Professional Documents

Culture Documents

PowerLink 50 100 ProductInfo C604-2

Uploaded by

gksmmtjdtn89Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PowerLink 50 100 ProductInfo C604-2

Uploaded by

gksmmtjdtn89Copyright:

Available Formats

PL 50/100

ENGLISH Fuses may be required on all phases in the electrical installation, depending on local

installation conditions and requirements.

Read and understand these instructions and the relevant manual before installing, During operation of the equipment, it is unavoidable that certain parts will carry dangerous

operating, or maintaining the device. For available software and complete documentation for voltages. Severe injury or damage to property can occur if the appropriate measures during

PowerLink 50/100 see: use are not taken:

• Make sure, that the equipment is properly connected to ground at all times and

mechanically fixed in the rack.

Siemens Industry Online Information platform SIOS

• Degree of protection by enclosure IP20.

Further Support • Device may only be operated in a dry location within a temperature range of

If special problems arise, or further information are required, please contact your Siemens -5 to +55 degree Celsius.

representative. Our Customer Support Center provides a 24-hour service. • This is a Class A device. It is intended to be operated in an industrial environment only. It

Siemens AG may cause harmful interference if operated in residential/light industry environment.

Smart Infrastructure • Hazardous voltages can be present on all components when the device is connected to a

Customer Support Center power source. Before opening the device, makes sure all power sources are

disconnected or switched off. Even after the power supply has been disconnected,

● Phone: +49 911 2155 4466 hazardous voltages can still be present within the device (capacitor storage).

● E-Mail: energy.automation@siemens.com

• The limit values indicated in the manual must not be exceeded; that also applies to

testing and commissioning.

Disclaimer of Liability

Although we have carefully checked the contents of this publication for conformity with the Statement of Conformity

hardware and software described, we cannot guarantee complete conformity since errors

cannot be excluded. The product is in conformity with the regulations of the following European Directives:

The information provided in this manual is checked at regular intervals and any corrections • EMC Directive 2014/30/EU

that might become necessary are included in the next releases. Any suggestions for • Low Voltage Directive 2014/35/EU

improvement are welcome. • RoHS Directive 2011/65/EU

Copyright

Used Symbols

Copyright © Siemens AG 2022 – All Rights Reserved

Caution, hazard. The documentation Protection class I / protective

The reproduction, transmission or use of this document or its contents is not permitted must be observed. earthing

without express written authority. Offenders will be liable for damages. All rights, including

rights created by patent grant or registration of a utility model or design, are reserved. CE conformity Hazardous voltage

Qualified Electrical Engineering

OpenSSL Note

Personnel

This product includes software developed by the OpenSSL Project for use in OpenSSL

Toolkit (http://www.openssl.org/).

This product includes software written by Tim Hudson (tjh@cryptsoft.com). Distributor statement according to WEEE-Guideline 2012/19/EU

This product includes cryptographic software written by Eric Young (eay@cryptsoft.com). Do not throw the device in the household trash! Please dispose of the device

according to the guidelines regarding electronic waste in your country.

Notes on Safety

This document contains notes that must be adhered to ensure personal safety and to avoid

Application

damage to property during commissioning and use.

However, it does not constitute a complete description of all safety measures required for PowerLink 50/100

installation, service, and maintenance of the device. Details are to be taken from the device The PowerLink system permits carrier frequency transmission of speech, data, telecontrol,

manual; those are mandatory. Keep it safe for later usage. and teleprotection signals via high voltage overhead power lines and cables.

Warning: Danger of severe personal injury or substantial damage to property

Hazardous voltages may occur in devices and modules during operation. Always

observe the instructions given in “Qualified Electrical Engineering Personnel” below.

Qualified Electrical Engineering Personnel

Qualified electrical engineering personnel must have up to date technical qualifications

as electrical technicians. Only these persons may commission, use, maintain,

decommission, and dispose of the device according to the state-of-the-art standards of

engineering in the high voltage power line environment.

Warning: Laser radiation! Danger of eye injury

This device may contain a class 1 laser. Do not look directly into the beam.

Unpacking a Device

• Check the package for external transport damage. A damaged packing may indicate that

Warning: Danger of damage due to static electrical charges the device inside is also damaged.

The printed circuit boards of numerical relays contain CMOS circuits. These shall not • Unpack the device carefully; do not use force.

be withdrawn or inserted under live conditions! The modules must be so handled that • Visually check the device to ensure that it is in perfect mechanical condition.

any possibility of damage due to static electrical charges is excluded. • Return a damaged device to the manufacturer or dispose it correctly. A defect device

During any necessary handling of individual modules, the recommendations relating to may not either be used or repaired by the user.

the handling of electrostatically endangered components (EEC) must be observed.

Note: Before commissioning the device, leave it in the final operation room for at least

In installed conditions, the modules are in no danger. 2 hours. This allows it to reach room temperature and to prevent dampness and

condensation.

Warning: Prevent the risk of possible over voltages Repacking a Device

The cable shield of the communication cable between Line Matching Unit (LMU, AKE) • If you store devices after incoming inspection, pack them in suitable storage packaging.

and the power line carrier communication devices (PowerLink) must be grounded on • If devices are to be transported, pack them in transport packing.

both ends.

• Put the accessories supplied in the packing with the device.

The grounding of the cable shield must be carried out on the LMU side itself and once

again before entering the station building or a ground connection within the building in Storing a Device

which the PowerLink devices or any other powerline carrier communication device are • Only store devices on which you have carried out an incoming inspection, thus ensuring

installed. that the warranty remains valid.

The grounding must be carried out using a connection that cannot be detached without • The relative humidity must be at a level where condense water and ice are prevented

tools. The grounding of the cable shields must not be removed until it is ensured that from forming.

by closing the short circuit switch on the LMU and attaching an additional grounding • If the device has been in storage for more than 2 years, connect it to the primary voltage

rod to the HV input, the LMU is voltage-free and safely grounded. source, and operate it for 1 to 2 days. This will cause the electrolytic capacitors to form on

the printed circuit board assemblies again.

Use as Prescribed • When the device is reshipped ensure that the transport requirements for the selected

The device may only be used for such applications as set out in the user instructions, and means of transport are met. The outer package alone is not adequate for transport

only in combination with equipment recommended and approved by Siemens. purposes.

Correct and safe operation of the product requires adequate transportation, storage,

installation and mounting in a control cabinet, as well as appropriate use and maintenance. Mounting

The device is designed for horizontal mounting in a cabinet or rack. Min. distance between

Only qualified electrical engineering personnel may install, set up, commission, attach two PL 50/100 devices is one unit of height (= 1.75 inches or 44.45 mm). The climatic

communication cables, power supply lines and ground to the device. conditions must be within the specified values (see technical data). Consider the weight and

Check and follow the electrical operating conditions, mechanics and climatic max. ambient position of the device to avoid personal injuries.

conditions for safe operation. Connect and operate the device only in conformance with the

values as specified in the ‘Technical Data’ below.

Commissioning must be carried out in accordance with good engineering practice and

under consideration of local installation rules and laws (also applicable and obligatory for

cabinet internal wiring).

Telecommunication Products, PL 50/100 Product Information

C53000-X6040-C604-2 Edition Sept. 2022 1

PL 50/100

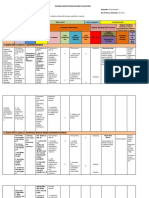

Commissioning Data rate up to 320 Kbps @ 32 kHz X X

Before making any connections, ground the equipment and the grounding Transmission power X X

terminal. 20 W / 50 W / 100 W, fine adjustment through software

• After switching on the external supply voltage and with the device switched off (switch Operation with or without frequency band spacing with X X

S1 enable/disable automatic cross talk canceller

• Power Supply on CSPi in down position) LED "i" (red) lights up on the PSPA2 power Digital interface

supply unit(s). The yellow LED (disabled) lights up on the power supply units.

Synchronous X.21 (max. 2 channels) X

• After switching on the device (switch S1 enable/disable Power Supply on CSPi, located

behind the front cover, in upper position) the OK LED (green) must light up on the Asynchronous RS 232 (max. 8 channels) X

power supply unit and on the CSPi module. TCP/IP (2 x electrical, 1 x optical) X

• The RX-AL LED must light up green if the device is connected to the transmission line, E1 (2 Mbps) for voice compression X

receiving properly from the remote station and receive levels are set correctly. G703.1 (64 kbps) 1) X

Correction of the receive level is only possible with the PowerSys service program. Analog interface

• Connecting the Service PC

A service PC and the service program PowerSys are needed for startup, maintenance, VF (VFM, VFO, VFS), max. 8 channels for voice, data, and X X

and diagnostic purpose of the PL 50/100 units. The service PC is connected to the protection signal 2)

ETH socket (Default IP address 192.168.20.5) on the front panel of the CSPI module Asynchronous RS232 (max. 4) via FSK X

with a RJ45 plug cable. Miscellaneous

• The service program PowerSys and the communication to the device via the serial

interface from the service PC or via a TCP/IP connection is described in the device Adaptive dynamic data rate adjustment X

manual. TCP/IP Layer 2 Bridge X

• The corresponding software package (formerly delivered on Integrated versatile multiplexer for voice and data X

DVD) is available for download on SIOS (Siemens Industry

Max. 5 compressed voice channels via VF interface 3) X

Online Support) platform free of charge, a registration is

Max. 8 voice channels via E1 interface X

required.

Product Support/Energy/Energy automation and smart StationLink bus for the cross-connection of max. 4 PLC X

grid/Smart communication/Download transmission routes (compressed voice and data without voice

compression on repeater)

• Test protocols are available for download under

Reverse FSK analog RTU/modem data via dPLC (2 x) X

https://www.ea-testreports.siemens.com

Enter BF code of device to view the requested test protocol Protection signal transmission system SWT 3000

in pdf format. The installed software package version

loaded into the device can be seen in the protocol. Integration of 2 devices in PowerLink 100 and 1 in PowerLink 50 X X

Module slot position PL 100 Remote operation via cable or fiber-optic cable1) identical to the X X

integrated version

Single purpose or multi purpose/alternate multi purpose mode X X

Element manager, based on a graphical user interface for the X X

control and monitoring of PLCand teleprotection systems

Command interface binary and in accordance with IEC 61850 X X

Remote access to PowerLink

Via TCP/IP connection X X

Via in-band service channel X X

SNMP compatibility for integrating NMS X X

Event memory with time stamp X X

Simple feature upgrade through software X X

1) Not applicable in PowerLink 50

2) Max. 7 VF channels for PowerLink 50

3) 4 compressed voice channels via VF for PowerLink 50

Technical Data

Power Supply

Input voltage

PSPA2-AC DC 38 V to DC 72 V

PSPA2-DC AC 93 V to AC 264 V (47 Hz to 63 Hz)

DC 85 V to DC 264 V

Power consumption PL 100

50 W Amplifier (AC/DC) Normal operation: 250 VA/140 W

Max *): 340 VA/200 W

1) CFS-2 part 100 W Amplifier (AC/DC) Normal operation: 390 VA/250 W

2) Integrated SWT3000-2 Max *): 520 VA/360 W

3) Integrated SWT3000-1 Power consumption PL 50

Module slot position PL 50

50 W Amplifier (AC/DC) Normal operation: 250 VA/140 W

Max *): 320 VA/180 W

*) Single tone operation

Climatic Conditions IEC 60721-3

During operation -5° C to + 55° C

During storage and transport -40° C to +70° C

Relative humidity 5 % to 95 %

Absolute humidity 29 g/m3 no condensation

Mechanical Design PL 100

19” frame

Dimensions 482 mm x 578 mm x 270 mm (W x H x D)

Weight with 50-W amplifier 21 kg

with 100-W amplifier 26 kg

1) IFC-2 or EN100 Degree of protection IP20

Functions/Features

Mechanical Design PL 50

Feature Digital Analog

PLC PLC 19” frame

system system Dimensions 482 mm x 266 mm x 270 mm (W x H x D)

Universally applicable in analog, digital, or mixed operation X X Weight 18 kg

Carrier frequency range 24 kHz to 1000 kHz X X Degree of protection IP20

Bandwidth selectable 2 kHz to 32 kHz X X

Telecommunication Products, PL 50/100 Product Information

C53000-X6040-C604-2 Edition Sept. 2022 2

You might also like

- Form16 2018 2019Document10 pagesForm16 2018 2019LogeshwaranNo ratings yet

- Pindyck TestBank 7eDocument17 pagesPindyck TestBank 7eVictor Firmana100% (5)

- Manual Retificador Elteck FlatPackDocument40 pagesManual Retificador Elteck FlatPacksgomesproNo ratings yet

- Voiceworks: U Us Se Er R''S S M Ma An Nu Ua Al LDocument31 pagesVoiceworks: U Us Se Er R''S S M Ma An Nu Ua Al LBratislav-Bata IlicNo ratings yet

- Basic Vibration Analysis Training-1Document193 pagesBasic Vibration Analysis Training-1Sanjeevi Kumar SpNo ratings yet

- Digital LiteracyDocument19 pagesDigital Literacynagasms100% (1)

- Marine Lifting and Lashing HandbookDocument96 pagesMarine Lifting and Lashing HandbookAmrit Raja100% (1)

- SWT3000 ProductInfo C605-4Document2 pagesSWT3000 ProductInfo C605-4gksmmtjdtn89No ratings yet

- Camera Control Unit: CCU-D50 CCU-D50PDocument31 pagesCamera Control Unit: CCU-D50 CCU-D50Pflorinf_uNo ratings yet

- IPoster User ManualDocument65 pagesIPoster User ManualAaron NobleNo ratings yet

- Manual d11x en deDocument56 pagesManual d11x en deAnpolNo ratings yet

- PaFI25 eDocument58 pagesPaFI25 eRafaelNo ratings yet

- General Precautions: Safety and Environmental PrecautionsDocument1 pageGeneral Precautions: Safety and Environmental PrecautionspaokjovanpfkNo ratings yet

- Manual D1101uv en deDocument28 pagesManual D1101uv en debrandy85No ratings yet

- PowerLogic™ ION7550 - ION7650 Installation GuideDocument30 pagesPowerLogic™ ION7550 - ION7650 Installation GuideAhmed RabaaNo ratings yet

- POINT I/O Protected Output Module: Installation InstructionsDocument28 pagesPOINT I/O Protected Output Module: Installation InstructionsВиталий ШеленковNo ratings yet

- en 00Document4 pagesen 00Javier Alarcon VelazcoNo ratings yet

- Sony PVM-L1700 LCD Video MonitorDocument137 pagesSony PVM-L1700 LCD Video MonitormbaykalNo ratings yet

- SPL Dualbanddeesser EngDocument16 pagesSPL Dualbanddeesser EngMich ValderNo ratings yet

- FUAA10011 Manual 20120426 UKDocument81 pagesFUAA10011 Manual 20120426 UKanddrejNo ratings yet

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- Acoposinverter X64 Acoposinverter P64New: Migration ManualDocument36 pagesAcoposinverter X64 Acoposinverter P64New: Migration ManualMarekNo ratings yet

- FLEX I/O AC Digital Input Modules: Installation InstructionsDocument24 pagesFLEX I/O AC Digital Input Modules: Installation InstructionsAndres ToroNo ratings yet

- CYANDocument216 pagesCYANranju02250% (2)

- m300 PDFDocument34 pagesm300 PDFCamtorNo ratings yet

- Ha 465492Document170 pagesHa 465492Gabriel Leite Dos SantosNo ratings yet

- Cinemate® 15/10: Home Theater SystemDocument48 pagesCinemate® 15/10: Home Theater SystemChidi GathunguNo ratings yet

- Parker 590C - Full Product Manual - NoteDocument241 pagesParker 590C - Full Product Manual - Notepyae soneNo ratings yet

- 506-507-508 ManualDocument31 pages506-507-508 Manualcs.makeNo ratings yet

- Fleximonitor: User'S GuideDocument52 pagesFleximonitor: User'S GuideIsac ClaroNo ratings yet

- BN68-05100C-01 Un5000m Asia Eng 180409.1Document36 pagesBN68-05100C-01 Un5000m Asia Eng 180409.1muhammad0umar-4No ratings yet

- Sistema de Conferenria Vissonic - Classic-DDocument24 pagesSistema de Conferenria Vissonic - Classic-DJoseanio GaldinoNo ratings yet

- UG0054-01 IMC-Panel-200 Operators Guide For IS750Document176 pagesUG0054-01 IMC-Panel-200 Operators Guide For IS750Ardian AriefNo ratings yet

- Pa800 201UM ENGDocument344 pagesPa800 201UM ENGTakis MatthaiouNo ratings yet

- HDL50 Manual PDFDocument28 pagesHDL50 Manual PDFJairoGRNo ratings yet

- DMC8000 Video Wall Controller Quick Guide-V1.00Document23 pagesDMC8000 Video Wall Controller Quick Guide-V1.00Birthley RagasaNo ratings yet

- Mitsubishi PLC FX3U - ENET - User - ManualDocument298 pagesMitsubishi PLC FX3U - ENET - User - ManualKiran Kumar PediredlaNo ratings yet

- Smartpack2 Basic Industrial: User's GuideDocument32 pagesSmartpack2 Basic Industrial: User's GuideraffaeleNo ratings yet

- Fronius IG Series User ManualDocument92 pagesFronius IG Series User ManualPE TruNo ratings yet

- Jenaer Ecostep-100 ManualDocument15 pagesJenaer Ecostep-100 ManualAdrien VAIDIENo ratings yet

- Installation Guide IO Monitor2 CAN Node (UDOC - 351509.033 - 1 - 2.1) - 1Document16 pagesInstallation Guide IO Monitor2 CAN Node (UDOC - 351509.033 - 1 - 2.1) - 1stmmanttoNo ratings yet

- Instruction Manual: TF-DVD7009Document28 pagesInstruction Manual: TF-DVD7009Roderick Lenhardt FontanNo ratings yet

- Pa800 160UM ENGDocument330 pagesPa800 160UM ENGFormatia FloraNo ratings yet

- Controller Camera CV - ManualDocument292 pagesController Camera CV - ManualJulham EfendiNo ratings yet

- Manual de Usuario de PLC XGT SeriesDocument97 pagesManual de Usuario de PLC XGT SeriesMarios ClubsNo ratings yet

- Parker 631 Full Product Manual PDFDocument185 pagesParker 631 Full Product Manual PDFEverton LuisNo ratings yet

- POINT I/O 8 Channel High Density Current Input Module: Installation InstructionsDocument24 pagesPOINT I/O 8 Channel High Density Current Input Module: Installation InstructionsMINH NHHUT LUUNo ratings yet

- Ingersoll Rand System Automation VX Accessory Box Installation ManualDocument12 pagesIngersoll Rand System Automation VX Accessory Box Installation ManualMike DavidNo ratings yet

- 1794-In102 - En-P - Flex IODocument20 pages1794-In102 - En-P - Flex IOmarceloNo ratings yet

- LEC-7230M Manual v0.1Document23 pagesLEC-7230M Manual v0.1B0gdanNo ratings yet

- PW7K1IN Install Guide 06112020Document22 pagesPW7K1IN Install Guide 06112020Leandro GonzalezNo ratings yet

- 690+ Series AC Drive: Software Product ManualDocument242 pages690+ Series AC Drive: Software Product ManualDanilo CarvalhoNo ratings yet

- HIPE AS InstMan (002GBv2 - 01c)Document52 pagesHIPE AS InstMan (002GBv2 - 01c)Bernardo PáramoNo ratings yet

- TMX 0404 SdiDocument21 pagesTMX 0404 Sdibouzahri boumedieneNo ratings yet

- PAC-IF013B-E Installation Operation Manual RG79F030H04Document24 pagesPAC-IF013B-E Installation Operation Manual RG79F030H04S KNo ratings yet

- 1055 Total Chlorine AnalyzerDocument65 pages1055 Total Chlorine AnalyzerEdvier MapayeNo ratings yet

- I-Line™ Plug-In Units / Unidades Enchufables I-Line™ / Unités Enfichables I-LineDocument41 pagesI-Line™ Plug-In Units / Unidades Enchufables I-Line™ / Unités Enfichables I-LineCetar CiracasNo ratings yet

- 42,0426,0048, en PDFDocument44 pages42,0426,0048, en PDFvestasvesNo ratings yet

- Wireless Surround Link: Downloaded From Manuals Search EngineDocument12 pagesWireless Surround Link: Downloaded From Manuals Search EngineMichael SinclairNo ratings yet

- 690+ Series: Frame G, H & JDocument149 pages690+ Series: Frame G, H & JDanilo CarvalhoNo ratings yet

- MS-7255 (v1.X/v2.X) Mainboard: CH0 Preface.p65 2006/10/26, 上午 09:46 1Document89 pagesMS-7255 (v1.X/v2.X) Mainboard: CH0 Preface.p65 2006/10/26, 上午 09:46 1Expanet SacNo ratings yet

- Módulos de Entrada e Saída XI-OCDocument122 pagesMódulos de Entrada e Saída XI-OCBruno OliveiraNo ratings yet

- 1756 En2t PDFDocument28 pages1756 En2t PDFLuccaNo ratings yet

- Manual de Usuario TC Electronic XO24Document23 pagesManual de Usuario TC Electronic XO24zjdxkwwnz8No ratings yet

- Dialog Suntel MergerDocument8 pagesDialog Suntel MergerPrasad DilrukshanaNo ratings yet

- SCDT0315 PDFDocument80 pagesSCDT0315 PDFGCMediaNo ratings yet

- Sample Annual BudgetDocument4 pagesSample Annual BudgetMary Ann B. GabucanNo ratings yet

- HRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesDocument6 pagesHRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesAkosi EtutsNo ratings yet

- TEVTA Fin Pay 1 107Document3 pagesTEVTA Fin Pay 1 107Abdul BasitNo ratings yet

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNo ratings yet

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajNo ratings yet

- Review of Related LiteratureDocument4 pagesReview of Related LiteratureCarlo Mikhail Santiago25% (4)

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocument28 pagesMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNo ratings yet

- Fidp ResearchDocument3 pagesFidp ResearchIn SanityNo ratings yet

- Newsletter 289Document10 pagesNewsletter 289Henry CitizenNo ratings yet

- Ytrig Tuchchh TVDocument10 pagesYtrig Tuchchh TVYogesh ChhaprooNo ratings yet

- Data Sheet WD Blue PC Hard DrivesDocument2 pagesData Sheet WD Blue PC Hard DrivesRodrigo TorresNo ratings yet

- 4 Bar LinkDocument4 pages4 Bar LinkConstance Lynn'da GNo ratings yet

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocument1 pageLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMNo ratings yet

- NOP PortalDocument87 pagesNOP PortalCarlos RicoNo ratings yet

- ST JohnDocument20 pagesST JohnNa PeaceNo ratings yet

- MORIGINADocument7 pagesMORIGINAatishNo ratings yet

- 18PGHR11 - MDI - Aditya JainDocument4 pages18PGHR11 - MDI - Aditya JainSamanway BhowmikNo ratings yet

- Assignment - 2: Fundamentals of Management Science For Built EnvironmentDocument23 pagesAssignment - 2: Fundamentals of Management Science For Built EnvironmentVarma LakkamrajuNo ratings yet

- Selvan CVDocument4 pagesSelvan CVsuman_civilNo ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- BCG - Your Capabilities Need A Strategy - Mar 2019Document9 pagesBCG - Your Capabilities Need A Strategy - Mar 2019Arthur CahuantziNo ratings yet

- Peoria County Jail Booking Sheet For Oct. 7, 2016Document6 pagesPeoria County Jail Booking Sheet For Oct. 7, 2016Journal Star police documents50% (2)

- Capital Expenditure DecisionDocument10 pagesCapital Expenditure DecisionRakesh GuptaNo ratings yet