Professional Documents

Culture Documents

Chloride Ball Valve FLV

Uploaded by

Lenin MagañaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chloride Ball Valve FLV

Uploaded by

Lenin MagañaCopyright:

Available Formats

info@flourvalve.

it

www.flourvalve.it

FLV SPECIAL USE VALVES

Ball VALVES

Special Use Ball Valves Series CL ................................................ 37

FLV SPECIAL USE VALVES 2

CL

CHLORINE

SERVICE

BALL VALVES

FLV SPECIAL USE VALVES

CL

Chlorine Service Ball Valves (CL)

Flour Valve® ball valves for chlorine service are designed for use with chlorine, cleaned

and assembled with required measures for a safe use in chlorine service equipment and

avoid valve contamination to the media purity. Some of the designs comply with the

Chlorine Institute Pamphlet 6: "Piping Systems for Dry Chlorine".

Chlorine

Chlorine is a hazardous and toxic material that irritates the respiratory, with a distinctive

pungent odor. Chlorine, chemical element symbol Cl, is nonflammable in both gaseous and

liquid states however; chlorine gas is a strong oxidizer, which may react with flammable

materials, and can support combustion when combined with other substances.

The Chlorine gas has an irritating odor that many people can detect with as little as 3.5ppm

(parts per million) chlorine present. Breathing air containing more than1000 ppm of chlorine

might be fatal.

Chlorine density is 3.2 kg/m3 (1.013 bar at 0 °C), because it is heavier than air, it tends to

accumulate at the bottom of poorly ventilated spaces. Chlorine boiling point -34.04 °C

(-29.27 °F) at a pressure of 1 atmosphere, the liquid must be stored under high pressure or at

low temperature. Chlorine melting point is -101.5 °C (-150.7 °F).

Chlorine Uses

Chlorine is mainly used in manufacturing chemicals; including solvents, pesticides and

herbicides, plastics and fibers, refrigerants and propellants. It is also an ingredient in bleach,

deodorizer and disinfectant. In addition, chlorine is widely used in bleaching pulp, paper and

textiles; disinfecting drinking water and swimming pool purification; plus in sanitation of

industrial and sewage wastes.

‘Chlorine’ term

Gas and liquid refer to the physical state of chlorine itself; dry and wet refer to the content of

moisture within the gas or liquid. Dry chlorine is either gaseous or liquid chlorine with less

than 150 ppm of water by weight. Chlorine containing more than 150 ppm is considered as

wet chlorine, gas or liquid.

Note: Flour Valve® offers metallic valves only for dry chlorine! Solubility of Water in Liquid Chlorine

600

500

PPM (W/W) water

400

Wet chlorine

300

200

100 Dry chlorine

0

-70 -50 -30 -10 10 30 50

PPM (W/W) water Temperature C

FLV SPECIAL USE VALVES 4

CL

General

Chlorine Service feature is available for part of Flour Valve’s valves series – check series ordering

codes for availability. Available valve sizes, types and variety of end connections are per each

relevant series ordering codes.

Design

Valves designed for chlorine in a liquid state should be equipped with an upstream pressure

relief hole in the ball (Ordering code -P250). The relief hole avoids trapped cavities in the valve

closed position and pressure buildup due to thermal expansion during liquid ammonia boil

off. A valve with relief hole in the ball is uni-directional, the relief hole must be positioned at the

upstream flow direction for complete in-line sealing. For Bi-directional valve design for liquid

chlorine a Self-Relief Seats (Ordering code -SRS) should be used with seats material of TFM or

CF PTFE, the SRS seat design dynamically release cavity pressure buildup and return to shutoff Self-Relieving-Seat

position once the over pressure is relieved. Valves designed for chlorine in the gaseous state do (SRS)

not require an upstream pressure relief hole.

Valve Materials for dry chlorine

Valves for dry Chlorine Systems are used with chlorine in gas or liquid state, usually at

temperatures between -101 °C (-150 °F) and +149 °C (+300 °F). Steel piping is commonly used

for handling dry chlorine, defined as containing no more than 150 PPM of water by weight.

Stainless steels of types 3xx might fail due to chloride stress cracking, particularly in presence

of moisture at ambient and elevated temperatures. Monel 400 and Alloy C22, or Alloy C276 are

the recommended materials for ball and stem, with TFM or CF PTFE seats. Body and stem seals

can be PTFE, CF PTFE or graphite for fire-safe valves.

Moisture Level Recommended Material

0 - 20 PPM Alloy C22 ball and Monel 400stem

20 - 50 PPM Alloy C22 ball and stem Cavity pressure relief

0 - 50 PPM Alloy C22 ball and stem (for end of line service (P250 Ball)

3 mm relief hole face

Note: For higher moisture levels up to 150 PPM, Alloy C22 is the recommended material of the upstream

construction for all metal parts.

FLV SPECIAL USE VALVES 5

CL

The following material of construction are recommended for dry chlorine service by the

Chlorine Institute, Pamphlet #6:

Temperature -29 ºC (-20 ºF) to 149 ºC (300 ºF) -46ºC(-50ºF)to 149ºC(300ºF) -60ºC(-76ºF)to 149ºC(300ºF)

Fluid State Gas or Liquid (<150ppm water) Gas or Liquid (<150ppm water) Gas or Liquid (<150ppm water)

Ends Threaded, Welded, Flanged Threaded, Welded, Flanged Threaded, Welded, Flanged

Body/Ends A216 WCB, Alloy C22, Alloy C276 A352 LCB, Alloy C22, Alloy C276 LF2, Alloy C22, Alloy C276

Ball/Stem Alloy C22, Alloy C276 Alloy C22, Alloy C276 Alloy C22, Alloy C276

Bolts ASTM A193 Grade B7, B7M (Ferritic Steels) ASTM A320 Grade L7 ASTM A320 Grade L7

Nuts ASTM A194 Grade 2H, 2HM (Carbon Steel) ASTM A194 Grade 4 (Carbon-Molybdenumsteel) ASTM A194 Grade 4 (Carbon-Molybdenumsteel)

Seats PTFE,TFM PTFE,TFM PTFE,TFM

Seals PTFE, Graphite PTFE, Graphite PTFE, Graphite

Warning: The HermetiX™ stem seal valve for chlorine service include different material

than PEEK.

Cleaning, Assembling and Packing

All valve components used for chlorine service, in gaseous or liquid state, are de-burred to a

high standard and specifically cleaned to remove any traces of oil, grease or hydrocarbon

materials prior to assembly.

Chlorine service valves are assembled in an oil-free restricted area by personnel who are

specially equipped and trained to perform this task. The assembling area, work surfaces,

equipment and tools are specially maintained to ensure cleanliness requirements are met.

Only lubricants compatible with chlorine are used.

• Valves are packed in open position with capped ends and plastic bagged

• Each valve is packed with a 'Silica-gel pack'

• A sticker on the plastic bag indicating“Chlorine Service”

Optional Accessories

Locking Device (LD)

As a safety measure, it is advisable that valve for ammonia service should

be equipped with spring loaded locking device do avoid unauthorized or

unintentional valve operation.

For more information see Habonim Valve Accessories catalog.

FLV SPECIAL USE VALVES 6

CAT-Chlorine Ball valves FLV

About Flour Valve®

Ball Valves & Actuators for the most demanding, challenging and We are leading in special ball valve-based control solutions,

hazardous applications are our passion and profession for the last emergency shutoff and specially designed solutions.

40 years.

Believing that supplying and developing the most effective, safe

We believe in designing, manufacturing and supplying control and and reliable products for the global leaders in the LNG and Gas

shutoff components and solutions that improves the overall safety, distribution market continually challenges us to improve our

integrity and sustainability of the systems they are installed in. capabilities and products.

Designed, manufactured and tested according to the highest Best coping with our prestigious customers’ most challenging

standards, our products allow us to partner within systems that requirements technically, operationally and commercially is our

flow and control varied gases and liquids in diverse markets promise fulfilled for decades.

especially where extreme temperatures and pressures are involved,

hazardous materials are used and system performances arecritical. Performing in Demanding Applications

Flour Valves S.P.A. Via Borzoli, Sestri, Génova, Italia 16154 I Tel.:+39.3208.0832.77

info@flourvalve.it www.flourvalve.it

http://www.flourvalve.it

You might also like

- Ball Valves As Per Chlorine Institute Pamplet 6Document14 pagesBall Valves As Per Chlorine Institute Pamplet 6Reddy SadhanaNo ratings yet

- Dome Valve BrochureDocument8 pagesDome Valve BrochurecpsusinNo ratings yet

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Document8 pagesFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanNo ratings yet

- OMB Bellows Seal ValvesDocument20 pagesOMB Bellows Seal ValvesPaulNo ratings yet

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- ChemicalDocument5 pagesChemicalisaac2408No ratings yet

- Chemical ResistanceDocument32 pagesChemical Resistancejb10No ratings yet

- Chemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpDocument13 pagesChemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpEdinsonNo ratings yet

- BallValve Body Trim MaterialDocument3 pagesBallValve Body Trim Materialsabes26No ratings yet

- DH Type Flash Condensing Deaerator Heads: DescriptionDocument2 pagesDH Type Flash Condensing Deaerator Heads: DescriptionSajjad AhmedNo ratings yet

- (Good) ChemicalResistanceGuide - Many SealsDocument13 pages(Good) ChemicalResistanceGuide - Many SealscrystaltanNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

- Trophy Seal™ Floating Equipment: CementingDocument2 pagesTrophy Seal™ Floating Equipment: CementingsatyendraNo ratings yet

- Chemical Resistance GuideDocument36 pagesChemical Resistance GuideHeiner PalaciosNo ratings yet

- SBF LongdDocument10 pagesSBF LongdcatalineulaNo ratings yet

- Chemline: Actuation and Actuated ValvesDocument44 pagesChemline: Actuation and Actuated ValvesRohit GadekarNo ratings yet

- Controls and Flowmeters PDFDocument40 pagesControls and Flowmeters PDFibharNo ratings yet

- Cera System Catalogue 2011Document36 pagesCera System Catalogue 2011prihartono_diasNo ratings yet

- Grove T41Document6 pagesGrove T41Den AbbasNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- LPG Pumps-CorkenDocument4 pagesLPG Pumps-CorkenAjit DyahadrayNo ratings yet

- Cosmolubric HF-130: Description Features/ BenefitsDocument1 pageCosmolubric HF-130: Description Features/ BenefitsLuHa1No ratings yet

- Giacomini - Modelo R850 Y R910 - Valvula EsfericaDocument14 pagesGiacomini - Modelo R850 Y R910 - Valvula EsfericaDiego Francisco Ancajima CuevaNo ratings yet

- Paint Selection Guide PDFDocument4 pagesPaint Selection Guide PDFAnindya Aulia PratiwiNo ratings yet

- Claron 10Document257 pagesClaron 10المهندس محمود خليلNo ratings yet

- Lusin Product Brochure en v1Document8 pagesLusin Product Brochure en v1ImeblaNo ratings yet

- GASKET - DESIGN - & - BOLTING Kamprofile PDFDocument77 pagesGASKET - DESIGN - & - BOLTING Kamprofile PDFPranpath NarupantawartNo ratings yet

- Metal and Rubber Chemical Resistance GuideDocument11 pagesMetal and Rubber Chemical Resistance GuideReza SalimiNo ratings yet

- Chemical Resistance Guide For Valves: March 25, 2010Document11 pagesChemical Resistance Guide For Valves: March 25, 2010akramhomriNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- 20brochure PDFDocument27 pages20brochure PDFparet999No ratings yet

- Catalog Pak KuntoDocument10 pagesCatalog Pak Kuntopt tabNo ratings yet

- Lab Catalouge - Goel Scientific - CanadaDocument36 pagesLab Catalouge - Goel Scientific - CanadaGoel ScientificNo ratings yet

- Piping SpecificationDocument5 pagesPiping SpecificationShandi Hasnul FarizalNo ratings yet

- OneSteel Valve Product CatalogueDocument40 pagesOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- Corken CompressorI100Document16 pagesCorken CompressorI100adriansya7No ratings yet

- Foam Chambers F 2011010 2Document6 pagesFoam Chambers F 2011010 2Anonymous B1AOOsmRMiNo ratings yet

- Generic Systems 2006Document4 pagesGeneric Systems 2006wfjerrNo ratings yet

- Corken LPG Pumps and CompressorsDocument24 pagesCorken LPG Pumps and Compressorssizweh100% (2)

- Corken ManualDocument24 pagesCorken Manualطارق سويد100% (1)

- Mmabr PDFDocument10 pagesMmabr PDFVlad AncutaNo ratings yet

- A - General Bray InternationalDocument16 pagesA - General Bray InternationalNestor QuevedoNo ratings yet

- Halton Marine Hvac CatalogDocument26 pagesHalton Marine Hvac CatalogEdson Da SilvaNo ratings yet

- Soluforce Catalogue PDFDocument32 pagesSoluforce Catalogue PDFsureshisisis100% (1)

- Technical Paper-WSD 2018Document6 pagesTechnical Paper-WSD 2018krbabu1969No ratings yet

- Vapour Pressure DataDocument44 pagesVapour Pressure Dataramsrivatsan50% (2)

- Perfect Chloro Systems - Gas ..Document6 pagesPerfect Chloro Systems - Gas ..nazar750No ratings yet

- Cryogenic Service Ball ValveDocument2 pagesCryogenic Service Ball ValvesaminasritnNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345No ratings yet

- 2005 Valve Catalog Full ASAHIDocument150 pages2005 Valve Catalog Full ASAHIRicardo Rodriguez MartinezNo ratings yet

- BR Epv Pres 02Document20 pagesBR Epv Pres 02Mano NegraNo ratings yet

- Spesifikasi Foam Chamber - Ansul - Ru-3-2018Document2 pagesSpesifikasi Foam Chamber - Ansul - Ru-3-2018Monalisa DoskiNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.From EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.No ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Lesson Plan Letter SDocument4 pagesLesson Plan Letter Sapi-317303624100% (1)

- Economics - Economics - Cheat - SheetDocument1 pageEconomics - Economics - Cheat - SheetranaurNo ratings yet

- LAB REPORT - MGCLDocument5 pagesLAB REPORT - MGCLKali stringsNo ratings yet

- Circuit Construction: Assignment 3Document45 pagesCircuit Construction: Assignment 3ali morisyNo ratings yet

- Oracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JDocument10 pagesOracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JLuis YañezNo ratings yet

- Project Analysis - M5 - MotorwayDocument6 pagesProject Analysis - M5 - MotorwayMuhammad Haroon ArshadNo ratings yet

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Document4 pagesKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975No ratings yet

- 3E Hand Over NotesDocument3 pages3E Hand Over NotesAshutosh MaiidNo ratings yet

- 03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaDocument48 pages03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaSudarshan GadalkarNo ratings yet

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- Macros and DirectiveDocument7 pagesMacros and DirectiveAbdul MoeedNo ratings yet

- Sub-Wings of YuvanjaliDocument2 pagesSub-Wings of Yuvanjalin_tapovan987100% (1)

- Swot Analysis of Indian EconomyDocument2 pagesSwot Analysis of Indian EconomymyeyesrbeautNo ratings yet

- CryptogrophyDocument37 pagesCryptogrophyFarah EssidNo ratings yet

- Chapter 4 Signal Flow GraphDocument34 pagesChapter 4 Signal Flow GraphAbhishek PattanaikNo ratings yet

- World BankDocument28 pagesWorld BankFiora FarnazNo ratings yet

- Lahore Waste Management CompanyDocument45 pagesLahore Waste Management CompanyHadia NasirNo ratings yet

- RS2 Stress Analysis Verification Manual - Part 1Document166 pagesRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- Kingroon ConfiguracoesDocument3 pagesKingroon ConfiguracoesanafrancaNo ratings yet

- QSasDocument50 pagesQSasArvin Delos ReyesNo ratings yet

- Kursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014Document12 pagesKursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014ihsanyusoffNo ratings yet

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDocument7 pagesPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- The Handmaid's TaleDocument40 pagesThe Handmaid's Taleleher shahNo ratings yet

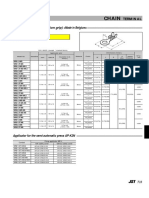

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- EDAG0007Document5 pagesEDAG0007krunalNo ratings yet

- Rosewood Case AnalysisDocument5 pagesRosewood Case AnalysisJayant KushwahaNo ratings yet

- Furniture AnnexDocument6 pagesFurniture AnnexAlaa HusseinNo ratings yet

- Shelly Cashman Series Microsoft Office 365 Excel 2016 Comprehensive 1st Edition Freund Solutions ManualDocument5 pagesShelly Cashman Series Microsoft Office 365 Excel 2016 Comprehensive 1st Edition Freund Solutions Manualjuanlucerofdqegwntai100% (10)