Professional Documents

Culture Documents

Gas Properties With Cooling

Uploaded by

Rufus D SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Properties With Cooling

Uploaded by

Rufus D SCopyright:

Available Formats

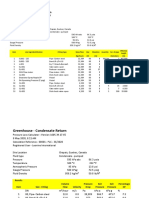

FLUE GAS ANALYSIS at 50% excess air - (Percentage)

FUEL - Teak 43% moisture, Ash= 0.51, S= 0.025

BOILER - SD 8000/1200

Furnace Arrangement - Cyclone

____________________________________________________________

Gas By volume By mass

Constituent Wet Dry Wet Dry

____________________________________________________________

Ar 0.732 0.931 1.048 1.216

CO 0.001 0.001 0.001 0.001

CO2 10.744 13.669 16.947 19.665

HCl 0.002 0.002 0.002 0.002

H2O 21.401 0.000 13.818 0.000

N2 61.610 78.385 61.859 71.777

O2 5.508 7.007 6.317 7.330

SO2 0.003 0.004 0.008 0.009

____________________________________________________________

Notes...

Fyrite measures the volume dry properties

Orsat gives measure of the volume dry properties

ie. Orsat CO2 = 13.67 % volume dry

There are no known limits on the use of this fuel

Continuous Emissions Monitoring

Net heat in 6.5 MWth

National Environmental Management:Air Quality Act, 2004

(South Africa ACT NO. 39 of 2004)

Heat input < 50 MWth using Lower CV NOT Required

Various flue gas properties...

Gas constant 297.996 J/kg K

Gas molecular weight 27.901

Specific heat capacity - initial 914.6°C 1.360 kJ/kg K

Specific heat capacity - flue exit 866.5°C 1.352 kJ/kg K

Specific heat capacity - wrapper exit 765.0°C 1.331 kJ/kg K

Specific heat capacity - Inlet 1st pass 765.0°C 1.331 kJ/kg K

Specific heat capacity - Exit 1st pass 332.3°C 1.198 kJ/kg K

Specific heat capacity - Inlet 2nd pass 332.3°C 1.198 kJ/kg K

Specific heat capacity - Exit 2nd pass 223.3°C 1.163 kJ/kg K

Specific heat capacity - ID fan 223.3°C 1.163 kJ/kg K

Density - initial 914.6°C 0.269 kg/m³

Density - flue exit 866.5°C 0.280 kg/m³

Density - wrapper exit 765.0°C 0.308 kg/m³

Density - Inlet 1st pass 765.0°C 0.308 kg/m³

Density - Exit 1st pass 332.3°C 0.528 kg/m³

Density - Inlet 2nd pass 332.3°C 0.528 kg/m³

Density - Exit 2nd pass 223.3°C 0.644 kg/m³

Density - ID fan 223.3°C 0.644 kg/m³

Viscosity - initial 914.6°C 48.457 µPas

Viscosity - flue exit 866.5°C 46.865 µPas

Viscosity - wrapper exit 765.0°C 43.147 µPas

Viscosity - Inlet 1st pass 765.0°C 43.147 µPas

Viscosity - Exit 1st pass 332.3°C 28.132 µPas

Viscosity - Inlet 2nd pass 332.3°C 28.132 µPas

Viscosity - Exit 2nd pass 223.3°C 24.028 µPas

Viscosity - ID fan 223.3°C 24.028 µPas

Process Flows

Fuel mass flow 2411.7 kg/hour

Fuel (8760 hours) 21126.4 ton/year

Steam rated mass flow 8400.0 kg/hour

Steam operating mass flow 7083.2 kg/hour

Steam (8760 hours) 62049.2 ton/year

Products (dry) 12898.8 kg/hour

Products (wet) 14967.0 kg/hour

Products of combustion (dry) 9450.7 Nm³/hour

Products of combustion (wet) 12023.9 Nm³/hour

Actual Products - 223.3°C 6.1 Am³/s

Ash (bottom) 8.3 kg/hour

Ash (8760 hours) 72.5 ton/year

Carbon dioxide in flue gases 211.0 g/Nm³

Carbon dioxide in flue gases 109.1 g/am³

Carbon dioxide in flue gases 704.6 g/s

Carbon dioxide in flue gases - 7083 kg/hr 358.1 kg/ton steam

Carbon dioxide in flue gases - 5.5 MW 128.8 g/MJ

Carbon dioxide in flue gases - 35.8 g/kWh

Carbon dioxide in flue gases - 1051.8 g/kg of fuel

Carbon dioxide in flue gases (8760 hours) 22219.7 ton/year

Carbon footprint 5592 ton/year

Dissociation at 914.5 °C 0.006 %

Dissociation at 765 °C 0.006 %

Dissociation at 223.3 °C 0.006 %

Carbon monoxide in flue gases 8.2 mg/Nm³

Carbon monoxide in flue gases 4.2 mg/am³

Carbon monoxide in flue gases 27.4 mg/s

Carbon monoxide in flue gases - EPA 566.4 mg/s

Carbon monoxide in flue gases - 7083 kg/hr 13.9 g/ton steam

Carbon monoxide in flue gases - 5.5 MW 5.0 mg/MJ

Carbon monoxide in flue gases 1.4 mg/kWh

Carbon monoxide in flue gases 40.9 mg/kg of fuel

Carbon Monoxide in flue gases 8.3 ppmvd

Carbon Monoxide Anticipated in the Flue Gas 6.6 ppmmw

Carbon Monoxide (wet) 6.6 ppm

Carbon monoxide in flue gases (8760 hours) 863.2 kg/year

CO is below 0.1% limit set in BS 845.

CO measurements are NOT required during performance testing.

CO Limits

Canada Threshold limit, O. Reg 127/01 20000 kg/year

CFR Vol. 76, No. 247, Dec 23, 2011 - CO 58.0 ppmvd

CFR Vol. 76 - CO, CEMS Alternative 1400.0 ppmvd

Grits - EPA released from the boiler 1.2 g/s

Grits - EPA released to atmosphere 1.2 g/s

Grits in the boiler flue gas 348.5 mg/Nm³

Grits in the boiler flue gas 180.2 mg/am³

Grits in the boiler flue gas 1.2 g/s

Grits in the boiler flue gas - 7083 kg/hr 591.7 mg/ton steam

Grits in the boiler flue gas - 5.5 MW 766.4 g/MW

Grits from the boiler (8760 hours) 36.7 ton/year

Grits - after grit collector 250.0 mg/Nm³

Grits - after grit collector 129.3 mg/am³

Grits - after grit collector 835.0 mg/s

Grits - after grit collector 7083 kg/hr 424.4 g/ton steam

Grits - after grit collector - 5.5 MW 152.7 mg/MJ

Grits - after grit collector 42.4 mg/kWh

Grits - after typical grit collector 1246.4 mg/kg of fuel

Grits after the collector (8760 hours) 26.3 ton/year

Grits - collected 329.1 mg/s

Grits - collected (8760 hours) 10.4 ton/year

Grit collector input performance 90.0 %

Grit collector calculated performance 28.3 %

NPI - PM 10 uncontrolled 2170.5 mg/s

ESP - from 2.2 mg/s

to 217.1 mg/s

Fabric Filter - from 2.2 mg/s

to 217.1 mg/s

Single high throughput cyclone - from 1302.3 mg/s

to 1953.5 mg/s

Single conventional cyclone - from 217.1 mg/s

to 1302.3 mg/s

Single high efficiency cyclone - from 108.5 mg/s

to 651.2 mg/s

Multi cyclones - from 162.8 mg/s

to 434.1 mg/s

Venturi scrubber - from 21.7 mg/s

to 651.2 mg/s

Condensation scrubber - from 2.2 mg/s

to 21.7 mg/s

Impingement scrubber - from 21.7 mg/s

to 1085.3 mg/s

Orifice scrubber - from 21.7 mg/s

to 434.1 mg/s

PM Limits

Canada Threshold limit, O. Reg 127/01 20000 kg/year

CFR Vol. 76, Dec 23, 2011 - Filterable PM 169.9 mg/s

NOx estimates - Standard (refer J.D Barnes) for oil/gas...

NOx volume flow wet (O2 = 7.0%)- measured 376.4 mg/Nm³

NOx volume flow dry (O2 = 7.0%) 478.9 mg/Nm³

NOx volume flow dry (O2 = 6%) - report as NO2 513.6 mg/Nm³

NOx volume flow wet 194.6 mg/am³

NOx volume flow dry (O2 = 11%) - Europe 341.3 mg/Nm³

NOx mass flow 4525.9 g/hour

NOx mass flow 1.3 g/s

EPA NOx (as NO2) 0.1 g/s

EPA NOx (as NO) 0.0 g/s

NOx mass (specific) - 7083 kg/hr 639.0 g/ton steam

NOx mass (specific) 229.9 mg/MJ

NOx mass (specific) 63.9 mg/kWh

NOx mass flow 1876.7 mg/kg of fuel

NOx mass (O2 = 7.0%) 233.4 ppmvd

NOx mass (O2 = 6%) - report as NO2 250.3 ppmvd

NOx - Anticipated in the flue gas (O2 = 7.0%) 183.4 ppmvw

NOx (wet) 302.4 ppm

NOx mass (O2 = 11%) - Europe 166.3 ppmvd

NOx mass flow (8760 hours) 39.6 ton/annum

NOx as fraction of exhaust gas 0.233 % vol x 1E3

NOx as NO2 0.5345 lb/MMBTU

European NOx limits

Level 1 - less than 260 mg/kWh

Level 2 200 mg/kWh

Level 3 150 mg/kWh

Level 4 100 mg/kWh

Level 5 70 mg/kWh

NOx abatement - typical results

NPI - NOx uncontrolled 998.2 mg/s

SCR - from 99.8 mg/s

to 299.5 mg/s

SNCR - from 99.8 mg/s

to 299.5 mg/s

SNCR with LNB - from 249.5 mg/s

to 349.4 mg/s

LEA - from 559.0 mg/s

to 898.4 mg/s

LNB (Air staged) - from 648.8 mg/s

to 748.6 mg/s

LNB (Flue gas recirculation) - from 798.5 mg/s

to 998.2 mg/s

LNB (fuel staged) - from 399.3 mg/s

to 499.1 mg/s

Total installed capital cost estimate

Standard Burner 179513 1990 CDN

Total NOx control installed 2717627 April 2013 USD

Annual Operating Costs...

Maintenance - Standard 4937 April 2013 USD

Maintenance - None 5963120 April 2013 USD

Maintenance - None 10167 April 2013 USD

ref. EPA-453/R-93-034 for fired heaters

Oxygen standard reference 6.0 %

Oxygen volume 7.0 % volume dry

Oxygen volume 5.5 % volume wet

Excess air 50.0 %

Sulphur dioxide in flue gases 98.9 mg/Nm³

Sulphur dioxide in flue gases 51.2 mg/am³

Sulphur dioxide in flue gases 0.3 g/s

Sulphur dioxide in flue gases - EPA 0.1 g/s

Sulphur dioxide in flue gases - 7083 kg/hr 168.0 g/ton steam

Sulphur dioxide in flue gases - 5.5 MW 60.4 mg/MJ

Sulphur dioxide in flue gases 16.8 mg/kWh

Sulphur dioxide in flue gases 0.5 g/kg of fuel

Sulphur dioxide in flue gases 44.0 ppmvd

Sulphur dioxide anticipated in the Flue Gas 34.6 ppmvw

Sulphur dioxide (wet) 79.5 ppm

Sulphur dioxide in flue gases (8760 hours) 10.4 ton/year

Typical conversion to SO2 95% sulphur

Typical conversion to SO3 1- 5% sulphur

Typical conversion to sulphate particulate 1- 3% sulphur

NPI - Sulphur dioxide uncontrolled 2.8 mg/s

Wet scrubber - Lowest achieved 0.1 mg/s

to upper value expected 0.3 mg/s

Semi-dry scrubber - Lowest achieved 0.3 mg/s

to upper value expected 0.6 mg/s

Dry scrubber - Lowest achieved 0.6 mg/s

to upper value expected 1.4 mg/s

Dry Sorbent Injection - SO2 abatement

Dry alkaline Sorbent chemical use 3.41 kg TRONA/kg SO2

Sodium sesqui-Carbonate required 35.5 ton/year

Cost delivered PPC, Dec. 2010 181.91 USD/MT

Sorbent cost 6466.0 USD/year

SO2 reduction 85.0 %

Sulphur Dioxide (85% reduction) in flue gas 5.2 ppmvw

Fly ash 30.0 ton/annum

Minimum flue gas temperature 200 °C

Trona gas exhaust analysis

Flue gas mass flow 14967 kg/hour

Argon (1.0) 1.048 % mass

Carbon monoxide (0.0) 0.001 % mass

Carbon dioxide (16.9) 16.954 % mass

Hydrogen Chloride (0.0) 0.000 % mass

Moisture (13.8) 13.823 % mass

Nitrogen (61.9) 61.858 % mass

Oxygen (6.3) 6.315 % mass

Sulphur Dioxide (0.0) 0.001 % mass

OR

Dry alkaline Sorbent chemical use 3.80 kg NaHCO3/kg SO2

Sodium sesqui-Carbonate required 35.5 ton/year

Cost delivered Solvay, 2002 181.91 USD/MT

Sorbent cost 6466.0 USD/year

Sulphur Dioxide (90% reduction) in flue gas 3.5 ppmvw

Moisture dew point in the hot gas 103.7 °C

Sulfurous acid (SO2) dew point estimate 56.9 °C

Sulphuric Acid Dew Point

_____________________________________________

Percentage SO3 Sulphuric acid dew point

% °C

_____________________________________________

1.0 114.2

1.5 117.5

2.0 119.9

2.5 121.8

3.0 123.4

3.5 124.7

4.0 125.9

4.5 126.9

5.0 127.8

_____________________________________________

Sulphur dioxide 0.0 % vol

Steam plant calculations manual by Ganapathy p94 table 2.9...

Hydrochloric acid dew point estimate 57.7 °C

Reference: Steam plant calculations manual by Ganapathy p94 table 2.9...

Dew point temperatures HBr, HNO3, HCl and sulfurous acids are within 6 °C

Dew point temperature of H2SO4 is within 9 °C

Environmental Protection Agency - EPA A-42 uncontrolled emissions

EPA A42 chapter Section 1.6

EPA boiler class Industrial

EPA heat rating 26.446 MM BTU/hour

Annual emission period 8760.0 hours/year

Carbon monoxide CO 566.4 mg/s 17.9 ton/year

Carbon dioxide CO2 649.7 g/s 20487.7 ton/year

Hydrogen chloride HCl 63.3 mg/s 1996.2 kg/year

Nitrogen oxides NOx 139.9 mg/s 4412.7 kg/year

Particulate matter PM - filterable 1.1 g/s 34.7 ton/year

Particulate matter CPM - condensable 56.6 mg/s 1786.1 kg/year

Particulate matter 10 µ filterable 989.5 mg/s 31.2 ton/year

Particulate matter 2.5 µ filterable 835.6 mg/s 26.4 ton/year

Sulphur dioxide SO2 83.3 mg/s 2626.6 kg/year

Sulphur trioxide -1 ND -1 NA

Sulphate particulate -1 ND -1 NA

Sulphur oxides SOx 83.3 mg/s 2626.6 kg/year

Sulphur in the ash -1 ND -1 NA

Total organic compounds TOC 129.9 mg/s 4097.5 kg/year

VOC non methane -1 ND -1 NA

Methane 70.0 mg/s 2206.4 kg/year

2,3,7,8 Tetrachlorodibenzo-p-dioxins 28.7 pg/s 0.9 mg/year

Tetrachlorodibenzo-p-dioxins 1.6 ng/s 49.4 mg/year

2,3,7,8 Tetrachlorodibenzo-p-furans 299.8 pg/s 9.5 mg/year

Tetrachlorodibenzo-p-furans 2.5 ng/s 78.8 mg/year

Metals...

Antimony 26.3 µg/s 830.0 g/year

Arsenic 73.3 µg/s 2.3 kg/year

Barium 13.7 µg/s 430.8 g/year

Cadmium 13.7 µg/s 430.8 g/year

Chromium total 70.0 µg/s 2.2 kg/year

Chromium hexavalent 11.7 µg/s 367.7 g/year

Cobalt 21.7 µg/s 682.9 g/year

Copper 163.2 µg/s 5.1 kg/year

Iron 3.3 mg/s 104.0 kg/year

Lead 159.9 µg/s 5.0 kg/year

Manganese 5.3 mg/s 168.1 kg/year

Mercury 11.7 µg/s 367.7 g/year

Molybdenum 7.0 µg/s 220.6 g/year

Nickel 109.9 µg/s 3.5 kg/year

Phosphorous 90.0 µg/s 2.8 kg/year

Potasium 129.9 mg/s 4097.5 kg/year

Selenium 9.3 µg/s 294.2 g/year

Silver 5.7 mg/s 178.6 kg/year

Sodium 1.2 mg/s 37.8 kg/year

Strontium 33.3 µg/s 1.1 kg/year

Tin 76.6 µg/s 2.4 kg/year

Titanium 66.6 µg/s 2.1 kg/year

Vanadium 3.3 µg/s 103.0 g/year

Yttrium 999.5 ng/s 31.5 g/year

Zinc 1.4 mg/s 44.1 kg/year

Environmental Protection Agency - EPA A-42 controlled emissions

NOx (NO2) - Standard 139.9 mg/s 4412.7 kg/year

NOx (NO) - Standard 0.0 pg/s 0.0 mg/year

Hydrogen Chloride Limits

Canada Threshold limit, O. Reg 127/01 - HCl 10000.0 kg/year

CFR Vol. 76, No. 247, Dec 23, 2011 - HCl 73.3 mg/s

Mercury Limits

Canada Threshold limit, O. Reg 127/01 - Hg 5.0 kg/year

CFR Vol. 76, No. 247, Dec 23, 2011 - Hg 2.9 µg/s

______________________________________________________________________

NOTE: The above are estimates, and calculated values.

The values measured in practice may vary significantly.

The above is not a performance guarantee.

The above is not contractually binding.

Normal pressure is 101.325 kPa.

Normal temperature is 0 °C.

Standard pressure is 101.325 kPa.

Standard temperature is 15 °C.

NOx = NO and NO2

SOx = SO2 and SO3, excluding sulphate particualtes

Most common flue gas analysers do not test for N2O

ND = no data

NA = not applicable

ng = nanograms - 1/1000,000,000 grams

pg = picogram - 1/1,000,000,000,000 grams

Check with Tanzania for specific statutory limits.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IWCF Prep Refresher - Subsea Supplement - Well Control EquipmentDocument29 pagesIWCF Prep Refresher - Subsea Supplement - Well Control EquipmentAustine Ameh50% (2)

- Gas Properties No CoolingDocument8 pagesGas Properties No CoolingRufus D SNo ratings yet

- Vancouver HumidtyDocument2 pagesVancouver HumidtyRufus D SNo ratings yet

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDocument30 pagesWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNo ratings yet

- 0611 SZL25 2.45 PaDocument2 pages0611 SZL25 2.45 PaRufus D SNo ratings yet

- Dioxin FuransDocument2 pagesDioxin FuransRufus D SNo ratings yet

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDocument30 pagesWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNo ratings yet

- Superheat HeaderDocument2 pagesSuperheat HeaderRufus D SNo ratings yet

- 0446 - MU To Surge Tank - 900Document2 pages0446 - MU To Surge Tank - 900Rufus D SNo ratings yet

- VU-40 - NG - Enbridge - 8760 HoursDocument1 pageVU-40 - NG - Enbridge - 8760 HoursRufus D SNo ratings yet

- SZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursDocument1 pageSZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursRufus D SNo ratings yet

- S 4500 - 1100 - Wood - 55% Wood - 8760 HoursDocument1 pageS 4500 - 1100 - Wood - 55% Wood - 8760 HoursRufus D SNo ratings yet

- Secondary SH SummaryDocument2 pagesSecondary SH SummaryRufus D SNo ratings yet

- 8000.1700 - Wood - 30% Moisture - 8760 HoursDocument1 page8000.1700 - Wood - 30% Moisture - 8760 HoursRufus D SNo ratings yet

- 0574 - CR240-80Document2 pages0574 - CR240-80Rufus D SNo ratings yet

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- DealkalizerDocument2 pagesDealkalizerRufus D SNo ratings yet

- Heating System Pressure DropDocument4 pagesHeating System Pressure DropRufus D SNo ratings yet

- GreensandfilterDocument1 pageGreensandfilterRufus D SNo ratings yet

- 1615.00209 - BCPDocument4 pages1615.00209 - BCPRufus D SNo ratings yet

- SoftenerDocument2 pagesSoftenerRufus D SNo ratings yet

- Tube ExpansionDocument1 pageTube ExpansionRufus D SNo ratings yet

- GlassfilterDocument1 pageGlassfilterRufus D SNo ratings yet

- Safety Valve VentDocument3 pagesSafety Valve VentRufus D SNo ratings yet

- CipDocument2 pagesCipRufus D SNo ratings yet

- 0259 - HMIP Chimney HeightDocument1 page0259 - HMIP Chimney HeightRufus D SNo ratings yet

- G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MDocument11 pagesG/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MRufus D SNo ratings yet

- Chimney CodesDocument3 pagesChimney CodesRufus D SNo ratings yet

- 0234 - Chimney Structural - R0Document7 pages0234 - Chimney Structural - R0Rufus D SNo ratings yet

- 0259 - CAA Chimney HeightDocument2 pages0259 - CAA Chimney HeightRufus D SNo ratings yet

- EffDocument7 pagesEffRufus D SNo ratings yet

- Rim Seal Fire Protection FraudDocument51 pagesRim Seal Fire Protection Fraudindiafightcorruption0% (1)

- Thermal Oxidation For VOC Control: 13.1 Combustion BasicsDocument17 pagesThermal Oxidation For VOC Control: 13.1 Combustion Basicsdardocapo100% (1)

- Petro PeruDocument3 pagesPetro PeruJorge Rodriguez HerreraNo ratings yet

- Me F420 1281Document5 pagesMe F420 1281Amar SheelwantNo ratings yet

- UntitledDocument11 pagesUntitledrian putraNo ratings yet

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDocument9 pagesTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamNo ratings yet

- PDD Vietnam Wind Power Plant No 1 - Binh Thuan 30MW V2Document42 pagesPDD Vietnam Wind Power Plant No 1 - Binh Thuan 30MW V2Zdravko StefanovskiNo ratings yet

- Power Magazine March 2014Document82 pagesPower Magazine March 2014Leon SanchezNo ratings yet

- Benefits of Cylindrical FPOsDocument40 pagesBenefits of Cylindrical FPOsGaurav SinghalNo ratings yet

- Research Proposal "Microstructural Failure Analysis of The Exhaust Valves of A Heavy-Duty Natural Gas Powered I.C Engine"Document13 pagesResearch Proposal "Microstructural Failure Analysis of The Exhaust Valves of A Heavy-Duty Natural Gas Powered I.C Engine"Afnan ButtNo ratings yet

- Ep Genysis Revised Sample StemazingDocument8 pagesEp Genysis Revised Sample StemazingCherry Ann HannischNo ratings yet

- Diesel Engine Power PlantDocument33 pagesDiesel Engine Power PlantVance NavalesNo ratings yet

- Petroleum Geology: Assignment: 1Document9 pagesPetroleum Geology: Assignment: 1Afiq AbdullahNo ratings yet

- Moge Web OffshoreDocument27 pagesMoge Web OffshoremmpetroengNo ratings yet

- CO2 Reforming of MethaneDocument8 pagesCO2 Reforming of Methanesorincarmen88No ratings yet

- Windmill Data Notes PDFDocument4 pagesWindmill Data Notes PDFHarshul GoelNo ratings yet

- E PR 360Document46 pagesE PR 360svnaik14No ratings yet

- Chapter 7. Introduction To Well ControlDocument15 pagesChapter 7. Introduction To Well ControlDJONBA OUKABONo ratings yet

- Practical Piping CurseDocument46 pagesPractical Piping Cursemsaad2100% (1)

- Prycegas LPG Personnel (Trainee)Document2 pagesPrycegas LPG Personnel (Trainee)Марк Артём Лимот АпаллаNo ratings yet

- SGMF T&C Guidelines 2017Document16 pagesSGMF T&C Guidelines 2017youngfpNo ratings yet

- Project 2 Maleic AnhydrideDocument11 pagesProject 2 Maleic AnhydrideAhmed Ali50% (2)

- Wheatstone Project Oil Spill Environmental Response PlanDocument160 pagesWheatstone Project Oil Spill Environmental Response PlanJoesphNo ratings yet

- CpsDocument100 pagesCpsPirrus Andrade50% (2)

- CONOCO - PetromindoDocument3 pagesCONOCO - Petromindotakato69No ratings yet

- RT EngDocument71 pagesRT EngMarcello RosiniNo ratings yet

- (Renewable Energy) - Chapter-1Document24 pages(Renewable Energy) - Chapter-1Mahmoud TarekNo ratings yet

- KKM Gas Industry enDocument20 pagesKKM Gas Industry enONURNo ratings yet

- GEO ExPro V11i6Document104 pagesGEO ExPro V11i6OsmanNo ratings yet