Professional Documents

Culture Documents

Wysong Power Squaring Shear Installation Maintenacne and Safety-Enh

Wysong Power Squaring Shear Installation Maintenacne and Safety-Enh

Uploaded by

Nathan RittenhouseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wysong Power Squaring Shear Installation Maintenacne and Safety-Enh

Wysong Power Squaring Shear Installation Maintenacne and Safety-Enh

Uploaded by

Nathan RittenhouseCopyright:

Available Formats

- -·

- ---

--------------------------------__..

SECTION IV

MAINTENANCE

1. FLYWHEEL COVER

2. TREADLE

3. TOP CENTER

INDICATOR

CD

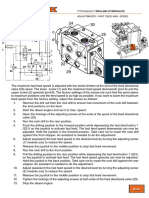

Fig. 27 - Parts lndentification - Blade Fig. 28 - Turning Flywheel by Hand.

Adjustment.

point of blade intersection. Due to inclined travel

of knife bar, the reading will not be correct if

checked at any other point. Use a sweeping mo

tion with feeler gauge, Fig. 30, rather than a jab

bing motion.

5. Continue rotating flywheel, check clearance

every 12 inches, until blades intersect midway

between last two blade bolts. Check clearance

with feeler gauge.

6. Taking same safety precautions, rotate fly

wheel until blades· intersect at center of table.

Check clearance. The center clearance should

be .001" less than _the clearance given for ends.

BLADE ADJUSTMENT - PROCEDURE Fig. 29 - Blades Intersection Point.

All power units have four table bolts on each end

except 3/s" and ½" shears, which have five on

each end. See Fig. 31, single (solid) end frame

shear for location. See Fig. 32 double end frame

shear for location.

If blade clearance check shows a deviation from

blade clearance tag by switch, proceed:

1. Loosen table bolts required, Fig. 31 or Fig. 32.

a. On one end of table if deviation is only on

one end, or,

b. Loosen bolts on both ends if deviation is

on both ends.

Sometimes pressure from table adjusting

lug, Fig. 31 or Fig. 32, will move the table

back to its original position. Fig. 30 - Checking Blade Clearance

Feeler Gauge.

21

You might also like

- Cat C-13 Valve LashDocument6 pagesCat C-13 Valve LashEwgeny100% (5)

- 3306 Valve AdjustmentDocument3 pages3306 Valve Adjustmentferdyak194% (18)

- Pragati - BTP Turret ManualDocument31 pagesPragati - BTP Turret Manualchidambaram kasi100% (17)

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang Setiawan100% (1)

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustVictor NunezNo ratings yet

- ITT CONTROLS Barton Chart Recorders 202e User Manual 1Document52 pagesITT CONTROLS Barton Chart Recorders 202e User Manual 1Edbaac BANo ratings yet

- Wysong Power Squaring Shear ManualDocument37 pagesWysong Power Squaring Shear ManualNathan RittenhouseNo ratings yet

- CBM820 Service ManualDocument41 pagesCBM820 Service Manualhaithembs2017No ratings yet

- Mechanical Adjustment of Hydrostatic Power Control Unit Linkage (Internal)Document7 pagesMechanical Adjustment of Hydrostatic Power Control Unit Linkage (Internal)Moicano P SánchezNo ratings yet

- AC PLAMI - : Mecanico de MantenimientoDocument8 pagesAC PLAMI - : Mecanico de MantenimientoFernando M CBNo ratings yet

- Cluth k2 ReconditioningDocument16 pagesCluth k2 ReconditioningPetrus Kanisius WiratnoNo ratings yet

- Chavter Five: Perform Steps 1-12 Clutch RemovalDocument4 pagesChavter Five: Perform Steps 1-12 Clutch RemovaldarkNo ratings yet

- WheelHorse Lawn Sweeper Manual 7-2513Document6 pagesWheelHorse Lawn Sweeper Manual 7-2513Kevins Small Engine and Tractor Service100% (1)

- Service Instructions Turbo Ii Air Pumps: Photo 1 A. Retaining Pin B. Mounting Bracket ScrewsDocument8 pagesService Instructions Turbo Ii Air Pumps: Photo 1 A. Retaining Pin B. Mounting Bracket Screwscarlos pachecoNo ratings yet

- Model Internal Shift Tray SH3000 SM FinalDocument7 pagesModel Internal Shift Tray SH3000 SM FinalricohcountermailNo ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Internal Shift Tray SH3030 Machine Code: D428 Field Service ManualDocument6 pagesInternal Shift Tray SH3030 Machine Code: D428 Field Service ManualДмитрий РазуваевNo ratings yet

- Parts: RoebuckDocument6 pagesParts: RoebuckCary BriefNo ratings yet

- Engine Valve Lash Inspect/Adjust: Pantalla AnteriorDocument6 pagesEngine Valve Lash Inspect/Adjust: Pantalla AnteriorEdison Pfoccori BarrionuevoNo ratings yet

- MN 03007Document16 pagesMN 03007hyarub9No ratings yet

- 158 Chapter Six: Note The Centrifugal Clutch Nut Has Left-Hand ThreadsDocument2 pages158 Chapter Six: Note The Centrifugal Clutch Nut Has Left-Hand ThreadsCody KeithNo ratings yet

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (3)

- Operating Manual For Disc Brake Type: SB 23 23-0598-01/3Document14 pagesOperating Manual For Disc Brake Type: SB 23 23-0598-01/3Julio RodriguezNo ratings yet

- 103 Cyl BoringDocument4 pages103 Cyl BoringDmitrolv DmitrolvNo ratings yet

- AK31 TurretDocument34 pagesAK31 TurretVladimirAgeev100% (1)

- File 94catalogo SumitomoDocument28 pagesFile 94catalogo SumitomoJaime Arreola100% (1)

- DS450 Shop Manual (Prelim)Document94 pagesDS450 Shop Manual (Prelim)GuruRacerNo ratings yet

- Er 82Document2 pagesEr 82Dibyendu ChakrabortyNo ratings yet

- M2a1 Boforstm - Part2Document98 pagesM2a1 Boforstm - Part2srahhalNo ratings yet

- JVC Mini Note Mp-Xv941de 841de 841gb 841gbex 841usDocument17 pagesJVC Mini Note Mp-Xv941de 841de 841gb 841gbex 841usSoporte Tecnico Buenos AiresNo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- Folga Valvula c9Document4 pagesFolga Valvula c9Victor NoschangNo ratings yet

- 07epa04mbe40005 PDFDocument14 pages07epa04mbe40005 PDFEduardo TorresNo ratings yet

- Testing & Adjusting Valve Lash C18Document4 pagesTesting & Adjusting Valve Lash C18Sapar SouzaNo ratings yet

- TM11-2609 Radio Beacon Equipment RC-163 1 PDFDocument109 pagesTM11-2609 Radio Beacon Equipment RC-163 1 PDFdavid_graves_okstateNo ratings yet

- D10T Valve LAsh AdjustDocument3 pagesD10T Valve LAsh AdjustSyahdiNo ratings yet

- Required Maintenance Operations: Gaining Access To The ValvesDocument5 pagesRequired Maintenance Operations: Gaining Access To The Valves87b94rw52nNo ratings yet

- Documents - MX Pragati BTP Turret Manual - PDFDocument31 pagesDocuments - MX Pragati BTP Turret Manual - PDFPetar Petrovic100% (3)

- Ascensor l10 (Lej-Mm00202)Document11 pagesAscensor l10 (Lej-Mm00202)gui9871No ratings yet

- 2000 2030 Maint Manual REV7 3 17Document27 pages2000 2030 Maint Manual REV7 3 17PiedmontNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Air Tech Second Stage Service Manual: Revised 3/2002Document20 pagesAir Tech Second Stage Service Manual: Revised 3/2002ValdrickNo ratings yet

- Training: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Feed Max. SpeedDocument1 pageTraining: T/T/Pantera/T/7 Drilling Hydraulics Adjustments / Fast Feed Max. SpeedVICTOR BEMENGUENo ratings yet

- Propeller Shaft AlighmentDocument5 pagesPropeller Shaft AlighmentDimasNo ratings yet

- Assenbly EW145BDocument20 pagesAssenbly EW145Bសុខ ប៊ុនណារ៉ង់No ratings yet

- BMW e39 Ремонт рулевой рейки тип 7831 7832 7852 только СервотроникDocument61 pagesBMW e39 Ремонт рулевой рейки тип 7831 7832 7852 только СервотроникqqwwNo ratings yet

- L16 24 ManDocument978 pagesL16 24 Manionut nicolaeNo ratings yet

- Pfaff 418, 438, 838 Service ManualDocument52 pagesPfaff 418, 438, 838 Service Manualrita.kulcsar.1990No ratings yet

- 68.1-100 Removal and Installation of Instrument PanelDocument3 pages68.1-100 Removal and Installation of Instrument PanelChristian Askøe VollmersNo ratings yet

- 6-1 Explanation of Cold AlignmentDocument18 pages6-1 Explanation of Cold AlignmentTuhoyoTarahao67% (3)

- Cat C11-C13-C15-C18 MANUAL DE CALIBRACIONESDocument27 pagesCat C11-C13-C15-C18 MANUAL DE CALIBRACIONESclaudio80% (5)

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- 2ZZGE EngineDocument8 pages2ZZGE EngineDavide FaelliNo ratings yet

- Subaru-Legacy 2005 EN Manual de Taller Motor 2c130bf569Document56 pagesSubaru-Legacy 2005 EN Manual de Taller Motor 2c130bf569miguelNo ratings yet

- TM9-1868 (Tyres)Document117 pagesTM9-1868 (Tyres)Hans Christian FrostNo ratings yet

- Instalacion y Pueta PuntoDocument5 pagesInstalacion y Pueta PuntoBrayan Sánchez ParedesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Singer Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetFrom EverandSinger Quantum Stylist 9960: Pocket Guide: Buttons, Dials, Settings, Stitches, and FeetNo ratings yet

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- TC 500 Service ManualDocument119 pagesTC 500 Service ManualNathan RittenhouseNo ratings yet

- CDK Arp-967Document37 pagesCDK Arp-967Nathan RittenhouseNo ratings yet

- 119118-General 09 Tool GrindersDocument217 pages119118-General 09 Tool GrindersNathan RittenhouseNo ratings yet

- TEG-160ES Parts ListDocument11 pagesTEG-160ES Parts ListNathan RittenhouseNo ratings yet

- Mthhs Parts ListDocument13 pagesMthhs Parts ListNathan RittenhouseNo ratings yet

- NALCO® 2594: Safety Data SheetDocument11 pagesNALCO® 2594: Safety Data SheetNathan RittenhouseNo ratings yet