Professional Documents

Culture Documents

LG Abs Hi121h

Uploaded by

Chu Chu0 ratings0% found this document useful (0 votes)

0 views1 pageOriginal Title

LG_ABS_HI121H

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views1 pageLG Abs Hi121h

Uploaded by

Chu ChuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

HI-121H(ABS High Impact Grade)

Item Test method Test Condition Unit Value

PHYSICAL

o

200 C/5kg g/10min 1.8

o

Melt Index ASTM D1238 220 C/10kg g/10min 20

o

230 C/3.8kg g/10min 6

Specific Gravity ASTM D792 - 1.05

Mold Shrinkage ASTM D955 % 0.4~0.7

MECHANICAL

kg/cm2 550

Tensile Strength ASTM D638 50mm/min MPa 54

2

lb/in 7,800

kg/cm2 22,600

Tensile Modulus ASTM D638 50mm/min MPa 2,210

lb/in2 321,000

Elongation at Yield ASTM D638 50mm/min % >6

Elongation at Break ASTM D638 50mm/min % 30

kg/cm2 800

Flexural Strength ASTM D790 15mm/min MPa 78

2

lb/in 11,400

kg/cm2 26,000

Flexural Modulus ASTM D790 15mm/min MPa 2,550

2

lb/in 369,000

.

kg cm/cm 20

o

1/4", 23 C J/m 200

ft-lb/in 3.7

kg.cm/cm 7

o

1/4", -30 C J/m 72

ft-lb/in 1.3

Izod Impact Strength(notched) ASTM D256

kg.cm/cm 22

o

1/8", 23 C J/m 220

ft-lb/in 4

kg.cm/cm 8

o

1/8", -30 C J/m 77

ft-lb/in 1.5

Rockwell Hardness ASTM D785 R-scale 109

THERMAL

o

1/4", 18.56kg/cm2 C 87

o

(annealed) F 189

o

1/4", 18.56kg/cm2 C 84

o

Heat Deflection Temp ASTM D648 (unannealed) F 183

o

1/4", 4.6kg/cm2 C 93

o

(annealed) F 199

o

1/4", 4.6kg/cm2 C 90

o

(unannealed) F 194

o

o C 99

1kg/120 C/h o

F 210

Vicat Softening Temp ASTM D1525 o

o C 94

5kg/50 C/h o

F 201

ELECTRICAL

HWI 3

HAI UL 746A 2

HVTR PLC Code 2

Arc Resistance ASTM D495 6

CTI UL 746A 0

FLAMMABILITY

1/8" HB

UL 94 1/10" class

Flammability 1/16" HB

1/8" FH3-34

IEC 707 mm/min

1/16"

CHRACTERISTIC High impact, Whiteness

*Note : 1)The values of properties in the above table have been obtained by the test pieces(natural color) manufactured under certain

of injection.

2)The listed values should be used for referential purposed only.

You might also like

- Frost Multidimensional Perfectionism ScaleDocument1 pageFrost Multidimensional Perfectionism Scalesshafiq3No ratings yet

- Le - Cpar Week 1Document3 pagesLe - Cpar Week 1Reniña Lucena CarpioNo ratings yet

- ULO2a - Basic Concepts of Crystal StructureDocument14 pagesULO2a - Basic Concepts of Crystal StructureCHARLIE AMOGUIS JRNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Technical Data SheetDocument16 pagesTechnical Data SheetChakkaravarthiEr100% (1)

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- ABSaf 312 ADocument2 pagesABSaf 312 AAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- ASTM - LUPOY GN5001RFG - FinalDocument2 pagesASTM - LUPOY GN5001RFG - FinalHector GonzalezNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Abs Xr409H: Description ApplicationDocument2 pagesAbs Xr409H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- Abs XR 404 LGDocument2 pagesAbs XR 404 LGLeandro LacerdaNo ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- Lupox Gp1000H: Description ApplicationDocument2 pagesLupox Gp1000H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- Injection Molding Grade: Description ApplicationsDocument2 pagesInjection Molding Grade: Description ApplicationsSangharshBhustalimathNo ratings yet

- LG Abs - Hi100hDocument2 pagesLG Abs - Hi100hqshakimNo ratings yet

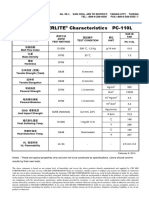

- UV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014Document1 pageUV Stabilized PC WONDERLITE Characteristics PC-115U: January 23, 2014DiegoTierradentroNo ratings yet

- Extrusion Molding: Description ApplicationsDocument2 pagesExtrusion Molding: Description ApplicationsbobNo ratings yet

- Injection Molding: Description ApplicationsDocument2 pagesInjection Molding: Description ApplicationsPhuoc Thinh TruongNo ratings yet

- Lexan FR Resin 505rDocument3 pagesLexan FR Resin 505rShabi HadashNo ratings yet

- FGI 1120: Material Specification For New PVC Geomembranes: Effective Date: September 1, 2019 Revised January 1, 2020Document9 pagesFGI 1120: Material Specification For New PVC Geomembranes: Effective Date: September 1, 2019 Revised January 1, 2020Eduardo Rojas ArayaNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Datasheet PA 12 Extended-6Document8 pagesDatasheet PA 12 Extended-6Lavin ZengNo ratings yet

- ABS Cycolac MG47Document3 pagesABS Cycolac MG47countzeroaslNo ratings yet

- PA717CDocument1 pagePA717Cjdstore99No ratings yet

- EPX82Document14 pagesEPX82BorisNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Document3 pagesSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailNo ratings yet

- Astmproperty Astmproperty: Grade ResintypeDocument2 pagesAstmproperty Astmproperty: Grade Resintypejulius hasan33No ratings yet

- 2021 - TDS - Iso - PB5903 AstmDocument1 page2021 - TDS - Iso - PB5903 Astm李万福No ratings yet

- 23882Document1 page23882skiu paket 31No ratings yet

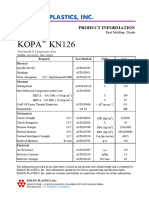

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- Sae PC Wonderlite Characteristics PC-110L: February 6, 2014Document1 pageSae PC Wonderlite Characteristics PC-110L: February 6, 2014Ilton EduardoNo ratings yet

- iCLINOMTER CASING2017 1Document7 pagesiCLINOMTER CASING2017 1Lale ÖnerNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- Lexan 243RDocument5 pagesLexan 243RMitja GorseNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- A GD VDBDocument3 pagesA GD VDBthehoang12310No ratings yet

- Abs Pa777dDocument1 pageAbs Pa777djdstore99No ratings yet

- General Q Resin KIBITON Characteristics PB-5903: November 13, 2013Document1 pageGeneral Q Resin KIBITON Characteristics PB-5903: November 13, 2013DiegoTierradentroNo ratings yet

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- Sabic PC PC1003RDocument5 pagesSabic PC PC1003RrtsultanNo ratings yet

- ExxonMobil HTA 001HDDocument1 pageExxonMobil HTA 001HDakshayNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Polylac PA747 - MDS - ENDocument1 pagePolylac PA747 - MDS - ENHimanshuDhamiNo ratings yet

- SABIC® PC Resin - PC1803R - Global - Technical - Data - SheetDocument3 pagesSABIC® PC Resin - PC1803R - Global - Technical - Data - SheetLeandro SalvadorNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- PBT Valox 420SEO 30%GLDocument3 pagesPBT Valox 420SEO 30%GLcountzeroaslNo ratings yet

- Astm Property IM17VDocument2 pagesAstm Property IM17VSaketh VandeNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Chi Mei Polylac PA 709S ABS ExtrusionDocument2 pagesChi Mei Polylac PA 709S ABS ExtrusionSayyid AbulkhairNo ratings yet

- Hyosung Topilene HJ646 PPDocument1 pageHyosung Topilene HJ646 PPChu ChuNo ratings yet

- SDS PP T03 LogoDocument5 pagesSDS PP T03 LogoChu ChuNo ratings yet

- TDS - PP 5705PR SabicDocument1 pageTDS - PP 5705PR SabicChu ChuNo ratings yet

- H T NH A Ldpe hp0724nn TdsDocument2 pagesH T NH A Ldpe hp0724nn TdsChu ChuNo ratings yet

- Lldpe HD21HS Qamar SPDC SpecsDocument2 pagesLldpe HD21HS Qamar SPDC SpecsChu ChuNo ratings yet

- Mike - Monthly PlannerDocument33 pagesMike - Monthly PlannerChu ChuNo ratings yet

- OI Calidades FinalesDocument8 pagesOI Calidades FinalesMarcelo VizcayaNo ratings yet

- Fusion WeldingDocument28 pagesFusion WeldingTHE SALEM AEROPARK100% (1)

- M Tech Thesis Format RGPVDocument5 pagesM Tech Thesis Format RGPVhollyschulzgilbert100% (2)

- 603 Quiz 3Document2 pages603 Quiz 3Cj SuarezNo ratings yet

- 212 - VRV 5 Heat Recovery Product FlyerDocument35 pages212 - VRV 5 Heat Recovery Product Flyerbahiniy286No ratings yet

- Pedu 202Document44 pagesPedu 202Mejane MonterNo ratings yet

- Dissertation Sainte Carmen de La MainDocument7 pagesDissertation Sainte Carmen de La MainPaperWritingServiceCheapOmaha100% (1)

- Lesson Plan in Science 3 - RevisedDocument5 pagesLesson Plan in Science 3 - RevisedJurnelene Lei UGOS0% (1)

- IB JIO FormDocument3 pagesIB JIO Formmallekedi shivajiNo ratings yet

- Sustainable Habitat: 24 - 28 September 2019Document2 pagesSustainable Habitat: 24 - 28 September 2019sajid khanNo ratings yet

- International Environmnet Law in IndiaDocument17 pagesInternational Environmnet Law in IndiaAnushka TRivediNo ratings yet

- Module 8 ANOVA or F TestDocument11 pagesModule 8 ANOVA or F TestArklon N. PerezNo ratings yet

- Module 3 Tip Session 3Document13 pagesModule 3 Tip Session 3IRIS JEAN BRIAGASNo ratings yet

- Chapter Three: Logic and LanguageDocument16 pagesChapter Three: Logic and LanguageTagayNo ratings yet

- Psop Assignment Dec 16, 2021Document8 pagesPsop Assignment Dec 16, 2021Ravi Nagar 47No ratings yet

- Speech Act TheoryDocument3 pagesSpeech Act Theorypak updatesNo ratings yet

- RTP-LASG8Q3M5W5Document9 pagesRTP-LASG8Q3M5W5Atheena Johann VillaruelNo ratings yet

- Ideal Gas Law NotesDocument4 pagesIdeal Gas Law NotesPrincess Jean GalabinNo ratings yet

- Chemisty Book Notes For Class XI - Chemical Bond - Gases005628Document23 pagesChemisty Book Notes For Class XI - Chemical Bond - Gases005628Mukhtiar AhmedNo ratings yet

- Water LandscapeDocument13 pagesWater LandscapePunniyaNo ratings yet

- Soil Mechanics - Chapter 2 ExamplesDocument12 pagesSoil Mechanics - Chapter 2 ExamplesSelino CruzNo ratings yet

- Cultural Diffusion and The Kingdom of Kongo Essay OutlineDocument3 pagesCultural Diffusion and The Kingdom of Kongo Essay OutlineAbenzer MamoNo ratings yet

- Score Tutorial: Gpat 2011 Test SeriesDocument11 pagesScore Tutorial: Gpat 2011 Test SeriesRambo FeverNo ratings yet

- Integration of Facilities Management (FM) Practices With Building Information Modeling (BIM)Document8 pagesIntegration of Facilities Management (FM) Practices With Building Information Modeling (BIM)Shamiel AmirulNo ratings yet

- Test Bank The Economy of Nature 6th Edition Robert E. RicklefsDocument21 pagesTest Bank The Economy of Nature 6th Edition Robert E. Ricklefsbachababy0% (1)

- OPS Materials Specifications For JointsDocument8 pagesOPS Materials Specifications For JointsKévin JacobNo ratings yet

- Alejandria - Olive - COT - Physci REVISEDDocument3 pagesAlejandria - Olive - COT - Physci REVISEDOLIVE ALEJANDRIANo ratings yet