Professional Documents

Culture Documents

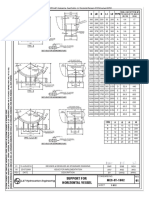

7-12-0002 Rev5 - Support For Horizontal Vessel

Uploaded by

SachinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-12-0002 Rev5 - Support For Horizontal Vessel

Uploaded by

SachinCopyright:

Available Formats

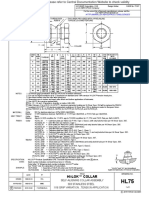

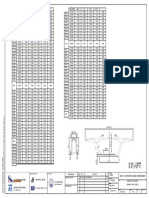

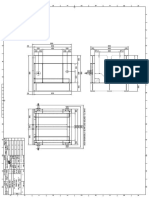

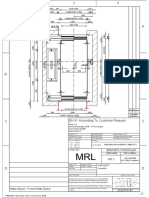

STANDARD No.

SUPPORT FOR

ORMO ENGNEERS

NDIA UWE)

IA Govt. of India Undertaking) HORIZONTAL VESSEL

7-12-0002 Rev. 5

Page 1 of 1

MAX. APPROX.

D LB H t../ L2 ie

TYPE SADDLE

L3 SADDLE

(M. TON) (KGS.)

10 150 10

D/18 OR 300 260 300 50 200 A 4.4 17

\ I 350 280 325 55 210 A 4.8 18

\ tii +

x _il 400 330 350 75 250 A 4.5 20

450 370 375 95 300 A 3.6 22

YM

11

-wwTs..

V) ''' OF 500 450 450 125 370 A 14.9 40

IIR0PERKM

L1 L/ 600 560 500 175 470 A 13.2 50

I 1 EARTHING Ir 170 it 700 650 550 225 570 A 11.0 55

2

. I =J 26 0 HOLES FOX 800 750 600 275 670 A 10.6 65

M 20 BOLTS 900 850 650 300 760 A 11.0 75

:

TYPE - A

IUD 1000

1200

950

1100

700

800

330

375

820

960

B

B

12.3

19.4

85

130

HOLE FOR 1400 1250 900 465 1150 B 19.7 140

SLIDING SUPPORT

1600 1450 1000 370 1300 C 23.3 165

1800 1600 1100 410 1450 C 39.1 260

D/18 2000 1750 1200 445 1600 C 43.5 290

O 9R

■ 2200 1950 1300 495 1800 D 49.1 295

i 110 111 2400 2150 1450 545 2000 D 53.5 390

ki iii

__.

..1 2600 2300 1550 585 2150 D 52.9 440

11 1

Li Li

N- II It

1 0

2800

3000

2500

2670

1650

1750

620

670

2300

2500

E

E

52.7

64.9

475

600

I- EARTHING 3200 2800 1850 710 2600 E 63.8 620

I 250

L

26 0 HOLES FOR 3400 3000 1950 760 2800 E 64.9 630

30 M 20 BOLTS

111111 3600 3200 2050 830 3000 E 60.5 725

TYPE - B

DUD ,

3800

4000

3350

3550

2150

2250

845

895

3150

3300

E

E

61.0

60.6

745

820

HOLE FOR

SLIDING SUPPORT

TYPE t1 t2 L3 t3

D/18 A 10 10 170 12

B 10 12 250 12

110 C 12 16 300 16

D 16 20 350 20

2-60 VENT

HOLE (TYP.) E 20 20 400 20

(REF. NOTE-5)

I L 1 I L1 I Li 140

EARTHING

I 250

L2

I 30 0 HOLES FOR

30 M 24 BOLTS

PARALLEL TO VESSEL

TYPE - C. D. E AXIS (TYP)

HOLE FOR

SLIDING SUPPORT

NOTES

ALL DIMENSIONS ARE IN mm UNLESS OTHERWISE STATED.

VESSEL DIAMETER 'D' REFERS TO THE OUTER DIAMETER OF THE SHELL.

FOR INTERMEDIATE DIAMETERS TAKE THE IMMEDIATE NEAREST DIAMETER SUPPORT.

WELDING SHALL BE DONE ALL AROUND AND SHALL BE CONTINUOUS FILLET WELD. WELD SIZE SHALL

BE 6 mm FOR VESSELS UPTO 1400 mm DIA. AND 8 mm FOR VESSELS ABOVE 1400 mm DIA.

PROVIDE 2 NO. 60 VENT HOLES IN SADDLE WRAPPER PLATE. THESE HOLES SHALL BE PROVIDED DIAGONALLY

OPPOSITE AND BE LEFT UNPLUGED AND SHALL BE FILLED WITH HARD GREASE ONLY.

WHERE EARTHING LUG CANNOT BE PUT AT AN ELEVATION OF 400 mm ABOVE THE SADDLE BASE PLATE

IT SHALL BE LOCATED AS HIGH AS POSSIBLE.

EARTHING LUGS ARE NOT TO BE PAINTED OR GALVANIZED.

DETAIL, DIMENSIONS AND NOTES IN ENGINEERING DRAWING TAKE PRECEDENCE OVER THOSE SHOWN HERE.

MATERIALS SHALL BE AS PER ENGINEERING DRAWING.

EARTHING LUG SHALL BE AS PER STANDARD 7-12-0026

5 30.06.2011 REAFFIRMED AND REISSUED AS STANDARD POREL e611'

RKT A M/SC DM

4 08.09.2006 REAFFIRMED AND REISSUED AS STANDARD POREL DNN AKM VC

Rev. Prepared Checked Stds. Committee Stds. Bureau

No. Date Purpose Convenor Chairman

Page 5021 of 10496 by by

Approved by

Format No. 8-00-0001-F4 Rev.0 Copyright EIL - All rights reserved

You might also like

- John Constantine, Hellblazer Vol. 01 - Original Sins (2011) GetComics - InfoDocument271 pagesJohn Constantine, Hellblazer Vol. 01 - Original Sins (2011) GetComics - InfoSergi100% (2)

- Heat TreatingDocument7 pagesHeat TreatingSachinNo ratings yet

- Gazebo - Type BDocument6 pagesGazebo - Type BDaniel OkereNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Us Expressive Self Portrait ProjectDocument37 pagesUs Expressive Self Portrait Projectapi-285692559No ratings yet

- Stress CategorisationDocument6 pagesStress CategorisationSachinNo ratings yet

- Medidas RetenesDocument106 pagesMedidas RetenesZivia ʕ•ᴥ•ʔ100% (1)

- Session 02 - Standard Format For Technical DrawingDocument28 pagesSession 02 - Standard Format For Technical DrawingThean ThoeurnNo ratings yet

- REDA (Data)Document20 pagesREDA (Data)saeedNo ratings yet

- Man Hour EstimationDocument8 pagesMan Hour EstimationSachinNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- The - New.yorker 27.december.2021Document94 pagesThe - New.yorker 27.december.2021William HsuNo ratings yet

- T-707-Calculations Based On Actual Thickness-R2Document25 pagesT-707-Calculations Based On Actual Thickness-R2SachinNo ratings yet

- Alpinevilla 1BHK (Layouts & Costings)Document14 pagesAlpinevilla 1BHK (Layouts & Costings)Adarsh A DNo ratings yet

- Amigurumi Pattern - Mad Hatter by CreativechaosofmargauxDocument8 pagesAmigurumi Pattern - Mad Hatter by CreativechaosofmargauxDurleny GomezNo ratings yet

- Module 4 LO 1-2 FDocument35 pagesModule 4 LO 1-2 FJade Allison Solis Bagasbas100% (1)

- MES ST 1002 - SaddleDocument2 pagesMES ST 1002 - SaddleDarshan PanchalNo ratings yet

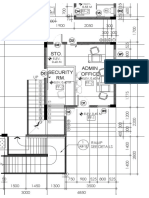

- Idesia PH1 Cluhouse - Admin OfficeDocument1 pageIdesia PH1 Cluhouse - Admin OfficeReymark LegaspiNo ratings yet

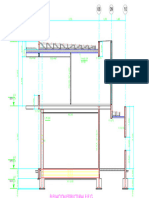

- Ing DetalleDocument1 pageIng DetalleGiselle Carrasco llancafilNo ratings yet

- Denah MWC Nu Pujon Revisi 1Document3 pagesDenah MWC Nu Pujon Revisi 1ansNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- Calplas CatalogueDocument59 pagesCalplas CatalogueMorris MorrisonNo ratings yet

- Bar Bending Schedule Indian Standard v3.2 - English - XLSMDocument8 pagesBar Bending Schedule Indian Standard v3.2 - English - XLSMdjebaili1993No ratings yet

- 20008-001-1703 01-12-005-13-A Palanca para Sin FinDocument1 page20008-001-1703 01-12-005-13-A Palanca para Sin FinKarlosdcd WikiNo ratings yet

- RMD For EmaarDocument61 pagesRMD For Emaaraliengineer953No ratings yet

- Duct Estm Faiz Bill 14.06.2013Document105 pagesDuct Estm Faiz Bill 14.06.2013ECOTEQ EngineersNo ratings yet

- Brosur Canter Super CapacityDocument2 pagesBrosur Canter Super CapacityYosuaNo ratings yet

- CompdwgDocument1 pageCompdwgdanpascoNo ratings yet

- Cord Conn Selec ChartDocument3 pagesCord Conn Selec ChartP Vikram MoudgalNo ratings yet

- WMKIDocument26 pagesWMKIandrewchong31No ratings yet

- Table 21 Double Flanged l/4. Bend:. (Cluuses 9.1: All Dimensions in Mil!metresDocument1 pageTable 21 Double Flanged l/4. Bend:. (Cluuses 9.1: All Dimensions in Mil!metresAkshat JainNo ratings yet

- Accessories e 1Document4 pagesAccessories e 1Việt Đặng XuânNo ratings yet

- Sheet 1 of 4 Advanced Exercise #3Document4 pagesSheet 1 of 4 Advanced Exercise #3Long NguyenNo ratings yet

- Plan View at Tos - El +104.000Document1 pagePlan View at Tos - El +104.000D7mey XNo ratings yet

- 1 PDFDocument1 page1 PDFAthaya Rizky PratamaNo ratings yet

- VOL IV Sec-6 Drawing MekanikalDocument9 pagesVOL IV Sec-6 Drawing MekanikalKomang SuantikaNo ratings yet

- March Pump Te 7 MD 50hz CurveDocument9 pagesMarch Pump Te 7 MD 50hz CurveintillimaidenNo ratings yet

- SD 5-1-111 Rev 1 TY - BeamsDocument1 pageSD 5-1-111 Rev 1 TY - BeamsAmel khanNo ratings yet

- CAT YSV: Msss El Salvador San SalvadorDocument11 pagesCAT YSV: Msss El Salvador San SalvadorNeto RubioNo ratings yet

- Air 02Document1 pageAir 02Praveen SubramanianNo ratings yet

- VesselsDocument9 pagesVesselsGoel ScientificNo ratings yet

- Quantity Calculation: Approach SlabDocument79 pagesQuantity Calculation: Approach SlabOkta SofyanaNo ratings yet

- High Precision Planetary Gearboxes: Apex Dynamics, IncDocument6 pagesHigh Precision Planetary Gearboxes: Apex Dynamics, IncR2m r2mNo ratings yet

- MS21254Document5 pagesMS21254Bogdan RusuNo ratings yet

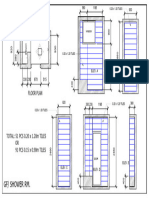

- GF/ Shower RM.: Floor PlanDocument1 pageGF/ Shower RM.: Floor Planar.christdelvivar.uapNo ratings yet

- Ellimo B - Igineb6: India Wind (A Bracket Support For Vertical VesselDocument1 pageEllimo B - Igineb6: India Wind (A Bracket Support For Vertical VesselsahilNo ratings yet

- Curbe de Functionare 50 HZ N 2900 1/min: 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 8 US G.P.M. Imp G.P.M. FeetDocument1 pageCurbe de Functionare 50 HZ N 2900 1/min: 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 8 US G.P.M. Imp G.P.M. FeetTNo ratings yet

- TibongDocument1 pageTibongcastrorexelNo ratings yet

- Faa-Tso Authorized Part - .... - C........ : Afl (RDocument1 pageFaa-Tso Authorized Part - .... - C........ : Afl (RRenato WatanabeNo ratings yet

- Ag Group: B Ring Mold - Inner AG-0005-BDocument1 pageAg Group: B Ring Mold - Inner AG-0005-BAnonymous IQD4PqB876No ratings yet

- Aeropuerto de Tulcán - Ecuador //SETUDocument3 pagesAeropuerto de Tulcán - Ecuador //SETUSebastian RomeroNo ratings yet

- Duct MeasurementDocument2 pagesDuct Measurementmudassir mNo ratings yet

- As Build Drawing: Cme RT Pole 6 M Site Name: Pondok Tjandra Site Id: Sda003Document36 pagesAs Build Drawing: Cme RT Pole 6 M Site Name: Pondok Tjandra Site Id: Sda003herry horasNo ratings yet

- Presion Neumaticos 931Document1 pagePresion Neumaticos 931kathy fernandezNo ratings yet

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumarNo ratings yet

- 5.1 Accessories Pe PN12,5 & PN 16 02 Jan 2018Document4 pages5.1 Accessories Pe PN12,5 & PN 16 02 Jan 2018Dannyadja RahardjoNo ratings yet

- Techtop ODPDocument3 pagesTechtop ODPHydro Energy GroupNo ratings yet

- TB-H AmenityDocument1 pageTB-H AmenityEdsel SiababaNo ratings yet

- Funcion Weibull: LN (T) LNLN (1/ (1-F (T) ) LNLN (1/ (1-F (T) )Document6 pagesFuncion Weibull: LN (T) LNLN (1/ (1-F (T) ) LNLN (1/ (1-F (T) )Edwin Freddy Huayta PaccoNo ratings yet

- Jmi Pacific Limited Ch. Karnchang: Si Rat - Outer Ring Road ExpresswayDocument1 pageJmi Pacific Limited Ch. Karnchang: Si Rat - Outer Ring Road ExpresswaykeaoreNo ratings yet

- Specification: Borewell Pump Discharge Chart: T0tal Depth in Feet Bore Well Pump Tower 1 HP 1.5 HP 2 HP 3 HP 5 HP 7.5 HP 10 HPDocument2 pagesSpecification: Borewell Pump Discharge Chart: T0tal Depth in Feet Bore Well Pump Tower 1 HP 1.5 HP 2 HP 3 HP 5 HP 7.5 HP 10 HPscbrajaNo ratings yet

- Borewell Compressor PumpDocument2 pagesBorewell Compressor PumpJagadish Gowda JagguNo ratings yet

- Pre Desain Denah Cibuni Guest Housen (03092019)Document9 pagesPre Desain Denah Cibuni Guest Housen (03092019)Agung SetiawanNo ratings yet

- Custom Ball Valve TITAN-810: Proprietary and ConfidentialDocument1 pageCustom Ball Valve TITAN-810: Proprietary and ConfidentialGundhi AsmoroNo ratings yet

- API Buttress RunningDocument1 pageAPI Buttress RunningEdwin MPNo ratings yet

- 210ton Sumitomo - PLATENDocument1 page210ton Sumitomo - PLATENcountzeroaslNo ratings yet

- HousingDocument1 pageHousingCaripahNo ratings yet

- FleetA Aug08 PDFDocument3 pagesFleetA Aug08 PDFAlex BurcăNo ratings yet

- "Designed and Engineered To Perform": Second EditionDocument96 pages"Designed and Engineered To Perform": Second EditionNathanNo ratings yet

- EN 81 According To Customer Request: Brackets / KonsollarDocument3 pagesEN 81 According To Customer Request: Brackets / KonsollarНиколай НиколовNo ratings yet

- Drawing 3Document4 pagesDrawing 3Nesreen Ahmed NaoumNo ratings yet

- Ajay Singh's Empowering Leadership_ Reviving SpiceJet From the Brink (1) (3)Document17 pagesAjay Singh's Empowering Leadership_ Reviving SpiceJet From the Brink (1) (3)SachinNo ratings yet

- E003 Rev1Document3 pagesE003 Rev1SachinNo ratings yet

- English SEA Term 1 Slogan Writing For Hunge StrikeDocument2 pagesEnglish SEA Term 1 Slogan Writing For Hunge StrikeSachinNo ratings yet

- gr3 Math ws3 ch2Document1 pagegr3 Math ws3 ch2SachinNo ratings yet

- 01 What Is BiomassDocument33 pages01 What Is BiomassSachinNo ratings yet

- Growth Plan - Mechanical GroupDocument6 pagesGrowth Plan - Mechanical GroupSachinNo ratings yet

- To Do ListDocument2 pagesTo Do ListSachinNo ratings yet

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDocument1 pageExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNo ratings yet

- 2BDocument4 pages2BSachinNo ratings yet

- BSPL 1242 Iot2 Me Cal 0004 Rev.a1Document70 pagesBSPL 1242 Iot2 Me Cal 0004 Rev.a1SachinNo ratings yet

- PV Newsletter - Volume 2012 Issue 8Document8 pagesPV Newsletter - Volume 2012 Issue 8SachinNo ratings yet

- Collapse StressDocument7 pagesCollapse StressSachinNo ratings yet

- Use of Appendices 1-9 and 1-10 of ASME Section VIII Division 1Document3 pagesUse of Appendices 1-9 and 1-10 of ASME Section VIII Division 1SachinNo ratings yet

- Boiler Riser TubesDocument8 pagesBoiler Riser TubesSachinNo ratings yet

- SOR 15-16 (June-18) - SoftDocument31 pagesSOR 15-16 (June-18) - SoftMiteshNo ratings yet

- Catalog Company PDFDocument74 pagesCatalog Company PDFYuliana Nina YuanitaNo ratings yet

- Stone Masonry, Stone Mortars - Stone Work Types of Masonry Ashlar Facing RubbleDocument2 pagesStone Masonry, Stone Mortars - Stone Work Types of Masonry Ashlar Facing RubbleManish ShashikantNo ratings yet

- SERVICE GATE Detail - 23-03-2023Document1 pageSERVICE GATE Detail - 23-03-2023AmulyaRajbharNo ratings yet

- Calculate and Color 2Document1 pageCalculate and Color 2nova kurniasariNo ratings yet

- Apply Quartz Paint L3 LG by Minilik .GDocument96 pagesApply Quartz Paint L3 LG by Minilik .Gminilikgetaye394No ratings yet

- 450 FFL - 20 FFL: Cold Water Systems Layout (Ground Floor)Document10 pages450 FFL - 20 FFL: Cold Water Systems Layout (Ground Floor)Boeun VibolNo ratings yet

- Short Oil Alkyd Resin: Principal PropertiesDocument1 pageShort Oil Alkyd Resin: Principal PropertiesNguyen HaiThachNo ratings yet

- Havells FansDocument44 pagesHavells Fansdesignanddrawing cphclwNo ratings yet

- Hardeep Dhindsa, Presentation, Apollo BelvedereDocument9 pagesHardeep Dhindsa, Presentation, Apollo Belvederezoya62684No ratings yet

- Jenny Saville PresentationDocument13 pagesJenny Saville Presentationapi-644927057No ratings yet

- Book 1Document4 pagesBook 1wayne huangNo ratings yet

- L05 - Drawings 3 - SectionsDocument35 pagesL05 - Drawings 3 - SectionsSolomon OpokuNo ratings yet

- Guideline and MechanicsDocument3 pagesGuideline and MechanicsEliza Mae LasanNo ratings yet

- Development of Photogrammetry in The U. S. Geological SurveyDocument32 pagesDevelopment of Photogrammetry in The U. S. Geological Surveysharonlly toumasNo ratings yet

- Send - Stationery For Kuantan UMP 1st Term 2018Document3 pagesSend - Stationery For Kuantan UMP 1st Term 2018Norhayati YusofNo ratings yet

- Circular Visions of Fertility and Punishment: Caliphal Ivory Caskets From Al-AndalusDocument24 pagesCircular Visions of Fertility and Punishment: Caliphal Ivory Caskets From Al-AndalusJuanna PerezNo ratings yet

- PDF Quarter 1 - Complete-1Document63 pagesPDF Quarter 1 - Complete-1Merbert PascuaNo ratings yet

- Ceramics Art and Perception Issue 105 July 2017Document164 pagesCeramics Art and Perception Issue 105 July 2017Steve100% (1)

- PT in MAPEH 10Document7 pagesPT in MAPEH 10MARIA CRISTINA TEMAJONo ratings yet

- The Elements and Principles of Architecture ACA2021-InDONESIADocument13 pagesThe Elements and Principles of Architecture ACA2021-InDONESIAADEDAYO JEREMIAH ADEYEKUNNo ratings yet

- Business Cards Logo Design Photoshop Editing Presentation Design Poster DesignDocument3 pagesBusiness Cards Logo Design Photoshop Editing Presentation Design Poster DesignAmazing K Makers (Havijithan)No ratings yet

- AW 6 - Graphic Design (Fundamentals of DesignDocument3 pagesAW 6 - Graphic Design (Fundamentals of Designangeladarleen eresoNo ratings yet