Professional Documents

Culture Documents

Duplais 1882 Schematic

Uploaded by

mkell3690 ratings0% found this document useful (0 votes)

3 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesDuplais 1882 Schematic

Uploaded by

mkell369Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Treatise on the Manufacture of Liqueurs and Distillation of Alcohols

by P. Duplais Ainé.

Fourth edition, review and additions by Duplais Jeune, Paris 1882

Volume II

--- pg 413 cont.---

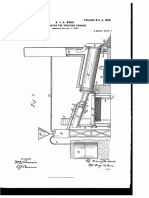

APPARATUS FOR THE MANUFACTURE OF ABSINTHE AND THE SCENTED SPIRITS.

This apparatus (Pl. VIII) is composed of the following parts:

A, boiler [still] encased by wood and containing as double-boiler another

vessel, which contains alcohol and the plants and seeds which are to

be distilled.

B, top or lid of the boiler.

C, closure hatch, fastening and dismounting with the greatest simplicity to

charge the boiler.

C’, closure hatch similar to the first, to discharge the plants after distillation.

D, capital surmounting the boiler, connected to it by a ring and finished with

an extension-piece carrying the alcoholic vapors to the coil.

E, cooler.

E', cooler outlet.

F, colorator, like the boiler, provided with taps to fill up and empty this

unit.

G, pump connected firmly to the wall using the G' collars.

H, piston rod [in this case, in a pushrod configuration].

I, eccentric [cam].

J, pulley.

K, bearing supports.

L, metal sump installed in the ground.

M, suction pipe.

M’, suction pipe to the colorator. --- pg 414 ---

N, three-way tap serving the suction pipe and making it possible for the

pump to suction from the sump, be it the alcohol and water that one

sends to the alembic, or the distilled product which is sent to the

colorator, or finally making it possible to draw from the colorator the

manufactured product to send to storage barrels.

N’, pipe used to draw off the colored product. [clearly connected to, or same

as M’]

O, pipe for advance or dispatch.

P, selection tap for pumping the liquid into the boiler to be distilled there,

or into the colorator.

P', pipe carrying the liquid to the colorator.

P", pipe carrying the liquid into the alembic.

R, tap and pipe for pumping the manufactured product to storage barrels.

S, funnel and pipe carrying the distilled products from the tank.

T, principal steam supply pipe coming from a generator.

U, steam bleed tap for [lit. by] the alembic.

V, steam bleed tap for the colorator.

Procedure for the apparatus. – This apparatus draws its principal

advantages from its great simplicity and from the small number parts

which constitute its configuration. A pump, by its multiple functions,

suffices to drive three different transfers, which are:

This document Copyright 2005 © Oxygenee.com and St Blasien

Electronic reproduction without permission strictly prohibited.

Treatise on the Manufacture of Liqueurs and Distillation of Alcohols

by P. Duplais Ainé.

Fourth edition, review and additions by Duplais Jeune, Paris 1882

Volume II

--- pg 414 cont. ---

1○ The filling of boiler A with water and alcohol to be distilled;

2○ The filling of the colorator F with the distilled product that has

discharged through the funnel and pipe S;

3○ The transfer [by suction pumping] of the product contained in

colorator F to the storage barrels.

Here is how one operates this apparatus.

Having filled with water and alcohol, in determined proportions,

the sump L, and having introduced through the upper opening of

boiler A the plants necessary for the manufacture of the absinthe, --- pg

415 --- one starts the pump, after having opened the tap P'P' [sic.; it is

evident however that flow is through tap P and pipe P”] immediately

boiler A fills from the contents of L. When the sump is empty, one

stops the action of the pump and one turns off tap U, and the

[distilled] product soon runs out of the coil and falls into S and will

again fill the sump L; but this time with spirits scented by the plants

that one had put in the alembic. The liquid is clear and for the most

part already has the qualities necessary for this liqueur; it remains to

color it. For that, the pump, fulfilling its second function, draws [by

suction] this liquid and sends it to the colorator F, which one took

care beforehand to furnish with coloring plants in quantity

proportional to that of the scented spirit which will be sent there. It is

by passing through the tap P and pipe P' that the scented spirit,

drawn from [sump] tank L and driven by the pump, arrives in the

colorator. Lastly, after this final operation which finishes the

fabrication of the absinthe, the pump fulfills its third function by

suctioning through pipe N’ the colored product contained in F, and

pumping it through the tap and pipe R to the barrels intended to

receive it.

This document Copyright 2005 © Oxygenee.com and St Blasien

Electronic reproduction without permission strictly prohibited.

You might also like

- Limprovement Vin Distilling Apparatus.: J. KunzeDocument3 pagesLimprovement Vin Distilling Apparatus.: J. KunzeHansel Sterling SeverinoNo ratings yet

- US1153992 - Collumn StillDocument4 pagesUS1153992 - Collumn StilletyseNo ratings yet

- Distillation LabwareDocument47 pagesDistillation LabwareMagikFungus100% (3)

- جدیدDocument45 pagesجدیدabasNo ratings yet

- Steam Powered Corkscrew StoryDocument8 pagesSteam Powered Corkscrew StoryAhmet MetinNo ratings yet

- Orsat ApparatusDocument6 pagesOrsat ApparatusArjun ReghuNo ratings yet

- Apparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Document4 pagesApparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Abdullah SimpsonNo ratings yet

- ExperimentDocument2 pagesExperimentParth AggarwalNo ratings yet

- Clements v. Odorless Excavating Apparatus Co., 109 U.S. 641 (1884)Document7 pagesClements v. Odorless Excavating Apparatus Co., 109 U.S. 641 (1884)Scribd Government DocsNo ratings yet

- Robert Leaute Distillation in AlembicDocument14 pagesRobert Leaute Distillation in Alembic156ro100% (2)

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827From EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827No ratings yet

- (No Model.) : F. StilesDocument2 pages(No Model.) : F. StilesKanishk JainNo ratings yet

- Turbine NotesDocument4 pagesTurbine NotesQuinton Tendai NyamhungaNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Tadano TR 500e 3 00101 ManualDocument22 pagesTadano TR 500e 3 00101 Manualmichaellittle030786drb100% (120)

- Us 2498806Document7 pagesUs 2498806regina pramuditaNo ratings yet

- A Further Improvement in The Sprengel PumpDocument4 pagesA Further Improvement in The Sprengel PumpMohammad-Mahdi TaghipourNo ratings yet

- GE2152 BCM Power Plant Engineering Notes 2Document13 pagesGE2152 BCM Power Plant Engineering Notes 2Alagar SamyNo ratings yet

- Design Construction EjectorDocument136 pagesDesign Construction Ejectorssmith2007100% (1)

- Victor MeyerDocument2 pagesVictor MeyerJulian de LaraNo ratings yet

- Orsat Gas Analysis ApparatusDocument3 pagesOrsat Gas Analysis ApparatusBalRam Dhiman100% (2)

- Ethanol RectificationDocument10 pagesEthanol RectificationAnatolij Pamiatnikh100% (1)

- Thermal LabDocument11 pagesThermal LabParam MehtaNo ratings yet

- Snow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Document8 pagesSnow v. Lake Shore & Michigan Southern R. Co., 121 U.S. 617 (1887)Scribd Government DocsNo ratings yet

- The Steam Engine.: 1-Basic PrinciplesDocument4 pagesThe Steam Engine.: 1-Basic PrinciplesKristian Marlowe OleNo ratings yet

- Boiler MountingsDocument11 pagesBoiler MountingsVikash MehtaNo ratings yet

- Tigercat FPT c87 t4f Engine Operator Service Repair ManualDocument22 pagesTigercat FPT c87 t4f Engine Operator Service Repair Manualwilliamjames200285ykt100% (108)

- FME Lab WorkDocument14 pagesFME Lab WorkVranda MaheshwariNo ratings yet

- Boiler Fittings and AccessoriesDocument30 pagesBoiler Fittings and Accessorieskowsar0221No ratings yet

- Teal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210Document4 pagesTeal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210juzmailmaNo ratings yet

- C12.3 Demonstrate An Ability To Warm Through An Auxiliary Steam SystemDocument1 pageC12.3 Demonstrate An Ability To Warm Through An Auxiliary Steam Systemab.alrashidi10No ratings yet

- Gas and Oil Engines, Simply Explained: An Elementary Instruction Book for Amateurs and Engine AttendantsFrom EverandGas and Oil Engines, Simply Explained: An Elementary Instruction Book for Amateurs and Engine AttendantsNo ratings yet

- Engineering Vol 69 1900-05-04Document35 pagesEngineering Vol 69 1900-05-04ian_newNo ratings yet

- AQ9 Boiler PDFDocument26 pagesAQ9 Boiler PDFВиталий РунцивNo ratings yet

- The Platen - Munters Absorption Refrigeration Cycle: AS Bsorption EfrigerationDocument5 pagesThe Platen - Munters Absorption Refrigeration Cycle: AS Bsorption Efrigerationbasheerahamed1991No ratings yet

- Research Paper On ME LabDocument12 pagesResearch Paper On ME LabJherel BerinNo ratings yet

- Acid CleaningDocument32 pagesAcid Cleaningsekhar_ntpcNo ratings yet

- Babcock BoilerDocument11 pagesBabcock BoilerKhuram IqbalNo ratings yet

- AMK H2 Plant TrainingDocument16 pagesAMK H2 Plant TrainingsoxalNo ratings yet

- Report On Acid CleaningDocument30 pagesReport On Acid CleaningAshutosh SachanNo ratings yet

- Alkali BoiloutDocument31 pagesAlkali BoiloutDuggineni Ramakrishna0% (1)

- Gas AbsorptionDocument7 pagesGas AbsorptionAnnerlynn Solano0% (1)

- Submitted by GAURAV NETAMDocument13 pagesSubmitted by GAURAV NETAMAbhishek KumarNo ratings yet

- Ite Note On Process PlantDocument14 pagesIte Note On Process PlantSam Wang Chern PengNo ratings yet

- It It: C, C, If Is IDocument1 pageIt It: C, C, If Is IreacharunkNo ratings yet

- Module 2 Boilers and PumpsDocument11 pagesModule 2 Boilers and PumpsJayanth SramNo ratings yet

- Oxygen PlantDocument10 pagesOxygen Plantshoaib705No ratings yet

- Condensers PDFDocument29 pagesCondensers PDFsandhya100% (1)

- 1 Feyzin GC Ang AccidentDocument20 pages1 Feyzin GC Ang AccidentEdwin AguirreNo ratings yet

- Bubble CapDocument1 pageBubble CapAkhil ViswanathanNo ratings yet

- Steam Cycle: Diah Susanti, PH.DDocument12 pagesSteam Cycle: Diah Susanti, PH.DDiana KamaliyahNo ratings yet

- Rankine Cycle: Isobaric Heat TransferDocument9 pagesRankine Cycle: Isobaric Heat TransferChristen RomeroNo ratings yet

- Boiler Exp 2Document9 pagesBoiler Exp 2Naimul Hoque Shuvo100% (1)

- Utility ManualDocument95 pagesUtility ManualMuhammad Haris HamayunNo ratings yet

- MC600 ManDocument156 pagesMC600 ManEsteban PauloNo ratings yet

- Pro.753687 en EU R4Document14 pagesPro.753687 en EU R4Rakshit SharmaNo ratings yet

- Poster Flender Com1 PDFDocument1 pagePoster Flender Com1 PDFvijaykumarnNo ratings yet

- Armor Piercing Bullets With Sintered Carbide Cores PDFDocument137 pagesArmor Piercing Bullets With Sintered Carbide Cores PDFfogdartNo ratings yet

- Data Envelopment Analysis: Models and Extensions: Production/Operations ManagementDocument4 pagesData Envelopment Analysis: Models and Extensions: Production/Operations Managementmithunrecdgp100% (2)

- Structured Text CheatsheetDocument1 pageStructured Text CheatsheetMauricio Rodriguez0% (1)

- 5950 Part 1-1990Document120 pages5950 Part 1-1990José Miguel100% (1)

- GP2500S/GP2501S - STN Color: Pro-Face Graphic Operator InterfacesDocument2 pagesGP2500S/GP2501S - STN Color: Pro-Face Graphic Operator Interfacesthanh_cdt01No ratings yet

- Project Management Dashboard TemplateDocument10 pagesProject Management Dashboard Templateindra prasetyaNo ratings yet

- 1964 US Army Vietnam War Military Police Traffic Control 203pDocument202 pages1964 US Army Vietnam War Military Police Traffic Control 203pwwwsurvivalebookscom100% (1)

- SulzerMixpac Industry CoatingDocument8 pagesSulzerMixpac Industry CoatingLewoskiNo ratings yet

- Siebel MAADocument31 pagesSiebel MAAboddu24No ratings yet

- Fund PoroDocument97 pagesFund PoroAgustín Ramos LópezNo ratings yet

- Syllabus Compendium For PCN Aerospace Sector ExaminationsDocument27 pagesSyllabus Compendium For PCN Aerospace Sector ExaminationstomcanNo ratings yet

- MQ-4C TritonDocument2 pagesMQ-4C TritonLeakSourceInfoNo ratings yet

- PMAC720Document3 pagesPMAC720felipeNo ratings yet

- Application of Neutralization TitrationsDocument21 pagesApplication of Neutralization TitrationsAsuncion Thea50% (2)

- Adaptive Antenna Systems: Widrow, E. GoodeDocument17 pagesAdaptive Antenna Systems: Widrow, E. GoodeKhal ZeratulNo ratings yet

- Optical Character Recognition Using MATLAB: J.Sashank Varma, G.V.N.S.Varma, K.Vikranth ReddyDocument5 pagesOptical Character Recognition Using MATLAB: J.Sashank Varma, G.V.N.S.Varma, K.Vikranth Reddyvikky23791No ratings yet

- Motor TestingDocument26 pagesMotor TestingGas Gas DucatiNo ratings yet

- Introduction To Igor Programming PDFDocument33 pagesIntroduction To Igor Programming PDFpaulklyuyevNo ratings yet

- SE160 e BrochureDocument2 pagesSE160 e BrochureAprilia KrisnawatiNo ratings yet

- Camera Tubes NDocument30 pagesCamera Tubes NRamakrishna VadlamudiNo ratings yet

- 21 CFR 177Document6 pages21 CFR 177i_flyNo ratings yet

- MANSAVER Catalog PDFDocument155 pagesMANSAVER Catalog PDFDejanNo ratings yet

- Is 2571-1970Document27 pagesIs 2571-1970Deboline MitraNo ratings yet

- How To Build Your Own Solid State OscilloscopeDocument100 pagesHow To Build Your Own Solid State OscilloscopemariopilarNo ratings yet

- Oxygen Booster ManualDocument27 pagesOxygen Booster ManualAldo Tolaba Quiroga100% (3)

- Kiln Performance - Efficiency FormulasDocument12 pagesKiln Performance - Efficiency FormulasMohamed ZayedNo ratings yet

- Cs Acrovyn CatalogueDocument83 pagesCs Acrovyn CatalogueBoboc AndreiNo ratings yet