Professional Documents

Culture Documents

Purlin Based Structure Analysis

Purlin Based Structure Analysis

Uploaded by

Prince MittalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purlin Based Structure Analysis

Purlin Based Structure Analysis

Uploaded by

Prince MittalCopyright:

Available Formats

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida

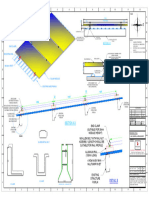

Simulation of PURLIN

BASED STRUCTURE

ANALYSIS

Date: Tuesday, January 8, 2019

Designer: Prince Mittal

Study name:PURLIN BASED STRUCTURE

Analysis type:Static

Table of Contents

Description........................................... 1

Assumptions ......................................... 2

Model Information .................................. 2

Study Properties .................................... 3

Units .................................................. 4

Description Material Properties ................................. 4

Purlin Based Structure Analysis Loads and Fixtures.................................. 5

Contact Information ................................ 7

Mesh information ................................... 8

Resultant Forces .................................... 9

Study Results ....................................... 10

Conclusion .......................................... 13

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 1

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Assumptions

Comments:

Wind Speed :- 190 kmph

Tilt Angle:- 30°

Material:- Aluminum

Grade:- 6063 T6

IS Code:- IS 8147-1976

Wind Load Code:- IS 875 Part 3

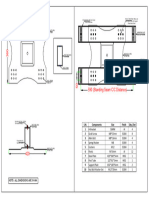

Model Information

Model name: PURLIN BASED STRUCTURE ANALYSIS

Current Configuration: Default

Solid Bodies

Document Path/Date

<L_MdInf_SldBd_Nm/> Treated As Volumetric Properties

Modified

Cut-Extrude2 D:\INDIA PROJECTS\08.

Mass:0.0655301 kg HARYANA\20. CELEBI

Volume:2.42704e-005 m^3 CARGO\PURLIN

Solid Body Density:2700 kg/m^3 BASED\PROFILE ANALYSIS

Weight:0.642195 N - REV2\BASE

CLAMP.SLDPRT

Dec 28 16:01:31 2018

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 2

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Cut-Extrude2 D:\INDIA PROJECTS\08.

Mass:0.0655301 kg HARYANA\20. CELEBI

Volume:2.42704e-005 m^3 CARGO\PURLIN

Solid Body Density:2700 kg/m^3 BASED\PROFILE ANALYSIS

Weight:0.642195 N - REV2\BASE

CLAMP.SLDPRT

Dec 28 16:01:31 2018

LPattern2 D:\INDIA PROJECTS\08.

Mass:2.08705 kg

HARYANA\20. CELEBI

Volume:0.000772982 m^3

CARGO\PURLIN

Solid Body Density:2700 kg/m^3

BASED\PROFILE ANALYSIS

Weight:20.4531 N

- REV2\PROFILE.SLDPRT

Dec 28 16:06:35 2018

<L_MdInf_ShlBd_Nm/> <L_MdIn_ShlBd_Fr/> <L_MdInf_ShlBd_VolProp/> <L_MdIn_ShlBd_DtMd/>

<L_MdInf_CpBd_Nm/> <L_MdInf_CompBd_Props/>

<L_MdInf_BmBd_Nm/> <L_MdIn_BmBd_Fr/> <L_MdInf_BmBd_VolProp/> <L_MdIn_BmBd_DtMd/>

Study Properties

Study name PURLIN BASED STRUCTURE

Analysis type Static

Mesh type Solid Mesh

Thermal Effect: On

Thermal option Include temperature loads

Zero strain temperature 298 Kelvin

Include fluid pressure effects from SOLIDWORKS Off

Flow Simulation

Solver type FFEPlus

Inplane Effect: Off

Soft Spring: Off

Inertial Relief: Off

Incompatible bonding options Automatic

Large displacement Off

Compute free body forces On

Friction Off

Use Adaptive Method: Off

Result folder SOLIDWORKS document (D:\INDIA PROJECTS\08.

HARYANA\20. CELEBI CARGO\PURLIN

BASED\PROFILE ANALYSIS - REV2)

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 3

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Material Properties

Model Reference Properties Components

Name: 6063-T6 SolidBody 1(Cut-

Model type: Linear Elastic Isotropic Extrude2)(BASE CLAMP-1),

Default failure Max von Mises Stress SolidBody 1(Cut-

criterion: Extrude2)(BASE CLAMP-2),

Yield strength: 2.15e+008 N/m^2 SolidBody

Tensile strength: 2.4e+008 N/m^2 1(LPattern2)(PROFILE-1)

Elastic modulus: 6.9e+010 N/m^2

Poisson's ratio: 0.33

Mass density: 2700 kg/m^3

Shear modulus: 2.58e+010 N/m^2

Thermal expansion 2.34e-005 /Kelvin

coefficient:

Curve Data:N/A

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 4

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 2 edge(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) -0.216614 -1328.84 -1.67886 1328.84

Reaction Moment(N.m) 0 0 0 0

Load name Load Image Load Details

Entities: 4 face(s)

Type: Apply normal force

Value: 55.125 N

Force-1

Entities: 2 face(s)

Type: Apply normal force

Value: 220.5 N

Force-2

Entities: 2 face(s)

Type: Apply normal force

Value: 1181 N

Force-6

Entities: 2 face(s)

Type: Apply normal force

Value: -1771 N

Force-7

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 5

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Entities: 2 face(s)

Type: Apply normal force

Value: 1181 N

Force-8

Entities: 2 face(s)

Type: Apply normal force

Value: -1771 N

Force-9

Entities: 2 face(s)

Type: Apply normal force

Value: 1181 N

Force-10

Entities: 2 face(s)

Type: Apply normal force

Value: -1771 N

Force-11

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 6

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Contact Information

Contact Contact Image Contact Properties

Type: Bonded contact

pair

Entites: 4 face(s)

Contact Set-1

Type: Bonded

Components: 1 component(s)

Options: Compatible

Global Contact mesh

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 7

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Mesh information

Mesh type Solid Mesh

Mesher Used: Standard mesh

Automatic Transition: Off

Include Mesh Auto Loops: Off

Jacobian points 4 Points

Element Size 15.5028 mm

Tolerance 0.775141 mm

Mesh Quality Plot High

Remesh failed parts with incompatible mesh Off

Mesh information - Details

Total Nodes 39615

Total Elements 20090

Maximum Aspect Ratio 56.461

% of elements with Aspect Ratio < 3 1.71

% of elements with Aspect Ratio > 10 37.7

% of distorted elements(Jacobian) 0

Time to complete mesh(hh;mm;ss): 00:00:14

Computer name:

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 8

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Resultant Forces

Reaction forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N -0.216614 -1328.84 -1.67886 1328.84

Reaction Moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 0

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 9

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Study Results

Name Type Min Max

Stress1 VON: von Mises Stress 4.218e+004N/m^2 2.017e+008N/m^2

Node: 19456 Node: 1644

PURLIN BASED STRUCTURE ANALYSIS -Stress-

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 10

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Name Type Min Max

Displacement1 URES: Resultant Displacement 0.000e+000mm 4.090e+000mm

Node: 42 Node: 2867

PURLIN BASED STRUCTURE ANALYSIS -Displacement

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 11

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 6.831e-007 1.138e-003

Element: 5503 Element: 713

PURLIN BASED STRUCTURE ANALYSIS -Strain-

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 12

Sunsource Energy Pvt Ltd

B-14, Sector 132, Noida Prince Mittal

1/8/2019

Name Type Min Max

Factor of Safety1 Automatic 1.066e+000 5.097e+003

Node: 1644 Node: 19456

PURLIN BASED STRUCTURE-Factor of Safety

Conclusion

From above results and charts, it is concluded that the given purlin based structure of Aluminum 6063 T6

material will be safe enough within the described conditions.

Analyzed with SOLIDWORKS Simulation <Label_Simulationof/><Model_Name/> 13

You might also like

- Damage Tolerance and Fatigue Behaviour of CompositesDocument32 pagesDamage Tolerance and Fatigue Behaviour of Compositesachyutha_krishnaNo ratings yet

- Chequered PlateDocument23 pagesChequered Platesaravanan428680% (10)

- Shallow Post and Pier Foundation Design - Frame Building News 2013Document17 pagesShallow Post and Pier Foundation Design - Frame Building News 2013Charlie HNo ratings yet

- Fluids Notes 1,2.3Document46 pagesFluids Notes 1,2.3Tobias Okoth100% (1)

- suggestedDemosToCorrespondingPhysicsTextbooks PDFDocument292 pagessuggestedDemosToCorrespondingPhysicsTextbooks PDFWilliam SaaNo ratings yet

- Self-Anchored Suspension Bridges - Part II Structural Behaviour and Main Span Possibilities PDFDocument123 pagesSelf-Anchored Suspension Bridges - Part II Structural Behaviour and Main Span Possibilities PDFdiegoNo ratings yet

- Cement Silo Design As Per IsDocument12 pagesCement Silo Design As Per Issoumi bhattacharyaNo ratings yet

- Gravity Wall (RCC) R0 (27!11!2017) 5m For TestingDocument81 pagesGravity Wall (RCC) R0 (27!11!2017) 5m For TestingLandon MitchellNo ratings yet

- 17.5 MWac A' Nama Poultry - Profile Analysis Report - Purlin Based - Rev0Document12 pages17.5 MWac A' Nama Poultry - Profile Analysis Report - Purlin Based - Rev0Prince MittalNo ratings yet

- 40 Ton 300 MMDocument13 pages40 Ton 300 MMM Ferry AnwarNo ratings yet

- Baranda 01-Analisis Baranda 01 Tolva-1Document19 pagesBaranda 01-Analisis Baranda 01 Tolva-1Carlos Edgardo Zavaleta MedinaNo ratings yet

- Rangka Static 1 1Document24 pagesRangka Static 1 1Febrian WibisonoNo ratings yet

- Simulation of : No DataDocument10 pagesSimulation of : No DataKevin RavenNo ratings yet

- 60 Ton 950 MMDocument13 pages60 Ton 950 MMM Ferry AnwarNo ratings yet

- MINI STRUCTURE-Static 3-5Document19 pagesMINI STRUCTURE-Static 3-5Projects RonukNo ratings yet

- Simulation of 360 Rotating EquipmentDocument13 pagesSimulation of 360 Rotating EquipmentkharvaNo ratings yet

- Asem 1 Static 1 2Document13 pagesAsem 1 Static 1 2Ahmad SutrisnaNo ratings yet

- Hadi Assemble 2-Static 1-1Document15 pagesHadi Assemble 2-Static 1-1Hafiz ShamNo ratings yet

- Simulation of Assem1: No DataDocument12 pagesSimulation of Assem1: No Dataadnan fejzicNo ratings yet

- Assem3-Study BAJA WFDocument13 pagesAssem3-Study BAJA WFMirajuddin MirajuddinNo ratings yet

- Truss2 Static 1 PiyushDocument23 pagesTruss2 Static 1 Piyushpiyush rajputNo ratings yet

- Drone 2 V7-Static 2-1Document13 pagesDrone 2 V7-Static 2-1stark x4No ratings yet

- Simulation of Nut: Sri Krishna College of Engineering and TechnologyDocument14 pagesSimulation of Nut: Sri Krishna College of Engineering and TechnologyVignesh VigneshNo ratings yet

- Assem1 Knuckle Joint Simulation 1SSDSSFSDocument11 pagesAssem1 Knuckle Joint Simulation 1SSDSSFSMayank kumawatNo ratings yet

- Estudio Termoestatico y Dinamico de Una Olla PDFDocument13 pagesEstudio Termoestatico y Dinamico de Una Olla PDFsofia salazarNo ratings yet

- Estudio Termico Olla PDFDocument13 pagesEstudio Termico Olla PDFsofia salazarNo ratings yet

- Estudio Termico Olla PDFDocument13 pagesEstudio Termico Olla PDFsofia salazarNo ratings yet

- Outer Boom-StaticDocument16 pagesOuter Boom-StaticSuresh DNo ratings yet

- Assembly K1-Static 1-2Document26 pagesAssembly K1-Static 1-2Kiara LarasatiNo ratings yet

- PROBLEMA 3.50 ACERO 1020 - 200lbfDocument14 pagesPROBLEMA 3.50 ACERO 1020 - 200lbfMissael Olmos ContrerasNo ratings yet

- Simulation of Run Both Flows: No DataDocument5 pagesSimulation of Run Both Flows: No DataJasNo ratings yet

- Simulation of Drill Bit: Company Address Line 2)Document10 pagesSimulation of Drill Bit: Company Address Line 2)Vignesh VigneshNo ratings yet

- Simulation of Drill Bit: Company Address Line 2)Document10 pagesSimulation of Drill Bit: Company Address Line 2)Vignesh VigneshNo ratings yet

- MODEL - 3 CONNECTING ROD-Carbon Steel-2Document9 pagesMODEL - 3 CONNECTING ROD-Carbon Steel-2Sri Tech EngineeringNo ratings yet

- PED EYE FOR PORTABLE RADIATON PROTECTION-Static 1-1Document14 pagesPED EYE FOR PORTABLE RADIATON PROTECTION-Static 1-1Candra ZulhendriNo ratings yet

- Static 2548 KG DistribuitDocument18 pagesStatic 2548 KG DistribuitMunteanu MihaiNo ratings yet

- Analisa Las-Static 1-1Document21 pagesAnalisa Las-Static 1-1Pramudya FebriantoNo ratings yet

- Bollard TestDocument19 pagesBollard TestsuryaNo ratings yet

- Analisis de Tanque GLPDocument11 pagesAnalisis de Tanque GLPMarlon ZareNo ratings yet

- J000 Za Simulaciju Krov Zaobljeni - 3mmDocument12 pagesJ000 Za Simulaciju Krov Zaobljeni - 3mmjobube89No ratings yet

- Assem1 Static 5 1Document13 pagesAssem1 Static 5 1DanieCybrog Njungkel MenantangmasadepanNo ratings yet

- Knuckle Joint SimulationDocument12 pagesKnuckle Joint SimulationMayank kumawatNo ratings yet

- Simulation of Part1: Jl. PKH. Mustafa No.23Document11 pagesSimulation of Part1: Jl. PKH. Mustafa No.23andhika KasyafaNo ratings yet

- Design of A QuadcopterDocument15 pagesDesign of A Quadcopterstark x4No ratings yet

- Assembly K1-Static 1-1Document24 pagesAssembly K1-Static 1-1Kiara LarasatiNo ratings yet

- Stand Jack 60 Ton MTN Tinggi 910Document14 pagesStand Jack 60 Ton MTN Tinggi 910M Ferry AnwarNo ratings yet

- MODEL - 3 CONNECTING ROD-Aluminium-1Document9 pagesMODEL - 3 CONNECTING ROD-Aluminium-1Sri Tech EngineeringNo ratings yet

- A - 2-Buckling 2-1Document10 pagesA - 2-Buckling 2-1moath farrajNo ratings yet

- Support RDM Study FinalDocument9 pagesSupport RDM Study Finalel chapoo JrNo ratings yet

- Kekuatan Sambungan Pengelasan Bucket Trashcar PLTU AdipalaDocument14 pagesKekuatan Sambungan Pengelasan Bucket Trashcar PLTU AdipalaazmaNo ratings yet

- Space Frame 2019-Torque-Force 25.4X1.6Document24 pagesSpace Frame 2019-Torque-Force 25.4X1.6luis nunezNo ratings yet

- 3 D Truss Exercise 6.18-Static 3-1 Right ResultDocument17 pages3 D Truss Exercise 6.18-Static 3-1 Right Resultmahfuzul_haqueNo ratings yet

- Eletrocentro - Estudo de Movimento-Eletrocentro - Balancim de Içamento - Acréscimo de Olhais-1Document16 pagesEletrocentro - Estudo de Movimento-Eletrocentro - Balancim de Içamento - Acréscimo de Olhais-1Vinicius Monteiro AmaralNo ratings yet

- PROBLEMA 5.15 - Acero 1020Document13 pagesPROBLEMA 5.15 - Acero 1020Missael Olmos ContrerasNo ratings yet

- Simulation of Paro - Direccional - 10 IN: No DataDocument11 pagesSimulation of Paro - Direccional - 10 IN: No DataAbraham PoolNo ratings yet

- Analisis Pelat Samping 3-Roll BendingDocument15 pagesAnalisis Pelat Samping 3-Roll BendingWibisono DNo ratings yet

- Double Riveted Zig-Zag Lap Joint-Static 6-1Document11 pagesDouble Riveted Zig-Zag Lap Joint-Static 6-1Vazeer AliNo ratings yet

- Automated ReportDocument39 pagesAutomated ReportPhillip An-perezNo ratings yet

- Problema 3.50 - Acero 1020 - 500LBF-1Document13 pagesProblema 3.50 - Acero 1020 - 500LBF-1Missael Olmos ContrerasNo ratings yet

- A Situation 2Document66 pagesA Situation 2Josef YangNo ratings yet

- Assemblage Total 03-Static 2-1Document10 pagesAssemblage Total 03-Static 2-1Fou Fou PalermoNo ratings yet

- A Situation 1Document57 pagesA Situation 1Josef YangNo ratings yet

- Analisis Statis Skala Deformasi 1Document16 pagesAnalisis Statis Skala Deformasi 1Sofi UdinNo ratings yet

- Problema 5.15-Acero 4340Document13 pagesProblema 5.15-Acero 4340Missael Olmos ContrerasNo ratings yet

- Simulation of Test 1: No DataDocument10 pagesSimulation of Test 1: No Datasiaga 1No ratings yet

- Redefined Tower ReportDocument26 pagesRedefined Tower ReportDaniel CampbellNo ratings yet

- UTS 2 - STRESS ANALISIS KEPALA PISTON-Static 1-1Document9 pagesUTS 2 - STRESS ANALISIS KEPALA PISTON-Static 1-1Raikhan AlyafiNo ratings yet

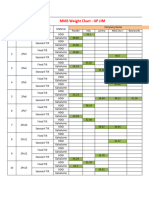

- MMS Weight ChartDocument8 pagesMMS Weight ChartPrince MittalNo ratings yet

- Part A Scope of WorkDocument81 pagesPart A Scope of WorkPrince MittalNo ratings yet

- Ongc 2mw BomDocument39 pagesOngc 2mw BomPrince MittalNo ratings yet

- STR - DWG - 15 MW Solar Power Project at Ibri - Purlin Loading - REV0Document5 pagesSTR - DWG - 15 MW Solar Power Project at Ibri - Purlin Loading - REV0Prince MittalNo ratings yet

- Design Review ChecklistDocument1 pageDesign Review ChecklistPrince MittalNo ratings yet

- For ColumnDocument1 pageFor ColumnPrince MittalNo ratings yet

- Fixed BaseDocument3 pagesFixed BasePrince MittalNo ratings yet

- Purlin Design - Hat-Section@170 (r0)Document4 pagesPurlin Design - Hat-Section@170 (r0)Prince MittalNo ratings yet

- 2X12MM 11Document17 pages2X12MM 11Prince MittalNo ratings yet

- Landscape Based Structure - StandardDocument1 pageLandscape Based Structure - StandardPrince MittalNo ratings yet

- 2X14MMS - 23° - MMS BoqDocument1 page2X14MMS - 23° - MMS BoqPrince MittalNo ratings yet

- Tata Steel Coil Weight DifferenceDocument1 pageTata Steel Coil Weight DifferencePrince MittalNo ratings yet

- 2X14MMS - 25° & 10° - MMS Boq - R0Document1 page2X14MMS - 25° & 10° - MMS Boq - R0Prince MittalNo ratings yet

- Life Line Post-ComponentsDocument1 pageLife Line Post-ComponentsPrince MittalNo ratings yet

- Fea Report - Mini Rail SystemDocument14 pagesFea Report - Mini Rail SystemPrince MittalNo ratings yet

- DBR - Wind Loading - Master File - Latest TemplateDocument2 pagesDBR - Wind Loading - Master File - Latest TemplatePrince Mittal100% (1)

- Expense Claim FormDocument2 pagesExpense Claim FormPrince MittalNo ratings yet

- Fence Boq - R1Document1 pageFence Boq - R1Prince MittalNo ratings yet

- Design of Elastomeric Bearing Pad: A. DiagramDocument4 pagesDesign of Elastomeric Bearing Pad: A. Diagramkenkenmusic100% (1)

- FED 2008 TakeuchiDocument6 pagesFED 2008 TakeuchiUmar FarooqNo ratings yet

- GOOD Constitutive ModelingDocument70 pagesGOOD Constitutive ModelingEng.Hossam NabilNo ratings yet

- Asae S296 PDFDocument3 pagesAsae S296 PDFJavier Gaete Obreque100% (2)

- Heat Transfer and Fluid Mechanics - HTFMDocument18 pagesHeat Transfer and Fluid Mechanics - HTFMShehab Abou GamrahNo ratings yet

- Wind Load Calculation With Gust FactorDocument7 pagesWind Load Calculation With Gust FactorIndustry Standard Structural DesignNo ratings yet

- CE 210 Assignment 1Document2 pagesCE 210 Assignment 1shadrick soleNo ratings yet

- Governing Equations of Fluid Dynamics AND An Aerodynamic Application: "Coanda Effect"Document11 pagesGoverning Equations of Fluid Dynamics AND An Aerodynamic Application: "Coanda Effect"Misch JidaNo ratings yet

- Variational Principles in Classical MechanicsDocument717 pagesVariational Principles in Classical MechanicsmiscNo ratings yet

- Control Tutorials For MATLAB and Simulink - Cruise Control - System ModelingDocument2 pagesControl Tutorials For MATLAB and Simulink - Cruise Control - System ModelingcesarinigillasNo ratings yet

- Tugas Pap Bu SusilaDocument4 pagesTugas Pap Bu SusilanatraNo ratings yet

- Heat TransferDocument3 pagesHeat Transferas2faasbujsacNo ratings yet

- Archimedes LABDocument3 pagesArchimedes LABRadovan Barker Sembiring100% (1)

- Open Channel Flow Case StudyDocument11 pagesOpen Channel Flow Case StudyKanishka WijesekaraNo ratings yet

- 286129Document23 pages286129Cristian WalkerNo ratings yet

- Lamjed Hadj Taieb Med Amine Guidara Noura Bettaieb Sami El Aoud Ezzeddine Hadj Taieb Water-Hammer Control in An Actual Branched Cast Iron Network by Means of Polymeric PipesDocument10 pagesLamjed Hadj Taieb Med Amine Guidara Noura Bettaieb Sami El Aoud Ezzeddine Hadj Taieb Water-Hammer Control in An Actual Branched Cast Iron Network by Means of Polymeric PipesAli TrikiNo ratings yet

- CIV312 Assignment 2Document4 pagesCIV312 Assignment 2louisNo ratings yet

- Gear Box Project Guide LinesDocument12 pagesGear Box Project Guide LinesteddiyfentawNo ratings yet

- Fem Objective QuestionsDocument11 pagesFem Objective QuestionsSree Murthy67% (138)

- 1966-Jaeger-Rock Failure Under He Confined Brazzilian TestDocument9 pages1966-Jaeger-Rock Failure Under He Confined Brazzilian TestMichel SartoNo ratings yet

- Est /ewd: Example 3b-4. A Pair of C250 X 30 Steel Channels Are Secured To The Wood Beam by Two Rows ofDocument2 pagesEst /ewd: Example 3b-4. A Pair of C250 X 30 Steel Channels Are Secured To The Wood Beam by Two Rows ofRomio AlaaNo ratings yet

- Curriculum Physics Program - Assignment 1 - Ryan Hamilton 91641872Document32 pagesCurriculum Physics Program - Assignment 1 - Ryan Hamilton 91641872api-435765102No ratings yet