Professional Documents

Culture Documents

Limprovement Vin Distilling Apparatus.: J. Kunze

Uploaded by

Hansel Sterling SeverinoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Limprovement Vin Distilling Apparatus.: J. Kunze

Uploaded by

Hansel Sterling SeverinoCopyright:

Available Formats

J. KUNZE.

lImprovement vin Distilling Apparatus.

Patented April 9;`1a72,.

No. 125,463.

efed

11

125,463

raton

4ilIlvIfTiaru STATES

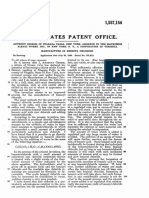

JULIUS KUNZ, OF GHATSWORTH, ILLINOIS.

'IMPROVEMENT' IN DISTZLLING> APPARATUS.

Specification forming part of Letters Patent No.125,463, dated April 9, 187 .

SPECIFICATION.

provided with faucet b to return the condensed

To all whom t may concern:

Be it known that I, J ULIUS KUNZE, of Chats

yof any suitable size, divided by partitions into

oil or water back to the still S.

B is a- column

worth, in the county of Livingston and State chambers. Partitions C C C are ot'dish-form,

of Illinois, have invented certain new and use

of the same diameter Vas the column, and se

ful Improvements in Distillation;77 and I do cured to its walls. They are provided with

hereby declare that the following is a full, clear, openings o o o", for vapors to freely ascend,

and exact description thereof, reference being and with rims or borders rl d el, to prevent the

had to the accompanying dra-win g making part condensed oil and water from passing through

of this specification, and to the letters of ref openings o o o, but to collect the same and

erence marked thereon, like letters indicating pass them down through the pipes I) D secured

like parts wherever they occur.V ^

totthe said partitions. Partitions E E E are

To enable others skilled in the art to construct of the shape of an inverted dish, for the pur

and use my invention, I will proceed to de pose of easily conveying the drops ot' oil and

scribe it.

water down, are of smaller diameter than col

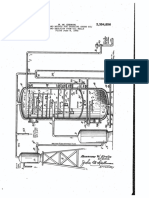

The accompanying drawing represents a ver umn B, and are secured to the same by strips

tical section of the-apparatus.

or staples f, leaving space F between wallsaud

The object of my invention is to produce, by partitionsopen. Thealcohol vapor mixed with

ordinary distillation, high wines or alcohol free oily and aqueous vapors goes from the still S

from fusil or other disagreeable essential oil, into vessel A, and from there ascends through

and of any desirable strength. The nature of opening o, spreads out right and left, goes

my invention consists iu the novel construction around partition E, again through opening o',

and arrangement of certain devices> in an ap around partition E', and so on, until it reaches

paratus, as hereinafter described and claimed. the top of column B, thus being subjected dur

My mode or method of purification ofthe al ing the passage to a great friction and concus

cohol vapor as it comes out of the still mixed

with fusil or other essential oil vapor an d aque

sion, losing` caloric, and thereby lowering in

temperature. rlhese frictions and reductions

ous vapor, and before it goes to the condenser, of temperature couden se a great deal offusil or

consists in subjecting the said vapor to a great other essential oil vapor, and also aqueous va

mechanical friction and concussion, and lower por, which, in a liquid state, are returned back

ing graduallyits temperature, thereby condens to vessel A, falling in drops, for instance, on

ing a considerable quantity of oil vapor and partition E, slide along it a-nd through space

aqueous> vapor, and thus separating the same F, drip down onto partition C, then through

from alcohol vapor; then in suddenly lowering pipes DD onto partition E', and so on, un

the temperature ofthe said vapor to such an eX til they reach the lowest partition G and pipe

tent as to precipitate or condense the Whole ot' g, through which they pass into vessel A, and

-,the oily or aqueous vapor, or the most of it, and from there can be returned to the still, it' de

return the same back to the still without con sirable, every time the work stops, or ot'tener.

densing the alcohol vapor ; and finally in puri

Thenumber of partitions in the column B de

fyin g the alcohol vapor from yet remaining pends upon the size of distilleryand the perfec

traces of oily vapor or other impurities, by tion of proposed puriticatiou ofthe alcohol va

charcoal, before it is condensed and turned into por. l use from Athirty to fifty partitions, and `

high wines or alcohol.l

even more. The partitions should be always so

The appara-tus to perform all the above said shaped and arranged as to submit the vapors to

operations is made ot' copper, and placed be a great friction against their surfaces, and to

tween the still S and condenser It of thefdis easily convey the condensed oily and aqueous

tillery. It is placed on .a suit-able foundation` vapors, in the shape of oil and water, back to

and consists of several pa-rts put up in the the vessel A. rIheir shape and a 1angement

shape of a column, although any other suita therefore maybe greatly modilied without sub~

ble shape may be adopted.

'

A isa vessel or holder, connected with still

stantially changing the principle underlying

the construction of the column and the object

S by pipe a to let in the alcohol vapor; also attained thereby. H is a precipitator or con

125,463

denser, to precipitate or condense at once all there by pipes u uinto the column B, where it

the oil vapors or aqueous vapor ascending with vaporizes again. T T are chambers to receive

alcohol- vapor to the top ofthe column B, and steam for the purpose of Warmin g the. alcohol

thus separate them from the said alcohol va vapor at the moment ot' its entering the char

por. The precipitator is a double Water-hold coal, if desirable. t t are the inlet and outlet

er, having a passage between the two Water pipes for the steam, which when used is re

holders for the vapors to pass. I is the inlet newed constantly. 'Vaste steam is intended to

pipe, through which water tills the spaces K be used for the purpose. By using steam here

K, and through the side pipes J J tills the less steam will be required for the column and

spaces L L, from which, by the pipes l Z, it vessel A, or even in the still S.

is conducted into and ills the space M, and

then goes out by a discharge-pipe, m. Nis the

passage for the alcohol vapor.` The Water in

the precipitator is in constant motion. The oil

vapors and aqueous vapors that ascended to

the top ofthe column B With alcohol vapor

It may be seen, from the above description

of the apparatus and of the successive opera

tions over the alcohol vapor, that by placing

my apparatus between the still and the con

denser in any distillery, an uninterrupted dis

conveyed down the column and returned to

the vessel A, While the alcohol vapor passes on

while the quantity ot' Wines produced from a

certain quantity of grain Will not be in -the

higher. ' P Pare the vessels for the charcoal

least diminished.

tillin g operation will be established, producing

Without being condensed, notv entering the by au ordinary distillation high Wines or alco

passage N, trom a sudden reduction in tem hol perfectly free from- fusil or_ other essential

perature, rapidly condense, and in drops are oils or impurities, and of any desirable strength,

holders Q, Q and steam-chambers T T. The

alcohol vapor from the precipitator H passes

by one or both pipes, qq, into the charcoal hold

ers Q Q, perforated at the bottom, and, Work

ing its way through the charcoal, becomes puri

The apparatus can easily be adapted also for

use in rect-ifying establishments.

'

Having thus fully described my invention,

what I claim as new, and desire to secure by

Letters Patent, is-f

fied ot' traces ot fusil-oil or other impurities `The combination of the vessel A and col

that perhaps were not condensed in the precipi umn B Wit-h the precipitator H, charcoal-ch am

tator H, and thus, perfectly puri?ed, passes bers Q, Q, and steam-chambersT T, when con

through pipes r rinto the distillery condenser structed and arranged to operate substantially

B, Where it is condensed into highwines or al as and'for the purpose set forth.

cohol in the ordinary manner. Entering the

vessel l? l) the alcohol vapor may partially

condense, in which case it is conducted from

Witnesses:

J ULIUS KUNZE.

WILLIAM ALTMAN,

JOHN A. SCHENK.

You might also like

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827From EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827No ratings yet

- جدیدDocument45 pagesجدیدabasNo ratings yet

- US1153992 - Collumn StillDocument4 pagesUS1153992 - Collumn StilletyseNo ratings yet

- US1586732 - Collumn StillDocument4 pagesUS1586732 - Collumn StilletyseNo ratings yet

- Duplais 1882 SchematicDocument2 pagesDuplais 1882 Schematicmkell369No ratings yet

- Us 2498806Document7 pagesUs 2498806regina pramuditaNo ratings yet

- ADI Distilling BookDocument60 pagesADI Distilling Bookbardchatigny100% (2)

- Craft Whiskey DistillingDocument13 pagesCraft Whiskey Distillinggauzz_erNo ratings yet

- Aloistiny,: - /vsodsidDocument5 pagesAloistiny,: - /vsodsidCristian GomezNo ratings yet

- Distillation LabwareDocument47 pagesDistillation LabwareMagikFungus100% (3)

- Us2181099 PDFDocument4 pagesUs2181099 PDFAt ChecoNo ratings yet

- Alkali BoiloutDocument31 pagesAlkali BoiloutDuggineni Ramakrishna0% (1)

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocument2 pagesNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfNo ratings yet

- Us 2509877Document3 pagesUs 2509877Mary Grace VelitarioNo ratings yet

- John BateDocument227 pagesJohn Batefersoto07100% (1)

- TP Distillation 2019Document32 pagesTP Distillation 2019Tarek LakelNo ratings yet

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNo ratings yet

- Orsat ApparatusDocument6 pagesOrsat ApparatusArjun ReghuNo ratings yet

- Imm/Ww A: MQW AttorneyDocument3 pagesImm/Ww A: MQW AttorneygabrielaNo ratings yet

- US1915354Document6 pagesUS1915354Muhammad Akbar FahleviNo ratings yet

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Document5 pagesRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfNo ratings yet

- Displacement of Oil From Porous Media by Water or Gas: Henry Welge (Tulsa Meeting, October 1947) LalloratoryDocument13 pagesDisplacement of Oil From Porous Media by Water or Gas: Henry Welge (Tulsa Meeting, October 1947) LalloratoryBuddy WalkerNo ratings yet

- Teal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210Document4 pagesTeal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210juzmailmaNo ratings yet

- Equipment For Production of An Alkylation Plant For Igh-Octane GasolineDocument5 pagesEquipment For Production of An Alkylation Plant For Igh-Octane GasolinejoefrizalNo ratings yet

- Ethanol RectificationDocument10 pagesEthanol RectificationAnatolij Pamiatnikh100% (1)

- Us 4396789Document7 pagesUs 4396789Elias JúniorNo ratings yet

- Distillation Columns (Or Towers)Document8 pagesDistillation Columns (Or Towers)prathapNo ratings yet

- Mother Earth Alcohol Fuel: Chapter 7 - Still DesignsDocument12 pagesMother Earth Alcohol Fuel: Chapter 7 - Still DesignsoneshashpleaseNo ratings yet

- Plumbery.: Many ManyDocument1 pagePlumbery.: Many ManyreacharunkNo ratings yet

- The Alchemist'S HandbookDocument1 pageThe Alchemist'S HandbookJoseph L. WalkerNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- SPE Separacion AguaDocument8 pagesSPE Separacion AguagermangsilvaNo ratings yet

- Us1951789 PDFDocument5 pagesUs1951789 PDFJames EdwardsNo ratings yet

- JoFI - FEB - Mechanics Register - Camphire As Lamp OilDocument5 pagesJoFI - FEB - Mechanics Register - Camphire As Lamp OilLee ColonNo ratings yet

- US1306865Document4 pagesUS1306865Kamal Vijay Ram R SNo ratings yet

- Jan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952Document3 pagesJan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952MuhlisaApriliaNo ratings yet

- Production of PetroleumDocument11 pagesProduction of PetroleumAlfurjani AbubakrNo ratings yet

- v50 1757-Page 301Document1 pagev50 1757-Page 301anoncbyNo ratings yet

- Ite Note On Process PlantDocument14 pagesIte Note On Process PlantSam Wang Chern PengNo ratings yet

- Engineering Vol 69 1900-05-04Document35 pagesEngineering Vol 69 1900-05-04ian_newNo ratings yet

- An AutomaticDocument4 pagesAn AutomaticPulbere NeagraNo ratings yet

- Smoke Tube Boilers: Tank (Scotch) BoilerDocument4 pagesSmoke Tube Boilers: Tank (Scotch) BoilerMeghanath AdkonkarNo ratings yet

- 14.11. Corrosion Potential of CondensateDocument1 page14.11. Corrosion Potential of CondensateRahimd FoxNo ratings yet

- James Watt Patent 1769 No 913Document3 pagesJames Watt Patent 1769 No 913pockyrevolution7455No ratings yet

- Raney Ni PurificationDocument5 pagesRaney Ni Purificationanjireddy1612No ratings yet

- 8 Us1706281Document5 pages8 Us1706281Stajic MilanNo ratings yet

- Processes and Apparatus For Producing Acetic Acid From. Ace Aldehyde.Document4 pagesProcesses and Apparatus For Producing Acetic Acid From. Ace Aldehyde.juanNo ratings yet

- 1916 Brewery CleaningDocument11 pages1916 Brewery CleaningAnonymous rpGIIxeONo ratings yet

- No. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterDocument5 pagesNo. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterpavandattaNo ratings yet

- Tigercat FPT c87 t4f Engine Operator Service Repair ManualDocument22 pagesTigercat FPT c87 t4f Engine Operator Service Repair Manualwilliamjames200285ykt100% (108)

- Group 3Document31 pagesGroup 3vdfbhgNo ratings yet

- Typical PFD For Sour Water Stripper ColumnDocument2 pagesTypical PFD For Sour Water Stripper ColumnKmt_AeNo ratings yet

- Evaporators: Waste Heat RecoveryDocument8 pagesEvaporators: Waste Heat RecoveryJitendra KumarNo ratings yet

- Introduction To Boilers: BoilerDocument31 pagesIntroduction To Boilers: BoilerNeeraj SoniNo ratings yet

- ANEXO 7 US2220570 A Absorción de Ácido Clorhídrico (05 de Noviembre 1940)Document7 pagesANEXO 7 US2220570 A Absorción de Ácido Clorhídrico (05 de Noviembre 1940)CésarSánchezRosasNo ratings yet

- Ideally The Boiler Should Be Degreased Before Re-UsingDocument4 pagesIdeally The Boiler Should Be Degreased Before Re-UsingwasimNo ratings yet

- Cacl2 Concntrating - 1 PDFDocument2 pagesCacl2 Concntrating - 1 PDFvahidNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficeIRIENE DELFITA TKIMNo ratings yet

- Crude Distillation PosterDocument1 pageCrude Distillation Postervivek_rec100% (1)

- Exceptions To The Octet Rule: Molecules With Electron-Deficient AtomsDocument22 pagesExceptions To The Octet Rule: Molecules With Electron-Deficient AtomsJohn RammNo ratings yet

- 2D Materials With Piezoelectric and Ferroelectric FunctionalitiesDocument14 pages2D Materials With Piezoelectric and Ferroelectric FunctionalitiesnamyefNo ratings yet

- Seven Stars Solar 20181107Document23 pagesSeven Stars Solar 20181107msagaliwaNo ratings yet

- Yag ManualDocument43 pagesYag ManualMi Sinziana100% (1)

- Simulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysDocument7 pagesSimulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysAdhityaEkoBagusNo ratings yet

- Product and Company Identification: Safety Data SheetDocument8 pagesProduct and Company Identification: Safety Data SheetAhmed KhameisNo ratings yet

- Lecture 23: Introduction To Valence Bond TheoryDocument18 pagesLecture 23: Introduction To Valence Bond TheoryElectro_LiteNo ratings yet

- IULTCS-IsO-En Leather Test MethodsDocument6 pagesIULTCS-IsO-En Leather Test MethodsTekstil DpeNo ratings yet

- Ferro Dia para Magnetism PDFDocument11 pagesFerro Dia para Magnetism PDFShanna-Kay Wood-Davidson100% (1)

- Isrm SM Petrographic Description - 1978 PDFDocument3 pagesIsrm SM Petrographic Description - 1978 PDFEvandro Santiago100% (2)

- Colorimeter NewDocument22 pagesColorimeter NewKarthik RajaNo ratings yet

- Combustion (English) - WikipediaDocument9 pagesCombustion (English) - WikipediaJuano Valls FerrerNo ratings yet

- CO2+R3N+H2O R3NH+ +HCO3 - : Base Catalyzed MechanismDocument5 pagesCO2+R3N+H2O R3NH+ +HCO3 - : Base Catalyzed MechanismsammarNo ratings yet

- ITDocument35 pagesITChidinma Glory Ejike87% (15)

- N4 Electrotechnics November 2016 MemorandumDocument7 pagesN4 Electrotechnics November 2016 MemorandumPetro Susan BarnardNo ratings yet

- Niper Jee SyllabusDocument6 pagesNiper Jee Syllabuskumar HarshNo ratings yet

- Lab ReportDocument6 pagesLab ReportShashaNo ratings yet

- Name of DefectDocument3 pagesName of DefectJana EncaboNo ratings yet

- Dokumentips Bridge Engineering by Victor Johnson Essentials of Bridge Engineering VictorpdfDocument2 pagesDokumentips Bridge Engineering by Victor Johnson Essentials of Bridge Engineering VictorpdfVivek KumarNo ratings yet

- MorleyPresentation (MHD) PDFDocument56 pagesMorleyPresentation (MHD) PDFRehman Ullah0% (1)

- Quantum Field Theory A Modern Introduction (Michio Kaku)Document8 pagesQuantum Field Theory A Modern Introduction (Michio Kaku)Daniel Parra0% (1)

- Qian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFDocument41 pagesQian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFHanim BasarudinNo ratings yet

- Purification of LDH 1Document25 pagesPurification of LDH 1chetanNo ratings yet

- Theoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneDocument21 pagesTheoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneVinayak SavarkarNo ratings yet

- Heat Transfer: Mechanical EngineeringDocument10 pagesHeat Transfer: Mechanical EngineeringVenkatasairamreddy KandulaNo ratings yet

- SHS ELS Module 1 and 2 FinalDocument28 pagesSHS ELS Module 1 and 2 Finalsei gosa100% (1)

- Chem HSSC 1 Model PaperDocument8 pagesChem HSSC 1 Model PaperPikoNo ratings yet

- Lesson 1: Basic Terminology and ConceptsDocument160 pagesLesson 1: Basic Terminology and Conceptsdiala alazraiNo ratings yet

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsDocument17 pagesZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsAbraham AvNo ratings yet

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (80)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterFrom EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterRating: 5 out of 5 stars5/5 (3)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (5)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- How to Do Nothing: Resisting the Attention EconomyFrom EverandHow to Do Nothing: Resisting the Attention EconomyRating: 4 out of 5 stars4/5 (421)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980From Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Rating: 4 out of 5 stars4/5 (21)