Professional Documents

Culture Documents

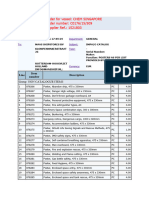

Check List For Water Mist Water Spray and Sprinkler System

Uploaded by

efendi kaptanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List For Water Mist Water Spray and Sprinkler System

Uploaded by

efendi kaptanCopyright:

Available Formats

Procedure for CHECKING WATER

MIST, WATER SPRAY AND SPRINKLER

SYSTEM:

The following checks must be carried out:

Perform a hydrostatic test and internal examination for gas and water pressure cylinders according

to flag Administration guidelines or, where these do not exist, EN 1968:2002 + A1.

flush all ro-ro deck deluge system piping with water, drain and purge with air

perform internal inspection of all control/section valves; and

check condition of any batteries, or renew in accordance with manufacturer's recommendations

verify proper operation of all water mist, water-spray and sprinkler systems using the test valves

for each section

visually inspect all accessible components for proper condition

externally examine all high pressure cylinders for evidence of damage or corrosion

check the hydrostatic test date of all high pressure cylinders;

functionally test all fixed system audible and visual alarms;

flow test all pumps for proper pressure and capacity

test all antifreeze systems for adequate freeze protection

test all system cross connections to other sources of water supply for proper operation

verify all pump relief valves, if provided, are properly set

examine all filters/strainers to verify they are free of debris and contamination

verify all control/section valves are in the correct position

blow dry compressed air or nitrogen through the discharge piping of dry pipe systems, or

otherwise confirm the pipework and nozzles are clear of any obstructions. This may require the

removal of nozzles, if applicable

test emergency power supply switchover, where applicable

visually inspect all sprinklers focusing in areas where sprinklers are subject to aggressive

atmosphere (like saunas, spas, kitchen areas) and subject to physical damage (like luggage

handling areas, gyms, play rooms, etc.) so that all sprinklers are inspected within one year

check for any changes that may affect the system such as obstructions by ventilation ducts, pipes,

etc.;

test a minimum of one section in each open head water mist system by flowing water through the

nozzles. The sections tested should be chosen so that all sections are tested within a five-year

period; and

test a minimum of two automatic sprinklers or automatic water mist nozzles for proper operation.

verify all control panel indicators and alarms are functional;.

visually inspect pump unit and its fittings

check the pump unit valve positions, if valves are not locked, as applicable.

verify all control, pump unit and section valves are in the proper open or closed position;

verify sprinkler pressure tanks or other means have correct levels of water;

test automatic starting arrangements on all system pumps so designed;

verify all standby pressure and air/gas pressure gauges are within the proper pressure ranges;

and

test a selected sample of system section valves for flow and proper initiation of alarms.

(Note – The valves selected for testing should be chosen to ensure that all valves are tested within

a one-year period.)

Testing Interval: 10 yearly

You might also like

- M-SCAT Guidance On Incident InvestigationDocument16 pagesM-SCAT Guidance On Incident InvestigationRachit Jain100% (1)

- Hydro Test Key PointsDocument16 pagesHydro Test Key PointsRahulNo ratings yet

- Pressure Testing Piping SystemsDocument3 pagesPressure Testing Piping SystemsWeny Astuti100% (1)

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Hydro TestDocument9 pagesHydro TestPrathap JohnNo ratings yet

- Autoclave PPMDocument5 pagesAutoclave PPMZaheer Ahmad100% (1)

- Boiler Safety ProgramDocument8 pagesBoiler Safety ProgramHussain KhanNo ratings yet

- Inline Hydro TestDocument7 pagesInline Hydro TestjeswinNo ratings yet

- O&M Manual SPAC-08N-10NDocument46 pagesO&M Manual SPAC-08N-10Nanwar sadat50% (2)

- Method Statement For Hydrostatic Pressure Testing of Chilled Water PipeworkDocument3 pagesMethod Statement For Hydrostatic Pressure Testing of Chilled Water Pipeworkamg007100% (3)

- 1 Building Maintenance Checklist HVACDocument17 pages1 Building Maintenance Checklist HVACamochieno100% (3)

- Maintenance Check List of HydraulicDocument7 pagesMaintenance Check List of HydraulicShubham SinghNo ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- Boiler & Pressure Vessel Inspection 6734Document15 pagesBoiler & Pressure Vessel Inspection 6734Yousuf MemonNo ratings yet

- Preventive Maintenance PlanDocument16 pagesPreventive Maintenance PlanAugust Hari0% (1)

- Api Tubing Casing Id CalculatorDocument45 pagesApi Tubing Casing Id CalculatorRyan LlanetaNo ratings yet

- Pneumatic Test - Write UpDocument7 pagesPneumatic Test - Write UpDilip0% (1)

- Piping Hydrotest ProcedureDocument9 pagesPiping Hydrotest Procedurewendypost73100% (1)

- 10 - Introduction To PROFIBUS DP and The HMI Operator PanelDocument31 pages10 - Introduction To PROFIBUS DP and The HMI Operator PanelMichele BacocchiaNo ratings yet

- Construction Procedure For HydrotestingDocument7 pagesConstruction Procedure For HydrotestingEddie Tai100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- NEE Boiler-Inspection GuidelineDocument70 pagesNEE Boiler-Inspection GuidelinepiyushagaNo ratings yet

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Method Statement For Testing & Commissioning of AHUDocument4 pagesMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Settling Tank DecantDocument23 pagesSettling Tank Decantjvan migvelNo ratings yet

- Leak Test Procedure InstrumentDocument10 pagesLeak Test Procedure InstrumentNAVANEETHNo ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- NFPA 13 PRESSURE TEST PROCEDURES (Fire Pro)Document2 pagesNFPA 13 PRESSURE TEST PROCEDURES (Fire Pro)Mechanical Engineer50% (2)

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 pagesGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Testing Precommissioning & Commissioning of FCUsDocument7 pagesTesting Precommissioning & Commissioning of FCUsFinito TheEndNo ratings yet

- Hydrotest Procedure For Piping SystemsDocument6 pagesHydrotest Procedure For Piping Systemscatherine100% (1)

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- Technical Service Bulletin: Commissioning Procedure For HydracapDocument10 pagesTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisNo ratings yet

- S211-7-2020 Operator's Manual (English) PDFDocument119 pagesS211-7-2020 Operator's Manual (English) PDFDiego Castañeda SantaNo ratings yet

- What's The Min &max Range of Pressure Gauge For Hydro TestDocument4 pagesWhat's The Min &max Range of Pressure Gauge For Hydro TestdushyantNo ratings yet

- Lab-Java Programming Intro IDocument83 pagesLab-Java Programming Intro IHeavenlyPlanetEarth80% (5)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Patriot MissileDocument19 pagesPatriot MissileBogdan Claudiu HututuiNo ratings yet

- Fire Sprinkler Systems#Document8 pagesFire Sprinkler Systems#aimiza50% (2)

- Firefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFDocument5 pagesFirefighting Sprinkler and Standpipe System Testing and Commissioning Method Statement - Method Statement HQ PDFjajakaNo ratings yet

- Method Statement Hydraulic Pressure Test For Swimming PoolDocument1 pageMethod Statement Hydraulic Pressure Test For Swimming PoolMohd Hafizul Hj TanalolNo ratings yet

- DevOps For VMware Administrators (VMware Press Technology) - 1-321Document321 pagesDevOps For VMware Administrators (VMware Press Technology) - 1-321mailboxrohitsharma100% (1)

- Preparation For Start UpDocument19 pagesPreparation For Start UpArjun Shantaram ZopeNo ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Check List For Water Mist Water Spray and Sprinkler SystemDocument1 pageCheck List For Water Mist Water Spray and Sprinkler Systemefendi kaptanNo ratings yet

- Check List For Foam SystemDocument2 pagesCheck List For Foam Systemefendi kaptanNo ratings yet

- Check List For Fixed Gas Fire-Extinguishing SystemDocument1 pageCheck List For Fixed Gas Fire-Extinguishing Systemefendi kaptanNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- Check List For Fixed Gas Fire-Extinguishing SystemDocument1 pageCheck List For Fixed Gas Fire-Extinguishing Systemefendi kaptanNo ratings yet

- A.S.M.E. Code On General Instructions Regarding Power Plant TestsDocument34 pagesA.S.M.E. Code On General Instructions Regarding Power Plant TestsDovah KiinNo ratings yet

- SOP Audit Formate - FinalDocument13 pagesSOP Audit Formate - FinalSobar Suryadi71No ratings yet

- WEBBH009 - Baghouse Maintenance GuideDocument1 pageWEBBH009 - Baghouse Maintenance GuidebulentbulutNo ratings yet

- Hydrotest Welding and NDTDocument11 pagesHydrotest Welding and NDTALFA ENGINEERINGNo ratings yet

- Hydranautics TAB142 LDocument9 pagesHydranautics TAB142 LMax JunghannsNo ratings yet

- Hvac Preventive Maintenance ChecklistDocument2 pagesHvac Preventive Maintenance ChecklistAlpesh Jain100% (1)

- Testing and Commissioning Method Statement Procedure For Argonite SystemDocument2 pagesTesting and Commissioning Method Statement Procedure For Argonite SystemHumaid ShaikhNo ratings yet

- Tempe Fire Department Policies and Procedures Hose Maintenance and Testing 405.03D Rev 3-12-97Document3 pagesTempe Fire Department Policies and Procedures Hose Maintenance and Testing 405.03D Rev 3-12-97Muhammad FerialNo ratings yet

- Controles de Materia ParticuladaDocument1 pageControles de Materia ParticuladaItalo VaccaroNo ratings yet

- 01 12FPS-NFPA ch02 - FDocument3 pages01 12FPS-NFPA ch02 - FMohamed Ilias HamaniNo ratings yet

- Hyd System Maintenance N PnematicsDocument22 pagesHyd System Maintenance N PnematicsMarcus ThianNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Pre Commissioning ChecksDocument25 pagesPre Commissioning Checkske72012No ratings yet

- Amsco CenturyDocument2 pagesAmsco CenturyAlexandra JanicNo ratings yet

- High-Pressure Boiler Inspection Procedures: A Complete ChecklistDocument6 pagesHigh-Pressure Boiler Inspection Procedures: A Complete ChecklistROHITNo ratings yet

- Mos Fcu T&CDocument7 pagesMos Fcu T&CKPNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- N2 PaddingDocument6 pagesN2 Paddingefendi kaptanNo ratings yet

- NORTH Hot Spots VDR PDFDocument2 pagesNORTH Hot Spots VDR PDFefendi kaptanNo ratings yet

- C Emergency ProceduresDocument16 pagesC Emergency Proceduresefendi kaptanNo ratings yet

- SureNav A4 FAQDocument1 pageSureNav A4 FAQefendi kaptanNo ratings yet

- Ordered Posters and Imo Signs For Chem SingaporeDocument5 pagesOrdered Posters and Imo Signs For Chem Singaporeefendi kaptanNo ratings yet

- B1 - Main Engine & ShaftingDocument29 pagesB1 - Main Engine & Shaftingefendi kaptanNo ratings yet

- Check List For Foam SystemDocument1 pageCheck List For Foam Systemefendi kaptanNo ratings yet

- List For Ch. EngDocument4 pagesList For Ch. Engefendi kaptanNo ratings yet

- Check List For Testing IncineratorDocument1 pageCheck List For Testing Incineratorefendi kaptanNo ratings yet

- Check List For Main and Emergency Fire PumpDocument1 pageCheck List For Main and Emergency Fire Pumpefendi kaptanNo ratings yet

- Check List For Ventilation System and Fire DampersDocument1 pageCheck List For Ventilation System and Fire Dampersefendi kaptanNo ratings yet

- Check List For Emergency Fire PumpDocument1 pageCheck List For Emergency Fire Pumpefendi kaptanNo ratings yet

- Check List For Ums Extension AlarmsDocument1 pageCheck List For Ums Extension Alarmsefendi kaptanNo ratings yet

- Check List For Main and Emergency Fire PumpDocument1 pageCheck List For Main and Emergency Fire Pumpefendi kaptanNo ratings yet

- Rankwise Suitability MatrixDocument8 pagesRankwise Suitability Matrixefendi kaptanNo ratings yet

- Test Record For Low-Location LightingDocument1 pageTest Record For Low-Location Lightingefendi kaptanNo ratings yet

- Stowage Factor Conversion TableDocument1 pageStowage Factor Conversion Tableefendi kaptanNo ratings yet

- Check List For Fixed Gas Fire-Extinguishing SystemDocument1 pageCheck List For Fixed Gas Fire-Extinguishing Systemefendi kaptanNo ratings yet

- B9 - Nitrogen GeneratorDocument12 pagesB9 - Nitrogen Generatorefendi kaptanNo ratings yet

- EcdissdfsfdsfdDocument1 pageEcdissdfsfdsfdefendi kaptanNo ratings yet

- TdıDocument43 pagesTdıefendi kaptanNo ratings yet

- Sop MbaDocument3 pagesSop MbaakshayNo ratings yet

- Computer Graphics - Lesson PlanDocument15 pagesComputer Graphics - Lesson PlansoniadrallNo ratings yet

- Aluminium Aluminum 6070 Alloy (UNS A96070)Document2 pagesAluminium Aluminum 6070 Alloy (UNS A96070)HARIPRASATH PNo ratings yet

- IntegratingBIMTechnologyintoLA (2014) PDFDocument115 pagesIntegratingBIMTechnologyintoLA (2014) PDFArnaldo RuizNo ratings yet

- Faculty Recruitment TestDocument8 pagesFaculty Recruitment TestSai Radha KrishnaNo ratings yet

- Civil Works BuildingDocument22 pagesCivil Works BuildingSarinNo ratings yet

- InteliMains 210 MC - Global Guide PDFDocument637 pagesInteliMains 210 MC - Global Guide PDFHakim GOURAIANo ratings yet

- CPP ReportDocument5 pagesCPP ReportSujay Hazra100% (1)

- Rockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareDocument23 pagesRockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareAlex RivasNo ratings yet

- PC Smart Ptsgob8wDocument11 pagesPC Smart Ptsgob8wJose LopezNo ratings yet

- RSAFRAMEDocument2 pagesRSAFRAMETIOCA01No ratings yet

- COGNEX In-Sight Product GuideDocument16 pagesCOGNEX In-Sight Product GuidedollareNo ratings yet

- A Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyDocument6 pagesA Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyWorld of Computer Science and Information Technology JournalNo ratings yet

- Power SteeringDocument31 pagesPower SteeringpeskeirasNo ratings yet

- Luminaria Terex RL4Document112 pagesLuminaria Terex RL4JuanJose Ore MuchaNo ratings yet

- Polywithe® - 8000 CLDocument1 pagePolywithe® - 8000 CLsébastien cardinaleNo ratings yet

- ESDR4Document4 pagesESDR4Eddy Skb0% (1)

- Bowmar MX55 Electronic Calculator ManualDocument22 pagesBowmar MX55 Electronic Calculator ManualDjango RodNo ratings yet

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Document8 pages600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirNo ratings yet

- Thermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Document2 pagesThermozorb Heatless Regenerative Air Dryer: TZ22 - TZ142Емил ГавриловNo ratings yet

- q64DA PDFDocument1 pageq64DA PDFSebastián LozadaNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- Varec 5000 5010 PDFDocument10 pagesVarec 5000 5010 PDFEduardo Rafael Lopez LezamaNo ratings yet