Professional Documents

Culture Documents

Fbioe 11 1170977

Fbioe 11 1170977

Uploaded by

ypherrera20201Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fbioe 11 1170977

Fbioe 11 1170977

Uploaded by

ypherrera20201Copyright:

Available Formats

TYPE Original Research

PUBLISHED 30 March 2023

DOI 10.3389/fbioe.2023.1170977

Mechanical assessment of two

OPEN ACCESS hybrid plate designs for pancarpal

EDITED BY

Wojciech Macek,

Gdansk University of Technology, Poland

canine arthrodesis under cyclic

REVIEWED BY

Andrew Gryguć,

loading

University of Waterloo, Canada

Andrea Avanzini,

University of Brescia, Italy

Ivan Zderic 1*, Peter Varga 1, Ursula Styger 1, Ludmil Drenchev 2,

*CORRESPONDENCE

Boyko Gueorguiev 1, Erik Asimus 3, W. Brian Saunders 4,

Ivan Zderic, Michael Kowaleski 5, Randy J. Boudrieau 5 and Loic M. Déjardin 6

ivan.zderic@aofoundation.org

1

AO Research Institute Davos, Davos, Switzerland, 2Bulgarian Academy of Sciences, Institute of Metal

SPECIALTY SECTION

Science, Equipment and Technologies with Center for Hydro- and Aerodynamics “Acad. A. Balevski”,

This article was submitted to

Sofia, Bulgaria, 3Ecole Nationale Vétérinaire de Toulouse, Toulouse, France, 4College of Veterinary

Biomechanics,

Medicine & Biomedical Sciences, Texas A&M University, College Station, TX, United States, 5Cummings

a section of the journal

School of Veterinary Medicine, Tufts University, North Grafton, MA, United States, 6College of Veterinary

Frontiers in Bioengineering

Medicine, Michigan State University, East Lansing, MI, United States

and Biotechnology

RECEIVED 21 February 2023

ACCEPTED 23 March 2023

PUBLISHED 30 March 2023

Pancarpal canine arthrodesis (PCA) sets immobilization of all three carpal joints via

CITATION

Zderic I, Varga P, Styger U, Drenchev L, dorsal plating to result in bony fusion. Whereas the first version of the plate uses a

Gueorguiev B, Asimus E, Saunders WB, round hole (RH) for the radiocarpal (RC) screw region, its modification into an oval

Kowaleski M, Boudrieau RJ and

hole (OH) in a later version improves versatility in surgical application. The aim of

Déjardin LM (2023), Mechanical

assessment of two hybrid plate designs this study was to mechanically investigate the fatigue life of the PCA plate types

for pancarpal canine arthrodesis under implementing these two features–PCA-RH and PCA-OH. Ten PCA-RH and

cyclic loading.

20 PCA-OH stainless steel (316LVM) plates were assigned to three study

Front. Bioeng. Biotechnol. 11:1170977.

doi: 10.3389/fbioe.2023.1170977 groups (n = 10). All plates were pre-bent at 20° and fixed to a canine forelimb

COPYRIGHT

model with simulated radius, RC bone and third metacarpal bone. The OH plates

© 2023 Zderic, Varga, Styger, Drenchev, were fixed with an RC screw inserted either most proximal (OH-P) or most distal

Gueorguiev, Asimus, Saunders, (OH-D). All specimens were cyclically tested at 8 Hz under 320 N loading until

Kowaleski, Boudrieau and Déjardin. This is

an open-access article distributed under

failure. Fatigue life outcome measures were cycles to failure and failure mode.

the terms of the Creative Commons Cycles to failure were higher for RH plate fixation (695,264 ± 344,023) versus both

Attribution License (CC BY). The use, OH-P (447,900 ± 176,208) and OH-D (391,822 ± 165,116) plate configurations,

distribution or reproduction in other

forums is permitted, provided the original

being significantly different between RH and OH-D, p = 0.03. No significant

author(s) and the copyright owner(s) are difference was detected between OH-P and OH-D configurations, p = 0.09.

credited and that the original publication Despite potential surgical advantages, the shorter fatigue life of the PCA-OH plate

in this journal is cited, in accordance with

accepted academic practice. No use,

design may mitigate its benefits compared to the plate design with a round

distribution or reproduction is permitted radiocarpal screw hole. Moreover, the failure risk of plates with an oval hole is

which does not comply with these terms. increased regardless from the screw position in this hole. Based on these findings,

the PCA plate with the current oval radiocarpal screw hole configuration cannot

be recommended for clinical use.

KEYWORDS

pancarpal canine arthrodesis, hybrid plate, locking compression plate, radiocarpal hole,

fatigue

Frontiers in Bioengineering and Biotechnology 01 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

1 Introduction

Pancarpal canine arthrodesis (PCA) sets immobilization of all

three carpal joints—The antebrachiocarpal or radiocarpal, the

middle carpal or intercarpal, and the carpometacarpal—To result

in bony fusion of their joint surfaces (Buote et al., 2009; Ernst, 2012).

It is a common and well-established salvage surgical procedure

indicated for a variety of carpal disorders including hyperextension

injuries, severe fractures, end-stage osteoarthritis, and neurologic

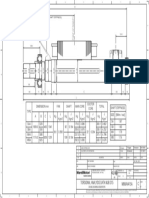

FIGURE 1

deficits (Parker et al., 1981; Gambardella and Griffiths, 1982; Lesser, LCP Pancarpal Arthrodesis Plate 2.7/3.5 mm with round (up) and

2003), and is considered a standard of care procedure in small oval (down) standard radiocarpal screw hole, 12 holes, length 151 mm.

animal veterinary medicine with the goal to restore reasonable limb

function.

Among different treatment options, such as pinning or external

fixation, the most common PCA procedure relies on dorsal plating

(Chambers and Bjorling, 1982). In this setting, the dorsally applied

plate spans all carpal joints while being fixed with screws to the

radius, the radiocarpal bone and usually the third metacarpal bone.

Although a dorsally positioned plate lies on the compression side of

the joints and is not favorable from a biomechanical perspective,

dorsal plating is commonly performed due to the ease of the dorsal

surgical approach compared to a palmar approach.

Carpal fusion angles between 0° (straight alignment) and 20° of

extension have been proposed in the literature (Chambers and

Bjorling, 1982; Guillou et al., 2012). The straight fusion

alignment limits the risk of plate failure under dynamic loading,

however, it is associated with both poorer paw placement during

stance and increased tendon pain (Hottinger et al., 1996). Therefore,

for a more physiological stance, a radiocarpal (RC) joint fusion angle

of approximately 15° to 20° is clinically preferred, which requires

bending of the PCA plate. This makes the bent plate more prone to

fatigue failure (Lesser, 2003). Indeed, failure of these pancarpal

arthrodesis plate types has been reported in literature with an

incidence of 2%–9% (DeCamp et al., 1993; Bristow et al., 2015).

Besides plate breakage, construct failures following dorsal plating

occur due to screw breakage or loosening and/or bone fracturing at

the peripheral ends of the plates (Johnson, 1980; Denny and Barr,

1991; Li et al., 1999; Whitelock et al., 1999). Furthermore, a FIGURE 2

mismatch between screw and metacarpal bone size is associated Pre-bending of round-hole PCA plates to 20° joint fusion angle;

(A) Photograph showing a plate fixed within the bending press; (B) A

with increased risk of metacarpal bone fracture through the consistent bending angle of all plates was obtained.

corresponding screw (Whitelock et al., 1999; Wininger et al.,

2007) when dynamic compression plates (DCPs) or limited-

contact DCPs (LC-DCPs) are used. These plates are also

considered as too bulky for the distal metacarpal region, leading

to increased wound dehiscence rates postoperatively (Worth and The locking plate design includes all combination plate holes to

Bruce, 2008; Guillou et al., 2012). accommodate either standard or locking screws—Except the

To overcome the limitations of compression plates, PCA plate standard RC plate hole. The rationale for the latter is that this

designs were specifically devised (Guillou et al., 2012; Zderic et al., critical anchor point allows to angle the screw and ensure

2021). Among them, hybrid plates with distally tapered profile for appropriate placement within the radiocarpal bone; Additionally,

both width and thickness became popular and accept application of tightening of this screw results in pull-out of the RC bone towards

smaller 3rd metacarpal screws for optimized stability and reduced the plate, preventing a caudal displacement of the RC bone. In one

risk of metacarpal fractures and wound dehiscence. However, screw plate version, the non-locking RC plate hole was designed as a round

loosening persisted as a major problem with standard compression hole (RH), while the other version features an oval “sliding” RC plate

plates not providing any mechanism to counteract this adverse effect hole (OH) to allow for adjustments of the plate position (Figure 1),

(Clarke et al., 2009; Bokemeyer et al., 2011; Ernst, 2012). For this facilitate the surgical use of the plate, and provide improved

purpose, taking advantage of both the tapered design and locking placement of a screw into the RC bone. Although the mechanical

plate technology, two new PCA plates were designed (Asimus et al., superiority of the round-hole plate versus oval-hole plate was

2017; LCP Pancarpal Arthrodesis Plates - Surgical Technique, 2019). recently reported in a biomechanical study demonstrating

Frontiers in Bioengineering and Biotechnology 02 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

(OH-D). Pilot holes with diameters of 2.8, 2.0, and 2.5 mm were

predrilled into the bone models prior to screw insertion. All 3.5 mm

screws (locking and compression/cortex ones) were tightened at a

final toque of 1.5 Nm, whereas the 2.7 mm locking screws were

locked at 0.8 Nm. All implants were made of implant-grade stainless

steel (316LVM), featuring a modulus of elasticity of 186 GPa, a yield

strength of ≥690 MPa, and an ultimate tensile strength of

860–1100 MPa (Disegi and Eschbach, 2000), and were produced

by the same manufacturer (DePuy Synthes, Zuchwil, Switzerland).

Mechanical testing

Mechanical testing of the specimens was performed using an

electrodynamic material testing machine (Acumen III, MTS Systems

Corp., Eden Prairie, MN, United States) equipped with a 3 kN load

cell. The test setup was adopted from a previous study and is shown

FIGURE 3 in Figure 3 (Zderic et al., 2021). Articulated fixtures with co-axial

Test setup with a specimen mounted for mechanical testing, alignment were used proximally and distally allowing free rotation

adopted from (Zderic et al., 2021).

in the sagittal plane. The distances between the bending point and

the proximal and distal articulations of the fixtures were identical for

all specimens. This guaranteed that the length of the proximal and

distal lever arms with respect to the radio-carpal bone was consistent

increased plate surface strains next to the OH compared to the RH between specimens. Using a sine profile, the specimens were

(Zderic et al., 2021), the biomechanical performance of both plate cyclically loaded in axial compression along the machine axis

designs has not been investigated under cyclic loading, which between 20 N valley load and 320 N peak compression at 8 Hz

warranted further evaluations under fatigue testing. until construct failure. The latter was defined when the machine

Therefore, the aim of this study was to investigate the transducer reached a test stop criterion of 20 mm axial displacement

mechanical behavior of the hybrid PCA plates with oval versus with respect to its position at the beginning of the cyclic test. The

standard round RC plate hole under cyclic loading. We force level and loading protocol were defined in a pilot study, where

hypothesized that 1) Ovalization of the RC hole will decrease they were found appropriate to produce fatigue failures in RH plate

the fatigue life compared to the round-hole plate, and 2) Within constructs within a range between 500,000 and 1,000,000 cycles.

the oval-hole plates, moving the screws from proximal to distal will

further decrease the fatigue life and increase plate failure

probability. Data acquisition and analysis

Strain levels inherent in the constructs under the given load

2 Methods magnitudes were assessed based on strain gauge data from a

previously performed study (Zderic et al., 2021) measuring

Specimens and preparation maximum plate surface strains on the same constructs under

quasi-static loading to 300 N. Those results were considered to

Ten RH and 20 OH hybrid PCA plates were consistently pre- define the corresponding minimum strains at the valley load of

bent to 20° joint fusion angle using a custom-made bending press 20 N, as well as to extrapolate them to the applied peak load level of

(Figure 2). The press was designed to bend the plates consistently 320 N. The minimum/maximum strains were further converted to

and accurately at a point centrally located between the distal radial the theoretical stress magnitudes, given the elastic modulus of

and the RC holes, and was adapted from previous studies (Guillou 186 GPa for implant-grade stainless steel (316LVM) (Disegi and

et al., 2012; Zderic et al., 2021). All plates were fixed to three cylindric Eschbach, 2000). Furthermore, the strain-force curve of the previous

cotton fabric bone model substitutes (HGW 2082 [Canevasite], study was considered to calculate the strain energy density of each

Amsler & Frey AG, Schinznach-Dorf, Switzerland) simulating the specimen, taking into account the converted stresses. Finally, the

radius, RC bone and 3rd metacarpus with lengths resembling a maximum stress was normalized to the common mechanical

cadaveric specimen (171, 10, and 123 cm, respectively) (Zderic et al., property parameters for stainless steel, namely yield strength

2021). Each plate was fixed first to the radius by placing 3.5 mm (690 MPa), ultimate tensile strength (1100 MPa), and fatigue

locking screws in plate holes 1 (proximal), 3, 5, and 6, whereas the strength (480 MPa) (Disegi and Eschbach, 2000).

metacarpus was fixed second by placing 2.7 mm locking screws Axial displacement and load were continuously recorded from

occupying holes 1 (proximal), 2, and 5. The RC bone was fixed last to the machine transducers at 64 Hz throughout testing. The numbers

the plate by occupying the RC screw hole with a standard 3.5 mm of cycles until construct failure were determined based on the

cortical screw. Ten OH plates were instrumented with the RC screw recorded machine data. In addition, the mode of failure of each

placed in the oval hole most proximally (OH-P) or most distally separate construct was recorded and subsequently analyzed.

Frontiers in Bioengineering and Biotechnology 03 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

TABLE 1 Outcome measures based on previous experimental strain gauge measurements (Zderic et al., 2021), presented for each group separately in terms of

mean value and SD.

Parameter Plate Location Group

RH OH-D OH-P

Maxiumum Strain at 320 N (µm/m) Bending Point 2302.2 (121.8) 1926.0 (206.5) 1911.4 (185.7)

Next to RC Screw 2264.6 (164.7) 3436.5 (497.8) 3551.1 (472.7)

Slot – 3588.6 (458.5) 3404.3 (461.2)

Maximum Stress at 320 N (MPa) Bending Point 428.2 (22.7) 358.2 (38.4) 355.5 (34.5)

Next to RC Screw 421.2 (30.6) 639.2 (92.6) 660.5 (87.9)

Slot – 667.5 (85.3) 633.2 (85.8)

Minimum Strain at 20 N (µm/m) Bending Point 160.0 (40.9) 81.2 (39.0) 69.1 (13.6)

Next to RC Screw 217.4 (40.0) 416.3 (208.3) 424.9 (194.5)

Slot – 358.7 (257.1) 286.6 (159.7)

Minimum Stress at 20 N (MPa) Bending Point 29.7 (7.6) 15.1 (7.2) 12.9 (2.5)

Next to RC Screw 40.4 (7.4) 77.4 (38.8) 79.0 (36.2)

Slot – 66.7 (47.8) 53.3 (29.7)

3

Strain Energy Density (J/m ) Bending Point 987.1 (91.3) 721.2 (156.6) 714.0 (147.3)

Next to RC Screw 934.0 (123.3) 2135.4 (577.1) 2268.6 (542.4)

Slot – 2369.5 (531.4) 2178.3 (549.8)

Maximum Stress Normalized to Yield Strength 690 MPa (%) Bending Point 62.1 (3.3) 51.9 (5.6) 51.2 (5.0)

Next to RC Screw 61.0 (4.45) 92.6 (13.4) 95.7 (12.7)

Slot – 96.7 (12.4) 91.8 (12.4)

Maximum Stress Normalized to Ultimate Tensile Strength 1100 MPa (%) Bending Point 38.9 (2.1) 32.6 (3.5) 32.3 (3.1)

Next to RC Screw 38.3 (2.8) 58.1 (8.4) 60.0 (8.0)

Slot – 60.7 (7.8) 57.6 (7.8)

Maximum Stress Normalized to Fatigue Strength 480 MPa (%) Bending Point 89.2 (4.7) 74.6 (8.0) 74.1 (7.2)

Next to RC Screw 87.8 (6.4) 133.2 (19.3) 137.6 (18.3)

Slot – 139.1 (17.8) 131.9 (17.9)

Statistical analysis among the parameters of interest was parameters, are summarized in Table 1. For both OH configurations,

performed using SPSS software package (version 27, IBM SPSS, peak plate stresses were overall the highest next to the RC screw and

Armonk, NY, United States). Mean and standard deviation (SD) the non-occupied portion of the oval hole. Considering pooled data

were calculated for cycles to failure. Shapiro-Wilk test was of all three groups together, the correlation between maximum

conducted to ascertain a normal data distribution within all strains and strain energy density was significant for each

groups. One-Way Analysis of Variance (ANOVA) with measured location (r ≥ 0.969, all p < 0.001). Maximum stresses

Bonferroni post hoc test was conducted to identify significant remained below the yield and ultimate tensile strength in each

differences between the groups. Pearson Correlation test was group. However, the fatigue strength was exceeded for both OH

used to investigate the relation between maximum plate stresses configurations next to the RC screw and next to the non-occupied

and strain energy density. Level of significance set at p = 0.05. portion of the oval hole.

The RH plates exhibited the highest number of cycles to failure

(695,264 ± 344,023 (mean ± SD), followed by OH-P (447,900 ±

3 Results 176,208) and OH-D plates (375,954 ± 166,848). The values for RH

plates were significantly higher versus OH-D plates (p = 0.028). No

Outcome measures for maximum and minimum plate strains, significant differences were detected between the OH-P and OH-D

together with the converted stresses, strain energy density, as well as groups, p ≥ 0.999 (Figure 4). There was no significant difference in

maximum stress normalization to the common material mechanical cycles to failure between the RH and OH-P plates (p = 0.092).

Frontiers in Bioengineering and Biotechnology 04 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

Finally, the third failure mode was a concomitant fracture of the

3rd and 4th (distal) radial screws at their head-shaft interface, which

was associated with plate lifting-off from the radius bone model.

Examples of plate failure modes are shown in Figure 5.

4 Discussion

This study evaluated the biomechanical performance of two

hybrid locking plate designs for pancarpal canine arthrodesis with

either a round or an oval RC hole design under cyclic loading. In

addition, the effect of occupying the two extreme ends of the oval RC

plate hole by a screw was investigated. The RH plates were associated

with a higher fatigue life compared to both OH constructs, with a

FIGURE 4 significant difference demonstrated between RH plates and OH-D

Cycles to failure in the three study groups presented in terms of

mean value and SD. Circular points indicate cycles to failure for

plates. These results clearly demonstrate that the specific advantage

individual specimens. Star shows significant difference. of surgical maneuverability provided by the current iteration of PCA

plates with an oval hole comes at the expense of reduced fatigue life.

Bearing in mind the relatively high rates of reported implant related

PCA failures (Johnson, 1980; Denny and Barr, 1991; Li et al., 1999),

Constructs predominantly failed by plate fracture at the level of these findings should be considered when applying OH hole plates

the distal radial combination hole in all groups (RH 6/10, OH-P 8/ to clinical patients.

10, RH-D 8/10). In most cases the fracture occurred at the locking The reduced biomechanical performance characterizing OH plates

portion of the combination hole, i.e., the distal radial locking screw is a logical consequence of the lowered area moment of inertia of the

(RH 6/6, OH-P 5/8, RH-D 4/8), followed by fractures through the plate around its RC hole. However, it is counterintuitive that all but one

cortex screw portion of the distal radial combination hole (RH 0/6, failure modes occurred in the near periphery of the RC region, namely

OH-P 3/8, RH-D 3/8). In one OH-D specimen, the plate fractured the distal radial combination hole or the proximal metacarpal holes.

through the RC screw hole. All plate fractures were initiated at the This is even more remarkable when considering the residual strains

undersurface of the plate. Most plate fractures were located at a originating from plate contouring, amounting up to approximately

single locale on one flank next to a screw hole, whereas any fractures 30%, as indicated by the finite element analysis from a previous study

with two locales were on both flanks next to the same screw hole, but (Zderic et al., 2021), which would presume material weakening in this

asymmetric, with one side exhibiting a larger fracture surface area. region (Figure 6). However, as demonstrated by this previous study, the

There were no plate fractures through the bending point of the residual stresses are not limited to the bending point but are also existent

plates. Plate fractures were predominantly associated with in proximity of the locking part of the distal radial combination hole.

concurrent distal radial screw fractures at the head-shaft interface Indeed, these residual stresses may have contributed to the plate failure

(RH 4/6, OH-P 4/8, RH-D 5/8). in this specific region. Other factors favoring these failure locations may

The second most common failure mode was fracturing of the be the used test setup, which did not permit contact between the three

1st and 2nd metacarpal screws at their head-shaft interface, bone segments (Figure 3). The plate was not constrained in both the RC

associated with plate lifting-off from the bone model (RH 3/ bone and bending point regions. Thus, using this test setup, the

10, OH-P 2/10, RH-D 0/10), which occasionally ended in plate’s arthrodesis construct acts as a bridge plating construct with the

excessive bending at the 3rd metacarpal screw hole (RH 1/3, working length defined by the distance of the innermost radial and

OH-P 1/2). metacarpal locking screws, upon which the transmitted forces are

FIGURE 5

Photographs visualizing failure modes after fatigue testing; (A) asymmetric plate fracture through the locking part of a distal radial combination hole,

posterior view; (B) asymmetric plate fracture through the compression part of a distal radial combination hole, anterior view. Debris in the locking part

indicate fractured screw; (C) excessive plate bending at the most distal screw hole following 1st and 2nd metacarpal screw breakage, lateral view; (D)

breakage of 3rd and 4th (distal) radial screws at their head-shaft interface, with numbers indicating length scale in centimeters; (E) asymmetric plate

fracture through the radiocarpal hole, posterior view.

Frontiers in Bioengineering and Biotechnology 05 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

FIGURE 6

Finite element analysis of the plate pre-bending process demonstrating residual stresses after its completion (Zderic et al., 2021). Residual stresses

also exist around the distal radial locking screw hole, as indicated by the red arrow, and are not limited to the bending point.

concentrated. In addition, the plates were pre-contoured to match the assume that the plates were applied with a 5° bend and without

clinical process of plate application; however, pre-contoured plates are additional intra-operative bending. This assumption is supported by

prone to axial bending leading to cumulated stresses on the affected a high rate of postoperative lameness (up to 67%), regardless of plate

screws along their nominal axes. These details may explain why plate type.

lifting-off was a common failure mode. Interestingly, plate lift-off due to The locking screw mechanism represents another important

screw failure is a clinically observed mode of plate failure. factor for the failure behavior of the constructs. Given the angle-

Although the failure modes were predominantly consistent within stable feature of this fixation, stresses are concentrated in the locking

and across the groups, they were not unanimously reliable. This region. As a result, plate fractures through the locking portion of the

phenomenon can be ascribed to the many factors affecting the combination hole with concomitant screw fracturing through its

failure behavior. The constructs with pre-contoured plates were head-shaft interface would be expected as the most common

instrumented with multiple screws and subjected to complex axial failure mode.

loading. It is evident that the outcomes in terms of failure modes would The investigated plates are somewhat unique hybrid plates, first

disperse more compared to standardized tests using test coupons, due to their tapered profile using different screw sizes proximally

although the parameters for specimen assembly were kept as and distally, but also because of their ability to accommodate either

reproducible as possible. The low number of failure modes detected locking or cortex screws, the latter being the only option in the RC

in our study is attributed to similar failure loads, and each of them hole. One potential solution to address the findings of the present

deems clinically relevant. In this regard, material contamination could study would be to modify the design of the RC hole with a variable-

be excluded as source of error, as evidenced by the failure analysis in a angle locking hole, allowing for angulated screw placement.

previous study, demonstrating that the material fulfilled the rigorous Considering the numbers of cycles to failure registered in this

norms for implant-grade stainless steel (Zderic et al., 2022). As a result study, it must be acknowledged that fatigue-like behavior rather

of these findings, the authors concluded that clinically translated plate than true fatigue behavior was investigated. In this regard, no typical

failures can instead rather be ascribed to bone healing disturbances, Wöhler curves could be generated based on different stress-strain

leading to their extended loading and ultimate failure. tests, nor was it possible to indicate a stress level inherent in the plate

The relatively high fusion angle of 20° was certainly a cross-section due to the complex loading scenario and the

contributing factor to plate lift-off. However, there is clinical inhomogeneous material cross-section. However, the load level

evidence in the literature supporting a high fusion angle of 20°. A was selected in a pilot study to achieve failure cycles according to

previous retrospective study compared the clinical outcome of recommended industry standards. True fatigue testing for steel

pancarpal canine arthrodesis performed with two types of would require cyclic loading over 1,000,000 cycles to reach its

dorsally applied hybrid non-locking plates (Bristow et al., 2015). endurance limit (ASTM, 1999), although high-cycle fatigue tests

While the overall postoperative complication rates were similar for are carried out for 107 or more cycles (Campbell, 2012). In our study,

both plates (46%), implant failure was reported in 2% of the cases. we did not reach the endurance limit of the plates, which also was

However, the authors did not assess plate bending angle and since not targeted, as an aggressive loading protocol, tailored to mimic

both plates feature a built-in 5° distal dorsal taper, it is reasonable to physiological loading, is required to estimate and compare the

Frontiers in Bioengineering and Biotechnology 06 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

mechanical competence of the tested constructs. Arthrodesis is contouring was not investigated. To date, studies investigating the

achieved on average within 12 postoperative weeks, but can effect of residual stresses emerging from plate pre-contouring on

range from 9 to 30 weeks (Michal et al., 2003). The their fatigue performance are lacking. We therefore anticipate that

corresponding number of load cycles lies within a relatively this investigation, by means of dedicated destructive, semi-

broad range between approximately 200,000 cycles and destructive or non-destructive techniques, may unveil new

1,600,000 cycles. This would correspond to a period of insights into this insufficiently explored area.

approximately 12–96 weeks, if activity is extrapolated from As with all studies, this study is not without limitations. First, an

humans (ASTM, 1999). An overlapping of these two ranges artificial bone model was used with material properties, which may not

indicates that a clinical failure cannot be excluded. These represent the complex material characteristics of several canine bones.

presumptions should be considered as worst-case scenarios, as This simplification however helped to determine the plates’ fatigue

the calculations were rather conservative, neglecting the gradual properties. Second, the bone configuration was chosen to simulate a

increase in load bearing of the bone healing over time. worst-case scenario with no bony interaction between the radiocarpal

The applied peak force of 320 N was selected based on front limb bone and the radius or metacarpals, which in most clinical cases does

ground reaction force of approximately 115% body weight. not represent the position or contribution of the RC bone relative to the

Considering that the plates used in this study would be remaining stability of the antebrachial bones. Nonetheless, this model

appropriate for dogs weighing between 16 kg and 46 kg, a 320 N mimics the immediate and short-term postoperative periods prior to

peak load would simulate loading conditions for an approximately bone healing contributing to construct stability. Third, streamlined

28 kg mid-size dog (Li et al., 1999; Clarke et al., 2009; Andreoni et al., uniaxial loading was applied at constant load magnitude, whereas the

2010). complex multidirectional forces occurring during a true gait were

The present study built upon a previous mechanical evaluation neglected, primarily since these forces in the canine antebrachium

of PCA plates (Zderic et al., 2021). Indeed, plates were instrumented remain largely unknown. Fourth, there was no clear association between

with strain gauges at the most sensitive locations, as predicted by a the number of cycles to failure and the corresponding mode of failure.

previous finite element analysis. Constructs were then loaded in the Again, this reflects to some extent the unpredictable nature of cyclic

same fashion under axial quasi-static compression over 10 cycles. testing.

Although a validated finite element model accurately predicted the Future studies should focus on three aspects to broaden the

weakened properties associated with the oval plate hole, actual knowledge of locking arthrodesis plates. First, a direct comparison to

failure locations were not precisely identified. This probably non-locking plates is missing and conclusions on the effectiveness of

occurred because the authors’ focus was limited to the RC the locking principle cannot be drawn. Of paramount importance

region, neglecting the peripheral boundary conditions at the would therefore be to provide evidence of their effectiveness over

distal radial and proximal metacarpal screw holes. compression plating in terms of implant loosening. Second, the

The peak principal stresses, as theoretically converted from effect of plate pre-shaping on the fatigue behavior remains to be

experimentally measured peak plate strains, remained explored and could help guide surgeons regarding the degree of

unexceptionally below the yield strength, and predominantly acceptable plate pre-contouring. This could be accomplished by

below the fatigue strength. These findings highlight the benefits comparing the structural and mechanical properties of plates pre-

of strain gauges measurements, which remain indispensable tools contoured at different angles. Third, plate design iterations with

for prediction of failure loads and determination of correct load reinforced flanks around the oval RC hole may enhance the fatigue

magnitudes in studies investigating the fatigue behavior of different life while preserving the positive features of the oval sliding hole.

constructs.

The present and the abovementioned studies represent the only

studies on arthrodesis plates using locking technology. Locking 5 Conclusion

compression plates were initially designed to increase construct

stability in poor bone quality and reduce the rates of screw loosening From a biomechanical perspective, despite the surgical

(Auer et al., 1995). In good bone quality, such as in the canine advantages of the PCA plate containing an oval radiocarpal

forelimb simulated here, the potentially overly stiff configuration screw hole, its fatigue life under the pre-defined load magnitude

may lead to different effects than expected, namely to earlier of 320 N is shorter when compared to the plate design with a round

construct failure as also suggested in previous studies (Fitzpatrick radiocarpal screw hole and therefore appears to mitigate the clinical

et al., 2009; Rowe-Guthrie et al., 2015). benefit of the oval hole. Moreover, the failure probability of the oval

The test setup in the current study was similar to that used in a RC hole plate is increased regardless of the position of the screw in

previous biomechanical comparison of non-locking hybrid plates this hole. Based upon these findings, the current iteration of the PCA

versus LC-DCPs (Guillou et al., 2012). Other biomechanical studies plate with an oval radiocarpal screw should be used with caution,

focused on the mechanical characterization of locking and non- and additional design features are likely necessary to increase the

locking plates (Wininger et al., 2007; Meeson et al., 2012; Rothstock fatigue life of oval RC-hole PCA plates.

et al., 2012; Rowe-Guthrie et al., 2015). In a recent study, Meeson

et al. (2012) subjected plates to quasi-static load to failure and fatigue

loading over 106 cycles in two independent test series of four-point Data availability statement

bending, concluding that fatigue failure during the convalescence

period of estimated 150,000–200,000 cycles is unlikely. However, the The raw data supporting the conclusion of this article will be

authors only considered straight plates and the consequences of pre- made available by the authors, without undue reservation.

Frontiers in Bioengineering and Biotechnology 07 frontiersin.org

Zderic et al. 10.3389/fbioe.2023.1170977

Author contributions Conflict of interest

LD, BG, EA, WS, MK, RB, and LD concepted the design of and The authors declare that the research was conducted in the

designed the study. IZ, PV, and US conducted the experimental absence of any commercial or financial relationships that could be

work and acquired the data. IZ and BG performed statistical construed as a potential conflict of interest.

analysis. IZ wrote the draft of the manuscript. All authors

contributed to manuscript revision, read, and approved the

submitted version. Publisher’s note

All claims expressed in this article are solely those of the authors

Acknowledgments and do not necessarily represent those of their affiliated organizations,

or those of the publisher, the editors and the reviewers. Any product

This investigation was performed with the assistance of the AO that may be evaluated in this article, or claim that may be made by its

Foundation via the AOTC System. manufacturer, is not guaranteed or endorsed by the publisher.

References

Andreoni, A. A., Rytz, U., Vannini, R., and Voss, K. (2010). Ground reaction force arthrodesis. Vet. Comp. Orthop. Traumatol. 25 (2), 83–88. doi:10.3415/VCOT-11-

profiles after partial and pancarpal arthrodesis in dogs. Vet. Comp. Orthop. Traumatol. 05-0077

23 (1), 1–6. doi:10.3415/VCOT-09-03-0030

Hottinger, H. A., DeCamp, C., Olivier, N., Hauptman, J., and Soutas-Little, R. (1996).

Asimus, E., Beale, B. S., Boudrieau, R. J., Dejardin, L. M., and Kowaleski, M. P. (2017). Noninvasive kinematic analysis of the walk in healthy large-breed dogs. Am.

“LCP pancarpal Arthrodesis Plate 2.7/3.5,” in AOTK System innovations (AO J. veterinary Res. 57 (3), 381–388.

Foundation).

Johnson, K. (1980). Carpal arthrodesis in dogs. Aust. Veterinary J. 56 (12), 565–573.

ASTM (1999). ASTM F382-99, standard specification and test method for metallic doi:10.1111/j.1751-0813.1980.tb02600.x

bone plates. West Conshohocken, PA: ASTM International.

LCP Pancarpal Arthrodesis Plates - Surgical Technique (2019). LCP pancarpal

Auer, J., Bishop, N., Bresina, S. J., Buchanan, J. S., Fürst, T., Gautier, E., et al. (1995). arthrodesis plates - surgical technique. DePuy Synthes Vet.

Point contact fixator: Part I scientific background. Design and Application. Injury 26(2).

Lesser, A. S. (2003). “Arthrodesis,” in Textbook of small animal surgery. Editor

S- B1-B77.

D. Slatter (Philadelphia: Saunders), 2174–2176.

Bokemeyer, J., Fischer, A., Sadan, M., Kramer, M., and Gerwing, M. (2011). Pancarpal

Li, A., Gibson, N., Carmichael, S., and Bennett, D. (1999). Thirteen pancarpal

arthrodesis using a" CastLess Plate" in dogs and cats. Tierarztliche Prax. Ausg. K.

arthrodeses using 2.7/3.5 mm hybrid dynamic compression plates. Veterinary

Kleintiere/heimtiere 39 (1), 7–16. doi:10.1055/s-0037-1622570

Comp. Orthop. Traumatology 12 (03), 102–107. doi:10.1055/s-0038-1632474

Bristow, P. C., Meeson, R. L., Thorne, R. M., Butterworth, S. J., Rutherford, S.,

Meeson, R. L., Goodship, A. E., and Arthurs, G. I. (2012). A biomechanical evaluation

Renwick, A. I., et al. (2015). Clinical comparison of the hybrid dynamic compression

of a hybrid dynamic compression plate and a CastLess Arthrodesis Plate for pancarpal

plate and the castless plate for pancarpal arthrodesis in 219 dogs. Vet. Surg. 44 (1),

arthrodesis in dogs. Vet. Surg. 41 (6), 738–744. doi:10.1111/j.1532-950X.2012.00985.x

70–77. doi:10.1111/j.1532-950X.2014.12183.x

Michal, U., Flückiger, M., and Schmokelt, H. (2003). Healing of dorsal pancarpal

Buote, N. J., McDonald, D., and Radasch, R. (2009). Pancarpal and partial carpal

arthrodesis in the dog. J. small animal Pract. 44 (3), 109–112. doi:10.1111/j.1748-5827.

arthrodesis. Compend Contin. Educ. Vet. 31 (4), 180–191. quiz 192.

2003.tb00129.x

Campbell, F. C. (2012). Fatigue and fracture: Understanding the basics. ASM

Parker, R. B., Brown, S. G., and Wind, A. P. (1981). Pancarpal arthrodesis in the dog:

International.

A review of forty-five cases. Veterinary Surg. 10 (1), 35–43. doi:10.1111/j.1532-950x.

Chambers, J., and Bjorling, D. (1982). Palmar surface plating for arthrodesis of the 1981.tb00627.x

canine carpus. J. Am. Animal Hosp. Assoc.

Rothstock, S., Kowaleski, M. P., Boudrieau, R. J., Beale, B. S., Piras, A., Ryan, M., et al.

Clarke, S. P., Ferguson, J. F., and Miller, A. (2009). Clinical evaluation of pancarpal (2012). Biomechanical and computational evaluation of two loading transfer concepts

arthrodesis using a CastLess plate in 11 dogs. Vet. Surg. 38 (7), 852–860. doi:10.1111/j. for pancarpal arthrodesis in dogs. Am. J. Vet. Res. 73 (11), 1687–1695. doi:10.2460/ajvr.

1532-950X.2009.00573.x 73.11.1687

DeCamp, C. E., Martinez, S. A., and Johnston, S. A. (1993). Pantarsal arthrodesis in Rowe-Guthrie, K. M., Markel, M. D., and Bleedorn, J. A. (2015). Mechanical

dogs and a cat: 11 cases (1983-1991). J. Am. Vet. Med. Assoc. 203 (12), 1705–1707. evaluation of locking, nonlocking, and hybrid plating constructs using a locking

compression plate in a canine synthetic bone model. Vet. Surg. 44 (7), 838–842.

Denny, H., and Barr, A. (1991). Partial carpal and pancarpal arthrodesis in the dog: A

doi:10.1111/vsu.12368

review of 50 cases. J. Small Animal Pract. 32 (7), 329–334. doi:10.1111/j.1748-5827.1991.

tb00943.x Whitelock, R. G., Dyce, J., and Houlton, J. E. (1999). Metacarpal fractures associated

with pancarpal arthrodesis in dogs. Vet. Surg. 28 (1), 25–30. doi:10.1053/jvet.1999.0025

Disegi, J., and Eschbach, L. (2000). Stainless steel in bone surgery. Injury 31, D2–D6.

doi:10.1016/s0020-1383(00)80015-7 Wininger, F. A., Kapatkin, A. S., Radin, A., Shofer, F. S., and Smith, G. K. (2007).

Failure mode and bending moment of canine pancarpal arthrodesis constructs

Ernst, T. S. (2012). Karpal-und Tarsalgelenksarthrodese bei Hund und Katze-

stabilized with two different implant systems. Vet. Surg. 36 (8), 724–728. doi:10.

Behandlungen und Ergebnisse in den Jahren 1996 bis 2010. lmu.

1111/j.1532-950X.2007.00326.x

Fitzpatrick, D. C., Doornink, J., Madey, S. M., and Bottlang, M. (2009). Relative

Worth, A., and Bruce, W. (2008). Long-term assessment of pancarpal arthrodesis

stability of conventional and locked plating fixation in a model of the osteoporotic

performed on working dogs in New Zealand. N. Z. veterinary J. 56 (2), 78–84. doi:10.

femoral diaphysis. Clin. Biomech. (Bristol, Avon) 24 (2), 203–209. doi:10.1016/j.

1080/00480169.2008.36813

clinbiomech.2008.11.002

Zderic, I., Dimitrova, R., Petkov, V., Sprecher, C. M., Mischler, D., Richards, R. G.,

Gambardella, P., and Griffiths, R. (1982). Treatment of hyperextension injuries of the

et al. (2022). Fractographic analysis of two different plate designs used for orthopaedic

canine carpus. Compend Contin. Educ. Pract. Vet. 4 (2), 127–131.

trauma surgery. Eng. Fail Anal. 139, 106440. doi:10.1016/j.engfailanal.2022.106440

Guillou, R. P., Demianiuk, R. M., Sinnott, M. T., Curcio, K., DeCamp, C. E., Haut, R.

Zderic, I., Varga, P., Styger, U., Drenchev, L., Gueorguiev, B., Asimus, E., et al. (2021).

C., et al. (2012). In vitro mechanical evaluation of a limited contact dynamic

Mechanical evaluation of two hybrid locking plate designs for canine pancarpal

compression plate and hybrid carpal arthrodesis plate for canine pancarpal

arthrodesis. Biomed. Res. Int. 2021, 1–8. doi:10.1155/2021/2526879

Frontiers in Bioengineering and Biotechnology 08 frontiersin.org

You might also like

- 115 - Myers, Hansen - Experimental Psychology - 7th Ed PDFDocument637 pages115 - Myers, Hansen - Experimental Psychology - 7th Ed PDFHillary Fajutagana73% (15)

- Martin Price ListDocument12 pagesMartin Price ListAmber Colvard100% (1)

- Radalert 50 ManualDocument25 pagesRadalert 50 ManualPedro NosseauNo ratings yet

- Fsurg 10 1085636Document7 pagesFsurg 10 1085636zxiaoxing087No ratings yet

- The Open Orthopaedics JournalDocument7 pagesThe Open Orthopaedics JournalhuynhkimhieuNo ratings yet

- 1997 Degenerative Changes at The Knee and Ankle Related To Malunion of Tibial FracturesDocument6 pages1997 Degenerative Changes at The Knee and Ankle Related To Malunion of Tibial FracturesstudmmaNo ratings yet

- Studyprotocol Open AccessDocument6 pagesStudyprotocol Open AccessKarthikeyan DNo ratings yet

- 2013artpolsi ActaBiomedicaDocument7 pages2013artpolsi ActaBiomedicaAli MoustafaNo ratings yet

- Comparison of Treatment Effects AfterDocument9 pagesComparison of Treatment Effects AfterFernanda PompeoNo ratings yet

- Management of Complex Orbital Fractures: Article in PressDocument5 pagesManagement of Complex Orbital Fractures: Article in Pressstoia_sebiNo ratings yet

- Clinical Outcomes of Locking Compression Plating Technique in Long Fracture of Dog With or Without Osteoinducer by Using CT Scan: 12 CasesDocument20 pagesClinical Outcomes of Locking Compression Plating Technique in Long Fracture of Dog With or Without Osteoinducer by Using CT Scan: 12 CasesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fractures of The Distal End of The Radius Treated by Internal Fixation and Early Function. A Preliminary Report of 20 CasesDocument6 pagesFractures of The Distal End of The Radius Treated by Internal Fixation and Early Function. A Preliminary Report of 20 Casessanjay chhawraNo ratings yet

- Nomenclatureclassification of Fractures of The Mandibular Condylar Head Loukota 2010Document2 pagesNomenclatureclassification of Fractures of The Mandibular Condylar Head Loukota 2010mandible removerNo ratings yet

- Cuñas MetalicasDocument8 pagesCuñas MetalicasOciel AcostaNo ratings yet

- McGonagle2019 Article TibiaPlateauFractureMappingAndDocument6 pagesMcGonagle2019 Article TibiaPlateauFractureMappingAndFarizka Dwinda HNo ratings yet

- Design and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyDocument9 pagesDesign and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyIJRASETPublicationsNo ratings yet

- Treating Patella Fractures With A Fixed-Angle Patella PlateDocument7 pagesTreating Patella Fractures With A Fixed-Angle Patella PlateAldrovando JrNo ratings yet

- New Concept in External Fixation: Acta Chirurgica Iugoslavica February 2005Document6 pagesNew Concept in External Fixation: Acta Chirurgica Iugoslavica February 2005TrajceNo ratings yet

- CJV 017Document9 pagesCJV 017malifaragNo ratings yet

- Periprosthetic Femoral Fractures Above Total Knee ReplacementsDocument10 pagesPeriprosthetic Femoral Fractures Above Total Knee ReplacementsSpelliardNo ratings yet

- Clroa 4 137Document5 pagesClroa 4 137dr. m a awalNo ratings yet

- Makita2017 PDFDocument46 pagesMakita2017 PDFousseynou ndiayeNo ratings yet

- TH THDocument7 pagesTH THNavin ChandarNo ratings yet

- 1 s2.0 S027823911501558XDocument8 pages1 s2.0 S027823911501558Xhyl776210No ratings yet

- Customized Implants For Acetabular Paprosky III Defects May Be Positioned With High Accuracy in Revision Hip ArthroplastyDocument9 pagesCustomized Implants For Acetabular Paprosky III Defects May Be Positioned With High Accuracy in Revision Hip ArthroplastyIrina DesyatykhNo ratings yet

- The Composite Spreader FlapDocument11 pagesThe Composite Spreader FlapameliNo ratings yet

- A 3-Dimensional Finite-Element Analysis Investigating The Biomechanical Behavior of The Mandible and Plate Osteosynthesis in Cases of Fractures of The Condylar ProcessDocument9 pagesA 3-Dimensional Finite-Element Analysis Investigating The Biomechanical Behavior of The Mandible and Plate Osteosynthesis in Cases of Fractures of The Condylar Processhyl776210No ratings yet

- Articulo 2Document3 pagesArticulo 2Alexander LozaNo ratings yet

- Operative Treatment of Peritrochanteric Osteoporotic Fractures With Proximal Femur Locking Compression Plate A Consecutive StudyDocument6 pagesOperative Treatment of Peritrochanteric Osteoporotic Fractures With Proximal Femur Locking Compression Plate A Consecutive StudyAthenaeum Scientific PublishersNo ratings yet

- 382 FullDocument5 pages382 Fullchalmers6400No ratings yet

- Acetabular Component PositioningDocument4 pagesAcetabular Component PositioningPurushotham NalamatiNo ratings yet

- Brace Technology Thematic Series: The Dynamic Derotation BraceDocument13 pagesBrace Technology Thematic Series: The Dynamic Derotation BraceSilma FarrahaNo ratings yet

- 2015 - Biomechanical Evaluation of Different Angle-Stable Locking Plating Systems For Mandibular SurgeryDocument30 pages2015 - Biomechanical Evaluation of Different Angle-Stable Locking Plating Systems For Mandibular SurgeryLeandro Nascimento Rodrigues dos santosNo ratings yet

- Ziegler 2019Document8 pagesZiegler 2019Joel GalindoNo ratings yet

- 2018 GEP KdrtaDocument22 pages2018 GEP KdrtaJoséAndrésTrejoCorzoNo ratings yet

- Bicolumnar 90-90 Plating of AO 13C Type Fractures - ScienceDirectDocument16 pagesBicolumnar 90-90 Plating of AO 13C Type Fractures - ScienceDirectNavin ChandarNo ratings yet

- Rawal 2016Document8 pagesRawal 2016ehabjawherNo ratings yet

- Kamatuday Appliance (Triple-Banded Space Regainer) : An Innovative ApplianceDocument3 pagesKamatuday Appliance (Triple-Banded Space Regainer) : An Innovative ApplianceIJAR JOURNALNo ratings yet

- Luenam 2018 Journal of Orthopaedic SurgeryDocument9 pagesLuenam 2018 Journal of Orthopaedic SurgeryECRNo ratings yet

- Suzuki Frame Results in The Treatment of Comminuted Phalanx FracturesDocument9 pagesSuzuki Frame Results in The Treatment of Comminuted Phalanx FracturesKha NguyenNo ratings yet

- Mastering Musculoskeletal Interventions: CVIR's Newest Special IssueDocument2 pagesMastering Musculoskeletal Interventions: CVIR's Newest Special IssuecontatoNo ratings yet

- Radiation Diagnostics of The State of The Posterior Longitudinal Ligament in Lumbar OsteochondrosisDocument5 pagesRadiation Diagnostics of The State of The Posterior Longitudinal Ligament in Lumbar OsteochondrosisCentral Asian StudiesNo ratings yet

- A Three-Dimensional Finite Element Analysis of STRDocument18 pagesA Three-Dimensional Finite Element Analysis of STRalexis jonathanNo ratings yet

- New Generation of Superior Single Plating vs. LowDocument8 pagesNew Generation of Superior Single Plating vs. LowRafael HaraNo ratings yet

- Falla de Placa DCP y Tornillo TranspedicularDocument11 pagesFalla de Placa DCP y Tornillo TranspedicularRicardo_CHES1986No ratings yet

- Bidimensionalc TechniqueDocument8 pagesBidimensionalc TechniquemisapopovNo ratings yet

- A Prospective Study For Evaluation of Functional Outcomes of Plate Osteosynthesis For Closed Intraarticular Calcaneal FracturesDocument13 pagesA Prospective Study For Evaluation of Functional Outcomes of Plate Osteosynthesis For Closed Intraarticular Calcaneal FracturesIJAR JOURNALNo ratings yet

- An Update in Qualitative Imaging of Bone Using Ultrashort Echo Time Magnetic ResonanceDocument12 pagesAn Update in Qualitative Imaging of Bone Using Ultrashort Echo Time Magnetic ResonanceGustavo Del PinoNo ratings yet

- Surgical Treatment For Terrible Triad Injury of The Elbow With Anteromedial Coronoid Fracture Through A Combined Surgical ApproachDocument12 pagesSurgical Treatment For Terrible Triad Injury of The Elbow With Anteromedial Coronoid Fracture Through A Combined Surgical ApproachAndrea OsborneNo ratings yet

- Treatment Distal Radius Fracture With Volar Buttre PDFDocument5 pagesTreatment Distal Radius Fracture With Volar Buttre PDFZia Ur RehmanNo ratings yet

- DRUJinstabilityreview - PDF 034407Document15 pagesDRUJinstabilityreview - PDF 034407Oscar Cayetano Herrera RodríguezNo ratings yet

- New Trends and Techniques in Open Reduction and Internal Fixation of Fractures of The Tibial PlateauDocument8 pagesNew Trends and Techniques in Open Reduction and Internal Fixation of Fractures of The Tibial PlateauCosmina BribanNo ratings yet

- Plate Fixation of Distal Radius Fracture and Related ComplicationsDocument9 pagesPlate Fixation of Distal Radius Fracture and Related ComplicationsHudzaifah Al AzmiNo ratings yet

- Hip Resurfacing Expectations and LimitationsDocument4 pagesHip Resurfacing Expectations and LimitationsCristian BenayNo ratings yet

- Incidence of Flexor Tendon Injuries in Complex Intra Articular Distal Radius Fractures Fixed With Volar Rim Plate OsteosynthesisDocument6 pagesIncidence of Flexor Tendon Injuries in Complex Intra Articular Distal Radius Fractures Fixed With Volar Rim Plate Osteosynthesiskainat fatimaNo ratings yet

- S/O Deepak Chakraborty Girish Road, Tarapur Silchar, Cachar District ASSAM-788003Document9 pagesS/O Deepak Chakraborty Girish Road, Tarapur Silchar, Cachar District ASSAM-788003Ali MoustafaNo ratings yet

- JCM 12 06172Document12 pagesJCM 12 06172Taulant MukaNo ratings yet

- Open Book FractureDocument7 pagesOpen Book FractureFebrian Parlangga MuisNo ratings yet

- Measurement of Bone Defects Adjacent To Acetabular Components of Hip ReplacementDocument9 pagesMeasurement of Bone Defects Adjacent To Acetabular Components of Hip Replacementehabede6445No ratings yet

- Granata 2015Document2 pagesGranata 2015Arthur AlbertNo ratings yet

- Ceramic EditorialDocument4 pagesCeramic EditorialDenis AlexandruNo ratings yet

- The Biomechanics of Lag Screw Insertion A ComparisDocument2 pagesThe Biomechanics of Lag Screw Insertion A ComparisCamilo Marin TovarNo ratings yet

- Cardiac Electrophysiology Without FluoroscopyFrom EverandCardiac Electrophysiology Without FluoroscopyRiccardo ProiettiNo ratings yet

- MGT Turbec t100 CCDocument28 pagesMGT Turbec t100 CCDk DamoNo ratings yet

- Micro Turbine Generator SystemDocument28 pagesMicro Turbine Generator Systemraj_turaka0072365100% (2)

- Office Electrical SafetyDocument13 pagesOffice Electrical Safety101arNo ratings yet

- Victaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsDocument2 pagesVictaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsRobson Custódio de SouzaNo ratings yet

- NCSE 2006 Mathematics Paper 1Document10 pagesNCSE 2006 Mathematics Paper 1Christian PatriceNo ratings yet

- 18-Item 19 - Nvis 6000 Electricity Lab PDFDocument2 pages18-Item 19 - Nvis 6000 Electricity Lab PDFWaleed MuradNo ratings yet

- Lesson Plan - Waterfalls NovDocument3 pagesLesson Plan - Waterfalls Novapi-711310485No ratings yet

- An Artificial Intelligence Based Neuro Fuzzy SymDocument6 pagesAn Artificial Intelligence Based Neuro Fuzzy SymbvinothhhNo ratings yet

- Siemens S5Document3 pagesSiemens S5abuzer1981No ratings yet

- Cartography As An Art and A Science?: Cartographic Journal The June 1995Document22 pagesCartography As An Art and A Science?: Cartographic Journal The June 1995Malena MastricchioNo ratings yet

- Financial ReportingDocument6 pagesFinancial ReportingDumisani NyirendaNo ratings yet

- Metro TrainDocument19 pagesMetro TrainSujeet Kumar0% (1)

- Hold Down Guide On Saddle For Pipes " - 68" NPS: Pipe Standard SupportsDocument3 pagesHold Down Guide On Saddle For Pipes " - 68" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Realism Introduction: The Term Realism Is Mostly Used As A Synonym For Power PoliticsDocument5 pagesRealism Introduction: The Term Realism Is Mostly Used As A Synonym For Power PoliticsImti LemturNo ratings yet

- Double Bearing TorsionalDocument1 pageDouble Bearing TorsionalSonidar GroupNo ratings yet

- Seq 5Document1 pageSeq 5api-199340076No ratings yet

- 3306 SnubberDocument4 pages3306 SnubberMina MagdyNo ratings yet

- DecDocument44 pagesDecCoaching GHYNo ratings yet

- ELVIS Resonancia RLCDocument3 pagesELVIS Resonancia RLCHermes PolancoNo ratings yet

- Cambridge Price ListDocument13 pagesCambridge Price ListManuthi HewawasamNo ratings yet

- Hempel's Curing Agent 95880Document13 pagesHempel's Curing Agent 95880Mohamed MahadeerNo ratings yet

- Geology 4th SemDocument2 pagesGeology 4th SemIkhlaq waniNo ratings yet

- Ja Biztown Journal: Biztee Lab WorksDocument5 pagesJa Biztown Journal: Biztee Lab Worksapi-439426007No ratings yet

- Investigation of 150/66 KV 100 MVA Transformer Internal FailureDocument6 pagesInvestigation of 150/66 KV 100 MVA Transformer Internal Failuredavid23281dNo ratings yet

- Ancient Age: Three Age SystemDocument5 pagesAncient Age: Three Age SystemCheska DocumentsNo ratings yet

- Weaccessgeneral Terms and Conditions SilanganDocument2 pagesWeaccessgeneral Terms and Conditions SilanganjenymazonmoralesNo ratings yet

- Module-Management Science Week 3-4Document9 pagesModule-Management Science Week 3-4toni tesoroNo ratings yet