Professional Documents

Culture Documents

IEEE STD 1246™-2002 Temporary Protective Grounding System Used in Substations

Uploaded by

Amany Hamdy0 ratings0% found this document useful (0 votes)

9 views40 pagesOriginal Title

IEEE Std 1246™-2002 Temporary Protective Grounding System used in Substations

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views40 pagesIEEE STD 1246™-2002 Temporary Protective Grounding System Used in Substations

Uploaded by

Amany HamdyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

IEEE std 1246-2002

(Poona EEE is 126-197)

1246™

IEEE Guide for Temporary Protective

Grounding Systems Used in

Substations

IEEE Power Engineering Society

Sponsored by the

Substations Committee

IEEE

Newton ev soreaaer sk

‘ahea 200

‘Recognized as an IEEE Std 1246™-2002

‘Amencan Natonal Standard (ANS) (Revsion of IEEE Sl 1240-1965)

IEEE Guide for Temporary Protective

Grounding Systems Used in

Substations

‘Sponsor

‘Substations Committee

of the.

IEEE Power Engineering Society

‘Approved 12 Septomber 2002

IEEE-SA Standards Board

Aeprovec 21 sanuary 2008

‘American National Standards Institute

‘Abstract: The design, perormance, use, testing, and instalation of tomporay protective

(rounding systems, eluding the connection pots, a Used I parmanan and mabieSubsatens,

tr covered in he guide

Keywords: grounding, personnel salty, protective grounding, salty, tomporay grounding,

imate rating, witetan rating

ang 203 rat la we eee ra

‘Sanne lan Sp SP hs eS etn,

para ptcaan may roan yom. AEN Sm an, et er

‘or psd pase

EE Sundar aun deo whine IEE Said te tnd Corti Caio te

IEEE Sunde Anocaton (EEE GA) Stnars Bou Te ERE dete Sasa hap» oes

elope roses approved by he Anson Nese! fdas at, il bon tte vote

‘remnant Yes wea eo

ay personal ny, rope tar

‘Ecstns any ogres or mpd watans,tcaiog My ped warty of mrcanaiy off fo a pee

aon ort be of he mural cst Hern oe tan ptt genet IE Sud acne

coin 48 18.

‘sco HEE Sind ot iy tte eno ps, pr

feet fase sasar reed ad soe ce ee ont sieae devia be

roo iene ale, lr

epbtiting ed making hi cena! le he IEEE ot geting or renin of oe sei

{iroroe wha os fens remy Norte IEEE waeahng prey Sue oe ant

‘iat Any eon le no te EEE Suncare drumet shod we pm the io

‘npn poems Sem thc of asta nh Ben coun

Inuepeetatne Oca guns may aie repre he mering of on of snd they ite 0

EWES Satin eptember EE, tte

‘Teper lo iapaon hese a ne oe Whey he mat as rey rss foal conerson,

‘Nets Annis cd poi tmp of is ld wy ue of le

‘ter oe tent ey piano hs ane option en wth pe the

‘Site oa of ny puts conmcin eih Te EEE Sa tbe one oe

‘Sipng rus for ws hee may eee bo IEEE sad efor once ies

‘toa eye op of opts teow enon,

Aston hosp pron at inulin prone ut yh ite

‘Fours Garon Enns, ne” pone atte srepat ep 9 Coprge Caras Cer To

Sane for pot of eng, sot Copp Carace Ca, Caster Srv, 23 Remo

Bry aoc, WA 835 USA, sis bth, Peep pts tyne aad ae

‘Slim cto ean abs be bad thou be Copp Cons Cte

Introduction

(This introduction is not 2 part of IEEE Sut 12462002, IEEE Guide for Temporary Protective

‘Grounding Sytns Used in Substations)

Practices for aplyng temporary protective grounds (TPG) in eubations vary from ity to tty

‘These pac ave come fom suber of docunents sch a ASTM F85S-1997, TEC 6120-1983,

sd TEE Sd 1048-1990 a wel a from Bld expercace derived fom bine maiteince practi

‘This rie war developed to cotaiate nto one document all he necessary lnoumaton forthe

sity to develop sound personel safety grounding prais im substations. The guide provides

‘sformation on the piysal comstrucson, application, and testing of TPGS as ty are ued in

‘beatons

“This revision ncades reveal pew definitions, which dary and ate to standard the use and

{Understanding of several soraonly used ter fr various temporary provnding practices 1 ako

‘ngs he ltromechanial forces prset with high shored caren and wih igh current

‘fet (asymmetry). I recent ets, then foes wee found to have sigan ina onthe abit) of

‘complete TPC asembis snluingatachment points, capable of succesfully handing these high

Participants

This eid guide was developed by Working Group Dé of the Substations Commits, Disribation

Subsiations Subcommittee. At the time of completion, the Working Group consisted ofthe flowing

membership:

Donald N. Lar, Secretary

Hanan. Abdallah Gary Engmann Mitt Pate

Smt Barnes Martin Havlea ‘ShasikantG, Patel

‘From M. roe: Bil Kahanck Brac Rockwell

Mike Bogdan Ricard . Kel Willseh

Sieve D. Brown Alan Kollar Gary Sins

Frank A. Denbrosk Steve Lads Bob Stewart

Gary DiTroa delliey D. Merynan Can Sida

‘Steve Midlesamp

Capt 60. Alte se. i

‘Te following members ofthe balloting group voted on this revi gue, Balloters may’ have voted

{or approval: dsapproal, or stetion. e

Hanna E. Abdallah Donal Land Psy Po!

‘Thomas M. Barns Stephen R Lambert Janes Ruger

Mike Bio ‘Thomas LaRowe Mark Simon

Charis Blazer Gregory Lu David Singleton

Frank A. Deabosk Jose Melanson Douglas Sith,

Wiliam Reve Dita [AvP (Sai) Mebopouloe HL Mele Sith

Xush Done Gary Mice ohn engin

Gura Dat Dain Abdul Mousa ‘Macolm Taaden

(Gary Eagmane Kyaw Myint Dane Torgron

Bran Erp ‘An Nesbaer Bake Uden

D. Lane Garett Benson Ne Janes Witsoe

Richard P. Kel Robert Nowell Pater Won

Hermans Koch Shaikan G. Patel San Zande

‘Terry Keummsey Gene Pesor Donald W. Zine

Past Pies

‘When the IEEE-SA Standards Board approved tis revised guide on 12 September 210, it had the

following mentership:

ames T, Cael, Char

ames H. Gurney, Viee Char

Jodie Gorman, Secretary

a een se

Se nee fearon ey ®

eres ean ives

ens a pees

eee Py ae ae

i oan erro ae

read ee

Also inlae ar the following nonvoting IEEE-SA Standards Bord Tiisons:

‘Alan Cookson, NIST Representative

Sutsh K- Aggarwal, NRC Reprsotaive

Savouls Amanatiis

TEE Siodards Managing Etor

® ‘roan © 20 EE. sa ean

Contents

1. Overview

scope

Referens

Defiations.

44 Consideration for temporry protective grounding tems

a

44

4“

49

General TPG.

Curent magnitie and duration

Special areas of concen. - :

‘TPG cable assembles. -

TPG abe :

Mull asembli

Avuhment points _

410 Cable extention

5. Appian s

51 Gene

$2 Locton of PGs

54 Methods

(6. Installation and removal

6

6a

Toots

“Testing for vote

Placing nd removing of TPG, -

‘en © 208 EEE. te a

1. State, capstve couple, and eltromagneticly coupled volte protection.

1 Protetveparments

8 Toso.

81 New TPG component and assembly testing.

2 Inservice inspection, maintenance and testing of TAGs.

Anges A (formative) Terminology

‘Anne B informative) Bibionraphy.

t

IEEE Guide for Temporary Protective

Grounding Systems Used in

Substations

4. Overview

14 Scope

“This ide covers the design, performance, si, testing, and installation of temporary protective

rounding systems, cluding the connection poi as abd in permanent and mete substations

‘Tis guide docs not adds serescapactor compensated ystems

12 Purpose

‘This guide sugunts god practices, techni iformaton and salty exitei to ast inthe ston

and application of temporary potctive grounding systems, inodng te connection ents, as wed

Jn permaneat and mobde rubstatins,

2. References

“This ide shall te asad in conjunction withthe following publications. When te following

publications ae superseded by an approved rvs, the ison shal apy

ASTM F4S6197, Sundar Specfetons for Teorey Prout Grounds to Se Used on

De-nergnad Eira! Power Lins and Eauipment”

1-199, Polyvinyl ChordeKsunted Cables of Ratt Voltas Up To and Iniing 40

1aV_Put | Gael Regine?

ony © 208 EEE. A eee 7

ve

Ec 60227-21997, Plyviny Chloride Inst Cables of Rated Voltages Up To an Incl 450/

150 V—Part 2 Text Method.

EC 0245-2-198, Rubber Insulated Cables of Rated Voltages Up To and inching 480/780 V—Part.

2 Test Methods

TEC 61230-1993, Live Working—Poruble Equipment fr Earthing or Farting and Short Ciruting

IEEE Std 1045-199, IEEE Guide for Proteive Grounding of Power Lines

3. Definitions

For the purposes ofthis guide, the flowing ems and detntions apply EEE 100 84) should be

reference for terms not defined inthe le

‘3 bracket gromdlag: The location of temporary protective grounds (TPG) on al sles of a worst

The lration ofthe TPGs can be immediately adjacent o oF some dance from te werkst

32 caster round assembly: A preassembled set of four cable or tar asics, with three phase

‘onnestiont and one ground conection, al terminating» common (ste) poi

3.3 catimiy: A coninnons, snbroten clr ct, For the perptss of tanporsy protective

founding any device capable of asforming voltage or producing a Sniant vlage 0p cannot

be considered as maintaining continuity. Examples include transformers, fies, rector, ressors,

eat breakers, abd line traps

5.4 equipotent 200 (gupta grounding): A general ter wed to describe he application of

temporary proactive prounds to lit the potential srs the worker's body. It len aot

‘wih wort or ingle point prounding, but also includes ote aplctons of temporary grounding

35 ground potential rise (GPH) The manu voliage that a station grounding gid:an ata lative

5.6 phaset-ground (paral) grog: The installation of temporary protective rounds fom each

Piatto round. The pron attachment pont canbe a commen pon forall free TPG proud

‘connection btwern an) separated TPC proud connacon posts equa

37 phasetorphane (hn) gromding: Te intalation of teporay protective grounds from phase to

Plasto pase with an adiioal TPG connecting from one af he the phase e ground

28 somce grounding: The location of TPGs to ensure that a st of temporary pr‘xive grounds is

Ieteen the workste and al posible soures of eure.

59 temporary protective ground equipment (TPG): Devices to limit the voltage erence between

any to tcl points atthe worksite to safe vale, and bavingrfient arent withstand rating

“Thee might const of cable ssembbes, pounding switches, or tmporse ial bar

{TSE und or pocsre o Cae ?a tendons owned by the ite of eral nd Esti

Srhetambe in tsi ermpond othe fhe Wap Ame

2 Ceo 08 EE eae

Protective ground i capable of earyng for spetied ine without fsing or msg the cable. The

"TPG are generally sated by this value. TPG subjected to this curent might be damped and should

ot be reused

2.1 wttand rating The caret a temporary protective ground shoul conduc fora specid tine 0

alow the protetve devi to clear the fat without tng damaged suliienty to prevent bag

fperable The TPG shoul be capable of passing «second west at this current rating afer beng cooked

(0 ambient temperature

5.12 morte (single-point) gromaing: The application of temporary protetive groxnds only in the

immediate viii ofan esl continous worksite, The loaton ofthe TPGs mart be close

nought the worksite fo prevent. haardowsGierencen potential acres & worker the worksite

e 210 imate rating (capacity): A cscuatat maximum symmetrical curent that a temporary

Considerations for temporary protective grounding systems

41 General TPG

“enporary protestve ground equipment is wil when growing a substation power bas and

equipment to protest personnel from high voltages tat can be indeed or appled becuse of

gunmen fare or operting error. The TPGs shouldbe prope asd and assed to protect,

‘enon! fom ijry during steady-state or abnormal power system operon.

‘42 Permanent or mobile substation

e ‘Thee TPG asembls are applicable for both mobile and prmaneat substations

43 Current magnitude and duration

‘Hound shal! be capable of carrying the maximum avadabl fat cuenta te alt bation without

fare forthe Graton of the a

43.1 Current magnitude including de offset

“The caren mgt is one of the rt actors to be considered when sng temporary protective

‘wounding sates. The fst curent consis oft rms ae component and a de oll cuent

omponent. The ms ae component is determined by the subvanset impedances ofthe routing

‘machinery, he impatance of transformer, and the impedance of Ines. The 6 oft component =

‘termined by the 1K rai atthe fal loaton looking bck into the power systema the ine of

‘al intaton onthe voltage waveform

Analyt stains that whon fl de fet occ in the cations with igh X/2 rato (such as

‘dost generating plant ora large ansmision substation), the short duration (610 yes) using

‘ret clings of grounding cables eaealated sing Onderdonk's equation as considered in ASTM.

#SS-1997 might wot be conservative, The adional bea fom the de cure component reduces

the cable curentcarying caps. The cable current-carrying capability forthe sesjele ang

‘edad about 25% when the 2/R vai s changed from 0-40 as shown in Table 22) and Table 2),

© —_—_ sora esnips sd rainon tans, ep 2 iy sin te

(iin epson so estomc soit ny Hl es: Wile one ak

omg 650 EE, gt cre A

the 1/8 rato canbe a igh s 50, under mot circumstances the X/R mati doesnt exceed 40 within

the rutatone. Several les avay from the subeations, the rato dominate by the inpedance

‘the line. The overall X/Rrati in such care canbe dterined fom the line's X/R at. The teal

ange of 1/Rratioe for nes from 2 to 20 depending on the conductor congation. Angle

Smal conductor ine wi have low X/ eo whi bundled large conductor ne wll hav higher

Mik so.

In ation tothe fee om fing eaten, the X/R rato and de of can produce extemely igh

Cavtent peaks in the fist fw clr mative to the ms crrent. While te cuent peaks are

‘roportona othe X/ rato, tho rate of ey x invery proportional othe Xo. Tae slowly

Usctying high curent peaks, correponding to her XR raion, create the most severe

‘ettomschaicl for, which can deuroy the TPG assembly long before i fais thermally. In

‘och e cue he worker mould be without protein for longer duration belore the lt clears. TEC

‘1230-1998 rqure texporarysuthng devo o withstand peak asymmetrical careat 2.5 ines

the rma current value

4.32 Fault duration including primary and backup relaying

“The aut durations nother rita fastor to be considered whe ising protective grounds. The fault

‘Station the tne rege ose theft by primary or backup relaying. The fa clearng ines

the sum of relay and breaker operation ties, Prinar) celia the ist ine of dese 1 leas 3

faut at highspeed. Even though ating the primary rely faut clearing Une maimizes the

[rounding eae zm the lblty of rimary relay operation should te evaluated i ass comsidered

Foesiing the protective ground

Backup relaying i provided or posible flure in the primary relaying system or for possible ure

‘ibe cout real or other protstie device Remote backup and loca backup ae wo forms of

backup proteton in common x on power systems In remote backup relying, els ae cared

ffom the system, one substation away ots where the fault har ceerred. I lol tack reshng.

faults re Seared focally i the sate subeation where the fuk as cured. Loa backup

Drofecton wil sar te aut om the sem in less te than that provided by remote backup

Protection, Uslzig the backup feny fl ering tine provides a conservatively aed protection

‘round. Since more than overlay operates to cl fault on the rem, the tine takes for 8

fpecie mumberof relay contact operation to ler a fut an be coven asthe Backup eesing

tle: Fr example, loc baker flue can 48 frm § 40 12 eyes to the peimaty ceaing time

‘Steond zoe or remote backup relying can ad from 121024 els tothe ria ering times

listed in‘Teble | for 4 765 EV stems Each uty should evaluate the pinary and backup rely

fault daring times on the power sytem aad determine whic ft cering tie owe for sing

the protestve ground

“Table 1—Typical faut clearing times for various system voltages

FS mary carne ne 7 Pir dare ie

‘ae! Toa)

Be 7 a a

‘ Cong © 20m EE. er

e {432 Creutt breaker reclosure considerations

“eats (EPRI EL-525 (BI) have indicate that the cooling of TPG between recosureis insignificant

the reclosing scheme isnot dled, the additonal fait duration aftr velo) should be

Ince inthe otal ine usd toe the TPG.

14.4 Spocial areas of concern

444 General

Any device capable of transforming voltage or producing a voltage op should notte considered as

‘naitaning cota for the purpose of personne! safety. Soh devi inlde arsformes, uss,

Feacios, resistor, cit breakers. and ie taps. Switches or other deves with novable contact,

‘ree, hough kein lowed poston, can ncoduce a signicam impedance betvon TPGS os

tedon one ideaf the desc and worker onthe opposite side Such deve, when betwen the worksite

{nd the TPG, sould be opera few ine a clean the contacts tnd reds he conic ean,

Subsauses 44.2 hough 4 6might be wef when planing instalation of TPOs on major equipment

in subtatons

442 Main power transformers

“The following shoud be considered when applying TPG

1) Tetum atio of many transformer males them capable of anomie ow oka to igh

‘elage venom tty a ot Sonne tothe noma power sour Taco normaly ow

e Votage an cane om onde checking nunc ction Seng pa, tnd

Sonu ae nao

1) Stree cent anfomer (Cy sondy ed opening fics mic of

‘oon offs ae age anon (V1 soda ae

co Durngonaraing inc ot soap anchors ne Rng an papa upon od be

tended one ih tama tn ng ld Not ny exh he pop an nd

caret, bo stefan the bon cn bul upa ate carp eer

443 Cireult breakers and creut switches

‘The TPG assembles shouldbe appli on both ies ofthe device when maintaining seit breakers,

Cioutewitehes, of other Seve that can have erat diconaccon not visible to the Worker.

‘Consideration sold be given to

4) Shoring of seit breaker bushing CT secondary leads

1) Applying # TPG assembly bemorn the breaker and is ee standing CT in dr to prevent

‘Graton of en keto loop that can cause scaling current abd epurow operation of

{44 Instrument and substation service transformers

ots and mito ec etformen, bce of hi ery Mh ts ra exten

Mabyeati aera ook posal oqpmen in sehen tale heaped lags

Se eee aoa onc done od wo priamaiohocaes cea ok

© RESETS Nous i stn se To ny fh of cag

TLE, nis aoa tte sony darn Shs oe lr fs ene

Cony © 20 An a s

445 Capacitor banks,

Satan cpr bana ein recta een teyosrouschas ten domes. Ate @

Sowing for itchy (pay 3 ml) ie dncrpad sapere tank sot ly

See ye epi cpm sho eases Whey to of mere

‘spate ult cn ere paral op wate shoal ene eed

{Pode and una unos Sg at win reach shoal bette or

‘446 Power cables and terminations

CCapacive energy stored in a power cable shouldbe disipated by an approved method before

rounding. Before cating a power cable for sping, TPGs should be applied st terminations st

ach end ofthe power cae

45 TPG cable assemblies

‘The TPG cable assemblies ypicaly coast of «combination of cable an ground cusps configured

forconnectng the phase conductors or eipnent to a substation grounding system, Refer a Tae 2

forselccung the sppropriste TPG cable tembes Bate onthe fault cearng tine and available alt

‘urent for thermal consideration For sktromeshancal considerations, TPO componets and

stebis shouldbe ested fora peak ajmmeireal caret of 23 times thers Brent, 0 an

Sppropite safety factor shouldbe ud forthe TPG cable assembly.

ATPG cable asembly consis of

9) Gromd nd The won nd coi ofan opcay Tune op) weommcet os

Gomnddaimores pond paar ae elon dP raven

Shy i ca tat

wy eee ke ie ty

3 SSR SEES cap (ay ihn “oe hn nt

Sng wt ome ie aning MA etd Cnt ee

‘acim sa sche trite) Seebeabe kg ead Spd

stat

Figure 1a), Figure I), ad Figure 1) show vations TRG cable assemblies

‘ cong © 200 EEE Al eed

®

K

Figure 1b}—Typlcal TPG assemblies

ror 28 EEE rte sone

Aor’ Aor

Figure 1¢}—Typical TPG assemble @

46 TPG cable

448.1 Conductor material

Annealed copper conductors are ust for temporary protective ground cables. The srands can be

Phin or tied, The diameters ofthe strange are geterallyspesfed by the manulacurer or By the

Trproprise standard. Compliance with the cable material rogerements should te cocked by

Intpection snd testing

“The elec resistance ofthe conductors a 20°C can be checked by the tet sven in IEC 60227

21997 and TBC 6024521958,

482 Sizing of protective ground cables

The withtand ating ofthe cable should be considered when sising he TPG cable asenbly. Typically,

{he withstand rating i 70 to 80% ofthe timate apa. The de oft curent hou be considered

ten slstingwcable sted tot timate expat fo short durations, Some ites we the uitimate

Capacity and repae the asiebly ater expat to fat Table 23), Tale 9), Table 2), and

‘Tobe 2) the senate curentcarying capably fora worst ease eof fr X/F aos f 4,20, e

To, and 0, respectively. Ifthe X/R rato unkowa, Table s) should be Wed

* igh © 200 EE. gh a

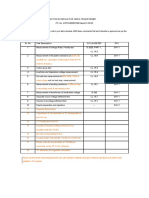

“Table 22}—Utimate curent-carying capabilities of copper grounding cables currents ae

eo ‘ns values, fr trequeney of 6 Hi; X/R— 40; curent n KA)

Caisse | Nenimlcoe | face | itoam [Soads | Soae | @oae | ioc

CWO’ | Metta) | didn | Gsm | twa | Oss | Ma's | er

Table 2b)—Unimate current-carrying capabllies of copper grounding cables

(currents are rme values, for Wrequency of 60 He; 7H = 20; current Ir KA)

Gaui | Nemimioos | sade | ode | Sade | Roam | ade | ii ace

Gwe | Sete ms | itm | Gsm | twa | O09 | M's” | eH

“Table 2e}—Utimate curren-carying capabilities of copper grounding cables (currents are

‘me values, for Frequency of 60 Hz; X7R 10; current in KA)

Case | Noma coee iegas | wows | Sods |@ ode] I ace

Gwe | Seen Gms | dod | Osan ||

© ry a a H

78 wa |» [ ee] [se

ed mew [| =} = | a]

ang © 00 EE. Ase se s

“Table 24}—Utmate current-carrying capabilities of copper grounding cable (currents re

values, for equency of 60 Hz; X/R= O;curent in KA)

ine | Somees_| Sates |e |e | ors [One| es

esha fi camp pan ns to Satrmapncn ceoacmen or

‘we ce Yar

48.2 Jacket

‘The following types of acktng materials are generally used in cable desons. primarily for the

1) A jacket bated ‘on compound of vulcanized ethylene propylene rubber (EPR) oF etyene

‘propylene dene monomer (EPDM).

by) Argeeralpurpose jacket bass on a compound of themoplastc polyinykloride (PVC),

©) coldesstn jacks used on «compound of thermoplastic PVC or oe of tscopolymer ot

‘icone rubber compounds.

A separating tape, made of suable materi might be placed between the conductor and the

Jacket. Consideration should be given to the Brevetardant characte of the chet mater

Because some jacking matrils produce tox umes i overheated, heir use shoul be ited a

‘outdoor applications. An indoor application could be permite with foredar veilation

The jacket should have adoqute mechanical strength and elastity within the temperature Knits to

which it can be exposed in nomal we. Complance can be checked by carrying ou th tests specied

foreach typeof jacking mater in the flowin references:

1) EC 0s02-1994 2] for EPR or similar compound. Aiton cables coved by this ype

‘of compound whould be subjected to Beading or songation txt st 50°C

2) TEC 2271-198 for a preral-parpowe compound.

0 ant © 200 EE. ht ane

“The applcable est methods and the results tobe obtained foreach typeof jacketing material are aso

specie in thee standards

“Te nce shouldbe cloly appli to the conductor or the separator any shoul be posi to

‘move the jacket without damping the srands. Thi shouldbe ebacked by visual ispecton

The jackets re availabe in several colors. Typical colors intoe orange, elo, Bick, and ren

There is no prfred color for the jacket The PVC (hemoplsis) jackets at ually made

Transparent, Some users prefer transparent jackets because it allows for visual ixpcton of the

ondustor. PVC (hermoplasc)jtekats can, over Une, Became opaque an bite

446.4 Cable sanding configuration

Cale stranding is specified in ASTM F55-1997. TPG cables are rpclly furnished in three spe

‘Te pe depends on both the abe and protective jacket. The major characteristics of these pound

cables a a fellow:

®) yet

1) Canducor—StandedsoR dra copper conductor with 66S strands or nore of #30 or

ieawe,

2) Socket Blastomer jacket, as rated by manufcturer,feible for ‘ttllaton and

‘Sovrable for continuous we within the temperatre range 40°C to 450°C

») pet

1) CondictorStande soft drawn copper condictor with 133 rand or mas foe #2,0F 289

stands or more fr 1/0 AWG, and greater.

SacketBlstomer jacket, sb raed by manufacuer, Sexble for installation and

‘evel fr sootiauous we within the emperatre range ~25°C to 430°C

©) Type tt

1) Condactor—Stranded soft drawn copper conductor wih 465 rand or mow of #30 AWG.

2) Jacker“Thermoplsi Jacket, strate by mansfucturer, exible Tor itallation and

‘ricable for continuous we within the temperature range °C to +4.

Use ofthe above cables shouldbe rrtictd to open areas or spaces with doquate vetlation so that

any fumes produced by overeating can be per

47 Clamps

‘Clamps shouldbe rtd for maximum ft curent and duration to which hey can be subjected. The

‘mp and condoctor assembly shouldbe eapuble of earring the fal caren for he specie tine

‘without damage or seperation fom the phase conductor or ground pit.

Clamps for grounding applications are caracterize by ther ime ver eurent ais, thei overall

[sera shape, an8 clamping conpurstion. The camp configuration should scope main and up

‘ondctr snes and have the appropiate ja conguration

Winadeguately rate, cletromecaniclfores de to fl an break the connection of the amp

ftom the phase conductor or even break te cimp. At lower curren, the high esstace of camped

‘connections can env overbeating. Inter cas, the elrped conseton ca loos and all

Copy © 2 EE. Al pte nee "

473 came pee

Asay af ns ar wae hinds cc sale site aps or mae

‘options Clamp ae designed to various shapes of bs-work, sanded oF sod eonductrs, ad

‘el ower strotures. See Figure 2 for pial ground camps

EE?

ott

Dae

eo

Figure 2—Typical ground clamp, stirup, and support stud used inthe uly Industry

{A camp an have ether smooth or sere ams. The smooth aw clamp is desined to minimize

‘conductor damage and sould be ed or cleaned conductors to ensure a clean conection. The

Sermied fw camp ae designed to bre through the buildup of eoroson er oxide fm on

the condacior I's cap wth setuted jaws i ud improper, the conductor wife could be e

damaged

2 Ceo 628 EE. Ages ne

472 Clamp materia

‘Camps are syplly made fom aluminum or copper alo. Coper cables shoud note ted ety

into aluminum alloy camps boss of coroson and esl loss of both etal contact and

‘mechanical strength, To minimize corosion cable terminations ean be tinned ora suitable corrosion

inhibitor ase. Even wih these prsauitions, care shold be taken not to expose the TPG cable

sembly tos corrosive stosphee or excuse moisture

447.3 Mechanical considerations

For high ful currents the lamps andthe terination are subject very high ectomchaicl

forces during faut conditions, spedally when long cables ref nscoued. Under sch condition,

large enctoragneti force can alr the cls to high velocities and the clamps called on fo

to much of ths Kinetic energy. Also, if TPG were fo fail mechanical, the ae would most

Tals be within the fit thee ele andthe worker would be without a peotxtin tthe remainder

To prevent volat cable whipping. te cables shoud be retin, wing rope. The restraint should

not crete «rip binding pon, but shoul! thor shock snd prevent the islet able movement

prosiced bythe cletromgntc foros. Cable should nt be twisted or wrapped around the strctre

(lctse tir cates tanformer el and cates cable overeating and pore fae Inston,

‘then thee ge de oft ith al arymmety the peak caren can be upto twist ale of te

‘ymmetrial peak curent. The mapete for canbe upto four ne as hgh in suchen Te should

‘emoted that lamps rte in acordance with ASTM F8SS-1997 are ested fr mkimum pea current

‘ronly 20% over the symmetrical peu current (7 tines thers caren) TEC 6120-193, on he

‘er hand, requesting at 77% peak oer the symmetrical peak current (25 Sines the 2s

carte.

‘The mechnial adequacy ofa given design and construction ofa clamp, fra gives felt current,

zpends onthe combination of able type and length, abd the typeof eable-o-ampsttachment with

ret adequate mechanical for one aplication, but iadeguate for anode. Only fullseale fal

‘rent tteon the most adverse application of cap woul allow one to determin its mechanical

‘uggednos and acceptably Tor the space eppeation

‘Moet substation applications involve three-phase TPGs, and there can te high chewomechancal

fore produce! between the individual TPG when subjected to high fault cues. A TPG assebly

‘hat would terse pas a single-phase test might not survive a three-phase tes. Examples would

Ince the chain grounding conigaratin (with two or toe TPGr tale in lowe pouty om one

‘ofthe condtor) and parle! grounding (ith ll thee TPG ground ends ache! toa common

Doin). Thus the TPG! wed in subsiation appcauons should be tested and pled with due

onidraion of these interphase Toc

474 Cableto-clamp termination

‘The mott critical component of the TPG cable assembly for withranding the extreme

lecwomechanical Tors probably the cable temination, and how it satached to the clap.

‘The cable canbe terminated the clamp in several ws. Typ cable ermination re compression

‘orexothermc pe ut wedge snd bolle able sonsacton cus be wed. Fo compen ferrules, the

‘manufacturer's specications shoud be followed soe, including compreston die type, sm,

‘reture, and compression pater (overlap Yrs nenoverap, how many compesions, ee)

‘Gabe tiation ere avaiable in three nd ponthreded form, Terminations wns toler should

ems © 20m EEE. ane fl

not be ul. Terminations shoul provide a lon-resitanceconcton athe cablto-amp interac

Due to the high mechanical foes, one ofthe most important requirements ofthe cre tom

termination isthe provision fr suai ret forthe cable

Heatsbrinkable tubing sosld be wed forall connections whore posible to minimize corrosion

tetwee the eable strand

Multiple assembles terminated atthe same point provide mltile paths for the fast erent This

reduos these requirement or any individual path (cable) However, unless the caren path have

‘gual impedance, should not be assed that the fl caren wil dive equally.

Extreme elecomechancl fr: pretent unr high fat current conditions can brik the lamp or

cable cominaton, lang « worker wihout poteedon. Unike thal energy, chetromechancl

ores om individual TPGs do not reduce ip the same proportion asthe caren. More iy,

the eletomechanical fore. on multiple asembles would be the same as that eloped by the

‘otal fault careat. This eae the vous loope eonsiting of phase condicis, TPGe, and

urentretum etaits primary determine the lectromectanical lores on # TPG rears of

salinity

Even if properly sian for fal current Gnhiding any dertngfectors for mle assembly),

‘the mana in which the TPGs ae physical Toeteé and arrange on the hase conductor can bake

signlcanimpact onthe ability a the mulpe assembles to hale sacl he ih i erent.

Temipht be possible fo redace cectromechnicel frees om mulple seme 5) providing 4

small separation @ m to 3m) betwee te individual TPG In Such a case a peop derating factor

of individul TPGs must be conser. The bt srranpoment, however, wl be one tht minis

‘ablemovement or allowscablemovemat ony ia direction tha the asain ets need to allow.

More than two parallel TPG shoul te avoided because of the uncerinty of el fat catent

semble by increasing conductors, voducing the Tequred protectin tine, neonguring the

fystom to reduce the valle fal cure, or combination of thee. Ir tore that two TPGe ate

‘ied, custom-designed assembles with special isalaon techniques shoud be consider

481 Path impedence

Wien itis necessary to use mulipleeporary grounds in paral per phase, vey importa

sure equal impedance of ach TPG. To be sure that Balanced erent ows throgh each TPG, the

Totowing ters should be made ea:

2) Sue and ype of sirupe

1) Siaeand pe of clamp

©) Length and umpacty ofeach conductor

{Simla conocton ofeach condor in the clamp

©) Ceanines of condor sirope and ating surfaces of caps

1 Tongue apled to each damp

8) Sur and location of ground ras to which the TPG ae atachod if appiabe

“The cleanliness of each conection and the torque applied to the clamps ae of maar importance.

Dirty srface o insufcienttorgu can res i overeating and faire.

“ Crp © 20m EE. maa

Inductive reactance soften more important thin resistance in terms ofthe total mpdance ofthe

e rounding cable However, dileencs in vostance where the cae connected 6 the clamp nd

‘bere the clamp i connecied to the phase conductor aa be very sigicat fn determining current

Because some unbulsce i invitble, 600 V insulated cable ahold be sed to revent potenti

‘roan, euling in the imum possible curent trough the worker. Inthe chain configuration,

Sith one ot the outer phases conmected trough + TPG to the ground whi the worter om the

‘Spposit outer phase the curen hough the worker Would te the musimum possible caveat. This =

‘rene ofthe addinal TPG conductor lng fom the coatacied phase to the groanded ple

Grounding the midle phase would reduce the current through the worker, as compared. wih

‘soundag one ofthe outer pass In conta if the worker smultanouly contact wo phases,

‘Shin rounding provies the nimi posible current rough the worker. Chaser TPGs provide

Some a the advantages ofboth pall tnd chan grounding

52 Location of TPGS

52:1 Source (oracket) grounding

Sours rounding wes TPG placed between the worksite and any possible energy sour. The energy

‘ours clude transformers, transmis nes snd generating uni andl ile bce othe

‘us from networked dstebuton ines, enerzed seconds of VTs, and bus crossings (possible

cncrgzed bus dropping on toa de-neygand bus, of vie vera). The TPGs connect the d-eergind

‘bso equipment tthe substation ground. The TPGs might be located an appreciable cstance fom

nt teu, pig cn on

Aine eng veo men to a te

Ee cee eine hme oomeen ae

a een ti ene mee

oe eee eect rate cee

Se re erecta eee ee ome gta

Foote pepe aome ete oma ere ea

ee EA genannten ros ae

® Figure 4a)—Example of improper source (bracket) grounding (1000 2 body Is assumed

‘teach worksite)

Ceo © 90 1EE. Me rane ”

Figure 40}Example of proper source (racket) grounding (1000 body I assumed

‘teach worksit)

iret otra the diferenc in body curent for inprope and proper bracket (pace) rounding

‘x io bry rsstace i asumed foreach work for thew cleltons. The tances represen.

the separation betwen the worksite ab the TPG or betwoen the worksite andthe sure (a) Pot)

tf euent tothe de-energized bu,

5.2.2 Worksite (single-point) grounding

In works rounding, th TPGs ae paced at capone ote workste They ae undo @

Coane the deen bus or equipment fo te baton grad oro pound: They ae

Seager we cary the masimuc fan cet, Soh sme tn nym ean ora

the works nthe vet of soadntls-nergaton, A percsied avantage that he workers

Sc wong tetecn two vale pound on eat iat Can Seen far of fo

‘tection, ang in tac of sk of me wort ara Typialy the coven hough the

sorter wl be pater if enrpuaton coun Bom the nde oppnte the TPG loson. To be

lnsotred a works pound ih TPGs ube nated ey ce ote sta workste (worker,

spon) A pod uc of ta i lc he TP wna Gan rence Yom he work

Sah sive ool Meshal whining of TPG placed oo closet the woke ight be a ety

one, The TPGr in ths sation soul rete An advantage fh cod hat ewer

523 Mutpoint grounds

Matipoint grounding sa combination of oth worksite and bracket o souregrouds. An advantage

‘of alii’ prouning follows om the pape ferent isin between ALL paths. Miulipcnt

‘rounding scanty reduces the crrent trough the worker, a compared wihsher worse ce

Frsket gounding: Due to redundancy of TPGe, the morker would be eter protaed even one of

the bracket TPGs were ofall mechanialy or ternal

‘he ino Toate don spon a ane nk ser, wine eins

MLE once ad rm tool od at Be CE

6 ‘eo © 208 EE At ane

il ot sare he siabe ft caret equally, TPG ae placed a close ax $m ca either sid of

‘he worst, they do not share equal current dviion~the maori ofthe caren fos inthe TPG

‘oust wo the outs of energy. At 6am the sl betneen Go ses of TPG onthe rer of 75% fo

25%, while at 128 m the splits closet 959 to 59. Thus, all TPs shouldbe sued as ough they ae

‘he only TPG installed, ofa erating factor should be considered (eter to 48 fr multiples of TGs

st the tne lotion,

5.4 Methods

54.1 TPG cable or bar assemblies

‘The TPG cable or bar asembles connect the phase conductors or equipment 1» substation

sounding system o Toe! grou,

5.42 Grounding switches

Grounding switches re pemmanently installed switches, kept i the open postion until required

Grounding switches ee used for connecting the bus (Geenergzed, Le Tor mainenance) tothe

substation grounding stem, They are often used to comnet he phase condvctrs to ound cecrode

‘hc the pase conductor ar too large in ameter orto hight aouomimodate 2 TPG effectively.

The advantages of grounding svitces ar thir operational convenience when fequst grounding i

uie, andthe capa of including mechanical interlocks to prevent inadvertely opening the

Svs or even to rer aces io an area Ground switcher thould be deignd t withstand the

‘asimum asymmetrical crest antipated at the subwaton. Grounding sachet have another

‘vantage in that they faciitate mtpont grounds in the station A datdvanage eat gros

Switches require maintenanee and might not cay operate when ealed upon, de o long erode

between operations. grounding stches ae and, TPGs canbe wed to enare worker protstion at

the woke For example, ground svilces might be leat a the ends of ong ton of us, with

"TPGs located atone of more works between the sound she.

543 Ground and test devices

‘A ground and tet devices a device wen mead switchpa for accessing the primary bus (ther

"nai bs ot “outgoing” bs) and ground bur within aside cel or ebice tprovies vite,

protective grounding in the work ae.

[As a pounding devie, it makes availble the ascewed primary bus and giound bus for

Interconsecting by an equipment operator. This interconnecting canbe done ether nana, ng

Standard TPGS, or through an integral "prounding™ switch

‘Asa testing device it makes the primary bus ang ground bus accesible for voltage and phase ration

eka Thee devices ar instal in pce of the sandard cout breaker.

6. Installation and removal

6.1 General procedures

‘The exact procedures for aplyng TPGs candi, depending o he ys, ain. and onion of

‘he equipment being isolated and grounded, and specie pois of the organization, The posite

Cop © 00 EE. Ae a ®

Neen

sr a azar invalid wih naling and removing TRG shoud conn ppropinte

personnel protcctive equipment can be used to minimize bum hazards, (For ‘urher rlvant 0

"oman oes sary ro EEE 564% 20 [b,Te TPO war eon he

Secon bine repent tn he pond hr eo oss cor of he

Stsonton pounding em hs an nde nes sets, pond mat pond reds oe

oul wits and scree pound Sods sha becapchi of craig hana ale

Sct cove ie olf opaton Tepe prosoartd Now sha be owe

4) Check grounding assembly to aes hat its n good operating conditon

3) lola the section of bus, ine, or esupment

©) sal bare if rogied (rope off ae)

{8 Tes for voltage onthe de-nergaed ba, Ine, oF equipment

{Clean ucas on bus and ground sectode oiowing approved suey procedues

1) Install assembly on ground Sree

2) Install sembly on de-neried bus ne or equipment

1) Remove assembly fom de-nerinl bus, ine, 0 eupment

1) Remove assembly fom ground eetrode

62 Tools

Livetin tool are protective operating vce made fom tbl isulaing materials Ground lamps,

‘sain tool, 08 messing nrrumentscan beatae to velne tools for working on ened

tr satel charge conductor, Live fol are aval in various shapes, Sey and ents

(6241 Clamp stick

lp ick acl of ne tel me when ma cope operon rare Toe)

Tren tok fave mechan! lng fo ngeove munciveabity am cone fond ame,

thik measurement equipment andor Sonos

To increase the works’ iting capabilites, hook it sick (hepher's book) with Hack and rope

‘Stembly reduce the efor required to ie and fos lagecxput clamps on an overbead Ds

1622 Bucket and platform truck

‘eket and platform tucks ae ue o reach otherwise nacoesible equipment or bus conductor

‘ing grounding. Livin tools stn be wed in conjunction with basket and plaform tucks for

‘ounding appeatons. Before work epins, the track frame sould be peopely pounded 0 the

‘station grounding system, (See 65.3)

629 Platforms

Pfs are wed to elevate the worker to the work are for beter aces. Platforms can be ether

{nslated or noninelte. Liven oo can lo be sed in conjunction wth torn or erounding

pplstions, Frames fr platforms shold be propel grounded before work bens

{63 Testing for voltage

Before any grounding connections ae made, the bu or equipment should be tested 0 veri iti

eencepad. The following device and ethods can be wed to detect the presence of vag On the ©

tis equipment, and ground eateode

» ent © 200 EEE AI aed

——————EEEE__—_—_—_—_—_—_—_—_—_—_—_—_______

6.31 Prosi vote dtcore

Dose seri th roe of ag sig hon le

ting the appropriate vee to.

163.2 Muttrange voltage detectors

“These devices ar cote field measurement detectors, which are ataced to liven tol nd have

robes that net tobe place rely onthe Baro be tee.

16.3.3 Fusing (buzzing or teasing)

Fusing, also known a cing or tet, # method wing conductive tol on the ead ofa camp

stick and dragging the conducive device along the bus. A buzing could inicate an eergied us

‘Since this echnige i ery subsve, ii NOT sugested.

66.4 Placing and removing of TPGs

‘The temporary protective grounding astmbly shouldbe placd a such locaton, and aranged in

‘ch & manner, to prevent the enployes frm bing exposed to hazardous diferenos in ssl

potential and movement ofthe asembly unr fal conltons,

eee

Prior to making sy grounding connection, ll contact connection surfaces should be sppropeiatly

leaned 0 remove an buildup of dito ress, o oxides. Protective coatings, such spat, shoul

‘be removed om se sures por to maxing Connections.

(Contet surfaces canbe cleaned using V-shaped wie brass, standard wise brushes, anes or ober

Similar tol. These cleaning tol can be obtained as ap atachmeat to Iver tool. Grounding

‘amps cama be obtained with serrated jaws to penetrate the coroson on a tularbus. Clamp

‘vith piercing toi can be uid to pencrte galvaniad surface if dented. asrep bol are

Sometimes found 16 be ineffective unde high fault current conditns Camps with seated js can

efor conductor suas, casing corona at higher vlags.

16.42 Order of connection of TPG

‘Whe 2 ground iso be attached wo bus, incoming ie, oF equipment, the ground-ent connection

old be stachd fist, and then the other ead should be attached by rane of «lve 109.

8.43 Order of removing TPGS

When a temporary protective ground isto be removed, the TPG assembly shuld be removed

® fiom the bus, Une, oF equipment using a Uveline tool before the grounded connections

removed.

iota © 20m. arn x

65 Equipment grounding

65.1 General

‘Workin substations docs not permit universal applications of grounding, Each job should be

‘haunted wth regard othe lve equipment installed atthe substation, oer wor, ad switching

fhe ngs andthe ope of work being done requiring grownding protection. Addon iin and

Piya res might be noamary to prevent contact with ve equipment

Induction current canbe serous prolem in substation. single ground wil drain off stati

Charges Appling two pounds to slong object can provide a oop for ekctromagnetic cure

Sn td the problens. Some egupment can alo bul up « charge due to espace coupling

‘Mi nearby ive codecs even the equipment lated. Refs to Annet A formar information.

“Temporary rounds ae wed to extend the permanent grounded work zone to include bus, ines,

‘Son and equpment, which ae normally energize

165.2 Electrical bonding for stati and capactive coupled voltage

White working ona cet dats rounded, a peron is protected by proper bonding techniques.

Bondi the etna onnestion between metalic parts or conductors anit purpose eo ensie

‘ery metalic part inte work aren soy conned together o minimize any potential difeencs.

Bonding is done by interconnecting all metalic segment of tial equipment that a perion can

touch aswel asthe vt seaflos,ee that are prt of common ground gi

652 Transport and work equipment

‘Vebisswisng any 176 of arial enupeent inthe visit of energized condctors or apart

‘Hout! be ouuuca. Ive vere ground sould be connected co te routing ype fit a

‘hclelast In ases where bce are carrying combunble matey, te ode of atachment should

te reveaed to minimize poesble parking atthe vei

Grounding the vehi provides fr auiskclezing ofthe eit the ves Becomes nerd, ths

‘eduig the time orespome of psoas inthe work area to the electra] har

“Enteral to the substation, rotation to personel is povided by ensuring that people onthe ground

{do notconac the ene or equipment whens being wd in the iil ofeerszed condos or

Sppuratus If however the venice i within fhe subwtaion grid andthe ei is propery deine

‘Ducking the vehi should be no wore than touching any eter grounésdsrasure or equipment

‘ring fat though he probably of an naertent energization ofthe vice would be higher.

‘No person standing othe ground shoal bein contact witha vb or an tached trae hie the

tour seal devie bsg moved in the vcity of energind conductors or appara. When ii

‘eco to operate he ones at ground or vei eve the operator shou be protected by one of

{he flloing method:

2) Stand on « metal operator’ paform intl fortis sie purpose.

1) Stand onthe deck of he vile

©) Stand on portable conducive mat atrial attache to the ground vehi,

‘Fae opee had et apn or cnt ie pete eet on ope

2 Creo 060 1EE At eee.

654 Are wolders

“The ground (wor) ea felectc are welders shoud be connected to the pies beng weed at» pint

closet the Weld location. The ground fad clamp should make a good electra eomnection wih the

‘work. Both the pound kad andthe eleva lend sal be propery insulated and shoud follow the

(Care shouldbe exerci in placing th ground lad so sto avoid incuding a transformer of CT

Winding the weld veut because a hazardous voltage can be induced in anaes winding The fat

that sta welding equipment operates onde oe nt eliminate the hazard, base the vliage is

Indyced when the ectode makes or breaks the oreut. Caulion must ao be execsed i attaching

leadener capacitor bak 0a to avoid Tormig ccul that wllcharethecapactos toa hazadous

7. Static, capacitive coupled,

protection

3nd electromagnetically coupled voltage

“This cane serves a gue to bp alleviate the adverse et of dichages betwen equipment or

‘Rractres and personel due to stat capacitive couple, and estromagneticaly cole voltages in

‘otasons when « works becomes isolated ffom th pound Ge, working aloft, wearing isated

boots

‘Te purpose of protective equipment apnnst sas, capacitive coupled, and levomagneially

‘ouped voltages to bring the worker and work surface to the same Setel potenti an8 Keep

‘hom tthe sme potential Uoughout the jo.

‘This use doesnot constitute a recommendation, but onl sages a method to alleviate the adverse

flats of dachares dv to stat, eaaetiv coop, and etromagnetaly coupled voltages. Many

‘les mipt not be afte by thie phenomenon.

7.1 Protective garments

Protective garments can ice conducive jackets, undersis,shirs, wou, boos an gloves

‘worm epaatly or in any combination adem necessary 1 migaethe averse aes of vollage

Sicharzes

“The fingers of conductive gloves cas be cut aff 1 improve dexterity ofthe worker,

72 Attachments

Atushments to pounded sel structure or ther grounded devices can be made with conductive

rape ose magne or clamps for ataching to the grounded structure. The eer end of the

ondicne strap fm conocedto the workers conductive garments A 'm long conductive sap

Sugased a an optimum manages lngth

8, Testing

18.1 New TPG component and assembly testing

‘The TG asembls or components shouldbe tested in aeordance with IEC 612301903, or with @

peak asymmetrical current of 25 times the ms Yale i ed i accordance with ASTM PASS-997

ep 2003 EE. At sere a

£82 In-service inspection, maintenance, and testing of TPGs ©

2:1 Vieualinepection

Make « close vst examination ofthe complete asembly.

1) Check for he presence of broken strands, especially near the cable terminaton

1) Check for damaged or bared jacket materi

©) heck for damage cae terminations.

{3 Ghesk the clamps for sharp edges, cracks, spits, or other dee

3 Replace toldred feruee with ompression or exothermic connections any dfs are ound,

‘Ser rel or replace the ately (remove fom Service), a appropriate,

12.2.2 Operation check

‘amine the individ components

2) Verify thatthe lamps operate smoothly and are fee of excesive looseness,

1) Chem the clam jw, eesrevs and Thane sews of dirt ol grease anor any comosion

1) Enoure thatthe interlace conection betwen the cable ermination and clamp ean,

{Verify thatthe abl termination tht to the clamp body

£23 Period testing of TPS

xp as town that TRG ant dams by ough wage const. Both vin and

Exo eros ®

18231 Viewl eet

“Thea ofthe weed orcompersinn cable termination o sustain detromechaicl force has been

‘rl demonstrated. The dist Camping of conductor to the ground cmp might be stsactory

‘Then 'now, but mechanical ses on the conductor diag is svi Me appear to degrade i

‘Mtotntatiy A thorough viva inspection rectal in the review of 1 TPG quality. Evidence of

‘broken strands or coronion wi he cable termination or the able ae sigs of is deeadstion and

Feat further invexieaion

2.32 Electra tet

An det test provides a mean of monitoring coetiaity and changes inthe tic! proper of

'7PO. The daccal tet shoul be performed aa TPG when itis new and a era thera

Dieeacesin the eletcal proper of the TPG wold bean ndcatin ofthe changing condition of

{he TPO. The let canbe prformed with de ora. Equipment commercially avaabl to perform. an

‘hota tt on 4 TPG cable seb.

23.21 Dict current st

1h de inthe range 10-25 A is passed trough the compete TPG cable assembly. The direst cure

‘tunes ofthe TPG cable apse the voltage ares te assembly dvd by the crrent. The

{en not sense to plassnent or suroundings of te TPG cable asembly being texted and,

therfore tends tobe more repeatable than the a st.

462322 Atri caret ot

eset psd teup e TPO cable sen. Typ thecurent masts soathunass —Q))

2578 Maser nme poser opt bce! 10 3% a be atin are cpa

ou roy © 00 EEA ea

ofthe cable. The current normally spi fr less than 1s. The TPG cable assembly mmpedance is

auld by dividing the measured voltage across the TPG bythe test creat AC tess ar esitve

{othe physical rangement ofthe TPG and wo the proximity of magnetic materia

(223. Teatng and maintenance nterata

“Tesing and maintenance intervals shoul depend on applicable codes, exposure, anne of use

individual eompany pois, ad operating proms

Con © 0 EE, Ase sen 2s

—————— eer ——e——r—_=<=_

‘Annex A e

(informative)

Terminology

|AA Voltages and currents at the worksite

AA. Systom voltage

Stes voltage refers tothe bus or hs olla and is eerally specifi in lols (RV), paseo

ae.

‘A12 Statle voltage

Sui ote fe voltage buildup on metalic oet (el structures, bus conductors) deo wind

ton ry conduction, or dasa strated so Figure AT, Generally, sate wolge Dui i es

fevers tha the other works voltages that ean ex

es ©

Figure A.—Statie voltage

A:1.3 Capacitive coupled voltage

Ccapuctive coupled voltages ypcly exit on an tlated objet in an ltr eld rom a eerie

‘Grates show in Fire Ad. The soatd object ean ba de-enerpid bos, met structure, oF

‘ast of equipment, ors person onan isla platform.

f

Figure A2—Capacive coupled vottage—equivalent circu

2% cea © sn EE At gh ee

Figure Al more epetntative ofthe letra rel stoned with apace coupled voltage

Figure A. represents one phase of an ened ac cut with its ground return, aml the section

betwen the open sites represents oe phase ofan we tut that hasbeen Svitchod out of servic.

. Age

Figure A.3—Copactve coupled votage—ircult components

When en obit comes into contact withthe de-energizd condoctr, the cist i at shown in

Figure A.4—Case of contact with de-energized conductor

Wen contacts est mae withthe conducior, the voles high, The eapucitor wil “dacarze” nto

the object. AS lng asthe stored energy i ot Very gg an the ial creat low, th ial volage

til be ver low. However, theresa rg amount of stored energy such sa deere (svitchod

‘ut transmission ne or substation operating bus parallel to an energie transmission lie of Bus, the

Salable dscharge carrnt ean be high sod extremely dangerous A single grou paced onthe

‘deenergued conductor wil elec charge the sae and caactive coupled vole

‘A.1.4 Electromagneticaly coupled voltage

lecromagneticaly indvced vole is simlar tothe ation that occurs ina transformer. When the

primary wining energized, the Fessling crrent Row indoses a voltae inthe secontary winding.

{Te same phenomenon ocr when ap energized conductor (primary winding) earn caren

dct oa denen ewtched ut) conductor (secondary Winding) In hs case, ts transformer

Capt 0 IE. Ae means n

ee

‘nea sircore instead of an ron core. A vag i ths developed at point B. Tis crits itso

gure Ae Both ends ofthe d-enerpinl conductor shoud be grounded to isin the potential

SineGas Som the worker in conte withthe d-nerged conductor, even thuph this provises 8

lost loop and allows cure to ow inthe de-neried condor

Figure A'—Electromagneticlly coupled voltage

AAS Currents

‘Under normal ecumsancs only rated oad curenti present at an enepied worksite, During de

‘rorgzcdalatnanee operons wth TPOs place, avaable faut currents all be consiee.

‘Tan ful current wl be substantially leper than the steady-state curren. fa ation the curent

ESymmety and its duration shoul be considered

“The asymmetry is funtion ofthe reactance vie by the rtitance(X/ rat he circ The

Tatut ht nonperod exponentaly desing ds component combined with te ac rymimetical

‘Smponent ss tutte in Pgure A (op graph) The peak cure! value can be insresse to almost

Figure Aé—Asymmetrical fault curent components (examole)

™ cor © 00 EE, eee

®

©

tic the symmetrical pk vale, The asymmetry causes an increas in tomes fore, ad

In the heating ofthe protective equipment component The botiom Bap of Figure A shows the

‘ppl caren waveform fom an osclgrsph,

A2 Safety criteria

A241 Sate body currents

tlectaly smut. The patie of carent that a ody eat tolerate depends on freuency,

Suraon, and physical condition of the body. Its the consensus of researchers, however, th

acral for eguences above 25 He and fora duration of few seconds, the threshak of pereption

i'mA, A curet of 9t025 mA makes i dict for person to reese thi grip rom a power

feu and at 390 A muncolar contractions can make Weahing dict At higher current &

sal hear can cease to function (etal Ablation). See TEEE Std 8020083) for move

Information concerning body current.

[As previously tated, the magnitude of curent a body can tolerate depends to 8 peat ete os

the Garaion of the shocks Researchers have oncladed that 99% ofall fesoas. could

titstand, witout ventclar Milton, crete with magnitude detemined by Equation (2)

tr Equation (2:

ane

be fora 50g (110 8) body w

for 70 kg (1551) body @

1 the rms magnitad of body curet (A),

(tithe duration ot caret expose.

Generally, Equation (I) wed for a more conservative approach, However, oe may ue Equation)

rovisd tha the sveragepopiton weight sane expered to bea ast 70k (1551,

Equation (1) and Equation (2) alo indicate tht mush higher body current can be allowed where fet

lopeatingprotetve dvs ean be relied onto limit fault uratins

22 Shock hazards

422.1 Touch votage

The potent diference between the ground potential se (GPR) andthe surface poentl atthe point

(See Figure A)

A222 Stop voltage

‘The diference in surface pote experince by a paron bridging distance of 1 m wih he fst

without contacting say grounded obj (Ser Figure A)

Capt © 200 IEA ean »

Figure A7—Basle shock situations

A222 Transtered voltage

[A special cs of touch voltage whee a voltages ranted into or ot of the subtton fom or

‘emote pot extral to the srtation sit (See Figure A7.)

‘A224 Mesh voltage

“The maximum touch voltage within mesh of «ground grid

A225 Metabto-motal touch voltage

“The dferene in potential btwsen metalic objets or siretures within the substation ite hat might

be bridged hy dst hand-tocband or handover contac.

©

x» Coo EE A ean

Annex B

(informative)

Bibliography

[BI] EPRI EL-528, Fusing Rearch on Penonal Grounding Cabls, Final Report, Jas 1987

(02 IB 0502198, Extruded Sold Dicletric Insulated Power Cable for Rated Vola rom 1 AV

Up To 304Y.

(83 IEEE Sua 0-200, IEEE Guide for Safety in AC Substation Grounding"

(4) IEEE 100, The Authorave Dictionary of IEEE Standards Tors, Seventh Eaton,

[is] HEEE Sud 1584-2002, IEEE Guide for Pesfrming Are-lash Hazard Calelstions.

(Ro) Reichman, J, Vainbere. M, and Kael J, “Shortcut capacity of temporary grounding

fables” Transactions on Power Devry, vo. no, pp 20-271, Jan 1988.

For further reading

[B7) ASTM B172-2001, tadutd Specification for Rope-Lay Stranded Copper Condiciors Having

Bunch Standad Members fr Eletal Conductor.

[Bs] ASTM B173-2001, Standard Speciation for Rope Lay Stranded Copper Conducors Having

Concent Stranded Member for Elta Conductors,

[B9]ICEA $-19.8/NEMA WC 3.1992, Rubbertnelted Wire and Cle forthe Transnison and

Dasribation of Elestcal Erg.

(B10) LEC sos. 2-42-1982, Environmental Tsing—Part 2: Tess, Test Ke: Sut Dione Tes or

‘Contacts and Connections

(BH EC eov.1-1996, Eects of Cureton Human Beings and LivstckPart 1: General

‘Aspects.

(Bia) IEC 60178-21987, Efex of Curent Passing Through the Human Body—Par: 2: Special

Aspect.

Sree tein mcs dow Aa ons one Hye oe of ei wl aes

TEER potas ae rite om Gib Engng Decent Way Ea Ego 12, USA

pine gbancon

Coy 6 8 EE. A ge son a

ns be 698 Re IEE Ronen Pt Decne Bs

(iq IEEE Sud 978.1964 (Real 191), IEEE Guide for In-Service Maintenance and Elta

“Testing of Live Line Tool.

pis) IEEE ses C¥7.09™1999,1EEE tanard Test Procedure fr AC High-Voltage Crest Breakers,

Raed on « Symmetrical Curent Basi

[6 Ruscbekke, H. ML, Electric Uy Syetoms nd Practices, Ah ed, New York: Wie, 198.

@

2 om © 200 EE. hs ann

‘To order IEEE standards,

(Cal +1 800678 IEEE (4355) nthe US and Caneda,

(Outside of the US ane Canad:

“3 732 981 0800

‘order by fax

1782 984 9687

EGE business hous: 8 am.£30 pm, (EST)

For Web access to IEEE standards Informatio,

hipstandardsi

019

For Information about IEEE standards on-line subscriptions.

hnipsetandards ieee orestlogole

‘S80 o-7981-2061-2

You might also like

- Hitachi Energy MV Surge Arrester Application GuidelinesDocument31 pagesHitachi Energy MV Surge Arrester Application GuidelinesAmany HamdyNo ratings yet

- Les Taches Actualisé 25 2 2016Document3 pagesLes Taches Actualisé 25 2 2016Amany HamdyNo ratings yet

- Four Aspects of The Quality of Life The Balance MoDocument11 pagesFour Aspects of The Quality of Life The Balance MoAmany HamdyNo ratings yet

- IEEE STD 1268™-1997-Guide-For-Safety-In-The-Installation-Of-Mobile-Substation-EDocument26 pagesIEEE STD 1268™-1997-Guide-For-Safety-In-The-Installation-Of-Mobile-Substation-EAmany HamdyNo ratings yet

- Handling Objection-FinalDocument49 pagesHandling Objection-FinalAmany HamdyNo ratings yet

- Force Calculation 28 MvaDocument12 pagesForce Calculation 28 MvaAmany HamdyNo ratings yet

- MTG Contest Proposal Power - Within - GenerationsDocument3 pagesMTG Contest Proposal Power - Within - GenerationsAmany HamdyNo ratings yet

- The Reality of Resistance To Change Behaviour at The Department ofDocument14 pagesThe Reality of Resistance To Change Behaviour at The Department ofAmany HamdyNo ratings yet

- WIE Affiity Group Petition FormDocument1 pageWIE Affiity Group Petition FormAmany HamdyNo ratings yet

- 16MVA Transformer Test Schedule CommentsDocument1 page16MVA Transformer Test Schedule CommentsAmany HamdyNo ratings yet

- Transformer ProtectiponDocument116 pagesTransformer ProtectiponAmany HamdyNo ratings yet

- Transformer Losses CalculationDocument4 pagesTransformer Losses CalculationAmany HamdyNo ratings yet

- Behavioral Public Administration Ad FontesDocument18 pagesBehavioral Public Administration Ad FontesAmany HamdyNo ratings yet

- Wor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Document11 pagesWor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Amany HamdyNo ratings yet

- Towards Effective Mitigation of The Digital Transformation andDocument22 pagesTowards Effective Mitigation of The Digital Transformation andAmany HamdyNo ratings yet

- The Impact of COVID-19 On The Efficiency of Packing Lines inDocument16 pagesThe Impact of COVID-19 On The Efficiency of Packing Lines inAmany HamdyNo ratings yet

- The Impact of Job Stress On Employee Productivity During Covid-19Document12 pagesThe Impact of Job Stress On Employee Productivity During Covid-19Amany HamdyNo ratings yet

- The New Era of Digital Transformation and COVID-19 Effect On TheDocument27 pagesThe New Era of Digital Transformation and COVID-19 Effect On TheAmany HamdyNo ratings yet

- Digitization of The Economy of Ukraine StrategicDocument8 pagesDigitization of The Economy of Ukraine StrategicAmany HamdyNo ratings yet

- MinitrackDTHICSS 542020Document2 pagesMinitrackDTHICSS 542020Amany HamdyNo ratings yet

- Water Absorption by Oil in MV SwitchgearDocument4 pagesWater Absorption by Oil in MV SwitchgearAmany HamdyNo ratings yet

- Revitalization of Remote Control Centre at Elektro Primorska (SloveniaDocument4 pagesRevitalization of Remote Control Centre at Elektro Primorska (SloveniaAmany HamdyNo ratings yet

- Barczak Sotysik Jarosz Zakrzewska KozowskiDocument18 pagesBarczak Sotysik Jarosz Zakrzewska KozowskiAmany HamdyNo ratings yet

- Enhancing Performance of Mwasalat Misr Company in GreaterDocument16 pagesEnhancing Performance of Mwasalat Misr Company in GreaterAmany HamdyNo ratings yet

- 2022 OpenNursingJournal theModerationEffectofAffectiveDocument9 pages2022 OpenNursingJournal theModerationEffectofAffectiveAmany HamdyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)