Professional Documents

Culture Documents

Polyflam® RPP 374 ND CS1 5V

Uploaded by

Mitja GorseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyflam® RPP 374 ND CS1 5V

Uploaded by

Mitja GorseCopyright:

Available Formats

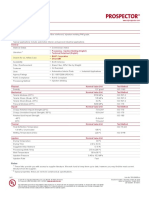

POLYFLAM® RPP 374 ND CS1 5V

Polypropylene Homopolymer www.ulprospector.com

LyondellBasell Industries

Technical Data

Product Description

20% talc filled flame-retardant PP-Homopolymer; without PBDE

General

Material Status • Commercial: Active

• Processing - Mold Shrink (English)

Literature 1

• Technical Datasheet

• E86615-252224

• E132739-103303121

• E490500-103228036

UL Yellow Card 2 • E493152-103728722

• E51193-242237

• E51193-104499251

• E344659-104109455

Search for UL Yellow Card

• LyondellBasell Industries

• POLYFLAM®

• Africa & Middle East • Europe

Availability • North America

• Asia Pacific • Latin America

Filler / Reinforcement • Talc, 20% Filler by Weight

Features • Copper Contact Stabilized • Flame Retardant • Homopolymer

UL File Number • E86615 (Europe) E51193 (US)

Processing Method • Injection Molding

Resin ID (ISO 1043) • PP TD20 FR(17)

Physical Nominal Value Unit Test Method

Density 1.45 g/cm³ ISO 1183/A

Melt Volume-Flow Rate (MVR) (230°C/2.16 kg) 5.0 cm³/10min ISO 1133

Water Absorption (Equilibrium, 23°C, 50% RH) 0.16 % ISO 62

Mechanical Nominal Value Unit Test Method

Tensile Modulus 3700 MPa ISO 527-1/1A/1

Tensile Stress (Yield) 27.0 MPa ISO 527-2/1A/50

Tensile Strain (Yield) 2.0 % ISO 527-2/1A/50

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength ISO 179/1eA

-30°C 1.8 kJ/m²

23°C 2.0 kJ/m²

Charpy Unnotched Impact Strength ISO 179/1eU

-30°C 12 kJ/m²

23°C 12 kJ/m²

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

0.45 MPa, Unannealed 118 °C ISO 75-2/Bf

1.8 MPa, Unannealed 80.0 °C ISO 75-2/Af

Vicat Softening Temperature

-- 92.0 °C ISO 306/B50

-- 155 °C ISO 306/A50

Ball Pressure Test (125°C) Pass IEC 60695-10-2

1 of 4 Form No. TDS-128796-en

UL LLC ©2023. All rights reserved. Document Created: Monday, November 20, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: June 2009

Last Updated: 9/29/2023

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

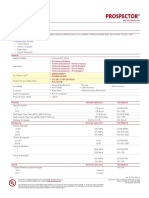

POLYFLAM® RPP 374 ND CS1 5V

Polypropylene Homopolymer

LyondellBasell Industries www.ulprospector.com

Thermal Nominal Value Unit Test Method

RTI Elec UL 746B

1.5 mm 105 °C

1.8 mm 105 °C

3.0 mm 105 °C

RTI Imp UL 746B

1.5 mm 105 °C

1.8 mm 105 °C

3.0 mm 105 °C

RTI Str UL 746B

1.5 mm 105 °C

1.8 mm 105 °C

3.0 mm 105 °C

Electrical Nominal Value Unit Test Method

Surface Resistivity > 1.0E+15 ohms IEC 60093

Volume Resistivity > 1.0E+13 ohms·m IEC 62631-3-1

Comparative Tracking Index 600 V IEC 60112

High Amp Arc Ignition (HAI) UL 746A

1.5 mm PLC 0

1.8 mm PLC 0

3.0 mm PLC 0

Hot-wire Ignition (HWI) UL 746A

1.5 mm PLC 3

1.8 mm PLC 3

3.0 mm PLC 2

Flammability Nominal Value Unit Test Method

Burning Rate

2.00 mm, Self-Extinguishing 0.0 mm/min FMVSS 302

2.00 mm, Self-Extinguishing 0.0 mm/min ISO 3795

Flame Rating UL 94

IEC 60695-11-10, -20

1.5 mm V-0

3.0 mm

• V-0

• 5VA

1.8 mm 5VA

Glow Wire Flammability Index IEC 60695-2-12

1.5 mm 960 °C

1.8 mm 960 °C

3.0 mm 960 °C

Glow Wire Ignition Temperature IEC 60695-2-13

1.5 mm 750 °C

1.8 mm 750 °C

3.0 mm 750 °C

Oxygen Index 29 % ISO 4589-2

Injection Nominal Value Unit

Drying Temperature 70 to 80 °C

Drying Time 2.0 to 4.0 hr

2 of 4 Form No. TDS-128796-en

UL LLC ©2023. All rights reserved. Document Created: Monday, November 20, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: June 2009

Last Updated: 9/29/2023

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

POLYFLAM® RPP 374 ND CS1 5V

Polypropylene Homopolymer

LyondellBasell Industries www.ulprospector.com

Injection Nominal Value Unit

Rear Temperature 180 to 199 °C

Middle Temperature 180 to 210 °C

Front Temperature 180 to 210 °C

Nozzle Temperature 180 to 220 °C

Processing (Melt) Temp 180 to 220 °C

Mold Temperature 38 to 71 °C

Injection Pressure 80.0 to 120 MPa

Holding Pressure 40.0 to 90.0 MPa

Back Pressure < 0.689 MPa

Cushion < 5.00 mm

Injection Notes

Mould surface contacting melt should

be of non-corrosive steel (content of chrome > 12%)

Notes

1 These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current literature

from the supplier.

2 A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL Prospector continually works to link Yellow Cards to

individual plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association

between these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

3 Typical properties: these are not to be construed as specifications.

3 of 4 Form No. TDS-128796-en

UL LLC ©2023. All rights reserved. Document Created: Monday, November 20, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: June 2009

Last Updated: 9/29/2023

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

POLYFLAM® RPP 374 ND CS1 5V

Polypropylene Homopolymer

LyondellBasell Industries www.ulprospector.com

Where to Buy

Supplier

LyondellBasell Industries

Wilmington, Wilmington USA

Telephone: 713-309-7200

Web: https://www.lyondellbasell.com/

Distributor

Plastic Service Centers

Telephone: 586-307-3900

Web: http://www.plasticservice.com/

Availability: North America

Plastics Plus, Inc.

Telephone: 248-393-0300

Web: http://www.plasplus.com/

Availability: North America

Resin Resource, Inc.

Telephone: 877-652-3431

Web: http://www.resinresourceinc.com/

Availability: North America

Tex-Co Resin Distribution, Inc.

Telephone: 877-908-3926

Web: http://www.texcoresin.com/

Availability: North America

4 of 4 Form No. TDS-128796-en

UL LLC ©2023. All rights reserved. Document Created: Monday, November 20, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: June 2009

Last Updated: 9/29/2023

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- Hostacom M2 N01 PDFDocument1 pageHostacom M2 N01 PDFbetoNo ratings yet

- Duracon® CP15XDocument3 pagesDuracon® CP15XRhekron PlasticsNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- Amcel KP20: Celanese Corporation - Acetal (POM) CopolymerDocument1 pageAmcel KP20: Celanese Corporation - Acetal (POM) CopolymerSamuelNo ratings yet

- Zytel® 101F Nc010: Dupont Performance PolymersDocument4 pagesZytel® 101F Nc010: Dupont Performance PolymersagungNo ratings yet

- Starex GR-4020: Lotte Advanced Materials Co., LTDDocument5 pagesStarex GR-4020: Lotte Advanced Materials Co., LTDsivalingabeastboy2002No ratings yet

- Technyl Star® A 205F Natural SDocument3 pagesTechnyl Star® A 205F Natural STiago GalloNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Zytel® Lc6601 Bk551: Dupont Transportation & IndustrialDocument2 pagesZytel® Lc6601 Bk551: Dupont Transportation & IndustrialbobNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- Nexeo Plastics Kingfa PBT RG151Document2 pagesNexeo Plastics Kingfa PBT RG151kls.thorodinsonNo ratings yet

- Hostalen H 2150Document3 pagesHostalen H 2150Silviu PadureanuNo ratings yet

- SE-316 Parts Data SheetDocument27 pagesSE-316 Parts Data SheetElnBEKKARYNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- Product PDF 301308Document2 pagesProduct PDF 301308Andrew JacksonNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Basf - C 218 v30 BlackDocument7 pagesBasf - C 218 v30 BlackfernandoincesaNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Product PDF 244478Document3 pagesProduct PDF 244478lorejaz84071127No ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- Product PDF 14364Document2 pagesProduct PDF 14364Gerente IngenieriaNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- POM F2003 Misubishi - ThailanDocument2 pagesPOM F2003 Misubishi - ThailanHD TalababuNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- Sasol Polymers PP HNR100Document3 pagesSasol Polymers PP HNR100Albert FortunatoNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- 4lex® 10F13500Document2 pages4lex® 10F13500srinivasaNo ratings yet

- PEI Ultem 2310R 30%GLDocument4 pagesPEI Ultem 2310R 30%GLcountzeroaslNo ratings yet

- Product PDF 181Document2 pagesProduct PDF 181RicardoNo ratings yet

- Ultradur® B 4300 G6Document4 pagesUltradur® B 4300 G6srinivasaNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RNguyễn Xuân KỳNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- Denyl 6 NDocument2 pagesDenyl 6 NPhung LucNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- SCG PP P483Ju: SCG Chemicals Co., LTDDocument2 pagesSCG PP P483Ju: SCG Chemicals Co., LTDTruc Thao NguyenNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- Zytel® HTN 51G35HSLR BK420Document3 pagesZytel® HTN 51G35HSLR BK420Vignesh CmvrNo ratings yet

- ABS CHIMEI Pa-757Document3 pagesABS CHIMEI Pa-757Muslim N FNo ratings yet

- 4lex® 10F13100Document2 pages4lex® 10F13100srinivasaNo ratings yet

- Akulon F130-C1: Property DataDocument2 pagesAkulon F130-C1: Property DataJackNo ratings yet

- Starex SD 0150Document5 pagesStarex SD 0150claudiaNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Polyflam Rabs 90000 Uv5 LS (E128762)Document3 pagesPolyflam Rabs 90000 Uv5 LS (E128762)simonNo ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- ECMALON - High Performance ResinsDocument5 pagesECMALON - High Performance ResinsNagendra GuptaNo ratings yet

- HA-PMMA 02 DentalDocument12 pagesHA-PMMA 02 Dentalhr granulabNo ratings yet

- Journal Template-Arab JournalDocument10 pagesJournal Template-Arab JournalHabte DebisaNo ratings yet

- Aerospace Application of Polymer Nanocomposite With Carbon Nanotube Graphite Graphene Oxide and NanoclayDocument20 pagesAerospace Application of Polymer Nanocomposite With Carbon Nanotube Graphite Graphene Oxide and NanoclayBüşraNo ratings yet

- Masterbatch Producrers in IndiaDocument39 pagesMasterbatch Producrers in IndiaFuture Innovations100% (1)

- Lectures 1 CompositeDocument4 pagesLectures 1 CompositeMuhammad AhmedNo ratings yet

- Crafco Roadsaver 522 PDS Sept 2016Document1 pageCrafco Roadsaver 522 PDS Sept 2016jorge silvaNo ratings yet

- Short Fiber-Reinforced Composite Restorations: A Review of The Current LiteratureDocument9 pagesShort Fiber-Reinforced Composite Restorations: A Review of The Current Literaturegerson fabian arangoNo ratings yet

- Reaction Injection Molding: Design GuideDocument34 pagesReaction Injection Molding: Design GuideasliNo ratings yet

- Sikadur - 31 Sba S-02inDocument4 pagesSikadur - 31 Sba S-02inmahantesh cNo ratings yet

- A New Approach To Improving The Properties of Brazed JointsDocument8 pagesA New Approach To Improving The Properties of Brazed Jointsdavid perezNo ratings yet

- Metalcor 1.4828 Aisi 309Document1 pageMetalcor 1.4828 Aisi 309Avn PrasadNo ratings yet

- CAB O SIL TS720pdfDocument2 pagesCAB O SIL TS720pdfsriatul2006No ratings yet

- Vestolit BR Textile-Coatings Web EN 2022-10Document12 pagesVestolit BR Textile-Coatings Web EN 2022-10Betty GonzálezNo ratings yet

- The Effect of Filler On Asphalt Cement Mastics. IowaDocument119 pagesThe Effect of Filler On Asphalt Cement Mastics. IowaCatalinaLixandruNo ratings yet

- Bulk Fill Resin Composites in DentistryDocument184 pagesBulk Fill Resin Composites in DentistryZilan MengütayNo ratings yet

- To Evaluate Effect of Preheated Composite Resin On Its Colour Stability When Immersed in Three Different Solutions - An in Vitro StudyDocument5 pagesTo Evaluate Effect of Preheated Composite Resin On Its Colour Stability When Immersed in Three Different Solutions - An in Vitro StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Recent Advances in Composites PDFDocument7 pagesRecent Advances in Composites PDFShriya Shahu100% (1)

- Schmidt + Clemens: Weld Repair Practices in High Temperature MaterialsDocument46 pagesSchmidt + Clemens: Weld Repair Practices in High Temperature MaterialsmanojballaNo ratings yet

- Direct Versus Indirect Inlayonlay Composite Restorations in Posterior Teeth. A Systematic Review and Meta-Analysis PDFDocument10 pagesDirect Versus Indirect Inlayonlay Composite Restorations in Posterior Teeth. A Systematic Review and Meta-Analysis PDFMel LlerenaNo ratings yet

- Astm D 1751Document2 pagesAstm D 1751Mohammad YaseenNo ratings yet

- Effect of Precipitated Calcium Carbonate On Physical, Mechanical and Thermal Properties of Cassava Starch Bioplastic CompositesDocument7 pagesEffect of Precipitated Calcium Carbonate On Physical, Mechanical and Thermal Properties of Cassava Starch Bioplastic CompositesShafly P L PrasDakeNo ratings yet

- Its Master 8483 1407201718 BibliographyDocument6 pagesIts Master 8483 1407201718 BibliographykusmiraNo ratings yet

- Sibelite WhitenessDocument4 pagesSibelite WhitenessLe PhongNo ratings yet

- 23-JRS Cellulose Fibers For Construction Chemical ProductsDocument32 pages23-JRS Cellulose Fibers For Construction Chemical ProductsAlan SantosNo ratings yet

- PVC Solvent CementDocument13 pagesPVC Solvent Cementsviruindia100% (5)

- Additives Reference Guide 2013Document80 pagesAdditives Reference Guide 2013Victor MelloNo ratings yet

- ABC of FRPDocument5 pagesABC of FRPKanupriya JainNo ratings yet

- Fuster Lopez Et Al. - 2008 - Filling Materials For Easel Paintings When The Ground Reintegration Becomes A Structural ConcernDocument7 pagesFuster Lopez Et Al. - 2008 - Filling Materials For Easel Paintings When The Ground Reintegration Becomes A Structural ConcernIsaac GoldNo ratings yet

- Module 7 - Non-MetalsDocument57 pagesModule 7 - Non-MetalsVivek KumarNo ratings yet