. and Tamayol, A. (2014) Numerical

Analysis for Curved Vortex Tube Optimization. International Communications in

Heat and Mass Transfer, 50, 98-107.

https://doi.org/10.1016/j.icheatmasstransfer.2013.11.012

[29] El May, O.T., Mokni, I., Mhiri, H. and Bournot, P. (2011) CFD Investigation of a

Vortex Tube: Effect of the Cold End Orifice in the Temperature Separation Me-

chanism. Science Academy Transactions on Renewable Energy Systems Engineering

and Technology, 1, 84-89.

[30] Abdelghany, S.T. and Kandil, H.A. (2015) Three-Dimensional Computational In-

vestigation of the Power Separation and Flow Anatomy in the Vortex Tube. Inter-

national Journal of Refrigeration, 20, 21-31.

[31] Behera, U., et al. (2005) CFD Analysis and Experimental Investigations towards Op-

timizing the Parameters of Ranque-Hilsch Vortex Tube. International Journal of

Heat and Mass Transfer, 48, 1961-1973.

https://doi.org/10.1016/j.ijheatmasstransfer.2004.12.046

[32] Farouk, T. and Farouk, B. (2007) Large Eddy Simulations of the Flow Field and

DOI: 10.4236/oalib.1104347 16 Open Access Library Journal

S. T. Abdelghany, H. A. Kandil

Temperature Separation in the Ranque-Hilsch Vortex Tube. International Journal

of Heat and Mass Transfer, 50, 4724-4735.

https://doi.org/10.1016/j.ijheatmasstransfer.2007.03.048

[33] Farouk, T., Farouk, B. and Gustol, A. (2009) Simulation of Gas Species and Tem-

perature Separation in the Counter-Flow Ranque-Hilsch Vortex Tube Using the

Large Eddy Simulation Technique. International Journal of Heat and Mass Trans-

fer, 52, 3320-3333. https://doi.org/10.1016/j.ijheatmasstransfer.2009.01.016

[34] Kandil, H.A. and Abdelghany, S.T. (2015) Computational Investigation of Different

Effects on the Performance of the Ranque-Hilsch Vortex Tube. Energy, 84, 207-218.

https://doi.org/10.1016/j.energy.2015.02.089

[35] Bramo, A. and Pourmahmoud, N. (2011) Computational Fluid Dynamics Simula-

tion of Length to Diameter Ratio Effect on the Energy Seperation in a Vortex Tube.

Thermal Science, 15, 833-848. https://doi.org/10.2298/TSCI101004008B

[36] Maurya, R.S. and Bhavsar, K.Y. (2013) Energy and Flow Separation in the Vortex

Tube: A Numerical Investigation. International Journal on Theoretical and Applied

Research in Mechanical Engineering, 2, 25-32.

[37] Pourmahmoud, N. and Bramo, A. (2011) The Effect of L/D Ratio on the Tempera-

ture Separation in the Counterflow Vortex Tube. International Journal of Research

and Reviews in Applied Sciences, 6, 60-68.

[38] Patel, R.B. and Bartaria, V.N. (2013) Experimental Investigation & Numerical

Analysis of Ranque Hilsch. International Journal of Engineering Research & Tech-

nology, 2, 1-6.

[39] Dincer, K., Tasdemir, S., Baskaya, S. and Uysal, B.Z. (2008) Modeling of the Effects

of Length to Diameter Ratio and Nozzle Number on the Performance of Counter-

flow Ranque-Hilsch Vortex Tubes Using Artificial Neural Networks. Applied

Thermal Engineering, 28, 2380-2390.

https://doi.org/10.1016/j.applthermaleng.2008.01.016

[40] Aydin, O. and Baki, M. (2006) An Experimental Study on the Design Parameters of

a Counterflow Vortex Tube. Energy, 31, 2763-2772.

https://doi.org/10.1016/j.energy.2005.11.017

[41] Andalibi, M.R., Azizi, S.H., Khameneh, P.M. and Janmohammadi, M. (2012) Effect

of Diameter and Diameter of Orifice on the Performance of Vortex Tube. Interna-

tional Journal of Science and Engineering Investigations, 1, 89-93.

[42] Skye, H.M., Nellis, G.F. and Klein, S.A. (2006) Comparison of CFD Analysis to Em-

pirical Data in a Commercial Vortex Tube. International Journal of Refrigeration,

29, 71-80. https://doi.org/10.1016/j.ijrefrig.2005.05.004

[43] ANSYS-Fluent. https://www.ansys.com/Products/Fluids/ANSYS-Fluent

[44] Fulton, C.D. (1950) Ranque’s Tube. Journal of the American Society of Refrigerat-

ing Engineers, 58, 473-479.

DOI: 10.4236/oalib.1104347 17 Open Access Library Journal

View publication stats

You might also like

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Study On Effect of Twisted Tape Insert Geometry in Heat ExchangerDocument4 pagesStudy On Effect of Twisted Tape Insert Geometry in Heat ExchangerEditor IJTSRDNo ratings yet

- Vortex Tube - A Review: NtroductionDocument5 pagesVortex Tube - A Review: NtroductionJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- LHPStudy of Performance Enhancement of Half Effect Vapor Absorption System Using Loop Heat PipesDocument11 pagesLHPStudy of Performance Enhancement of Half Effect Vapor Absorption System Using Loop Heat PipessretertNo ratings yet

- Manuscript 1 PDFDocument8 pagesManuscript 1 PDFDiyar NezarNo ratings yet

- Experimental Study On The Performance Enhancement of A Water ChillerDocument8 pagesExperimental Study On The Performance Enhancement of A Water ChillerDiyar NezarNo ratings yet

- Design of Heat Transfer Surfaces in Agitated VesseDocument26 pagesDesign of Heat Transfer Surfaces in Agitated VesseNuala DominionNo ratings yet

- Challenges in Supercritical CO2 Power Cycle Technology and First OperationalDocument16 pagesChallenges in Supercritical CO2 Power Cycle Technology and First OperationalAdven Brilian100% (1)

- Comparative Analysis of Forced Draft Cooling Tower Using Two Design Methods A ReviewDocument4 pagesComparative Analysis of Forced Draft Cooling Tower Using Two Design Methods A ReviewEditor IJTSRDNo ratings yet

- Chemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With FixedDocument8 pagesChemie Ingenieur Technik - 2021 - Pernica - Transient Thermal Stress Calculation of A Shell and Tube Condenser With Fixedganis supriadiNo ratings yet

- Jet Impingement Cooling: January 2005Document10 pagesJet Impingement Cooling: January 2005Abhishek Sharma 123No ratings yet

- Geometric Modifications and Their Impact On The Performance of The Vortex TubeDocument12 pagesGeometric Modifications and Their Impact On The Performance of The Vortex Tubeabcpqr123456No ratings yet

- Design of Heat Transfer Surfaces in Agitated Vessels: April 2017Document26 pagesDesign of Heat Transfer Surfaces in Agitated Vessels: April 2017Pijush DasNo ratings yet

- Report Vortex TubeDocument68 pagesReport Vortex TubePravinSharmaNo ratings yet

- CFD Based Simulation and Analysis of Thermal & Non Thermal Equilibrium Cryogenic ModelDocument4 pagesCFD Based Simulation and Analysis of Thermal & Non Thermal Equilibrium Cryogenic ModelEditor IJTSRDNo ratings yet

- Helically Coiled TubesDocument11 pagesHelically Coiled TubesBenNo ratings yet

- Helix AngleDocument5 pagesHelix AnglenaveenNo ratings yet

- Literature ReviewDocument2 pagesLiterature Reviewkhizar abbasNo ratings yet

- Energy and Flow SeparationDocument8 pagesEnergy and Flow SeparationrshegdeNo ratings yet

- ThesisDocument46 pagesThesisManideep AnanthulaNo ratings yet

- Experimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerDocument13 pagesExperimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerMontserratt Escobedo ÁlvarezNo ratings yet

- Rdme 7Document5 pagesRdme 7emir123456No ratings yet

- 2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFDocument11 pages2019-Design of Helical Coil Heat Exchanger For A Mini Power Plant PDFAshish AgrawalNo ratings yet

- Simulation of Shell and Helical Coil Heat Exchanger For Hot and Cold Fluid Flowing Fe2o3 Nanofluid With Water As Its Base by Using CFDDocument14 pagesSimulation of Shell and Helical Coil Heat Exchanger For Hot and Cold Fluid Flowing Fe2o3 Nanofluid With Water As Its Base by Using CFDIJRASETPublicationsNo ratings yet

- Effect of Volume of Evaporator and Bed Heat Exchanger On Performance of Adsorption ChillerDocument8 pagesEffect of Volume of Evaporator and Bed Heat Exchanger On Performance of Adsorption ChillerDe KanjutNo ratings yet

- Study of Flow and Heat Transfer Analysis in Shell and Tube Heat Exchanger Using CFDDocument8 pagesStudy of Flow and Heat Transfer Analysis in Shell and Tube Heat Exchanger Using CFDBigNo ratings yet

- International Journal of Heat and Mass Transfer: S.F. de Vries, D. Florea, F.G.A. Homburg, A.J.H. FrijnsDocument11 pagesInternational Journal of Heat and Mass Transfer: S.F. de Vries, D. Florea, F.G.A. Homburg, A.J.H. FrijnsAndrei ChornyNo ratings yet

- 1 s2.0 S2214785320405644 MainDocument7 pages1 s2.0 S2214785320405644 MainFelipe CruzNo ratings yet

- Vortex Tube Final ReportDocument23 pagesVortex Tube Final ReportSarju PoudelNo ratings yet

- Modeling of A Miniature Loop Heat Pipe With A Flat EvaporatorDocument21 pagesModeling of A Miniature Loop Heat Pipe With A Flat EvaporatorMayank AgarwalNo ratings yet

- 2011 - Experimental Analysis On Vortex Tube Energy Separation PerformanceDocument8 pages2011 - Experimental Analysis On Vortex Tube Energy Separation Performanceemir123456No ratings yet

- Design of Evaporator Cooling Coil For Cooling Load Abhijeet Samal1 Mechanical Engineering B.M.S College of Engineering, BengaluruDocument4 pagesDesign of Evaporator Cooling Coil For Cooling Load Abhijeet Samal1 Mechanical Engineering B.M.S College of Engineering, BengaluruPT VeritasNo ratings yet

- Effect of Inclination Angles On Heat Transfer Characteristics of A Closed Loop Pulsating Heat Pipe (CLPHP)Document6 pagesEffect of Inclination Angles On Heat Transfer Characteristics of A Closed Loop Pulsating Heat Pipe (CLPHP)nikhil gulhaneNo ratings yet

- Thermal Modeling of Heat Exchanger: A Review: January 2017Document7 pagesThermal Modeling of Heat Exchanger: A Review: January 2017Preciously OmnesNo ratings yet

- Numerical Investigation of Air Cooled Condensers Using Different RefrigerantsDocument4 pagesNumerical Investigation of Air Cooled Condensers Using Different RefrigerantsEditor IJTSRDNo ratings yet

- CFD Analysis of Double Tube Helical Coil Heat Exchanger For Different Heat Transfer..Document7 pagesCFD Analysis of Double Tube Helical Coil Heat Exchanger For Different Heat Transfer..Jitendra KumarNo ratings yet

- CFD Analysis of Tube in Tube Helical Coil Heat ExchangerDocument6 pagesCFD Analysis of Tube in Tube Helical Coil Heat ExchangerMohsen SalehiNo ratings yet

- Heat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisDocument6 pagesHeat Transfer Analysis of A Helical Coil Heat Exchanger by Using CFD AnalysisPRAVEEN HNo ratings yet

- Design of Shell Tube Heat Exchanger Using Vibration AnalysisDocument5 pagesDesign of Shell Tube Heat Exchanger Using Vibration AnalysisIJRASETPublicationsNo ratings yet

- A Review On Study of Heat Transfer Analysis of Helical Coil Heat ExchangersDocument5 pagesA Review On Study of Heat Transfer Analysis of Helical Coil Heat ExchangersEditor IJTSRDNo ratings yet

- 46 PDFDocument4 pages46 PDFNishant ChaudharyNo ratings yet

- 1 s2.0 S1876610214009102 MainDocument9 pages1 s2.0 S1876610214009102 Mainzahed1371yahoo.com ghanbaryNo ratings yet

- CFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerDocument8 pagesCFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Vortex Tube PDFDocument9 pagesVortex Tube PDFGerryNo ratings yet

- Two-Dimensional Model of A Delugeable Flat Bare Tube AirCooled Steam Condenser BundleDocument16 pagesTwo-Dimensional Model of A Delugeable Flat Bare Tube AirCooled Steam Condenser BundleedamiandcrNo ratings yet

- Thermo Electric GenerationDocument6 pagesThermo Electric GenerationJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- JOBARIVORTEXTUBEDocument10 pagesJOBARIVORTEXTUBEAhmed AlaaNo ratings yet

- Analysis and Comparison of Shell and Helical Coil Heat Exchanger by Using Silica and AluminaDocument19 pagesAnalysis and Comparison of Shell and Helical Coil Heat Exchanger by Using Silica and AluminaIJRASETPublicationsNo ratings yet

- Literature Review Heat ExchangersDocument6 pagesLiterature Review Heat Exchangersc5rr5sqw100% (1)

- Condensation Heat Transfer Coefficient of A Mini TubeDocument8 pagesCondensation Heat Transfer Coefficient of A Mini TubegiangfvuNo ratings yet

- CFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidDocument19 pagesCFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidIJRASETPublicationsNo ratings yet

- Heat Transfer Enhancement of Concentric Heat Exchanger Using Mpound TechniquesDocument11 pagesHeat Transfer Enhancement of Concentric Heat Exchanger Using Mpound TechniquesIJRASETPublicationsNo ratings yet

- 362Document48 pages362mani4beNo ratings yet

- Fluids: Numerical Simulations of The Flow Dynamics in A Tube With Inclined Fins Using Open-Source SoftwareDocument16 pagesFluids: Numerical Simulations of The Flow Dynamics in A Tube With Inclined Fins Using Open-Source SoftwareNicolàs Ortega GarcìaNo ratings yet

- CFD Analysis For Natural Convection of A Vertical Tube With Various Fin ConfigurationsDocument50 pagesCFD Analysis For Natural Convection of A Vertical Tube With Various Fin ConfigurationsAyaz AhmedNo ratings yet

- Review On Hypervelocity Impact Over Different Blunt BodyDocument5 pagesReview On Hypervelocity Impact Over Different Blunt BodyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Experimental Research On Internal Working Process of Rotary Vane Expander in CO2 Refrigeration SystemDocument10 pagesExperimental Research On Internal Working Process of Rotary Vane Expander in CO2 Refrigeration SystemkennethNo ratings yet

- An Experimental, Computational and Flow Visualization Study On TheDocument18 pagesAn Experimental, Computational and Flow Visualization Study On TheMustafa AksuNo ratings yet

- CFD Analysis of Cone Shaped Coil Heat Exchanger by Using Copper Oxide Nanofluid With Ethylene Glycol and Water As Its Base FluidDocument16 pagesCFD Analysis of Cone Shaped Coil Heat Exchanger by Using Copper Oxide Nanofluid With Ethylene Glycol and Water As Its Base FluidIJRASETPublicationsNo ratings yet

- Development of Software For Designing of Heat ExchangerDocument5 pagesDevelopment of Software For Designing of Heat ExchangerAdel HandiNo ratings yet

- VVI Control ValvesDocument13 pagesVVI Control ValvesPRONOJIT HUNTERNo ratings yet

- Production of Activated Carbon From Coconut ShellDocument17 pagesProduction of Activated Carbon From Coconut ShellNiraj NeupaneNo ratings yet

- CH02 - Conduction - Sept 9 - 2017Document190 pagesCH02 - Conduction - Sept 9 - 2017Love StrikeNo ratings yet

- Confidence in Fluid System Design - Mentor GraphicsDocument31 pagesConfidence in Fluid System Design - Mentor GraphicsDiego AguirreNo ratings yet

- ITT Vogel Xylem Pomp MP MPA MPB MPV Download FolderDocument16 pagesITT Vogel Xylem Pomp MP MPA MPB MPV Download FolderIvanNo ratings yet

- Tutorial Fluid Dynamics SolutionDocument14 pagesTutorial Fluid Dynamics SolutionAimeenul AzfarNo ratings yet

- 5.membrane Based Bioseparation-PurificationDocument55 pages5.membrane Based Bioseparation-Purificationobs6732100% (1)

- Stream-Gaging Procedure: A Manual Describing Methods and Practices of The Geological SurveyDocument298 pagesStream-Gaging Procedure: A Manual Describing Methods and Practices of The Geological SurveyEinstein DamilolaNo ratings yet

- TH 3358 PDFDocument84 pagesTH 3358 PDFSergio SmithNo ratings yet

- Rev Intouch 15f Equipments Schedule Me1-Layout1Document1 pageRev Intouch 15f Equipments Schedule Me1-Layout1Carlo Miguel M JerusaIemNo ratings yet

- P&Id P&ID P&Id P&Id Piping & Instrument Diagram Piping & Instrument Diagram PG G PG GDocument23 pagesP&Id P&ID P&Id P&Id Piping & Instrument Diagram Piping & Instrument Diagram PG G PG GAmirNo ratings yet

- HL 40 InsulationDocument2 pagesHL 40 InsulationSky MoonNo ratings yet

- Data Sheet For LBV ActuatorDocument1 pageData Sheet For LBV ActuatorSinaNo ratings yet

- A Study of Liquid Metal AtomizationDocument22 pagesA Study of Liquid Metal AtomizationAlisha Allison0% (1)

- P0408 HM TP M TS 003Document79 pagesP0408 HM TP M TS 003SurangaGNo ratings yet

- Operating Instructions: Oil Sealed Rotary Vacuum PumpDocument11 pagesOperating Instructions: Oil Sealed Rotary Vacuum PumpAlejandro PalominoNo ratings yet

- Heat Transfer Studies in A Spiral Plate Heat Exchanger For Water - Palm Oil Two Phase SystemDocument8 pagesHeat Transfer Studies in A Spiral Plate Heat Exchanger For Water - Palm Oil Two Phase SystemhusseinNo ratings yet

- Supercritical CO2 Dyeing of PETDocument32 pagesSupercritical CO2 Dyeing of PETAmdeworkNo ratings yet

- Directional Spool Valve Type SG and SP: Versions For Direct Pipe Connection or Manifold MountingDocument8 pagesDirectional Spool Valve Type SG and SP: Versions For Direct Pipe Connection or Manifold MountingThiago LimaNo ratings yet

- Foodmax Chain HT-XDocument2 pagesFoodmax Chain HT-XALFREDO CANTOS CORNEJONo ratings yet

- Mechanical Seal TrainingDocument42 pagesMechanical Seal Traininglopes_anderson5078No ratings yet

- Catalogue PQDF-K Water Cooled Inverter Flooded Chiller PDFDocument16 pagesCatalogue PQDF-K Water Cooled Inverter Flooded Chiller PDFUmar MajeedNo ratings yet

- NTT Data JKT3 Delivery (At Site) 20200602.REV.7Document1 pageNTT Data JKT3 Delivery (At Site) 20200602.REV.7agung sudarsonoNo ratings yet

- Chapter 3 - Fundamental Design and Runoff Quality EstimationDocument36 pagesChapter 3 - Fundamental Design and Runoff Quality EstimationEncik ComotNo ratings yet

- F S & S S P: Iltration Ystems Ump Weeper IpingDocument2 pagesF S & S S P: Iltration Ystems Ump Weeper IpingRadu LesnicanNo ratings yet

- Theory of Fire ExtinguishmentDocument70 pagesTheory of Fire ExtinguishmentThanawat TeamtanongNo ratings yet

- Swage Nipple Mss SP 95Document3 pagesSwage Nipple Mss SP 95sunerNo ratings yet

- Plasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401Document9 pagesPlasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401balajeemech2010No ratings yet

- Spec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Document4 pagesSpec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Jona RochaNo ratings yet

- REFRIGERATION AND AIR CONDITIONING R16 Nov 2019 PDFDocument2 pagesREFRIGERATION AND AIR CONDITIONING R16 Nov 2019 PDFPawan YNo ratings yet

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (598)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- The Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessFrom EverandThe Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessRating: 4.5 out of 5 stars4.5/5 (254)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (139)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignFrom EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignRating: 4 out of 5 stars4/5 (19)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (700)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1425)

- Protecting Pollinators: How to Save the Creatures that Feed Our WorldFrom EverandProtecting Pollinators: How to Save the Creatures that Feed Our WorldRating: 4 out of 5 stars4/5 (8)

- Remnants of Ancient Life: The New Science of Old FossilsFrom EverandRemnants of Ancient Life: The New Science of Old FossilsRating: 3 out of 5 stars3/5 (3)

- The Good Rain: Across Time and Terrain in the Pacific NorthwestFrom EverandThe Good Rain: Across Time and Terrain in the Pacific NorthwestRating: 4 out of 5 stars4/5 (110)

- Fen, Bog and Swamp: A Short History of Peatland Destruction and Its Role in the Climate CrisisFrom EverandFen, Bog and Swamp: A Short History of Peatland Destruction and Its Role in the Climate CrisisRating: 4 out of 5 stars4/5 (24)