Professional Documents

Culture Documents

Fracturing-Modeling-Pdf Compress 23

Uploaded by

Mohamed MamdouhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fracturing-Modeling-Pdf Compress 23

Uploaded by

Mohamed MamdouhCopyright:

Available Formats

Section 300

FRACTURING ENGINEERING MANUAL

Schlumberger May 1998

Dowell

Fracture Modeling

Page 23 of 35

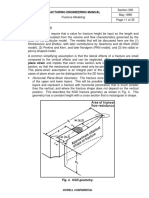

Note that the second calibration test performed on the well is also included on this

profile, and ends at a little over 100 min. A shut-in time is obtained and then the

main fracturing treatment starts at approximately 250 min. A PL-3D model

(GOHFER) from Marathon Oil Company was used to match the bottomhole pressure

as well as the surface casing (annulus) pressure. The simulation used stress and

elasticity data from the top of the log to the bottom. These data were used to give 22

layers for input. Fig. 13 shows the pressure match (dotted lines) from the start of the

treatment to the point of shutdown. Fig. 14 and Fig. 15 show the fracture length and

fracture width profiles from the simulation.

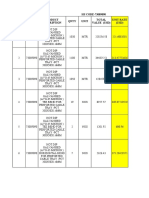

Table 3. Design Information

Fluid Volume, BBL Proppant Volume,

lbm

Stage Design Actual Fluid Type Proppant Design Actual Proppant

Conc. Type

(lbm/gal)

1 1500 1571 40-lbm linear 0 0 0 None

2 0 0 Shut-in 0 0 0 None

3 1000 576 Slickwater 0 0 0 None

4 3000 2908 50-lbm x-link 0 0 0 None

5 300 293 50-lbm x-link 1 12,600 11,110 100-Mesh

Sand

6 400 477 40-lbm x-link 0 0 0 None

7 400 337 40-lbm x-link 1 16,800 14,150 20/40

Ottawa sand

8 500 500 40-lbm x-link 2 42,000 41,120 20/40

Ottawa sand

9 500 437 40-lbm x-link 3 63,000 54,910 20/40

Ottawa sand

10 600 623 40-lbm x-link 4 100,800 105,330 20/40

Ottawa sand

11 800 755 40-lbm x-link 5 168,000 133,630 20/40

Ottawa sand

12 900 807 40-lbm x-link 6 226,800 227,250 20/40

Ottawa sand

13 900 934 40-lbm x-link 7 264,600 300,100 20/40

Ottawa sand

14 900 935 40-lbm x-link 8 302,400 292,420 20/40

Ottawa sand

15 300 240 Slickwater 0 0 0 None

DOWELL CONFIDENTIAL

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- X Te Interface Serv LetDocument2 pagesX Te Interface Serv LetValeria Rendon NoyolaNo ratings yet

- Stowage Plan On Barge Mitra AbadiDocument1 pageStowage Plan On Barge Mitra AbadifajrikarNo ratings yet

- Sub-Contractor DPR No 559 DTD 09.09.2019Document6 pagesSub-Contractor DPR No 559 DTD 09.09.2019Jayaaditya BoyinaNo ratings yet

- Polycab LDC-LP-No.-02-Dtd-1st-June-2018Document25 pagesPolycab LDC-LP-No.-02-Dtd-1st-June-2018Amol N. BankarNo ratings yet

- Pole DetailsDocument2 pagesPole Detailsirshad khanNo ratings yet

- Design of Precast Pier Cap - 1Document24 pagesDesign of Precast Pier Cap - 1Ankush SharmaNo ratings yet

- CABLE LDC LP No. 05 DTD 16th Nivember 2018Document25 pagesCABLE LDC LP No. 05 DTD 16th Nivember 2018UNNI VENUGOPALNo ratings yet

- V.D Calculations - 01Document4 pagesV.D Calculations - 01Ahmed MagdyNo ratings yet

- Bulk Material StockDocument8 pagesBulk Material StockAshanmugam SunfaceNo ratings yet

- CHL Mass Sizes of VVPSS Equipments (Updated)Document3 pagesCHL Mass Sizes of VVPSS Equipments (Updated)RanchojiNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- Ito Ung Sa Citi Hardware Lahat Subtotal 18 654 TransportationDocument2 pagesIto Ung Sa Citi Hardware Lahat Subtotal 18 654 TransportationEsther Oilynjoy MelendrezNo ratings yet

- PENDOPODocument5 pagesPENDOPOsafa mediantoNo ratings yet

- Belt Cleaner: Head PulleyDocument7 pagesBelt Cleaner: Head PulleyAgung Pandega PutraNo ratings yet

- JOMAR Feb 24 26Document34 pagesJOMAR Feb 24 26Joemar de MateoNo ratings yet

- Order/Estimate Form: Sr. No Description Quantity Rate AmountDocument1 pageOrder/Estimate Form: Sr. No Description Quantity Rate AmountDr Sachin Chitnis M O UPHC AiroliNo ratings yet

- Lifting Sketch New-20Document1 pageLifting Sketch New-20Mujahid AyyubNo ratings yet

- Load ScheduleDocument1 pageLoad ScheduleAlvin ConcepcionNo ratings yet

- Лебёдка RE-8000-10000-12000-12000X-1Document20 pagesЛебёдка RE-8000-10000-12000-12000X-1SanyaKlimNo ratings yet

- 2023-06-28 KEI Wires Price ListDocument1 page2023-06-28 KEI Wires Price ListCpgeorge JohnNo ratings yet

- ESP Calculation (External Static Pressure Calculation)Document54 pagesESP Calculation (External Static Pressure Calculation)Ajeet KumarNo ratings yet

- Elec LoadDocument6 pagesElec LoadLayca MacanasNo ratings yet

- Perforated Cable Tray DatabaseDocument6 pagesPerforated Cable Tray DatabasemrsuhelNo ratings yet

- JMaurici@20170221114911Document3 pagesJMaurici@20170221114911ToniNo ratings yet

- Apepdcl Cost Data 2018-19Document110 pagesApepdcl Cost Data 2018-19dorababu2007100% (1)

- Daftar Harga Uv Set WonderDocument5 pagesDaftar Harga Uv Set Wondersilmi ilaNo ratings yet

- Dompdf OutDocument1 pageDompdf OutAndika Martha DinataNo ratings yet

- K30brouchure Rev2Document3 pagesK30brouchure Rev2Patriot TeguhNo ratings yet

- FLETE FinalDocument12 pagesFLETE FinalsadhafzNo ratings yet

- Kagaoan Bill of QuantitiesDocument10 pagesKagaoan Bill of QuantitiesMichael EncarnacionNo ratings yet

- Schedule Curva SDocument12 pagesSchedule Curva Sanantyo kurniawanNo ratings yet

- ImensiupdateDocument4 pagesImensiupdateAlterSon Grafi KalayNo ratings yet

- 33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedDocument2 pages33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedFelix MgimbaNo ratings yet

- Reach 1 Stitch Concrete BBS-JP7-JP6Document2 pagesReach 1 Stitch Concrete BBS-JP7-JP6Eticala RohithNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

- Sys GDG 01 Des - 31 DesDocument384 pagesSys GDG 01 Des - 31 DesnoviNo ratings yet

- Screen and Cyclones in Concentrators PDFDocument11 pagesScreen and Cyclones in Concentrators PDFAnonymous C0lBgO24iNo ratings yet

- Parts Available For: E-1 (Water Pump /cooling Fan) : Ref No. Part Number Description Reqd. No MOQ MRP (RS.)Document1 pageParts Available For: E-1 (Water Pump /cooling Fan) : Ref No. Part Number Description Reqd. No MOQ MRP (RS.)senthilnaveenNo ratings yet

- Design-Analysis PT 2Document3 pagesDesign-Analysis PT 2chuck laygoNo ratings yet

- Duct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityDocument10 pagesDuct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityVipul HodawdekarNo ratings yet

- Calculation For Civil Work ExpensesDocument1 pageCalculation For Civil Work Expensesgajendrabanshiwal8905No ratings yet

- Patriot6000 8000 9500Document46 pagesPatriot6000 8000 9500Rogelio TafoyaNo ratings yet

- Panel Board SchedDocument3 pagesPanel Board Schedchuck laygoNo ratings yet

- Motor Control CentreDocument6 pagesMotor Control CentreAhsan SiddiquiNo ratings yet

- 1190 HardwareDocument2 pages1190 HardwarejacksonNo ratings yet

- HMAG Data Sheet v1 3 DynaserDocument4 pagesHMAG Data Sheet v1 3 DynaserMiguel CabezasNo ratings yet

- Rod Shaped Proppant PsDocument2 pagesRod Shaped Proppant PsbayuNo ratings yet

- Electrical LoadDocument2 pagesElectrical LoadkrakatuaNo ratings yet

- 172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : NeededDocument3 pages172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : Neededmesut ekşiNo ratings yet

- Slab Culvert 2m ModelDocument1 pageSlab Culvert 2m ModelMonjit GogoiNo ratings yet

- W.E.F. 03rd Sep.21 2021-22/PP/09 B: Aluminium Primary Metal - Bharat Aluminium Co. LTD & Vedanta LTDDocument1 pageW.E.F. 03rd Sep.21 2021-22/PP/09 B: Aluminium Primary Metal - Bharat Aluminium Co. LTD & Vedanta LTDSamuelNo ratings yet

- U B Enterprises: SR. Column 2 Column 3 Column 4Document2 pagesU B Enterprises: SR. Column 2 Column 3 Column 4rajubhai7078929065No ratings yet

- Polycab Cable Price List DTD 1st May 2017Document21 pagesPolycab Cable Price List DTD 1st May 2017dheerajdorlikarNo ratings yet

- Company Price ListDocument1 pageCompany Price ListUsman UmarNo ratings yet

- Lista Consumurilor de Resurse MaterialeDocument10 pagesLista Consumurilor de Resurse MaterialeCucutianu RobertNo ratings yet

- Cable and Materials DetailsDocument12 pagesCable and Materials DetailsSubhadipSamanta OfficialNo ratings yet

- Sistema Contra IncendioDocument173 pagesSistema Contra IncendionicolasosedaNo ratings yet

- BOMS Uploaded in SAPDocument4 pagesBOMS Uploaded in SAPFRANK YIGANo ratings yet

- Calculo Del Flete Terrestre Y Rural Agua Potable: PáginaDocument3 pagesCalculo Del Flete Terrestre Y Rural Agua Potable: PáginaMateus Velasquez GarciaNo ratings yet

- 04-Hydraulic-Fraturing Compress 31Document1 page04-Hydraulic-Fraturing Compress 31Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 24Document1 page04-Hydraulic-Fraturing Compress 24Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 14Document1 page04-Hydraulic-Fraturing Compress 14Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 27Document1 page04-Hydraulic-Fraturing Compress 27Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 34Document1 page04-Hydraulic-Fraturing Compress 34Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 16Document1 page04-Hydraulic-Fraturing Compress 16Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 7Document1 page04-Hydraulic-Fraturing Compress 7Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 49Document1 pageHyd0001 Basic Hydraulics PR - 49Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 9Document1 pageHyd0001 Basic Hydraulics PR - 9Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 2Document1 page04-Hydraulic-Fraturing Compress 2Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 29Document1 pageFracturing-Modeling-Pdf Compress 29Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 9Document1 page04-Hydraulic-Fraturing Compress 9Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 6Document1 page04-Hydraulic-Fraturing Compress 6Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 42Document1 pageHyd0001 Basic Hydraulics PR - 42Mohamed MamdouhNo ratings yet

- 04-Hydraulic-Fraturing Compress 4Document1 page04-Hydraulic-Fraturing Compress 4Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 37Document1 pageHyd0001 Basic Hydraulics PR - 37Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 38Document1 pageHyd0001 Basic Hydraulics PR - 38Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 48Document1 pageHyd0001 Basic Hydraulics PR - 48Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 53Document1 pageHyd0001 Basic Hydraulics PR - 53Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 31Document1 pageFracturing-Modeling-Pdf Compress 31Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 5Document1 pageHyd0001 Basic Hydraulics PR - 5Mohamed MamdouhNo ratings yet

- Hyd0001 Basic Hydraulics PR - 40Document1 pageHyd0001 Basic Hydraulics PR - 40Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 27Document1 pageFracturing-Modeling-Pdf Compress 27Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 20Document1 pageFracturing-Modeling-Pdf Compress 20Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 15Document1 pageFracturing-Modeling-Pdf Compress 15Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 11Document1 pageFracturing-Modeling-Pdf Compress 11Mohamed MamdouhNo ratings yet

- PDF Section6 Stimulation Equipment - Compress - 16Document1 pagePDF Section6 Stimulation Equipment - Compress - 16Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 32Document1 pageFracturing-Modeling-Pdf Compress 32Mohamed MamdouhNo ratings yet

- Fracturing-Modeling-Pdf Compress 25Document1 pageFracturing-Modeling-Pdf Compress 25Mohamed MamdouhNo ratings yet

- PDF Section6 Stimulation Equipment - Compress - 18Document1 pagePDF Section6 Stimulation Equipment - Compress - 18Mohamed MamdouhNo ratings yet

- SecuritizationDocument46 pagesSecuritizationHitesh MoreNo ratings yet

- Ci Thai RiceDocument4 pagesCi Thai RiceMakkah Madina riceNo ratings yet

- Bank Danamon Organization ChartDocument4 pagesBank Danamon Organization ChartFaisal Agus NugrahaNo ratings yet

- Measuring Temperature - Platinum Resistance ThermometersDocument3 pagesMeasuring Temperature - Platinum Resistance Thermometersdark*nightNo ratings yet

- RMC 102-2017 HighlightsDocument3 pagesRMC 102-2017 HighlightsmmeeeowwNo ratings yet

- Decision Trees For Management of An Avulsed Permanent ToothDocument2 pagesDecision Trees For Management of An Avulsed Permanent ToothAbhi ThakkarNo ratings yet

- Multimodal Essay FinalDocument8 pagesMultimodal Essay Finalapi-548929971No ratings yet

- Project Document EiDocument66 pagesProject Document EiPrathap ReddyNo ratings yet

- Pantalla MTA 100Document84 pagesPantalla MTA 100dariocontrolNo ratings yet

- HRMDocument118 pagesHRMKarthic KasiliaNo ratings yet

- The Kicker TranscriptionDocument4 pagesThe Kicker TranscriptionmilesNo ratings yet

- Alkosign Product CatalogeDocument20 pagesAlkosign Product CatalogeShree AgrawalNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughNo ratings yet

- Dakua Makadre PresentationDocument12 pagesDakua Makadre PresentationEli Briggs100% (1)

- Epreuve Anglais EG@2022Document12 pagesEpreuve Anglais EG@2022Tresor SokoudjouNo ratings yet

- Airport & Harbour Engg-AssignmentDocument3 pagesAirport & Harbour Engg-AssignmentAshok Kumar RajanavarNo ratings yet

- Organization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaDocument4 pagesOrganization Culture Impacts On Employee Motivation: A Case Study On An Apparel Company in Sri LankaSupreet PurohitNo ratings yet

- Experiment - 1: Batch (Differential) Distillation: 1. ObjectiveDocument30 pagesExperiment - 1: Batch (Differential) Distillation: 1. ObjectiveNaren ParasharNo ratings yet

- AssignmentDocument47 pagesAssignmentHarrison sajorNo ratings yet

- Derebe TekesteDocument75 pagesDerebe TekesteAbinet AdemaNo ratings yet

- Manual For Tacho Universal Edition 2006: Legal DisclaimerDocument9 pagesManual For Tacho Universal Edition 2006: Legal DisclaimerboirxNo ratings yet

- TESTDocument27 pagesTESTLegal CheekNo ratings yet

- Math Review CompilationDocument9 pagesMath Review CompilationJessa Laika CastardoNo ratings yet

- 5066452Document53 pages5066452jlcheefei9258No ratings yet

- EdisDocument227 pagesEdisThong Chan100% (1)

- Conservation Assignment 02Document16 pagesConservation Assignment 02RAJU VENKATANo ratings yet

- Recruitment SelectionDocument11 pagesRecruitment SelectionMOHAMMED KHAYYUMNo ratings yet

- Amendments To The PPDA Law: Execution of Works by Force AccountDocument2 pagesAmendments To The PPDA Law: Execution of Works by Force AccountIsmail A Ismail100% (1)

- Chapter 08 - Change in Accounting Policy: Problem 8-1 (AICPA Adapted)Document5 pagesChapter 08 - Change in Accounting Policy: Problem 8-1 (AICPA Adapted)Kimberly Claire AtienzaNo ratings yet

- Smart Gas Leakage Detection With Monitoring and Automatic Safety SystemDocument4 pagesSmart Gas Leakage Detection With Monitoring and Automatic Safety SystemYeasin Arafat FahadNo ratings yet