Professional Documents

Culture Documents

Troubleshooting Checklist v1.0

Uploaded by

Rubén Casaperalta WarthonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Troubleshooting Checklist v1.0

Uploaded by

Rubén Casaperalta WarthonCopyright:

Available Formats

INITIAL TROUBLESHOOTING CHECKLISTS Version 1.

0

PRINT QUALITY GENERAL ISSUES

Is the power cord free from damage?

Check that supplies are

Is the power supply line voltage within 10% of the

genuine Lexmark supplies.

rated line voltage?

Is the media being used

Is the printer properly grounded? (Check the power

recommended for the device?

cord ground terminal.)

Try using media from a newly

Are wires, cords and cables connected properly?

opened package and check the

Is the device on a level surface in a well-ventilated

result.

area?

Check supplies status. Replace

Is the room temperature between 16 and 32 degrees

supplies that are low or empty.

C (60 and 90 degrees F)?

Match settings to media.

Is the relative humidity between 20% and 80%?

Print and keep the menu

Is the device near anything that generates ammonia

settings page so you can

gas, high temperatures, high humidity (water faucets,

restore the settings later if

kettles, humidifiers), cold spaces, open flames, dusty

necessary.

spaces?

Set Print resolution and Toner

Is the device exposed to direct sunlight?

darkness

Are genuine Lexmark supplies and parts being used?

Check the transfer roller, toner

Are electronic products sending signals that interfere

cartridges(s), and transfer belt

with WIFI signals?

for damage. Replace if

necessary.

Check maintenance kit for end

of life.

Print the advanced print quality REPEATING PAPER PATH (JAMS)

samples to see if the problem Media tapped, fanned and loaded correctly?

remains. Use tray 1 to test print Media in good condition?

quality problems. Media size, type and weight (gsm) supported?

Make sure the correct print Paper guide set according to size?

driver is used. Sheets loaded under top load line?

Settings match actual media?

Tray properly inserted?

SCANNER ISSUES Tray lift and gear operational?

Settings correct? Pick rollers clean and not worn?

Media okay? (Too heavy? Has Tray free from damage?

adhesive? Hole punched?) Pick roller assembly free from damage?

Does POR clear problem? Pick roller assembly working?

Paper guides adjusted Transport (separator) roll operational?

properly? Paper path free from debris or obstruction?

Pick mechanism broken? Input sensor working and not damaged?

Are sensors working okay? Imaging unit (IU) in good condition?

(Sensor test) Fuser roll working and not damaged?

Is firmware current? Fuser exit and narrow media sensor working and not

Are cables connected? damaged?

Rear door properly closed?

IF SCANNER FAILS TO FEED: Output bin sensor working and not damaged?

Overfilled? Output bin not full of sheets?

Side guides too tight? Does the slit glass or flatbed glass need to be

Curled media? cleaned?

Broken pick mechanism? Are the ADF pick rolls and separator pad okay?

Dust on rollers? Has the first scan sensor been checked/cleaned?

Media stopper disengages? Are the side restraints set correctly?

You might also like

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Facebook HackingDocument1 pageFacebook Hacking친제임스0% (2)

- FTP-00950 Troubleshooting UV Printer Ink Curing Issues BDocument8 pagesFTP-00950 Troubleshooting UV Printer Ink Curing Issues BJorge Sanchez HidalgoNo ratings yet

- Manpreet Singh: Technical SkillsDocument2 pagesManpreet Singh: Technical SkillsAshish SharmaNo ratings yet

- Quiz-HP PageWide Printer Theory and Troubleshooting Fundamentals - Service and SupportDocument14 pagesQuiz-HP PageWide Printer Theory and Troubleshooting Fundamentals - Service and SupportAlves Carvalho0% (1)

- LIBRO Biomagnetismo Manual 1Document121 pagesLIBRO Biomagnetismo Manual 1Doctora Luisa0% (5)

- MXB355W MXB455W Trouble ShootingDocument62 pagesMXB355W MXB455W Trouble ShootingGaeliusEnvoyNo ratings yet

- MX 3070Document56 pagesMX 3070Hoang Minh Pham NguyenNo ratings yet

- Chapter 8. Troubleshooting: 8.1 Procedure of Checking The SymptomsDocument26 pagesChapter 8. Troubleshooting: 8.1 Procedure of Checking The SymptomsAivars LīpenītsNo ratings yet

- mx4050n Ex FaqDocument60 pagesmx4050n Ex FaqRobin EeftingNo ratings yet

- M4 Operation Manual PDFDocument58 pagesM4 Operation Manual PDFpruebasNo ratings yet

- Apple Portable StyleWriter Service SourceDocument49 pagesApple Portable StyleWriter Service SourceAdrian Iulius BujenițăNo ratings yet

- UP BOX Manual 4.7.1 ENGDocument37 pagesUP BOX Manual 4.7.1 ENGtimostaunNo ratings yet

- HumaLyte Plus ServiceDocument26 pagesHumaLyte Plus ServiceAyaovi Jorlau100% (1)

- HZBB-10B Intelligent Tester of Transformer Ratio-User ManualDocument12 pagesHZBB-10B Intelligent Tester of Transformer Ratio-User ManualGio CJNo ratings yet

- Speech Oriented Devices and Touch PanelsDocument21 pagesSpeech Oriented Devices and Touch PanelsSaurav SharmaNo ratings yet

- Laser Printer Print DefectsDocument30 pagesLaser Printer Print DefectsGurpal Singh Kalsi50% (2)

- Radiology QaqcDocument7 pagesRadiology QaqcAnn Caroline FerrerNo ratings yet

- AD-1191 Instruction Manual: Printer For A & D Scales & BalancesDocument34 pagesAD-1191 Instruction Manual: Printer For A & D Scales & BalancesOrgamus von RotterdamNo ratings yet

- AB-58C ManualDocument15 pagesAB-58C Manualrafiknet10No ratings yet

- FJ-1825 ManualDocument29 pagesFJ-1825 ManualErkan KabakçıNo ratings yet

- QJ 1825 Manual Ploter de ImpresionDocument50 pagesQJ 1825 Manual Ploter de ImpresionFeRchiitoo VeNnegass0% (1)

- MX 7090N 8090N Troubleshooting GuideDocument58 pagesMX 7090N 8090N Troubleshooting GuideIrmantas RojusNo ratings yet

- TX-3245 ManualDocument43 pagesTX-3245 ManualErkan KabakçıNo ratings yet

- Fenomastic Stain Resistant EmulsionDocument3 pagesFenomastic Stain Resistant Emulsionمحمد عزتNo ratings yet

- cd410 Thermal Label Printer ManualDocument7 pagescd410 Thermal Label Printer ManualklmakwanaNo ratings yet

- Feedback FormDocument9 pagesFeedback FormgNo ratings yet

- FJ-3245 ManualDocument24 pagesFJ-3245 ManualErkan KabakçıNo ratings yet

- UV Printer (A3L) - 1390 ManualDocument10 pagesUV Printer (A3L) - 1390 ManualSonia NaickerNo ratings yet

- cp3505 Error Messages PDFDocument24 pagescp3505 Error Messages PDFbehzadNo ratings yet

- 508c STM Manual Aus NZ July 2014Document28 pages508c STM Manual Aus NZ July 2014metrolabadequaciesofstandardNo ratings yet

- CLJ - 3550 3500 3700troubleshooting PDFDocument158 pagesCLJ - 3550 3500 3700troubleshooting PDFThePathToHomeNo ratings yet

- Seiko Troubleshooting Error CodesDocument24 pagesSeiko Troubleshooting Error CodesSandINo ratings yet

- Imagewriter LQ: Service SourceDocument18 pagesImagewriter LQ: Service SourceMassimo Del GaudioNo ratings yet

- Sensors PriceDocument9 pagesSensors PriceHITACHIINMAENo ratings yet

- User's Guide: Faqs How To Use This Manual Safety Precautions Before PrintingDocument202 pagesUser's Guide: Faqs How To Use This Manual Safety Precautions Before PrintingMariaStreinuNo ratings yet

- Medeli MC-710 (Instruction Manual)Document32 pagesMedeli MC-710 (Instruction Manual)AgeuBandeiraNo ratings yet

- Hls7000dn Use QSG Leb502001Document35 pagesHls7000dn Use QSG Leb502001jillNo ratings yet

- Sonic Tension MeterDocument28 pagesSonic Tension MeterandreNo ratings yet

- Setting Guide: 7.1 Printer OverviewDocument15 pagesSetting Guide: 7.1 Printer OverviewSoraphong NaknoppakoonNo ratings yet

- Stylewriter 1200Document72 pagesStylewriter 1200Massimo Del GaudioNo ratings yet

- Touch Screen SensorDocument24 pagesTouch Screen SensorAnkit PandeyNo ratings yet

- Laser Printer Print Defects - Black Pages: Problem Cause Solution How Common CommentsDocument30 pagesLaser Printer Print Defects - Black Pages: Problem Cause Solution How Common CommentsLouis ChenNo ratings yet

- Epson U200 ManualDocument55 pagesEpson U200 ManualfgarnicaNo ratings yet

- Information Sheet 1.3.2 - DocumentationDocument15 pagesInformation Sheet 1.3.2 - DocumentationJohn Kenley SerranoNo ratings yet

- A3 19 - Manual EnglishDocument43 pagesA3 19 - Manual EnglishMarco VieiraNo ratings yet

- HJ-1604 ManualDocument26 pagesHJ-1604 ManualErkan KabakçıNo ratings yet

- Testing Lucas Voltage Regulators (Triumph)Document4 pagesTesting Lucas Voltage Regulators (Triumph)caldasferreirasoutoNo ratings yet

- Fy-3206 Usb PDFDocument38 pagesFy-3206 Usb PDFgato00No ratings yet

- Ta Print QualityDocument4 pagesTa Print QualityHon Haing ENo ratings yet

- The 5 Types of Touch Screen Technology.! Which One Is Best For You?!Document5 pagesThe 5 Types of Touch Screen Technology.! Which One Is Best For You?!hondmeNo ratings yet

- 2018 Color Field Awareness GuideDocument15 pages2018 Color Field Awareness GuideЮлиян ЯкимовNo ratings yet

- August Tech FestDocument20 pagesAugust Tech FestChalez ZengeretsiNo ratings yet

- KIP 9000 Service Manual Ver A - 0Document761 pagesKIP 9000 Service Manual Ver A - 0Evan DuncanNo ratings yet

- Multiparameter Bench Photometer: Instruction ManualDocument72 pagesMultiparameter Bench Photometer: Instruction ManualOperaciones Aqua CareNo ratings yet

- Aw MD700 Manual G10 150706Document73 pagesAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraNo ratings yet

- 1 - Instruction Manual Nano9Document30 pages1 - Instruction Manual Nano9davidNo ratings yet

- Instruction Manual Nano7Document29 pagesInstruction Manual Nano7Amogelang TshukuduNo ratings yet

- 600super User ManualDocument57 pages600super User ManualsoporteNo ratings yet

- Chpt18b Printers & NotebookDocument18 pagesChpt18b Printers & NotebookPradeep TiwariNo ratings yet

- Ricoh FT 3113-3313-3613 SMDocument295 pagesRicoh FT 3113-3313-3613 SMDragan NedicNo ratings yet

- Communication for Command and Control Systems: International Series on Systems and ControlFrom EverandCommunication for Command and Control Systems: International Series on Systems and ControlNo ratings yet

- What Happened to My Computer?: Tips and Short Guide For the Everyday PC UserFrom EverandWhat Happened to My Computer?: Tips and Short Guide For the Everyday PC UserNo ratings yet

- (M11-MAIN) - Writing Executable StatementsDocument46 pages(M11-MAIN) - Writing Executable StatementsMAEGAN THERESE GABRIANANo ratings yet

- Cse 438 LDocument7 pagesCse 438 LZobayer AhmedNo ratings yet

- AUTOSAR SWS DiagnosticEventManager-已解锁 120-125Document6 pagesAUTOSAR SWS DiagnosticEventManager-已解锁 120-125965658391No ratings yet

- DX DiagDocument8 pagesDX DiagPerdi FirdausNo ratings yet

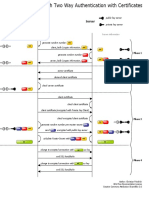

- SSL Handshake With Two-Way Authentication With CertificatesDocument1 pageSSL Handshake With Two-Way Authentication With CertificatesShailendra PandeyNo ratings yet

- Giving Technical and OperationalDocument165 pagesGiving Technical and OperationalJONALYN NGAPPOLNo ratings yet

- GoodBoy 3D Printed Arduino Robot DogDocument27 pagesGoodBoy 3D Printed Arduino Robot Dogfran manNo ratings yet

- Orca - TUTORIAL - MD at Main Hundredrabbits - Orca GitHub PDFDocument4 pagesOrca - TUTORIAL - MD at Main Hundredrabbits - Orca GitHub PDFSAKANA617No ratings yet

- Gmail - DFA Passport Appointment System - Payment Reference - 20230426 - 095130746Document1 pageGmail - DFA Passport Appointment System - Payment Reference - 20230426 - 095130746Psextrememultiplayer InternetcafeNo ratings yet

- Ch-04-Tiny College Case StudyDocument1 pageCh-04-Tiny College Case StudyAftab AhmadNo ratings yet

- Love Bug Project ProposalDocument16 pagesLove Bug Project Proposalapi-389071958No ratings yet

- 3KW 5KW User Manual 20201012Document37 pages3KW 5KW User Manual 20201012Amith Prasanna0% (1)

- Name-Muskan Agarwal Assignment-1 CodingclubDocument12 pagesName-Muskan Agarwal Assignment-1 CodingclubMuskan AgarwalNo ratings yet

- Canon PRO 6100S and 4100S BrochureDocument8 pagesCanon PRO 6100S and 4100S BrochureNope SmithNo ratings yet

- Murr Network Technology11-20Document42 pagesMurr Network Technology11-20AMNo ratings yet

- JEEHELL User Guide PDFDocument196 pagesJEEHELL User Guide PDFIvan GarciaNo ratings yet

- Koolprog User GuideDocument18 pagesKoolprog User GuideramonluhrNo ratings yet

- Empowerment Technology: Quarter 1 - Module 1 ICT in The Context of Global CommunicationDocument49 pagesEmpowerment Technology: Quarter 1 - Module 1 ICT in The Context of Global CommunicationVillaErnestNo ratings yet

- Cubic SplineDocument4 pagesCubic Splineomar shadyNo ratings yet

- Andrew Haiman Broadcast Engineer ResumeDocument2 pagesAndrew Haiman Broadcast Engineer Resumeapi-298531757No ratings yet

- iDVR PRO CMS Software Manual PDFDocument56 pagesiDVR PRO CMS Software Manual PDFbetillo76No ratings yet

- ESP8266 Module V2Document1 pageESP8266 Module V2Julian MNo ratings yet

- Linear Regression CalculatorDocument3 pagesLinear Regression CalculatorUnknown GuyNo ratings yet

- Ditto X4 LooperDocument14 pagesDitto X4 LooperLolo LolailoNo ratings yet

- Generations of ComputerDocument17 pagesGenerations of ComputerElrey AguadoNo ratings yet

- Database Keys: Ruben A. Parazo Faculty, Department of Computer StudiesDocument17 pagesDatabase Keys: Ruben A. Parazo Faculty, Department of Computer StudiesPaula Rodalyn MateoNo ratings yet

- Lecture 8 - Security at The Application LayerDocument34 pagesLecture 8 - Security at The Application Layermonaabdelaziz963No ratings yet