Professional Documents

Culture Documents

A85780-26 Attachment 24 To IR No. 5.1 - L3R-WDS-4 - A5T7S8

A85780-26 Attachment 24 To IR No. 5.1 - L3R-WDS-4 - A5T7S8

Uploaded by

AMALENDU PAULOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A85780-26 Attachment 24 To IR No. 5.1 - L3R-WDS-4 - A5T7S8

A85780-26 Attachment 24 To IR No. 5.1 - L3R-WDS-4 - A5T7S8

Uploaded by

AMALENDU PAULCopyright:

Available Formats

Enbridge Pipelines Inc. Enbridge Response to NEB IR No.

5 - Condition 21

Line 3 Replacement Program Attachment 24 to IR No. 5.1

Filed August 31, 2017

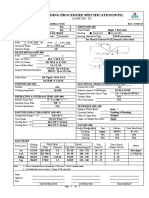

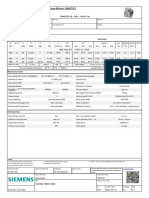

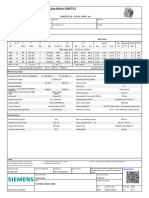

SMAW WELDING PROCEDURE DATA SHEET L3R-WPDS-4 Rev.0

PROJECT: Line 3 Replacement REF. WELDING PROCEDURE No.: ENB-WPS-166 Rev. 0

APPLICATION: Section & Tie-in Welds SUPPORTING PQR No.(s): CRC Weld I.D. 1142-40

SERVICE TEMPERATURE: -5°C

CODE & SPEC:CSA Z662-15, Enbridge PCS002 Version #3.0

MATERIAL GRADE: CAN/CSA-Z245.1, Gr. 483 PIPE SIZE (OD TYPICAL):

CARBON EQUIVALENT: 0.31% Maximum 914 mm (36.0 in.) X 11.8, 12.7, 15.1 , & 19.1mm WT

PREHEAT TEMPERATURE: 120°C (248°F) minimum for an area at least 51 mm (2.0 in.) on each side of the weld joint for the

entire circumference prior to welding. Temperature shall be maintained at or above 120°C (248°F) until completion of the Fill 1

pass. Reheating is permitted after completion of the second pass prior to fill 1.

INTERPASS TEMPERATURE: Remaining fills & Cap pass: 50°C (122°F) minimum, 204°C (400°F) maximum.

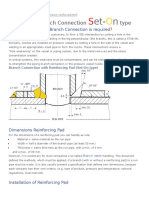

REMOVAL OF LINE-UP CLAMP: TIME INTERVAL BETWEEN PASSES:

Internal: Root bead to be complete prior to internal clamp removal. Root/Hot Pass: 10 minutes maximum.

External: When external line-up clamps are used, the root bead Hot Pass/1st Fill: 60 minutes maximum.

shall be uniformly spaced around the circumference of the joint and Welds shall be filled to 50% of wall thickness prior to

where practicable, shall have a cumulative length of at least 50% of leaving 24 hours when approved by Enbridge. Refer to

the circumference prior to removal. PCS-002 (6.14.4) for welds made using LH consumables.

MINIMUM NUMBER OF WELDER: TECHNIQUE:

Two welders for all weld passes: Stringer or Weaver: Root & Hot Pass – stringer

Root pass, Hot Pass, & Fill 1: (SMAW) Fill/Cap – stringer or weave.

Remaining Passes: (SMAW) Single or Split Pass: Root, Hot Pass, Fill 1: Single

Fill 2: Single

Remaining Fills: Single/Split

Cap Pass: Single/Split

WELDING POSITION: DIRECTION OF WELDING: Root/Hot Pass – Vertical

5G (Pipe horizontal, fixed position.) Down, Remaining Pass(es) Vertical Up.

TYPICAL PASS SEQUENCE:

30° (+5°-0°)

2.0mm ± 0.4mm

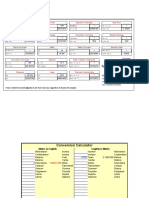

WELDING PARAMETERS

PROCESS: Shielded Metal Arc Welding POLARITY: Direct Current Reverse Polarity

Class Size Arc Speed Heat Input

Pass Amps Volts

(Trade Name) mm (in.) mm / min. (i.p.m.) kJ / mm (J / inch)

134 – 343 (0.66 – 1.54)

Root E6010 (Lincoln 5P+) 4.0 (5/32) 114-172 20 – 33

(5.3 – 13.5) 16,880 – 39,176

E8010-P1 4.0 (5/32) 167 – 546 (0.54 – 1.36)

Hot Pass 123-215 20 – 34 13,594 – 34,489

(Lincoln Shield-Arc 70+) 4.8 (3/16) (9.8 – 21.5)

E8018-C3 51 – 168 (0.83 – 2.52)

Fill #1-Uphill 2.4 (3/32) 76-115 19 - 30

(Excalibur) (2.0 – 6.6) 21,034 – 63,811

E8018-C3 41 – 100 (1.59 – 4.29)

Fill #2-Uphill 3.2 (1/8) 94-160 18 – 29

(Excalibur) (1.6 – 3.9) 40,400 – 108,937

E8018-C3 46 – 74 (3.15 – 4.88)

Fill #3-Uphill 4.0 (5/32) 127-213 18 – 29

Excalibur) (1.8 – 2.9) 80,133– 123,916

E8018-C3 53 – 206 (0.69 – 2.37)

Cap - Uphill 2.4 (3/32) 73-121 19 – 29

(Excalibur) (2.1 – 8.1) 17,580 – 60,219

Note(s) - The use of a stripper pass is optional. Weld reinforcement height 3.5 mm maximum. Weld Repairs performed prior to

NDT are restricted to the weld cap.

Contractor Acceptance: Date:

Print Name & Sign

Page 1 of 1

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- John Coltrane Licks For GuitarDocument2 pagesJohn Coltrane Licks For GuitarRudj GinanneschiNo ratings yet

- ASME Material List in ExcelDocument69 pagesASME Material List in ExcelAMALENDU PAULNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- Summary of ASME Section VIIIDocument3 pagesSummary of ASME Section VIIIAMALENDU PAUL100% (2)

- (Ancient Maps) Maps of The Late Medieval Period 1300 - 1500Document105 pages(Ancient Maps) Maps of The Late Medieval Period 1300 - 1500api-3707729100% (2)

- Telltale HoleDocument3 pagesTelltale HoleAMALENDU PAULNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Engineer Guide Summary DEC 2020Document25 pagesEngineer Guide Summary DEC 2020AMALENDU PAULNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Edr 01 Dec 2018Document21 pagesEdr 01 Dec 2018AMALENDU PAULNo ratings yet

- Tank Settlement Report As Per API 653Document2 pagesTank Settlement Report As Per API 653AMALENDU PAUL100% (8)

- Appendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Document24 pagesAppendix B3-10 Welding Procedure Specification EPI-11-WP6 Rev.1 - A4A2E9Tahir AliNo ratings yet

- Hoskold FormulaDocument12 pagesHoskold FormulaGodShot ShaiyaNo ratings yet

- VHDL Implementation of A MIPS RISC Processor PDFDocument6 pagesVHDL Implementation of A MIPS RISC Processor PDFMitali DixitNo ratings yet

- Painting Course Important Topic: DFT WFT X 100Document6 pagesPainting Course Important Topic: DFT WFT X 100AMALENDU PAUL100% (1)

- Report of Storage TankDocument44 pagesReport of Storage TankAMALENDU PAUL100% (1)

- Introduction To Process Plant Layout & Piping DesignDocument91 pagesIntroduction To Process Plant Layout & Piping DesignRaj Kamal0% (1)

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Stopuri Spate (Donut Style) : Proceduri Codari Vag ComDocument33 pagesStopuri Spate (Donut Style) : Proceduri Codari Vag ComMitrutz Vintila100% (2)

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- 1LE1003 0DA21 7AB4 Datasheet enDocument1 page1LE1003 0DA21 7AB4 Datasheet enkamal_arbabNo ratings yet

- A85780-16 Attachment 14 To IR No. 5.1 - L3R-WPDS-3 Rev. 2 - A5T7R8Document1 pageA85780-16 Attachment 14 To IR No. 5.1 - L3R-WPDS-3 Rev. 2 - A5T7R8silvanopipeNo ratings yet

- 1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE1001-0EB42-2FB4 Datasheet enDocument1 page1LE1001-0EB42-2FB4 Datasheet enAde FaisalNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- 1LE1502 1EB23 4AA4 Datasheet enDocument1 page1LE1502 1EB23 4AA4 Datasheet enRasool SabeghiNo ratings yet

- 1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- 1LE1503-1EA23-4AB4 Datasheet enDocument1 page1LE1503-1EA23-4AB4 Datasheet enpatilshailesh123No ratings yet

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- 1LE1523-1EB43-4AA4 Datasheet enDocument1 page1LE1523-1EB43-4AA4 Datasheet enmuhammad nazmiNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5503-3AB73-5AB1Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5503-3AB73-5AB1Aleksandar DejanovicNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3105B Simotics SD - 100 L - Im V1 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3105B Simotics SD - 100 L - Im V1 - 4PrifkikhafidNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- 1le1502 2BB03 4aa4Document3 pages1le1502 2BB03 4aa4Atlanta Bolivia100% (1)

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- 1LE1501-1EB43-4JA4 Datasheet enDocument1 page1LE1501-1EB43-4JA4 Datasheet enIbraheem AlfalahatNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2310A Simotics XP - 315 S - Im V1 - 2PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2310A Simotics XP - 315 S - Im V1 - 2PMARIAM100% (1)

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PToko DownloadNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- 1le1503 3ab53 4ab4Document2 pages1le1503 3ab53 4ab4Whipman ArduinoNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- BGAS Study Material Gist2Document4 pagesBGAS Study Material Gist2AMALENDU PAULNo ratings yet

- 1 - Piping CBT API 571 AnsDocument5 pages1 - Piping CBT API 571 AnsAMALENDU PAULNo ratings yet

- CBT Piping QuestionsDocument3 pagesCBT Piping QuestionsAMALENDU PAULNo ratings yet

- Bsibv Itp 08-2 Itp For CWC Dpe Rev. 0Document9 pagesBsibv Itp 08-2 Itp For CWC Dpe Rev. 0AMALENDU PAULNo ratings yet

- BSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0Document5 pagesBSIBV-ITP-09-1 For Liquid Epoxy Coating On Fittings Rev. 0AMALENDU PAULNo ratings yet

- PAINTDocument10 pagesPAINTAMALENDU PAULNo ratings yet

- Formula For Tecnical - 12 Mar 2019Document80 pagesFormula For Tecnical - 12 Mar 2019AMALENDU PAULNo ratings yet

- M337x - 387x - 407x - Release Note - English PDFDocument3 pagesM337x - 387x - 407x - Release Note - English PDFGiovane SchmechelNo ratings yet

- Title - Real Time Pathfinding and OptimizationDocument15 pagesTitle - Real Time Pathfinding and OptimizationVARUN 2K19-SE-142No ratings yet

- Inductor Color Code GuideDocument2 pagesInductor Color Code GuideBarry Bj Shaide100% (1)

- Eichelberger (1978) Anesitic Vlcanism and Crustal EvolutionDocument7 pagesEichelberger (1978) Anesitic Vlcanism and Crustal EvolutionSedarta SebayangNo ratings yet

- Frequency AdverbsDocument4 pagesFrequency AdverbsAlexander ScrNo ratings yet

- Mann Kendall Statistic and COVDocument11 pagesMann Kendall Statistic and COVMayankNo ratings yet

- Corporate Finance Canadian 7th Edition Jaffe Test BankDocument26 pagesCorporate Finance Canadian 7th Edition Jaffe Test Bankdoijethrochsszo100% (30)

- Sample Size and Power CalculationDocument31 pagesSample Size and Power CalculationRendy Adhitya PratamaNo ratings yet

- Monitoring BladesDocument9 pagesMonitoring BladesmruizbarriosNo ratings yet

- Computer Communication Networks: Midterm ReviewDocument38 pagesComputer Communication Networks: Midterm ReviewANISH GIRI GEL GERİ GERİNo ratings yet

- Assignment 7Document10 pagesAssignment 7Nahian KabirNo ratings yet

- Curriculum Guide in Science Grade X S.Y. 2020-2021: St. Scholastica'S Academy Tabunok, Talisay City, CebuDocument15 pagesCurriculum Guide in Science Grade X S.Y. 2020-2021: St. Scholastica'S Academy Tabunok, Talisay City, CebuWarley JabelNo ratings yet

- Formulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid DispersionDocument16 pagesFormulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid DispersionBaru Chandrasekhar RaoNo ratings yet

- Previous GATE Questions On Number SystemsDocument4 pagesPrevious GATE Questions On Number SystemshelithiNo ratings yet

- Applications of Fluid Mechanics in DiffeDocument11 pagesApplications of Fluid Mechanics in DiffeGodwin King-NyamadorNo ratings yet

- The Psychology of Morbid Curiosity - Development and Initial Validation of The Morbid Curiosity ScaleDocument10 pagesThe Psychology of Morbid Curiosity - Development and Initial Validation of The Morbid Curiosity Scale畏No ratings yet

- Expt 7 Compound CircuitsDocument10 pagesExpt 7 Compound CircuitsDamien ManceraNo ratings yet

- CE2080 Practice QuestionsDocument11 pagesCE2080 Practice QuestionsRishabhDuttNo ratings yet

- Assignment No. 4Document2 pagesAssignment No. 4saurabhpatankar5No ratings yet

- Distillation Column Design and SimulationDocument29 pagesDistillation Column Design and Simulationhinman714No ratings yet

- Chapter 3-Compression MembersDocument41 pagesChapter 3-Compression MembersGamtesa EjetaNo ratings yet

- United States Patent Office: Patented June 16, 1964Document3 pagesUnited States Patent Office: Patented June 16, 1964Vansala GanesanNo ratings yet

- Create Customer Project in SAP S/4HANA Cloud Using SAP Process Automation RecorderDocument16 pagesCreate Customer Project in SAP S/4HANA Cloud Using SAP Process Automation RecorderLohithNo ratings yet

- TMT Boron CoatingDocument6 pagesTMT Boron Coatingcvolkan1100% (2)